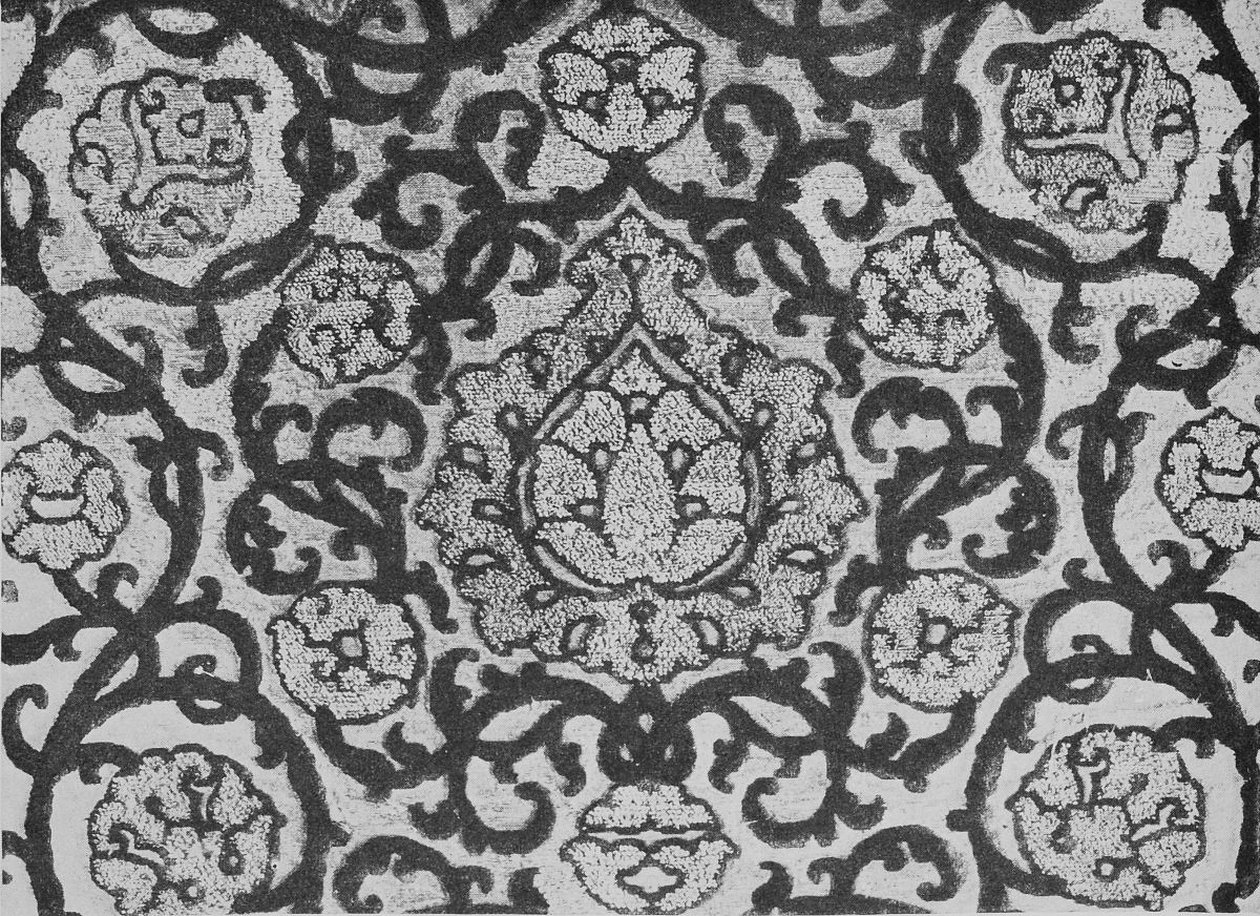

People got bored with ordinary fabrics back in ancient times. There was a need to decorate clothes and bring new life to them. At first, the pattern was applied manually. Especially in India, where a lot of cotton fabrics were produced at the very beginning of the textile industry. Later, artists, teaming up with fabric manufacturers, came up with a new method.

The essence of it was as follows: an ornament was cut out on boards, paint was applied, the canvases were stretched and beaten on them. This is how fabrics with a printed pattern were obtained. They were called printed.

What is printed fabric

Today, printed fabric is a fabric made from almost any material that has a pattern printed on it. The name comes from the canvas onto which the pattern was printed using paints and boards. At the very beginning, the pattern or design was applied to boards, and then they were applied to the canvas and tapped until printed. The paint was absorbed and the pattern remained on the textile.

Nowadays, a printed pattern on fabric is a pattern created mechanically. Modern printed fabric is made using printing machines. Not only natural materials are used as a base, but also synthetic and semi-synthetic ones.

Important! Dyes used today allow to avoid negative consequences and preserve all the properties of the material. At the same time, very high-quality and rich patterns of different shapes are obtained. These can be both ordinary dots and a three-dimensional pattern.

When choosing printed fabric, you should consider the quality of the paint and the type of fabric and its weave, because each type of fabric requires different care.

Story

As already mentioned, the history of printed fabric originates in India. Since ancient times, it has been used to make bed linen. Thanks to the bright and unusual colors of this country, calico fabrics appeared, which have become widespread throughout the world.

Europe and the Middle Ages

After India, the technology migrated to Egypt, where cotton fabrics began to be decorated with printing. This happened only in the 15th century. Europe learned about this method only in the 17th century and only after the import of fabrics from the East. They quickly gained popularity and were in demand, displacing materials of one color.

Important! In addition to bed linen, printed textiles began to be used for furniture upholstery, interior decoration and sewing original and high-quality clothing for wealthy people.

Today, printed fabric is available to everyone and is sold in almost any textile store.

New time

The bulk of printed fabric in modern times was produced in Germany. This is due to the fact that fabrics produced and imported from Italy were very expensive. That is why the Germans began to make their own textiles, the patterns on which were printed using precious metals, such as silver and gold.

A more advanced method of printing was invented in Switzerland, where it was done using copper recessed plates. Later, a cylindrical shaft was invented for dyeing fabric in various patterns and colors.

Distribution of printed fabrics in Russia

The spread of printed textiles in Russia was happening in parallel with Europe. The only thing was that there were no stencils and molds for printing and they were imported from Germany and Italy. At first, these were prints with images of patterns and flowers, and then entire paintings and biblical scenes began to be produced.

Monasteries played a special role in this branch of the textile industry, since printing became almost a sacred craft. The first printing manufactories appeared in Russia in the 18th century. The technology remained virtually unchanged and all the same methods were used as in the times of handicraft production in the Middle Ages.

This continued until the beginning of the 20th century, when large textile enterprises began to form. This is what largely determined the commitment to traditions in the production of Russian printed patterns on fabric.

Application technology

Modern printed fabrics are produced by several methods of painting. Nowadays, this is done with the help of machines, but skilled craftsmen can apply paint manually, which is a long and labor-intensive process. The cost of such products is appropriate. The other methods under consideration require special equipment.

Machine printing

One of the largest technologies used today. The essence of the process is that the design on the canvas is printed using a machine, the actions of which make it similar to a printer. When painting in one color, one shaft is used. If there are several colors or a pattern needs to be made, then multi-shaft machines are needed.

Important! The shaft is a full cylinder made of copper alloys. An engraved pattern is applied to it, which is then used to imprint the image onto the canvas.

Dyes are applied to the cylinder in several ways:

- Direct, when the paint is applied to white or light-colored fabric;

- Etching, in which the material is dyed smoothly in one color, and the composition applied to the roller is printed on the fabric, etching the original color and forming a two-color pattern.

- Reserve, when a composition is first applied to the material, preventing it from being painted in some places. Repeating this operation allows you to get beautiful multi-colored patterns and designs.

Spraying

It is also called airbrushing. A method of painting that involves spraying dyes onto the surface of the fabric through stencils that are previously placed on the fabric and form patterns. This technology is not as widespread as the first one, since it is not always convenient:

- The dye stream should always be directed towards a specific area of the fabric;

- It is necessary to constantly monitor the uniformity of painting;

- Some of the dye is wasted because it is sprayed into the air and lands on the stencils.

Using Grid Templates

This method allows you to create a beautiful photo film print in several stages:

- At the very beginning, a metal frame with a mesh made of polymer materials is placed on the fabric, onto which a synthetic fabric with a cut-out pattern is laid out;

- Dye is poured onto all of this and rubbed in using rubber plates - a squeegee;

- After applying several types of paint, the procedure is repeated, changing the stencil.

Polychromatic method

This technology was developed and implemented by British craftsmen and textile workers. It is popular because the painting process is fully automated. The fabric is fixed in a horizontal position and moves along a conveyor. At this time, paint is sprayed onto it from nozzles.

Important! The most important thing is that the dye composition and intensity can be adjusted, as well as the direction of delivery, resulting in a large number of different designs and patterns.

Sub-static

The last method is thermal printing, which:

- Paint is applied to sheets of special paper, which can sublimate when temperatures rise;

- The sheets are placed on damp textiles and pressed under temperature;

- The dye gradually permeates the fabric and is adsorbed.

Types of printed fabrics

Due to the large number of technologies, paint can be applied to almost any fabric. Most often used for textiles used for curtains, bed linen, home clothes.

Atlas

Satin is characterized by pleasant tactile sensations, printed satin also has a beautiful appearance. Its most popular use has become sewing evening wear and exclusive bed linen. And all because this material is hygienic, does not electrify and does not accumulate dust due to its gloss. With careful handling, satin can retain its properties for a long time.

Calico

Calico is most often used for sewing high-quality bed linen with hygroscopic properties, tactile pleasantness and good air permeability. Such cotton fabric is wear-resistant and holds the pattern for a very long time.

Poplin

It is cheaper than calico and has similar properties, but it is still less durable and dense, and is not particularly strong. The fabric is widely used to make bed linen, clothing, and home textiles. Its properties mean that it should be cared for more carefully.

Satin

Another material that is stuffed and used to sew bed linen. Such linen is characterized by density, smoothness and shine. New methods of applying paints allow three-dimensional patterns to be stuffed onto satin.

Knitwear

Printed knitwear is no different from regular knitwear in its properties. It is soft, hygienic, practical, elastic. Its pleasant tactile sensations and durability have made it a popular material for creating men's and women's clothing, as well as children's clothing, socks and stockings. Printed knitwear fabrics, in addition to these properties, also have a beautiful appearance. We can distinguish printed staple, biflex, ribana, footer, etc.

Chiffon

Printed chiffon is used to sew dresses, sweaters, blouses and other light items. Moreover, it is used to make light scarves and shawls. Its main advantage is that it allows the body to breathe, which means it is ideal for hot weather. Printing makes it even more refined and beautiful, adding drawings and three-dimensional patterns to its surface.

Silk

It is natural or synthetic silk with applied patterns or designs. Unlike standard single-color material, printed silk has not only quality but also decorative characteristics, and is one of the most popular fabrics among fashion designers. Externally, such silk is similar to staple

Thus, the traditions of fabric printing, which originated in ancient times, are actively used to this day. In addition to these fabrics, they also print matting, biflex, stapler and other materials. Modern technologists have made great strides and have moved a little away from the first methods of manufacturing such materials, but this has been beneficial for people, because many ways have appeared to make beautiful patterns on textiles, using it for bed linen and clothing.