Despite the fact that textile manufacturers have recently been producing a huge amount of cheap synthetic fabrics, most people prefer to buy products made from natural fibers. Calico, which is widely used not only in the manufacture of textile products, but also in other areas of life, is proof of consumer affection.

In order to choose the right product from this fabric, the consumer must know what calico is and what types of it exist. This is covered in detail in the article.

What is calico?

Calico is a cotton, dense fabric with a plain weave of thick threads "criss-cross". There are 2 types of calico depending on the thickness and method of processing the threads.

Bleached

A thin snow-white fabric with a density of 125 to 142 g/m². The structure of the material is matte and nasty. White calico is considered a fabric of high comfort and aesthetics. To have an even white color, it is treated with special bleaches that are safe for humans and the environment. Manufacturers produce fabrics 1 or 2 meters wide.

Plain calico has a number of positive properties:

- Absorbs moisture well;

- the fabric is pleasant and soft to the touch;

- does not turn yellow over time;

- easy to wash;

- creates a comfortable microclimate for the body;

- does not stretch after washing.

- does not deform.

White earth calico is used for sewing medical clothing, shoe covers, bed linen, packaging materials and shirts.

Important! Bleached fabric has one variety - plain-dyed calico. Its structure is the same as bleached, only it is dyed in some color. Colored calico is used to produce clothing, table and bed linen, and baby diapers. Plain-dyed calico of blue, green, gray, and red colors is especially popular on the market.

Unbleached

The thread weight of unbleached calico varies from 142 to 160 g/m². All GOST criteria are observed during its production, and the fabric is processed the least. The fabric has a yellowish tint, is not dyed or bleached. It is very coarse and durable.

Unbleached, or as it is also called, raw calico, is of great importance in the manufacturing industry, so it is best to consider it as a separate section of the article.

Raw calico

The production of unbleached raw calico is a set of complex technological stages. But, despite the difficulties, raw calico is one of the most popular on the market. Its popularity is explained by significant advantages and methods of application.

Application

Coarse calico is purchased by representatives of companies that deal with:

- Manufacturing covers for sports equipment and camping gear. The covers are lightweight, durable, do not wrinkle, protect well from dirt, dust, and are easy to clean.

- Production of mattress covers. Products made of coarse calico hold well, do not slip, and are breathable. Suitable for the production of covers for orthopedic mattresses.

- Shoe industry. Absorbs and evaporates moisture. The fabric is ideal here as an inner lining.

- Sewing specialized uniforms and work gloves. Products made from coarse calico are “not afraid” of chemicals, allow air to pass through, retain heat, do not provoke allergies, and are easy to care for;

- Production of bags and souvenir bags. It will be easy to apply a print or company logo to the product. The fabric holds the dye well. Strong bags can withstand quite a large load, are easy to wash and iron.

- For the production of technical bags. The fabric can be used to create bags for money, postal items, storage of bulk products, and collection of geological samples.

- Furniture industry. Due to its wear resistance and high level of strength, coarse calico is used for rough upholstery of spring blocks, as well as for lining parts of upholstered furniture.

- Manufacturing of stretch ceilings. The fabric is light and dense in its structure, easy to sew and install. The fabric is not afraid of dampness and does not rot. The ceiling made of calico will last more than 25 years.

- Sewing industry. Double-sided fabric allows air to pass through and is used for sewing suit linings.

Advantages

Harsh calico has an unattractive appearance, but it has many advantages:

- Resistant to rot and abrasion.

- No deformation during operation due to high density.

- Minor shrinkage when wet.

- Long service life - from 20 years.

- Absorbs water well.

- The material can be easily washed from any type of dirt.

- The fabric dries quickly and is easy to iron.

- Wide range of applications.

- Affordable price on the market in comparison with analogues.

- The same density on the front and back sides, which contributes to less wear.

- Calico is an eco-fabric, the production of which does not harm nature.

- Light weight considering the high density of the material.

- Keeps you warm in the cold and prevents you from overheating in the heat.

- One of the most durable cotton fabrics.

- Does not accumulate static electricity.

Please note! Coarse calico also has its negative aspects that buyers do not like. These include stiffness, lack of smoothness, shine, and the formation of pellets.

Care instructions

In order for calico products to serve for many years, they need to be properly cared for. There is nothing complicated about this, it is only important to follow a couple of rules and recommendations:

- You can use various powders and conditioners, as the fabric is resistant to chemical reagents.

- It is recommended not to use too high a spin speed, as it may result in items not being ironed properly.

- To make the items easy to iron, do not overdry them; it is better to leave them slightly damp.

- You can set the washing machine to the normal mode, but for washing children's clothes or linen made from bleached fabrics, it is better to choose the delicate mode.

- After purchasing or sewing a product made of calico, it is recommended to wash it, you can simply rinse it in warm water. This will make the material softer and remove foreign odors.

- To preserve the brightness of the colours, the product should be turned inside out.

- Clothes and bedding made of calico should be washed at a water temperature of 30 to 60 degrees. Undyed varieties can be washed at a higher temperature.

- Dry in the usual way, hanging on a line. Machine drying is allowed.

About the manufacturers

The quality of the fabric and its consumer characteristics will depend on which manufacturer made the fabric. The following manufacturers are especially popular on the Russian textile market:

CalicoKhBK "Shuiskie Sitsy" is deservedly in demand. The fabric is distinguished by its wear resistance and practicality. The density of the material produced by this factory complies with GOST and is 142 g per 1 m².

Textile factory "Ivanovo" produces all existing types of calico, 100% cotton. Ivanovo fabric is distinguished by its high quality, beautiful colors and affordable price. The low price makes it accessible and popular.

The company "Boomerang" is one of the largest suppliers of fabric in Russia. It has been working with large wholesalers for 30 years. It offers a wide range of fabrics, including different types of calico at low prices.

Turkey is the world leader in the production of cotton fabric. Calico from Turkey is a lightweight, high-quality material, in most cases consisting of 100% cotton or having up to 15% synthetic additives. The fabric has bright, saturated colors, does not wrinkle, does not fade, and does not roll.

Another country famous for producing high-quality calico is Pakistan. Pakistani fabric contains 80% cotton and 20% synthetic admixture. Light and soft material. The fabric is breathable, allowing the body to breathe. At the same time, the material is durable and wear-resistant. The only thing that can stop the consumer is the high cost of this material.

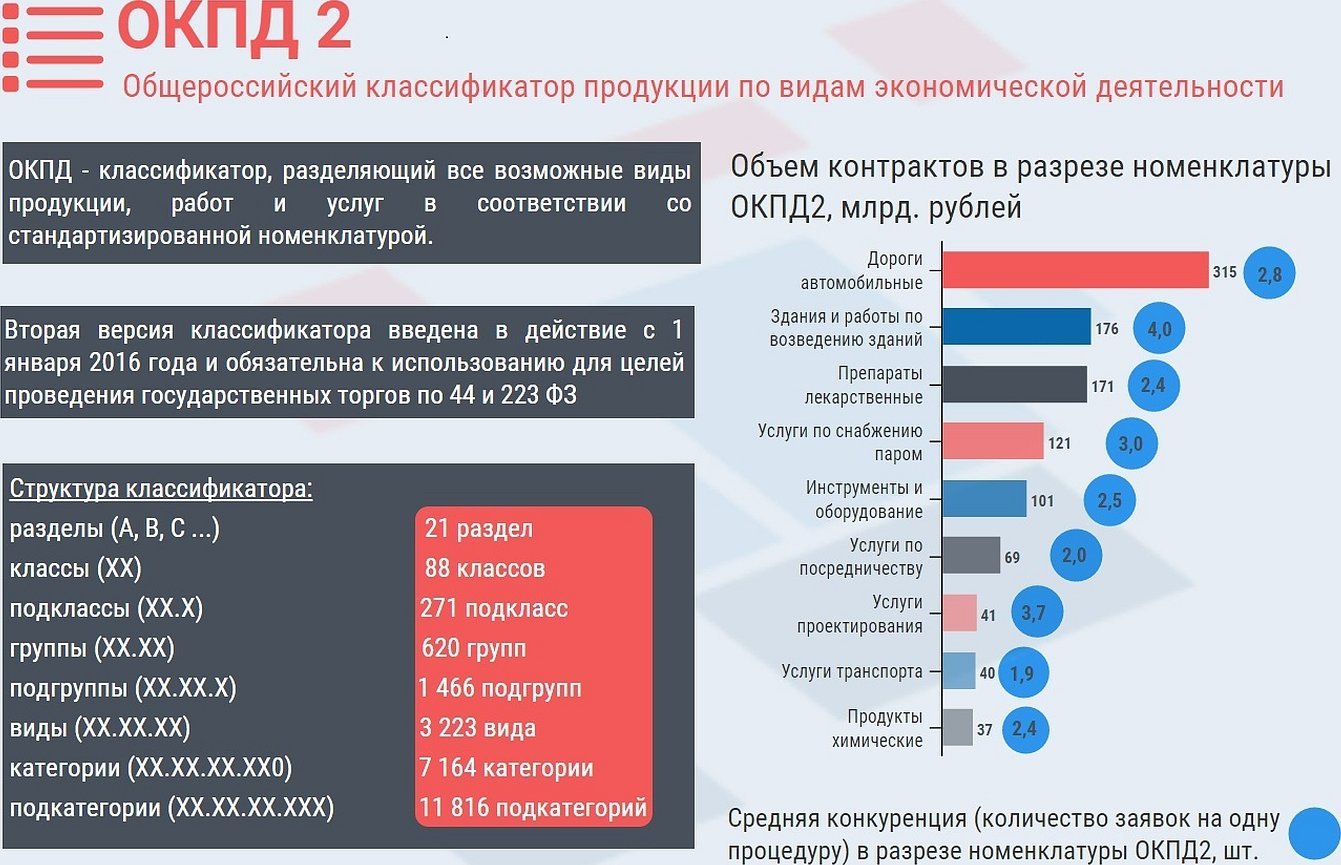

Classifier OKPD 2

Like any goods, individual types of calico have their own codes in OKPD 2 (All-Russian Classifier of Products).

This is necessary to comply with customs requirements when importing or exporting services or products abroad and beyond. The OKPD 2 code allows you to quickly confirm the product's compliance with GOST. Thus, the registration of relevant documents at customs occurs 2 times faster. Generally accepted rules apply throughout the territory of the Russian Federation and beyond.

Codes and names according to OKPD 2 are presented in the table:

| Product | Section name | OKPD code 2 |

| Bleached calico | Other materials and products for technical purposes, not included in other groups | 13.96.16.190 |

| Coarse calico | Other materials and products for technical purposes, not included in other groups | 13.96.16.192 |

Calico fabric has been one of the most popular in the production of goods for several decades. Its natural composition, as well as various characteristics depending on the type, allow it to be used for a variety of purposes.