Non-woven fabric is a popular material on the consumer market. The need for it is due to its excellent properties and characteristics. Geotextiles are widely used in various fields of activity and are distinguished by their wear resistance, reliability and availability.

What is non-woven needle punched fabric

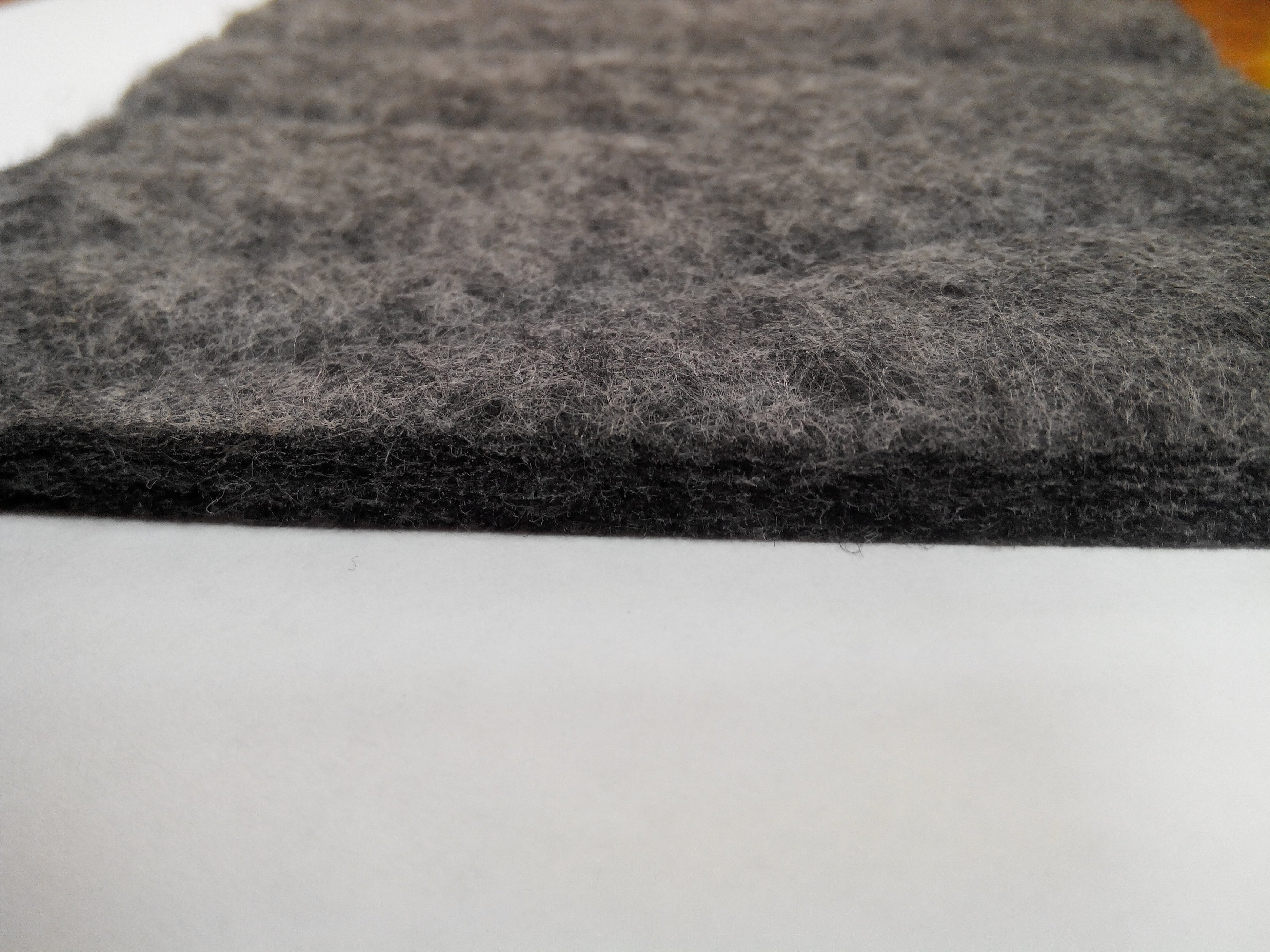

Needle-punched nonwoven fabric is a product whose fibers are oriented randomly or in a direction. Textiles are represented by loose material folded into a roll. This name was obtained due to the procedure of using special needles. Textiles mainly play the role of an insulating component in the decoration of residential premises, and are also used in construction, repair and air filtration.

A bit of history

The type of material originated in Europe in the 30s of the last century. France is considered its birthplace, because it was there that the first special equipment aimed at the production of non-woven fabrics was created.

Interesting: Initially, viscose with chemical additives was used as a raw material, but later people realized that the fabric could be woven using other methods and other components. After 30 years, such weaving appeared in Russia. The fabrics were created on domestic machines by felting, knitting and gluing. Since its appearance and to this day, geotextiles have enjoyed great popularity. Why are these fabrics so popular? And the reason for this is their versatility and a number of significant advantages.

Raw materials for the production of non-woven materials

The fabrics are woven from various threads. Among them are both natural and artificial components. Popular products are made of viscose, polyester, cotton, wool, polypropylene, flax, lavsan, as well as second-rate raw materials.

Technology of creating non-woven needle-punched products

A large number of threads of certain sizes are carefully mixed together to achieve good adhesion of the fibers. The woven fabric is then spread evenly on a horizontal surface in a layer of the required thickness and rolled with a special roller to give it the desired shape. After this, jagged needles connect the threads together, and the result is cut or continuous pieces of fabric. Subsequently, the fabric undergoes heat treatment, and its shape is preserved for a long time.

Note: The material is in layers of varying thickness, which are then rolled into rolls and sold in this form.

They are protected from the elements and will therefore not rot when exposed to the sun's ultraviolet rays.

Performance characteristics of nonwoven fabric

The fabric is distinguished by its density. Its characteristics vary from 100 grams to 1 kilogram per 1 square meter; everything depends on the raw materials used in production, as well as on the processing technology and creation technique. According to the structure, multilayer, dense and through fabrics are distinguished. Foil or other materials can also act as a backup.

Among the advantages of the material, the following factors characteristic of non-woven fabric can be highlighted:

- Firmness and elasticity;

- Strength;

- Frost resistance;

- Thermal insulation and sound insulation;

- Maintains shape and eliminates vibrations;

- It is an unfavorable environment for the appearance and reproduction of fungi, bacteria and mold.

Application areas of the material

Textiles have found a place in various spheres of human activity. They are actively used in the production of warm floors and floor coverings with thermal insulation. They are used as a film under the roof, as a protection for waterproofing, when working with the roof.

As you can see, tension fabric has found wide application in construction, therefore it often becomes an important item when performing repair work on roads and railways.

Non-woven fabric also plays an important role in the construction of hydraulic structures; it is capable of leveling oil and gas pipelines.

Non-woven needle-punched product can provide effective drainage. Groundwater and water left over from precipitation will not stagnate on the roof, thereby reducing the load on the surface and increasing its durability.

It filters air and water well, removing unnecessary, tiny particles of dirt and stones.

In addition, the fabric is used in the manufacture of clothing and in the shoe industry. It is needed to create insoles and insulated wardrobe items.

The pads that cover the springs of upholstered furniture items are made from the same fabric.

Non-woven cloth rags

Depending on its characteristics and performance properties, the material comes in different grades.

Dornit

The country that created dornite is our country. The domestic fabric was created in 1977, and it has not been replaced by anything yet. It is made of nitron, polypropylene or lavsan. This type of fabric has found wide application in various fields: from clothing and footwear to landscape design and mechanical engineering.

The advantages of dornite are its durability (at best it can last up to 50 years), availability and strength. It is fire-resistant, moisture-resistant and quite easy to implement. An important factor is the ecological purity of the canvas. It is used:

- when packing items,

- as an insulating component for pipes and heating mains,

- in construction and repair,

- during finishing of premises for soundproofing and thermal insulation and during the production of suspended ceilings,

- when filtering air,

- and also to separate soil layers, isolate plant roots and prevent the rise of groundwater.

Important: Textiles allow separating layers of sand or other bulk material and soil from each other. This ensures wear resistance of roads, which means reducing the degree of their destruction. Dornit performs the same function when placed under paving slabs. It also reduces soil erosion and vegetation growth, so that the slabs do not deteriorate and green grass does not grow through them.

Batting

The softest and thinnest (up to 12 mm) version of non-woven needle-punched fabric. It can be created on the basis of natural components or from chemical components. Thin fabric can tear, but this can be easily fixed with a crochet hook or knitting needles. The most expensive option is wool batting. It can perfectly retain temperature, but easily gets wet and becomes the heaviest, but despite this, it needs washing, that is, products made of batting can be washed. Cotton batting is distinguished by its thermal insulation.

Previously, it was widely used in the creation of warm clothing, and now you can find it in the form of insoles, in toys and furniture. Such needle-punched fabric can be found in bed linen in hospitals, as it is hypoallergenic and harmless, and therefore meets all the conditions of GOST. Among the disadvantages, one can highlight the instability to moisture, because cotton batting is easily exposed to water. Currently, polyester material is often used in the creation of clothing.

This includes sintepon - a light, thin textile similar to cotton wool. It is inexpensive, but can retain heat for a long time.

Attention: When producing needle-punched fabrics for interior decoration, or more precisely for providing sound insulation and floor insulation, the linen version of batting is preferred.

Felt

A dense woolen type of material is characterized by high air conductivity and low thermal conductivity. The raw material is taken from the down of animals: goats, sheep, rabbits. Wool fibers adhere well to each other after a procedure using hot water and steam. The most popular type of felt is felt. It is used to make hats, insoles, felt boots and other warm footwear.

Glass fiber

During repairs, to level the surfaces, they resort to the help of thin fiberglass, presented in the form of a web. The canvas-stitched material is ideal for covering cracks in walls. Externally, it is very fleecy, is in a roll form and adheres to the surface with glue.

The large number of varieties of fabrics that are commonly nonwoven allows this type of textile to be in demand on the consumer market. This material will be needed for a long time, since its amazing characteristics do not require the development of a new alternative fabric.