At the beginning of the production of fabrics and textiles, it was exclusively natural. Cotton, for example, began to be used more than 10 thousand years ago for weaving threads. Natural fabrics have long been among the most popular and remain so to this day. This is due to their properties.

Natural textiles, which are also called classic, can be of plant origin (cotton, jute, hemp, flax), animal origin (wool and natural silk), mineral origin (asbestos, awn). Today's material will tell you about such a classic fabric as linen fabric. First, you need to consider flax, what it is and how flax is used, the fiber of which is almost the most popular in the world.

Description of the plant

What is flax? It is an annual and perennial herbaceous plant with whole leaves. In total, more than two hundred species of this plant are known, used for various purposes. The most popular are: sowing flax, blue and yellow flax. This "grass" has been known for hundreds of years and is actively used not only for the textile industry, but also for feeding livestock, weaving threads or making medical products and attributes. Areas sown with flax look like blue lakes, reflecting the sky and surrounding surface.

The crops reach a height of no more than one and a half meters and, as already mentioned, can be annual or perennial. Regardless of this, they are removed every year and sown anew. The stems, like the leaves, are cylindrical, smooth and straight. During flowering, flowers appear at the top of the stem, in which seed pods ripen. Flax seeds are oily and have an oval shape. Now there should be no questions about what flax looks like

Important! The medical and technological industries value these seeds for their high content of linolenic acid and oil.

The plant of the ornamental species requires careful care, but this does not prevent gardeners from growing them. The most common are two subspecies of common flax: long-leaved and curly. The first is smooth, with a high stem, on the top of which flowers bloom. The second is low and branched.

Where flax grows

The homeland of flax is Western Asia. From there it came to Egypt. The Greeks bought it in Spain. The developed species feel great in almost all climate zones. Today it is the second most popular crop after cotton, used in the creation of textiles. The main producers and exporters of flax are Russia, Poland, the Netherlands, France.

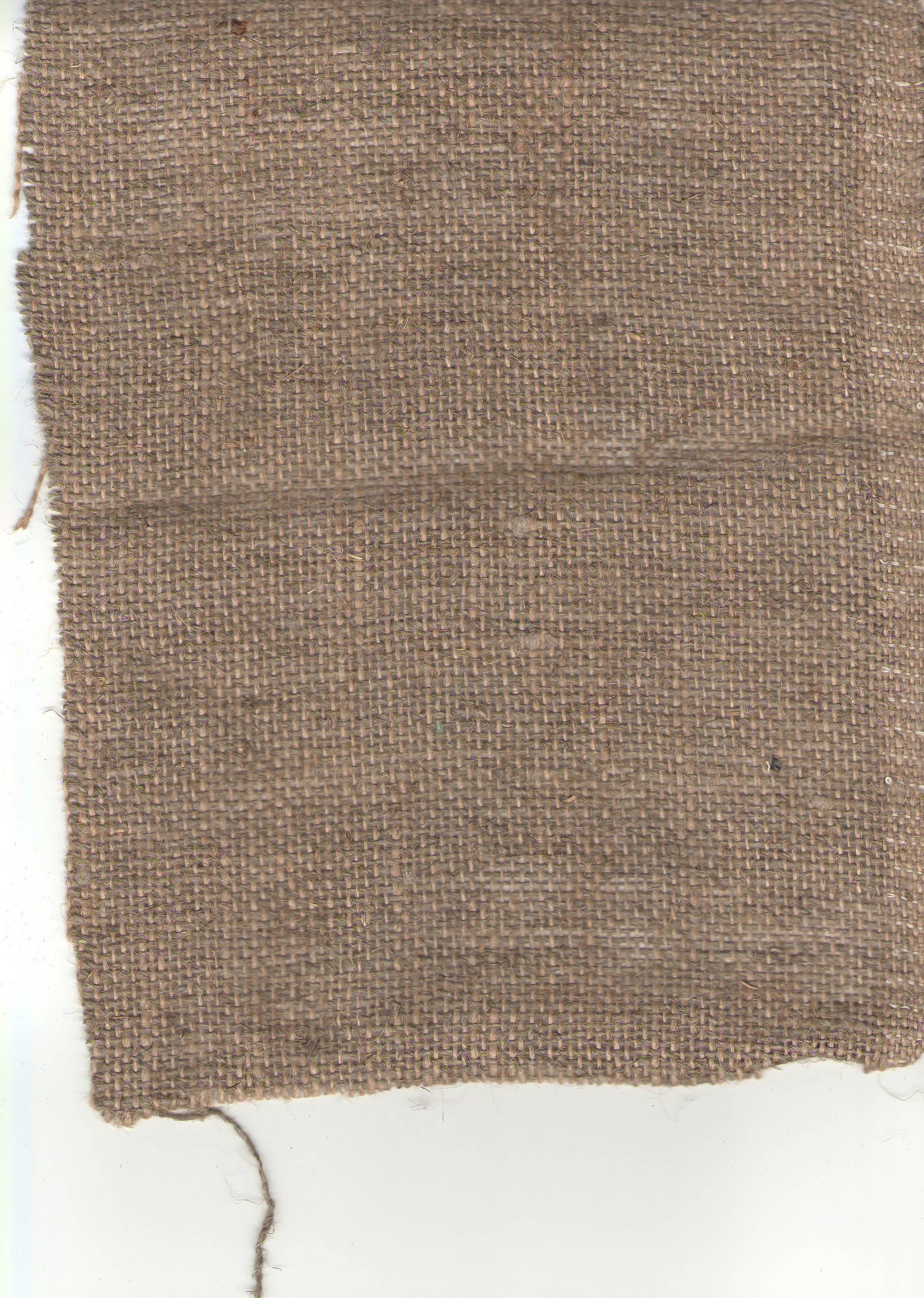

Important! In addition to fabrics, this material is used to make burlap, threads and ropes, twine, tarpaulin and much more.

Plantations used for collecting oil are mainly located in Russia, the USA, Argentina, India, Canada. It is delivered to any production facilities by highway, railways and ships. It is used in many coloring materials such as varnishes and enamels, linoleum, oilcloths. The dry residue in the form of cake is used as cattle feed.

Types and varieties of decorative flax

The plant serves not only for industrial purposes, but also for decorative purposes. Species used "for beauty":

- Flax large-flowered. A tall plant, reaching more than 50 cm in height. Small and bright leaves with flowers;

- Common flax. It is inferior to specially bred plants in beauty, but is also often planted in front gardens;

- Austrian flax. One of the most spectacular. Capable of overwintering in the middle zone;

- Flax Taurica. Beautiful yellow flowers that gather in bunches;

- Perennial flax. Classic version with small but bright flowers.

Useful properties of the plant in tissues

Plants of this species are mainly used to create fabrics. They are popular due to their properties. Clothes made from this fabric prevent the development of many diseases, fungi and bacteria on the body. This is explained by its bactericidal properties: the fabric inhibits the vital activity of microflora and has a microbial sorption greater than cotton.

Important! That is why it is used in the medical industry to make bandages. It has been proven that wounds wrapped with such bandages heal faster.

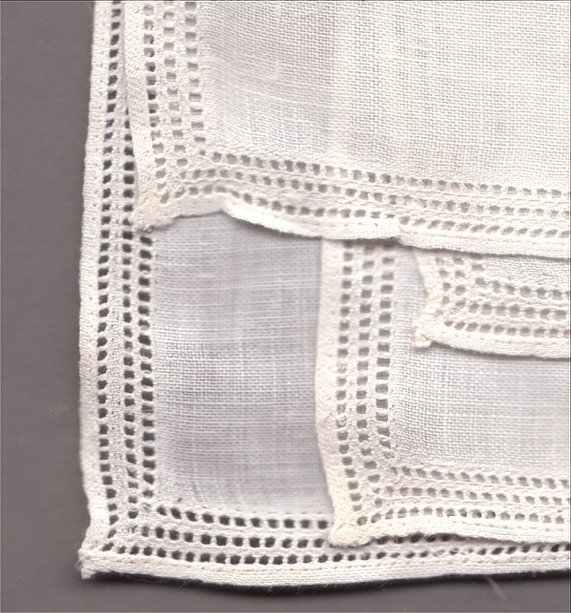

Linen clothing allows the body to breathe and does not clog the pores of the skin. This promotes normal blood circulation and increases endurance. Properly woven clothing is light and transparent. Ancient weavers could make the fabric so transparent that even through several layers the body was visible, and the attire itself passed through a ring. It was so thin.

Another property of the fabric is its durability. It is twice as tear-resistant as cotton and three times as tear-resistant as wool. Linen absorbs moisture well and also removes heat. This explains its popularity in hot and humid countries. Water evaporates from the surface of the fabric as quickly as from the surface of a reservoir. That is why it is always damp and cool. Allergy sufferers will also like linen, because it does not cause any effects on the skin or respiratory system.

Linen bed linen improves sleep, does not stick to the body and does not accumulate static electricity. In hot weather, the temperature under the linen fabric is a few degrees lower, and in the cold season - it warms. Unlike cotton fabrics, which turn yellow after washing, linen, on the contrary, becomes whiter and whiter.

Important! It is recommended to sleep on linen bed linen for people with allergies and sensitive skin or those who have dermatological skin diseases. You can wrap yourself in such a sheet if you get sunburned in the hot summer.

Everyone knows that after installing plastic windows, the house may start to smell bad. Plastic evaporates radioactive gas, which can have a negative effect on the human body. Salvation from it can be not only regular airing, but also linen bed linen, which reduces the level of radiation and weakens the radiation several times. The same can be said about clothing. It not only protects from window radiation, but also from solar radiation and rays.

It is worth remembering that the fabric is very wear-resistant. It does not lose its shape and quality after exposure to the sun, boiling, multiple washings, hot ironing.

Linen fabric: history and modernity

Flax has been used as long as cotton, but despite this, its history goes back more than 5,000 years. Archaeologists find more and more recent references to the fabric and its fragments. Research indicates that this plant was included in the list of agricultural crops in Switzerland back in the Stone Age. It was used to weave ropes and threads for hunting and fishing. This is evidenced by the artifacts found.

When craftsmen began to make the corresponding fabric, it was a luxury item in the East and in Ancient Egypt. Already from those times, active development of technologies for the production of high-quality products began: the fabric turned out to be thin, but strong, because good fabric is the foundation of good clothing.

Christians considered and consider such clothes a symbol of purity and hygiene. That is why priests wear clothes only made of pure linen without using other materials.

After that, handicraft production came to an end, and the first European manufactories began to appear. There, linen fabric is still expensive and considered premium. In Russia, it has always been more accessible and cheaper.

Today, the most exquisite fabrics of this kind are produced in Italy and Ireland. The largest quantities of linen fabric are produced in the USA and Canada.

Features of production

The technological process of production is based on special spinning machines and technology for preparing fibers for spinning.

The plant, collected in the fields, is first soaked, and thanks to modern technology, this time has been reduced to a week. During the soaking process, the water is constantly changed. This also accelerated the process. After this, the process of drying the stems begins. They are rolled into clods for ease of movement to the scutching shop.

It is a room with drums where the stems are placed. The device separates the necessary and unnecessary parts, feeding clean fibers on the output belt.

Important! One machine does it all. First, it separates the lump into individual stems and straightens them, passing them to the scutching stage, where the straight stems are collected into bundles and scutched by blades.

Further production involves working with raw materials using spinning machines. For this, the fibers are first combed and then, in the required state, are sent to the spinning machine. The result is a thread from which yarn and the final fabric will be created. The threads can also be used to produce other fabrics. All actions of the belt conveyor production must be carried out according to GOST.

Where is flax used in light industry?

First of all, flax is used in the textile industry. This is based on its properties and appearance. It is used to make fabrics for sewing:

- Clothes;

- Accessories;

- Tablecloths and kitchen napkins;

- Bed sheets;

- Toys and design elements in the form of ribbons and other things;

- Curtains;

The fabric, in turn, can be divided into several types: sack, technical, packing table, clothing and others. The finishing can also be different from untreated and rough to translucent printed and boiled. Based on this, the textile will look different. Untreated fiber is often used in plumbing.

High-quality paints and enamels, oilcloths and linoleum are made from linseed oil. Moreover, the oil has long been in demand, both among people and animals, as a laxative.

The fiber obtained from oil flax is used to make tarpaulin materials, twine, and heat-insulating materials. The seeds and briquettes of the flax are used in animal husbandry to feed livestock due to the fact that the meal contains a large amount of proteins in its composition.

Important! The medical industry should not be forgotten. Linen material has found application in the production of environmentally friendly and hygienic masks, bandages, gauze and other medical accessories.

Linen textiles are second only to cotton in popularity, but surpass it in many respects, possessing properties that are unique among many fabrics.