Due to its high technological and aesthetic features, the textile product has a wide range of applications. Satin ribbon belongs to the category of decorative and finishing ribbon-weaving products and is a favorite among needlewomen.

- History of origin

- Composition and production technology

- Main production cycles:

- Basic warp/weft overlap patterns:

- Decorating ribbons is done using:

- Application areas

- Satin ribbons: what can be made from them?

- What to make from satin ribbons with your own hands

- Decorative gift basket

- Making a bow with a diameter of 14 cm

History of origin

In Ancient Greece, women used thin strips of fabric to decorate their hair. They were made from plant fibers. Women in Ancient Rome decorated their heads with headbands. Gold and precious stones were used to decorate them. In the 14th century, the era of sericulture began in Ancient China.

A special interweaving of silk fibers allowed to obtain a glossy fabric. It began to be called satin, that is, satin is what has a "smooth" surface (translated from Arabic). The fabric quickly began to spread around the world. Only representatives of high society had the opportunity to buy such luxury and beauty.

And when did ribbons appear? After cutting out the outfits, there were scraps of fabric left. They were used for finishing furniture, making various accessories. Cutting work with rolled fabric led to the appearance of long strips that were used to decorate outfits. In the 15th century, King Louis XI invited Italian craftsmen who were supposed to teach the French a new production of making ribbons.

A large number of weaving machines were installed in Lyon. The French nobility began to appear in society in dresses decorated with ribbons. Lyon became famous for its textile production. Today, manufacturers use both natural and synthetic fibers for its production. It remains in demand and relevant to this day.

Additional information! In London's Victoria and Albert Museum of Decorative Arts and Design, there is a man's outfit. To decorate it, craftswomen used more than 250 yards (228.6 m) of textile ribbons.

Composition and production technology

Several centuries ago, only natural fibers of flax, cotton or silk were used to make ribbons. Until the 20th century, satin ribbon had a high price due to its complex production. Today, natural fibers do not play a big role in the manufacture of the product, as manufacturers have begun to use chemical fibers - viscose, acetate, polyamide and polyester.

The linear density of viscose threads is 8-29 tex. of various structures: twisted, folded, pneumatically connected. To enhance the gloss of the surface of the product, a large number of acetate threads are added. Strength and resistance to external damage depends on the number of polyamide (nylon) threads.

Main production cycles:

- prepare raw materials for production;

- make a strip;

- finish the finished product.

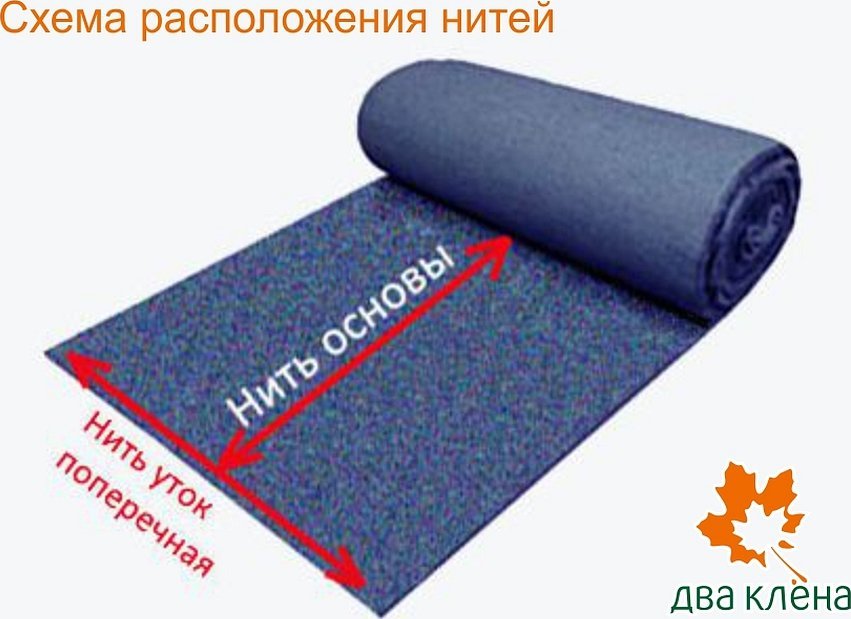

Additional information! First, the fibers are wound onto a weft spool (spool diameter 30-80 mm) to make a base.

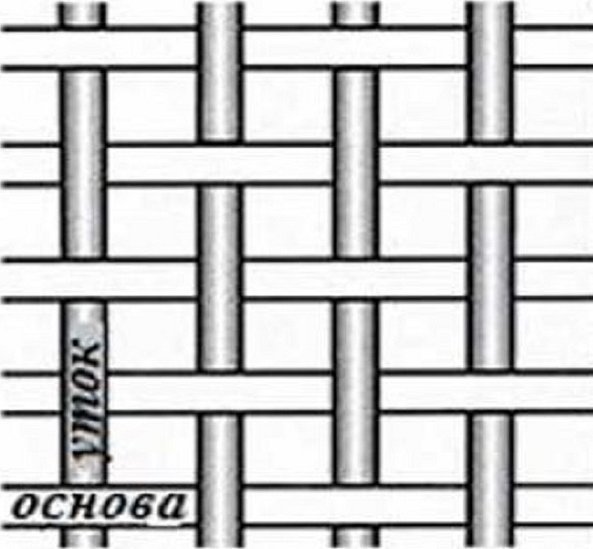

The weft is the threads that are arranged horizontally in the weave. In satin weave, the warp threads come out on the front side.

Basic warp/weft overlap patterns:

- 5/2;

- 7/3;

- 8/3.

In this type of weaving, narrow stripes are even, shiny, and have vertical patterns.

Decorating ribbons is done using:

- Hot stamping - application of company logos. Used to decorate soft toys, champagne, collectible wines and other items.

- Thermal lifting - obtaining relief printing. The technology allows you to decorate envelopes, invitations, business cards and other types of products.

- Full-color sublimation printing ‒ deep penetration of paint into the fabric. It helps to obtain a smooth surface that does not fade under the influence of ultraviolet rays. Saturated shades retain their original appearance for a long time.

Manufacturers produce glossy material in reels, from 0.3 cm to 12.0 cm. The narrower its width, the cheaper its cost. There are also strips 0.6 cm, 1.2 cm, 2.5 cm, 3.0 cm, 4.0 cm, 5.0 cm, 8.0 cm, 10.0 cm, 12.0 cm wide. It has different degrees of hardness. This depends on the technology and impregnation used by the manufacturers.

For your information: The shiny material does not fade, can be washed and ironed at any temperature. But the slightest snag will change the aesthetic appearance.

Application areas

Narrow woven strips can be considered the simplest and most inexpensive materials for decorating clothes, as well as for use in creative projects. Manufacturers have introduced to the market not only plain ribbons, but also ones with children's patterns, polka dots, various colors and other prints.

Satin ribbons: what can be made from them?

- Headbands. Not only single-colored material is used for decoration, but also combined in the product. Prepared decorative elements are attached to the headband.

- Bracelets. For production, various textile thin strips are used, they are woven according to the volume of the hand.

- Flowers. For them, it is better to use a ribbon 4-5 cm wide. Cut it into 6-7 cm lengths and make petals. When assembled, flowers can be used to decorate clothes, hoops, and paintings. For flowers, it is better to use a tinted ribbon. Craftswomen make it themselves using acrylic paints. To do this, wet a single-color strip with water. Apply paint along its edges. It will dissolve in the material in different directions. As a result, you will get a beautiful, decorative strip with different shades, from which you will get an unusual flower.

- Easter eggs. To decorate the festive table on Easter Sunday, polystyrene eggs are used. They are easy to decorate with multi-colored ribbons and get an original interior decoration.

- Pictures. Textile strips are used for volumetric embroidery. Pictures with a sea of flowers will decorate any interior.

Today, many modern creative trends have emerged. One of them is the Japanese technique of making decorative flowers - kanzashi. Each flower can be considered a real work of art.

Additional information! According to an ancient Greek legend, the craftswoman Arachne challenged the powerful goddess Athena. The deity of war and wisdom turned the needlewoman into a spider.

What to make from satin ribbons with your own hands

It is not difficult for beginning craftswomen to make various children's decorations for phone cases, backpacks, as well as baubles for young fashionistas and other decorative options.

Decorative gift basket

- Take an oval-shaped soap.

- Insert pins from the bottom and top at a distance of 6-7 mm from each other.

- Weave from top to bottom between pins with ribbon of your choice around the soap.

- Form the sides: weave along the bottom and top of the product, and along the heads of the pins.

- Make a handle. Attach wire to the top edge and braid with ribbon.

- The basket is ready!

To make sure the basket is not empty, you can fill it with flowers made from the same material in other colors. There are many master classes on making hair ornaments that craftswomen can use. Let's look at the step-by-step execution of a bow that will decorate the head of a little fashionista.

Making a bow with a diameter of 14 cm

- Cut a 5 cm wide ribbon into 6 pieces of 14 cm each. Fold in half, gather on a thread, gather into a flower. Secure with a knot.

- Cut a 2.5 cm wide ribbon into 6 pieces of 10.5 cm each. Also assemble into a flower.

- Cut the silver ribbon into 6 pieces, 15 cm and 8 cm long. Make ears.

- Glue onto the large and small flowers so that the lower part of the ears is directed towards the middle.

- Glue a flower of a smaller diameter onto a large flower.

- Prepare a felt circle Ø5.5 cm. Sew on.

- Attach the hair clip.

- To decorate the center of the flower, prepare a decorative ornament - a bead, heart or flower. Decorate the product with decor.

- The hair decoration is ready!

Ribbons have entered our lives as a necessary attribute. They are used to decorate gifts in boxes, wedding processions, for embroidery and other solemn and pleasant moments.