The quality of the fabric directly depends on its density. This article discusses how to correctly measure the density of the material and which one is best to choose for bed linen.

Surface density

This definition indicates the number of warp and weft threads that are present on 10 cm of material.

For example, in a matting the thread is strong, heavy, they are located at a large distance from each other. Such a material will be of medium density.

Linear density

Linear is a combination of actual and maximum density. It is indicated as a percentage. When these values are the same, the linear will be 100%. The yarn in such materials is without shifting and crumpling, will touch each other.

If the linearity is greater than 100%, the threads will begin to shift.

Important! In the opposite case, the density is below 100%, then the yarn is located at a distance from each other. This indicator can be seen with the naked eye on Dior materials.

What fabric density is suitable for bed linen?

To understand what is the best fabric density for bed linen, you need to know what characteristics it should have. Good bed linen sets should be comfortable, "light", hypoallergenic, wear-resistant and wrinkle-free. All these indicators depend on the density of the fabric. This indicator is determined by the method of weaving the threads, their number.

The durability of the material is determined by the type of strength. The thread weave standard will be: 110-150 for chintz, for satin - 110-250.

If the label says a value less than 120, then you cannot buy such bedding, it will quickly deteriorate.

The variety of materials depends on the type of raw material used, as well as on the methods of weaving the threads.

Materials for bed linen are obtained using this method of weaving yarn:

- plain - weaving of longitudinal/transverse threads;

- satin - any transverse thread with an outlet on the outer part of the product, covers 4 longitudinal ones.

These fabrics have a satin weave:

- Cotton satin;

- Blackout;

- Polysatin;

- Mako-satin;

- Crepe satin.

When choosing underwear, you need to consider the weaving method.

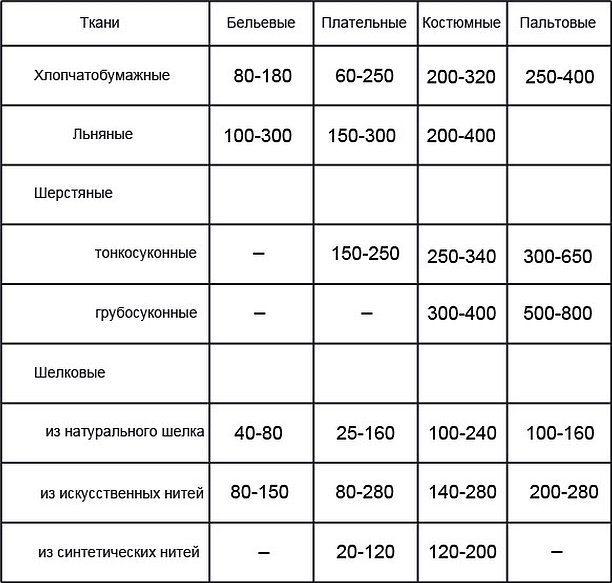

Density indices for different fabrics

To determine the density index, you can use the calculation:

МSp = 0.01* (ToPo+TuPu).

Where: To is the linear density of the warp threads, measured in tex;

Tu is the linear density of weft threads, tex;

Po — base indicator, number of threads per 100 mm of fabric;

Pu is the weft indicator, the number of threads per 100 mm of fabric.

Satin density

Classic satin has an indicator of 90-120 weaves per 1 cm2. It is dyed using pigment printing and treated with alkali. This method of processing the material gives it shine and prevents pellets from forming.

Printed satin is stronger - up to 160 weaves per 1 cm2. To make a pattern on the fabric, a reactive printing method is used.

Printed fabric. This method of applying a pattern to the material helps to make bed sets with a pattern that is uniform in style but varied in size for duvet covers and pillowcases. It has the same density as printed satin.

Satin-Jacquard

It is also called stripe satin. This material has an indicator of 180-230 in 1 cm2. It is double-sided, the pattern is made using colored threads in the process of creating the fabric. It looks like a thin tapestry. At the same time, the main background has a matte surface, and parts of the pattern are shiny, located as if below the main background.

Bamboo fiber fabric

Bamboo linen is quite shiny and silky. Bamboo fabric absorbs odors, dries quickly, and is hypoallergenic. Care for such linen should be thorough: wash with detergents for colored materials, do not use bleaches, do not dry or wring in the machine. Density is determined from 120 g / m². Fabric blinds are also made from it.

Calico

According to GOST, calico consists of 100% Chinese cotton. Bed linen sets are made of fabric obtained from thick threads with a plain cross weave. The quality of fabrics is determined by the thickness of the threads: the thinner the thread, the greater the density of the product. Calico of poor density (70 g / m²) is called sparse. Average indicators will be 80-110 g / m². Good bed linen sets made of calico have a high density of 120-130 g / m², they are low in price and very comfortable, soft and elastic. Such sets are often used in hospitals.

Poplin

In the production of poplin, a plain weave of threads is used, like in calico, but the yarn differs in thickness.

A very thin thread will be used as a base, a thick one is taken for the weft. Small scars are clearly visible on the surface of the material. The average density of the fabric is 120-130 g / m². Poplin has more scars than calico. Poplin is quite soft. When buying, it is better to take domestic manufacturers. Poplin sheets are easy to wash and iron.

Tencel

Wood cellulose, it is extracted from eucalyptus, is used as a material for creating silk tencel fabric. Pleasant, environmentally friendly, hypoallergenic fabric has bacteriostatic qualities. Such underwear is purchased by people with delicate skin.

The material quickly absorbs water, adjusts to the temperature in the house, and allows air to circulate. It is quite difficult to care for them: they can only be washed with liquid powders, and they must be stored in a well-ventilated place, out of direct sunlight.

Flax

Eco-friendly, unpainted flax material is in great demand among many people. During cultivation, flax is not sprayed with pesticides. The beauty of the fabric lies in the natural shade of ivory. Such unpainted material reacts well to the skin, preventing the reproduction of microbes or allergies.

Bed linen sets are quickly washed, cool in the sultry heat, and dry quickly. The density parameter is approximately 130-145 g/m². But such products have a high price.

Ranforce

The indicator of this material will be from 120 g / m². For the production of premium fabrics, threads of the highest grades are used. In the process of weaving, they lie tightly with each other, the surface of the material is smooth, delicate and soft. Due to the increased linear density, this material is endowed with wear resistance and special strength. Also, this fabric is treated with alkali, and it receives the following qualities: increased strength, smoothness, hygroscopicity, pigments are easily absorbed. Bed linen made of ranfors looks bright, has a sheen, soft.

Biomatin

It is made on the basis of cotton, the threads of which are impregnated with hypoallergenic solutions using a special technique. The density of the fabric is no more than 130 g / m², very similar to premium calico. From such material you can create things and bedding for children with sensitive skin.

Bamboo

Sets made of such fabric are just beginning to gain popularity in Russia. They are made of bamboo mass. It has different density, from 90 g/m², very soft and pleasant to the touch. It has an average price.

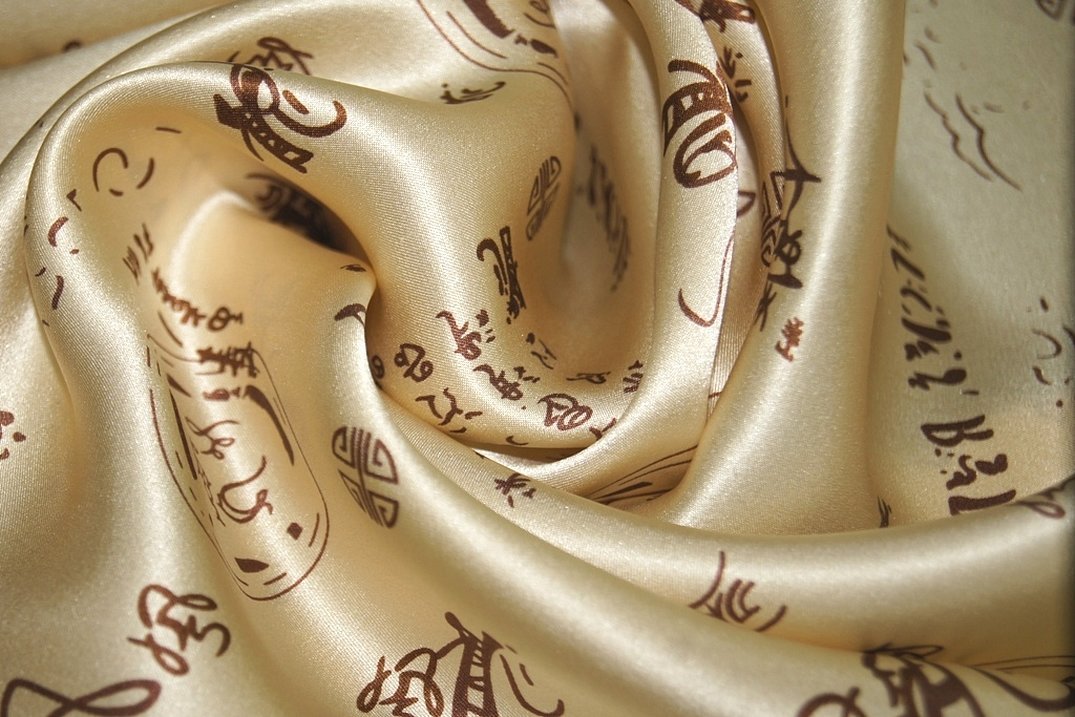

Silk

This material comes from China, but the most popular fabrics are hand-made in Japan. There are more than 500 types of silk fabrics produced there. Silk density is indicated in Momi (mm). The higher this indicator, the better the fabric. The density value can be within 6-30 mm, for the creation of bed linen, material with an indicator of 16-20 mm is used.

Mako

This is an Egyptian cotton-based fabric with a density of 220 g/m². It looks very similar to silk. Reactive printing is used to apply the pattern, it becomes part of the threads, does not fade under the influence of sunlight and tolerates washing well. It is a soft fabric to the touch, which stretches well.

Percale

Similar in appearance to poplin, the outer part of percale is brighter and shinier than the inner part. Smooth, wear-resistant fabric is made from long-staple cotton, with a plain weave. The yarn has one length, which gives the product wear resistance (over 700 washes), as well as smoothness and shine. Treatment of threads with a special solution protects against the appearance of pellets, stretch marks, and runs.

Important! Bed linen made from such percale does not generate static electricity, it is used for children and people with skin diseases or allergies.

In conclusion, we need to sum it up. To find out the fabric index, you need to look at the label, or calculate the density measurements using the calculation formula.