In the process of evolution, biological species have developed a protective mechanism of camouflage. Mimicry is the ability to change, blend in color and shape with the environment, which allows living organisms to survive. This method helps predators hunt. In certain areas of human activity, camouflage means are also necessary. Camouflage fabric has been developed and used for these purposes.

History of camouflage fabric

Man has been using camouflage material since ancient times. Hunters used animal skins, plant branches, and body paint to blend into the environment. Unnoticed, they could get closer to their prey and strike it. Warriors used the same techniques.

For your information! Until the end of the 19th century, soldiers' uniforms mainly served as a way to differentiate individual units. Military kits differed in color, shape, and clothing details. These features allowed military leaders and soldiers to better navigate the battlefield.

It is believed that the British were the first to use camouflage fabric during the Anglo-Boer War (late 19th century). The white color of the British uniforms stood out against the background of tropical vegetation. For the purpose of camouflage, by decision of the command, the troops began to introduce uniforms of khaki color (translated from Hindi as "dusty") of a greenish-gray shade.

The observant Japanese quickly got their bearings and, after the British, also began to dress their soldiers in protective-colored uniforms. This gave them certain advantages in the Russo-Japanese War. The soldiers of the Russian army wore white tunics and dark-colored trousers.

By the time of the First World War, most armies had re-equipped with uniforms made of single-color fabric in various shades of protective colors.

After the revolution, in the 1920s, the Soviet authorities decided to organize the VMSh (Higher Camouflage School). Based on research, they came to the conclusion that a single protective color was not enough to fully blend into the terrain. A camouflage fabric with randomly scattered spots ("amoebas") was developed. The camouflage fabric in a bag-shaped form provided a good camouflage effect.

The search for new solutions for camouflage uniforms was also underway in the German army. The Germans developed several sets for different terrain and types of units. In the Soviet troops, camouflage suits and robes were mainly used in special units: engineering, assault, reconnaissance, sniper.

Please note! Having analyzed the experience of camouflaging the enemy, Russian developers at the end of World War II came up with a protective pattern of three colors in the form of cross-stitch. The mosaic pattern created an optical effect of blurring, did not focus the enemy's attention on the object (deforming function). Light-colored blots were applied over the main pattern. At a long distance, the main pattern merged, and the "amoebas" broke it up (imitating function). The principle of visual blurriness began to be used in American troops 50 years later (the "pixel" pattern).

Work on creating new types of camouflage fabrics is ongoing. At the beginning of the 20th century, fabrics made of natural fibers were mainly used for sewing uniforms: cotton, linen, wool. As the textile industry technologically developed, new materials appeared. Special impregnations, a combination of different synthetic fibers gave them the required characteristics.

Khaki fabrics (camouflage) with various patterns are used to conceal military equipment, fortifications in the form of camouflage nets. The base is made of burlap, jute, synthetic fibers. Camouflage fabric is attached on top of them in a patchwork manner.

Application areas

Nowadays, the scope of application of camouflage fabrics has expanded significantly. In a sense, they have received the same recognition as denim. Military style has become part of youth subculture. It is not uncommon to see clothes in camouflage colors on fashion catwalks in haute couture collections.

Main areas of application:

- military;

- hunting, fishing;

- tourism.

In paramilitary units there are two types of uniform: a festive uniform and field camouflage.

The field form differs:

- drawing;

- types of materials;

- complete set (winter, summer set).

Important! Field uniforms are selected, it is claimed, based on the specifics of the military activities of the units, the location. For example, the uniform of tactical and operational groups that can be in ambush for some time should imitate the background of the area as much as possible. They even make fabrics for special forces that blend in with the fence in color. There are many types of camouflage material coloring: "Bhutan", "Birch", "Flora", "Oak", etc.

For the print of hunting camouflage suits, it is important that it blends in with the flora and relief as much as possible. For example, the fabric called "twilight" is an imitation of the forest-tundra nature. White spots in the form of moss are scattered on a greenish-brown background.

Fabric production and characteristics

Camouflage fabrics are often used in extreme conditions and therefore must meet certain requirements. Among them:

- the form must be durable, serve for a long time, and not be subject to significant deformation;

- wear out as little as possible and not fade in the sun;

- the material must “breathe”, allow air to pass through, and be ventilated;

- be resistant to moisture, protect from wind.

Important! For certain military units, additional material characteristics are required. For example, resistance to chemical reagents, fire, infrared remission (cannot be detected by night vision devices). The latter property is achieved by applying special reflective dyes.

Varieties

All fabrics are divided into several types:

- synthetic materials made of nylon, polyester;

- combined synthetic fabrics;

- new generation - membrane fabrics;

- wool fabric camouflage made from natural fibers;

- blended (combination of synthetic and natural fibers).

Fleece

Polyester material appeared 40 years ago. Due to a number of advantages, it has found wide application, including for sewing a certain part of field uniform sets. Light, warm, breathable fabric does not restrict movement, is quite elastic. It is used to sew jumpers, parkas for the military.

Features of the fleece uniform:

- easy to wash;

- dries quickly after wringing;

- good thermal insulation properties;

- wear-resistant, hypoallergenic material.

There are also disadvantages: it is electrified and easily flammable. Fabrics intended for sewing field uniforms undergo special additional treatment, which partially eliminates the disadvantages.

Oxford

The polyester or nylon fibers of the material are interwoven not in individual threads, but in groups, which creates a texture reminiscent of fine matting.

Depending on the thickness of the weave (210-1800 den), it is used to make different products.

They sew from Oxford material:

- tents, backpacks;

- shoes;

- jackets;

- special clothing.

The wide range of applications is determined by the characteristics of the material. Among them:

- heat resistance;

- long service life of products;

- water resistance;

- tear-resistant.

Additional characteristics are achieved through impregnations and surface protection with special films.

Raincoat

Fabric made of synthetic fiber with moisture-resistant impregnation is designed to protect against wind and rain. It is used for sewing field uniform outerwear. For insulation and tactile comfort, a two-layer membrane fabric is used.

Specifications:

- easy to wash, does not require ironing;

- resistant to pollution;

- wear-resistant;

- durable;

- almost impossible to deform.

Important! The top layer of insulated uniform jackets is usually made from raincoat fabric.

Greta

This is a mixed fabric made of polyester and cotton. The peculiarity of the weaving of the threads is that the cotton fiber is on the inside, and the synthetic fiber is on the outside. As a result, products made of greta fabric are pleasant to the touch. At the same time, the material has the universal properties of synthetic fibers. Impregnations are used to enhance water repellency. Uniforms, jackets, and work clothes are sewn from the material.

The material has the following properties:

- easy to wash, does not shrink;

- abrasion resistant;

- synthetic fibers protect the material from dirt, water, stains;

- does not wrinkle;

- hypoallergenic;

- keeps its shape and does not deform.

The fabric is available in a wide range of camouflage colors.

Shirting fabric

Shirts in military uniforms are divided into two categories. The first is not worn in field conditions, they are sewn from mixed fabrics, a combination of natural fiber and synthetics. The field version of the shirt assumes that it will be worn under a bulletproof vest. A tactical shirt meets the following requirements:

- does not create discomfort when moving;

- ventilated;

- absorbs and removes sweat.

Based on the specifics of the clothing, a field shirt is sewn from at least two different fabrics: the body part is made of synthetic fabric, for example, polyester, and the sleeves are made of natural, mixed fabrics.

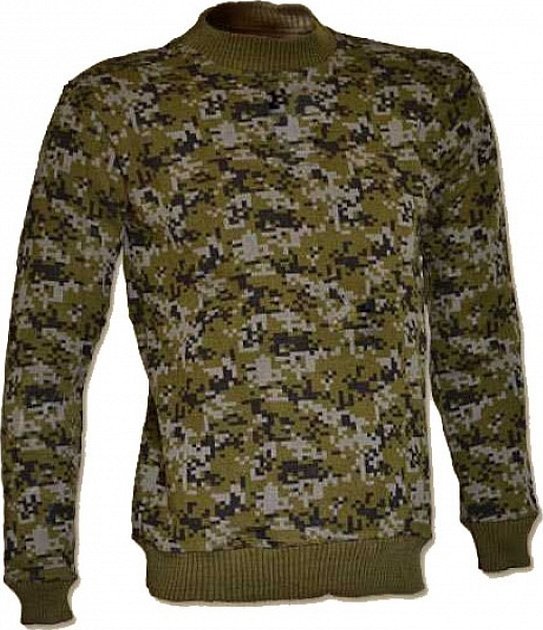

Woolen

Woolen fabric for camouflage should be warm, wearable, comfortable, practical. Natural yarn warms well, but has a number of disadvantages. It shrinks when washed, can cause irritation, is not strong enough, stretches. Therefore, warm clothes for field conditions, jumpers, sweaters are made from a mixture of wool and synthetic fibers (polyester, acrylic threads, etc.).

The percentage ratio varies, but wool thread predominates. Additionally, fabric protective pads are sewn onto the areas that are most susceptible to abrasion. Thanks to this technology, the items remain warm, but also become wear-resistant and do not stretch. Wool camouflage is worn over thermal underwear.

Sewing factories buy camouflage fabrics from manufacturers in rolls in meters. Wool knitwear is supplied in single items.

Thus, there are many types of camouflage fabric. And each is used in one case or another. The main thing when choosing is to evaluate the pros and cons of the material, as well as the purpose of the purchase.