The advent of computer technology, the Internet and information carriers has forever changed humanity and its attitude to printed books: they are read less often. Time has passed and people have become convinced that no electronic material gives the same sensations when reading as an old-fashioned paper book.

In this regard, interest in printed publications has increased. In order for them to remain beautiful and not fall apart, they need to be bound. Many fabrics are used for this, but the most popular and accessible of them is calico. This article will tell you: what is calico, the definition of which is often confused with colloquialisms.

Description of fabric

The first thing to say is different calico. Some people don't know what different calico is, the meaning of which doesn't exactly come from book binding. The origin of the phrase "completely different calico" arose as an approval of something. "This is a different calico" is a figurative expression "Not at all what it used to be."

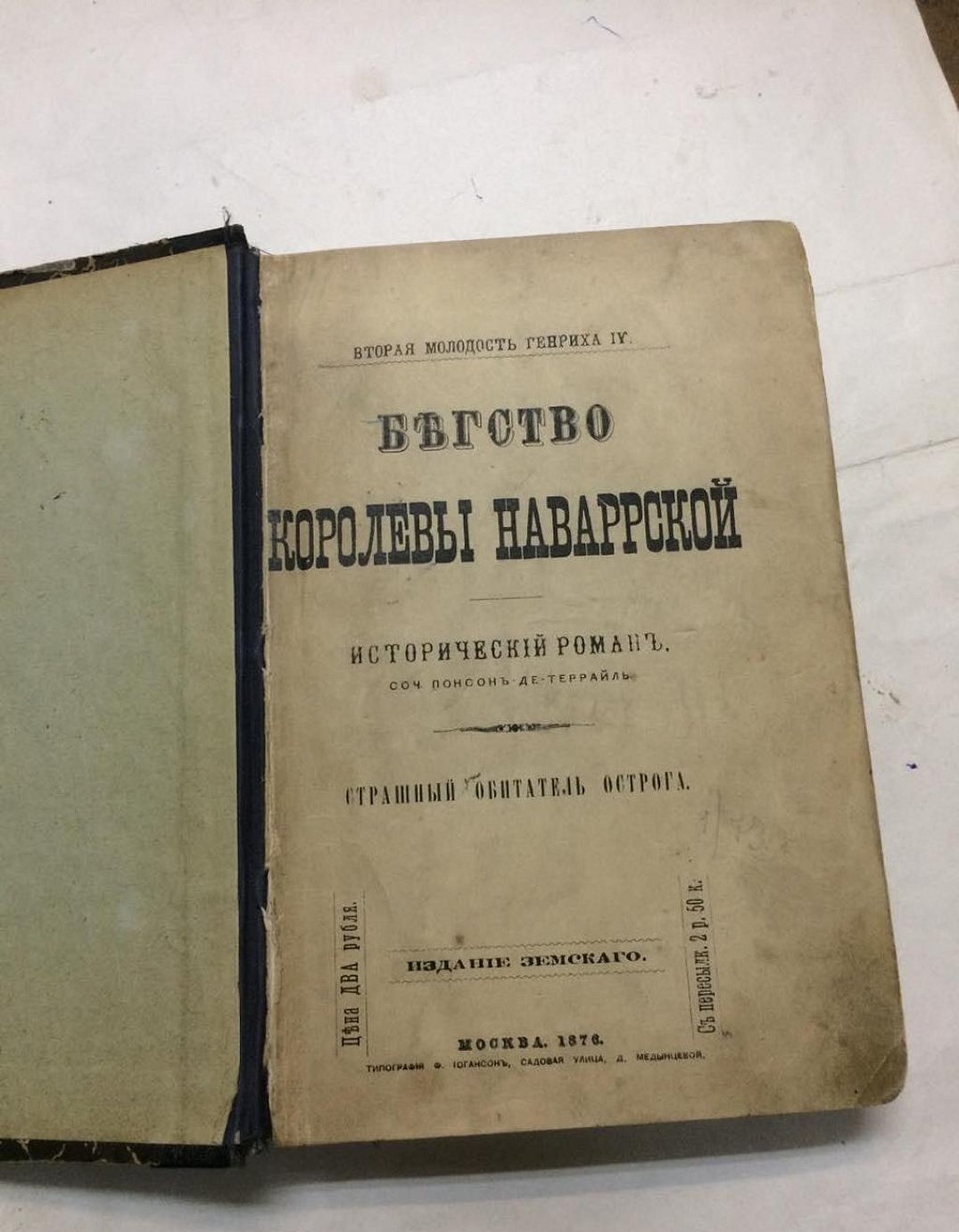

Now it is worth moving on to the physical calico used in book binding. The creation of books and printing began in the 2nd century AD. Even then, people could sew sheets of papyrus and cover them with leather materials. This happened for a long time and for more than 15 centuries, the creation of books was an episodic activity, since it was an expensive pleasure and was made only to order.

Mass bookbinding appeared only towards the end of the 19th century, together with the development of book printing and book trade. Bookbinding workshops began to appear, working with special technologies and tools.

Important! To stitch books to protect them from environmental factors, leather materials and fabrics were used, including calico.

The history of its origin is still a mystery. At the moment, there are several versions of where the material came from:

- European;

- Indian.

Some scholars argue that the truth lies somewhere in the middle: calico was invented in Asia and perfected in Europe.

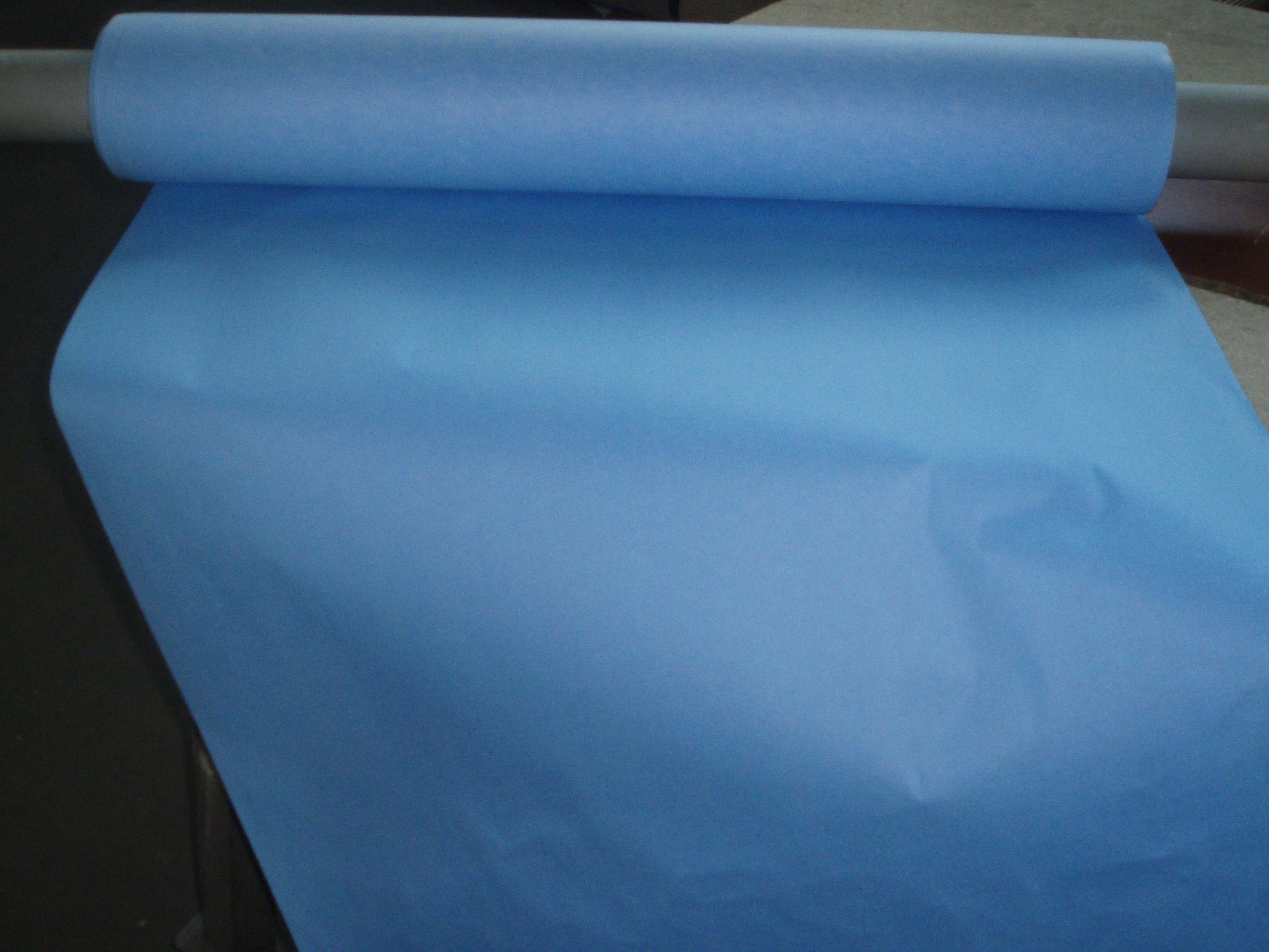

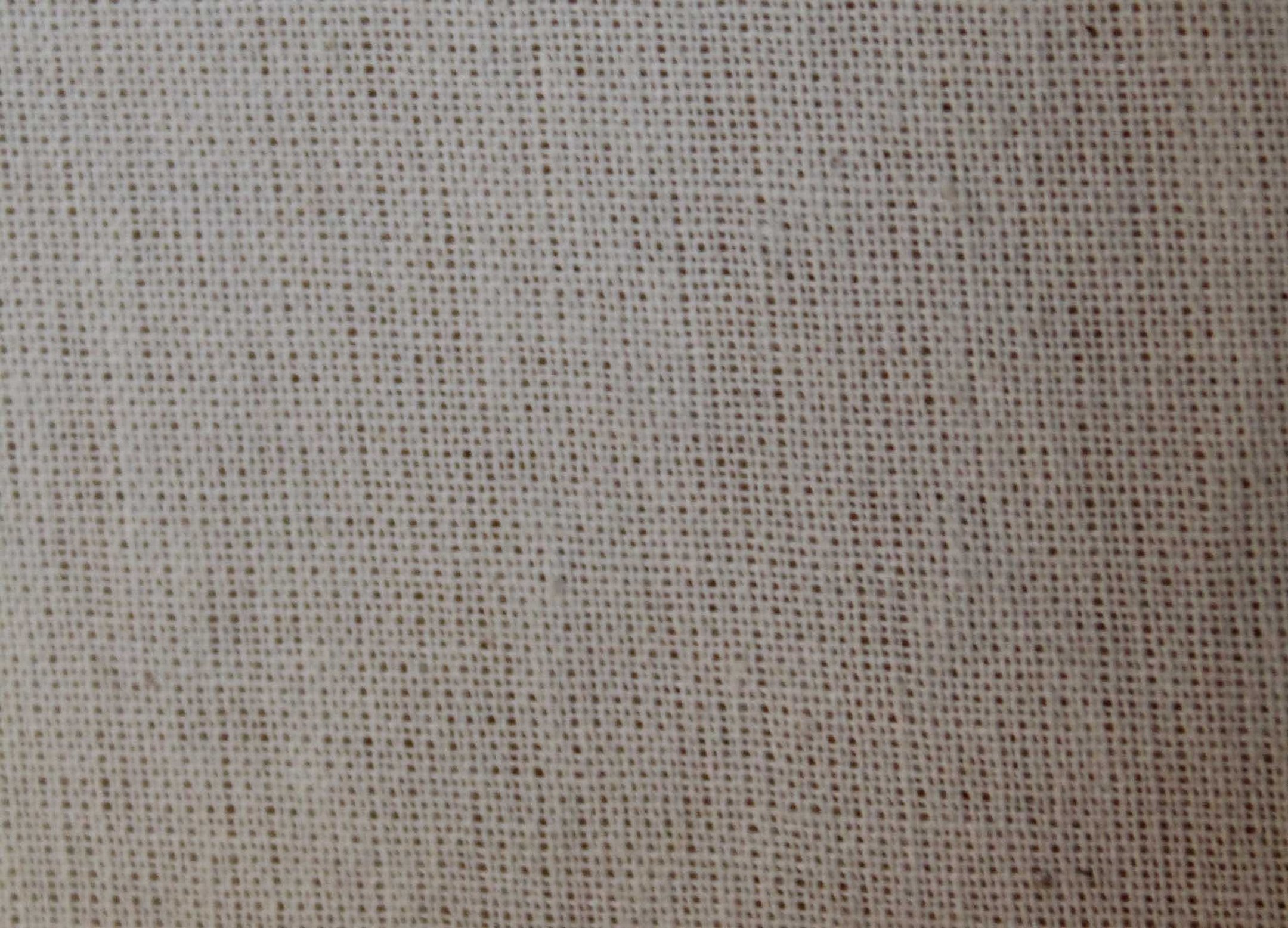

Calico itself is a type of muslin, which is a coarse cotton fabric that has been processed in a special way.

How Calico is Made

To produce this fabric, untreated and unbleached calico is used. In general, the technology includes several stages:

- The raw calico is treated with acid dyes that match the colour of the primer that will be applied at the next stage;

- Dry until completely dry and iron;

- Applying a primer to the reverse side, which consists of kaolin clay, casein glue, starch and water. The primer is applied so that the weight of the layer does not exceed 20 g/m2;

- Making and applying the primer to the face. Its difference is that 0.5-1% of dye is added to its composition;

- The front side is covered with primer using special devices once or twice;

- The fabric is smoothed out again and, using embossing, patterns can be created on it, if required.

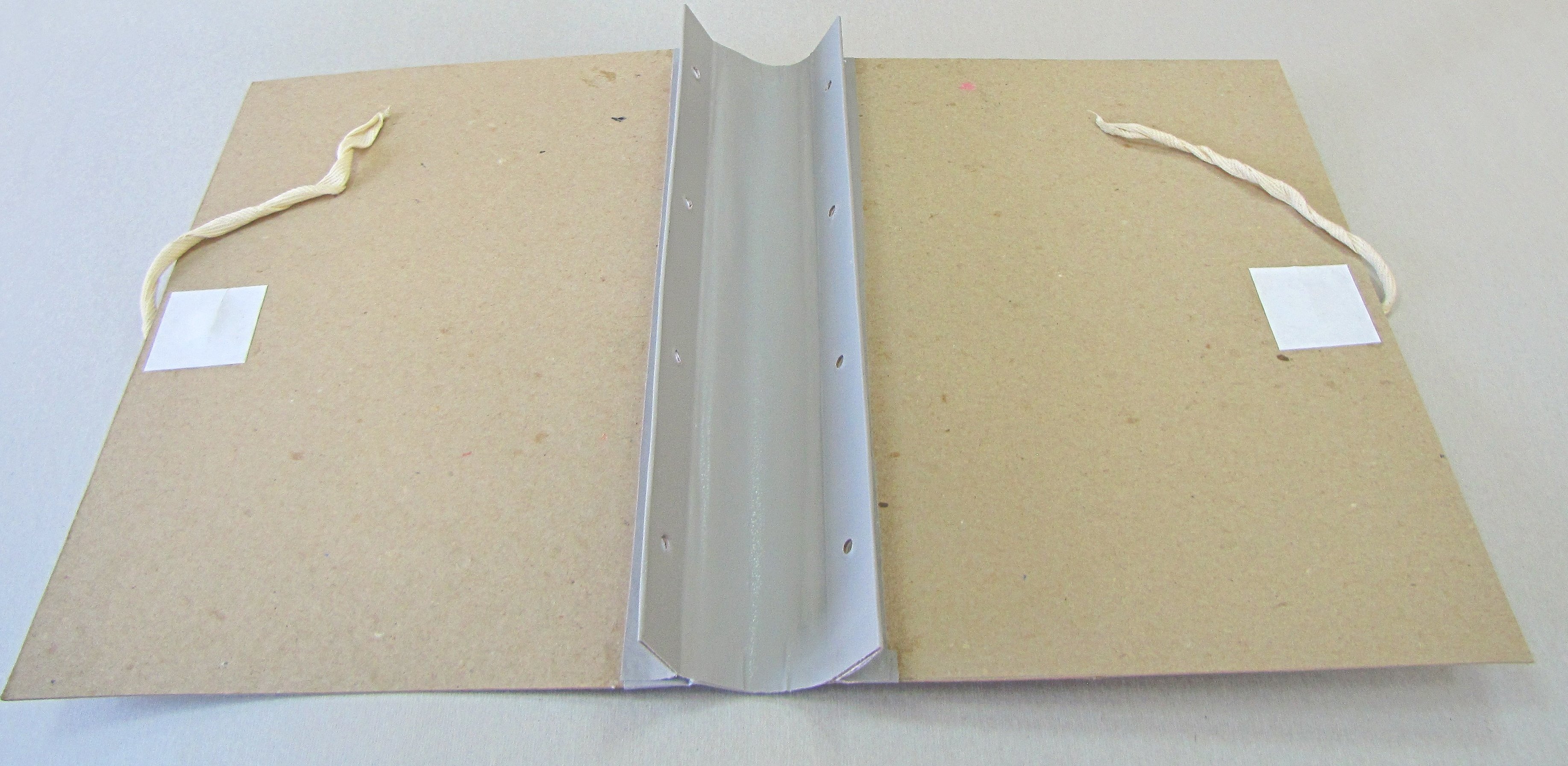

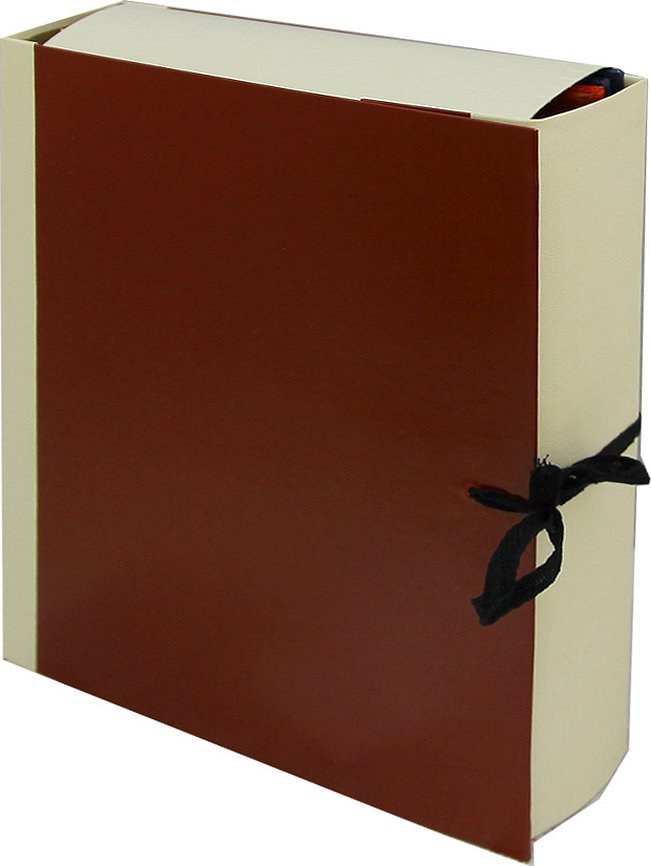

Important! When binding, the canvas is placed on the cover, that is, the lid, and the flap - the main strip that connects the pages and the cover together.

The requirements for the final product may vary, so two types of fabric are usually produced:

- Used for the production of lids and covers with a density of 170 g / m2. It is called KP;

- Used for making folds with a density of 135 g / m2. This fabric has a matte surface for better adhesion to adhesive materials. It is called KF.

Another difference between them is that the rigidity of the first material is several times greater than that of the second.

Types of calico fabrics

The textile industry does not stand still. Even calico is developing and improving. Today, new types of calico have been created, differing in the type of calico:

- Standard ordinary version, created on the basis of "Modern" materials;

- A higher quality, bleached fabric made from premium fibres.

Calico can also differ in the type of technological processes used in its creation:

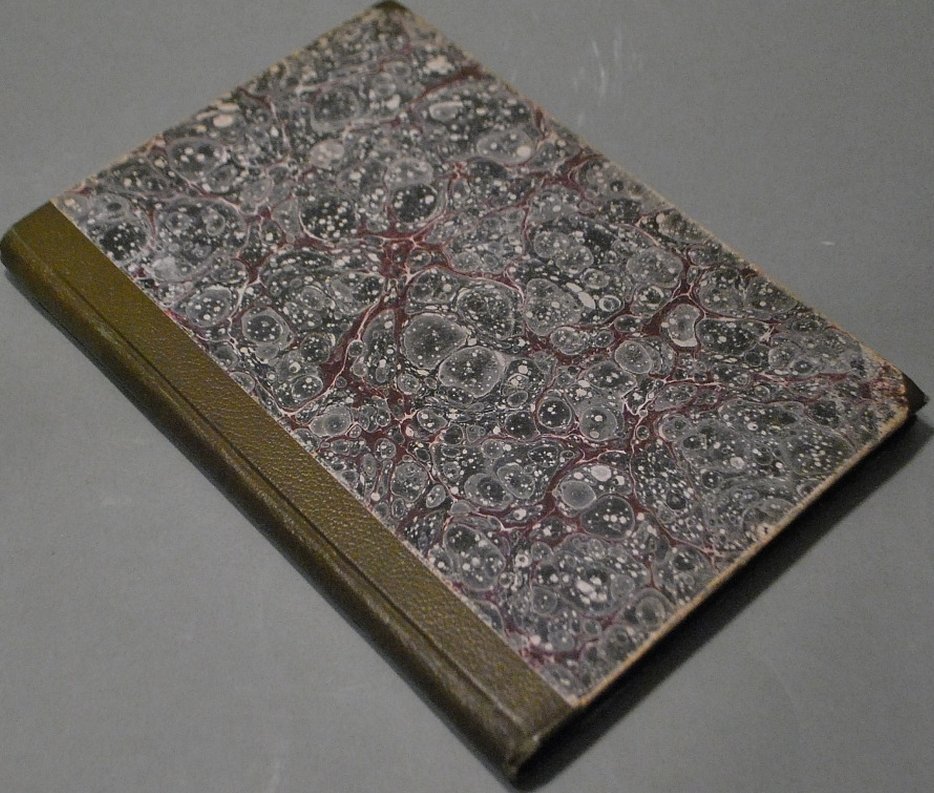

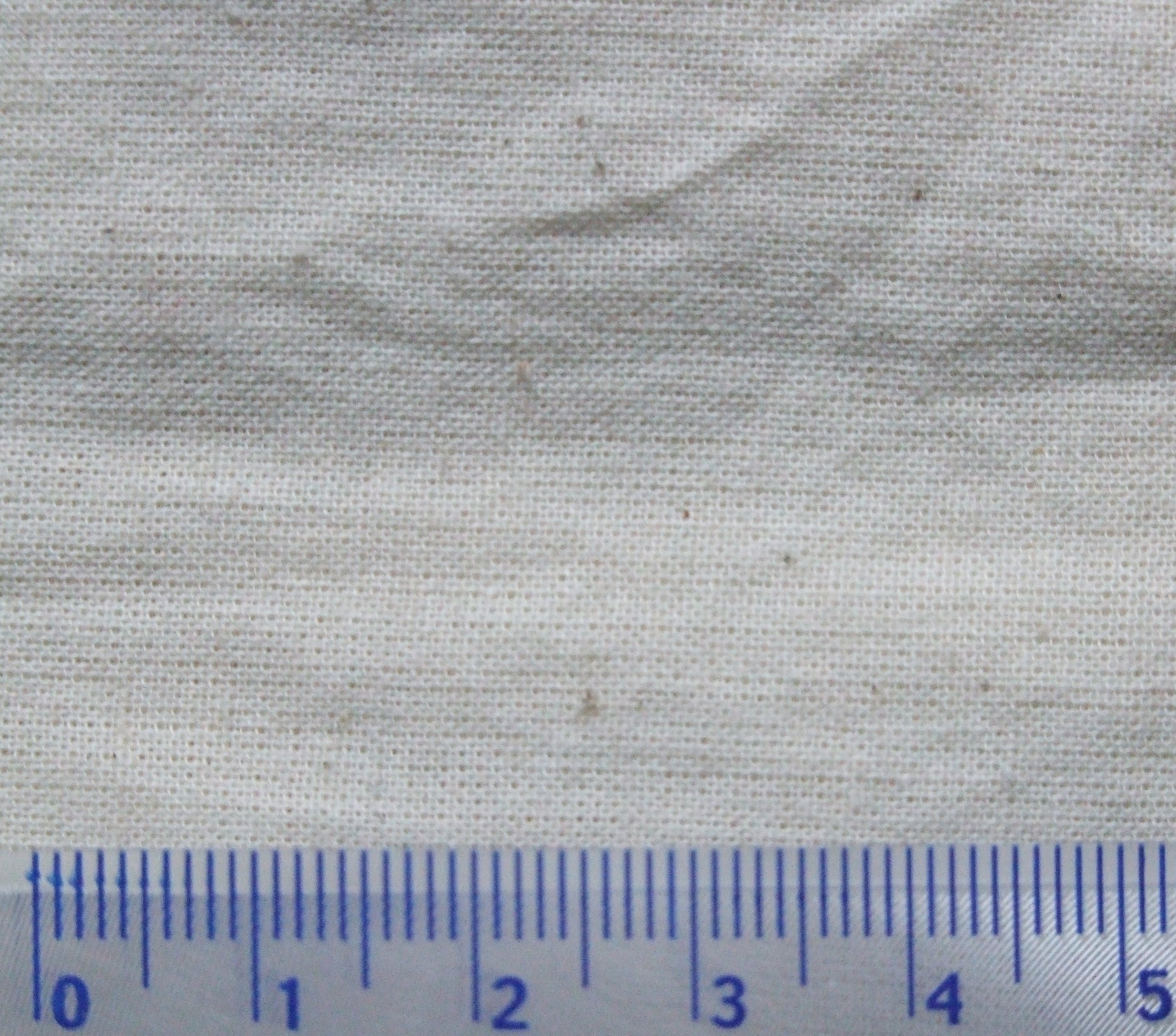

- Some consumers prefer to see the structure of the fabric, its fibers and threads. To make such material, a ground material made of starch is applied to the back side, and a transparent material is applied to the front side. As a result, the texture of the fabric, its appearance and color become an additional decoration of the book cover.

- Some people like smooth and even bindings. To do this, a nitrocellulose solution is applied to a transparent layer of primer. After this, the coating looks nicer and acquires water-repellent properties. The downside of this method is that books stick to each other if they are on one tight shelf.

- Modern solutions involve adding latex to the primer to give the material a beautiful appearance and quality. The primer is applied in the usual way.

- Recently, they started using leatherette. It is the same fabric based on calico, but on the back side of which they apply a regular primer, and on the front side - nitrocellulose film and pigments.

A bit of lyricism. Books and albums in calico binding have truly magical properties. Having picked up such a book and read a couple of pages, you want to read it all: from cover to cover. These feelings and experiences cannot be compared with computer versions and e-books, since they are different spheres of activity. Books develop the intellect and make you experience a lot of emotions.

Where is calico material used?

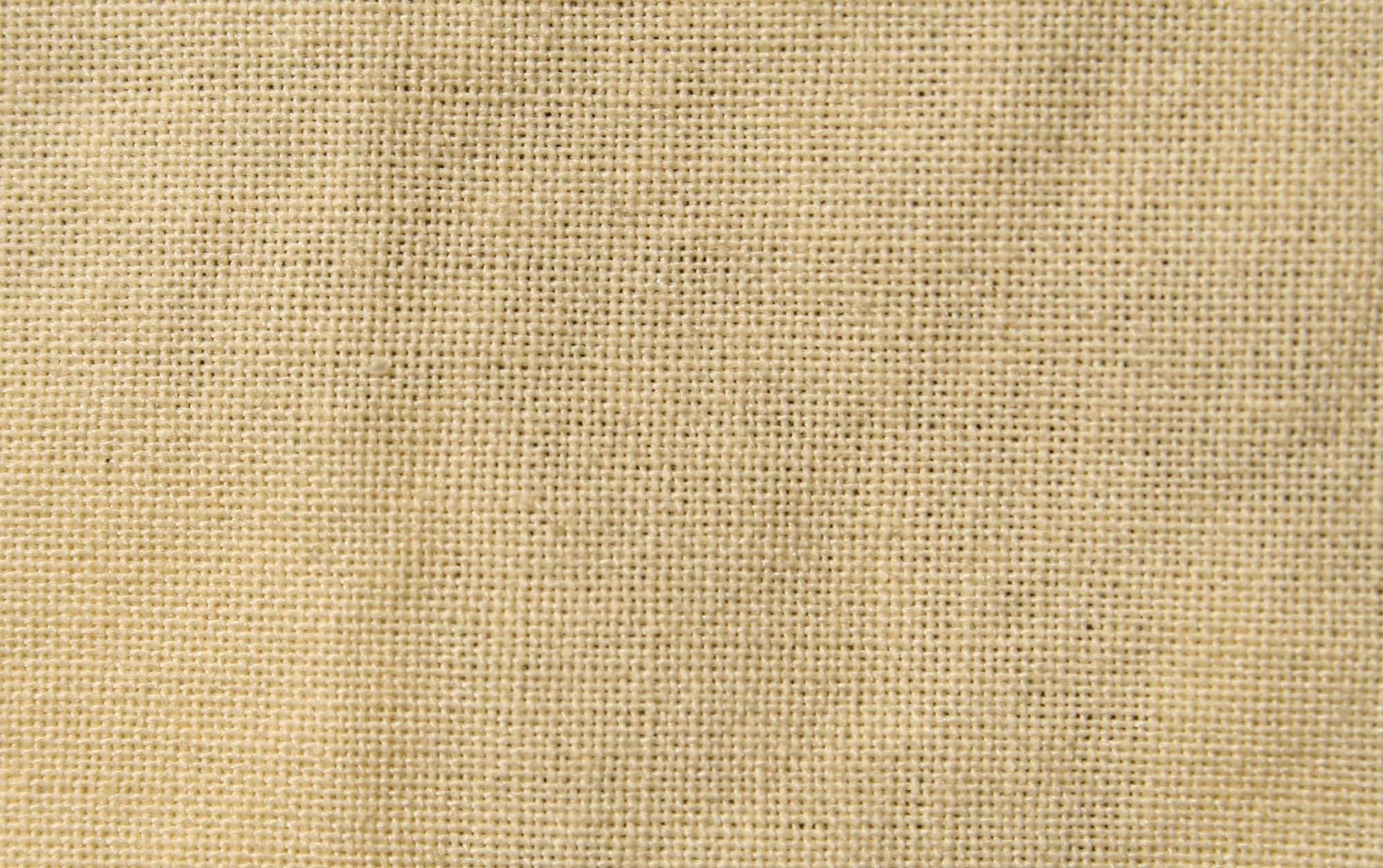

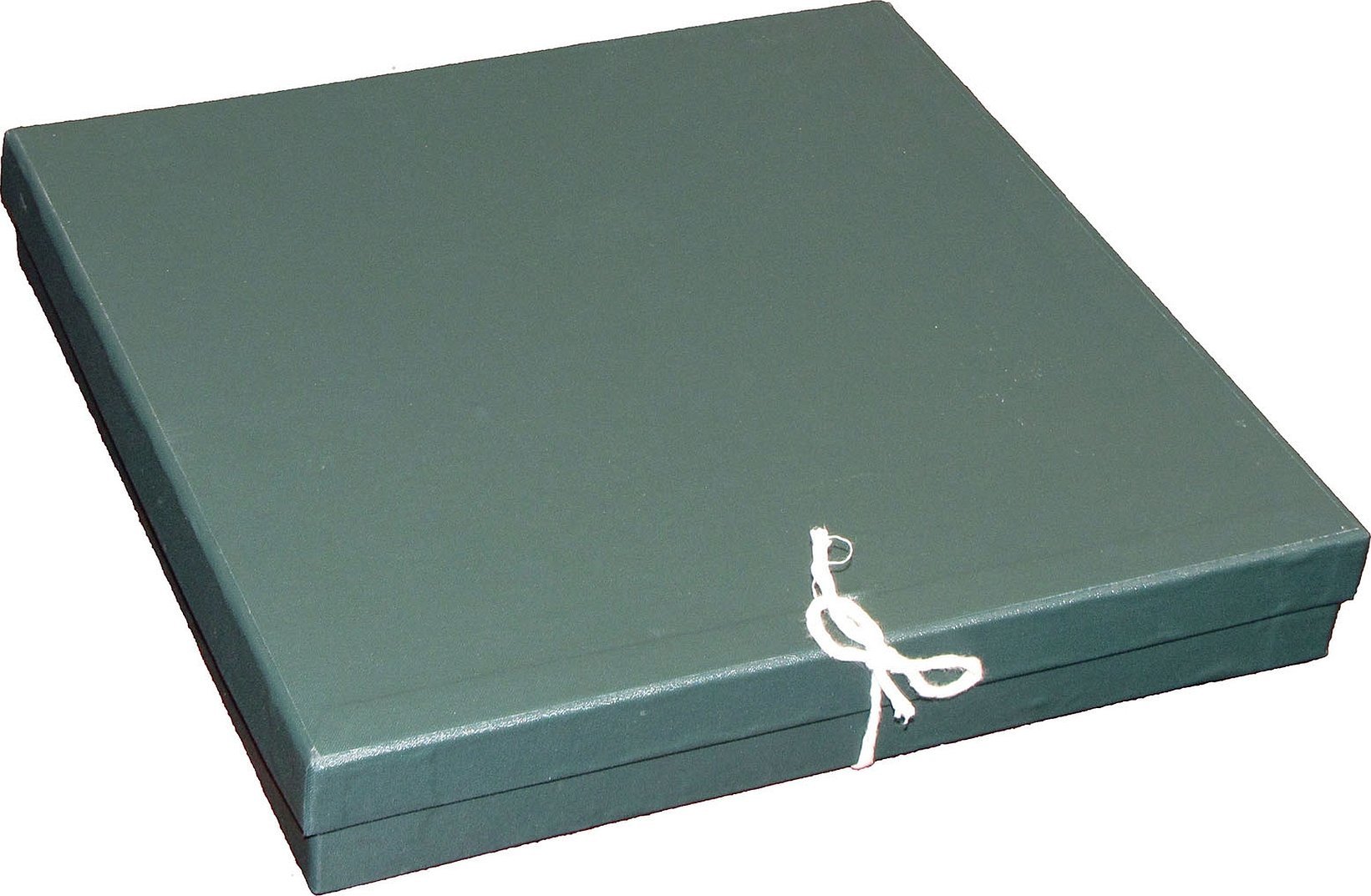

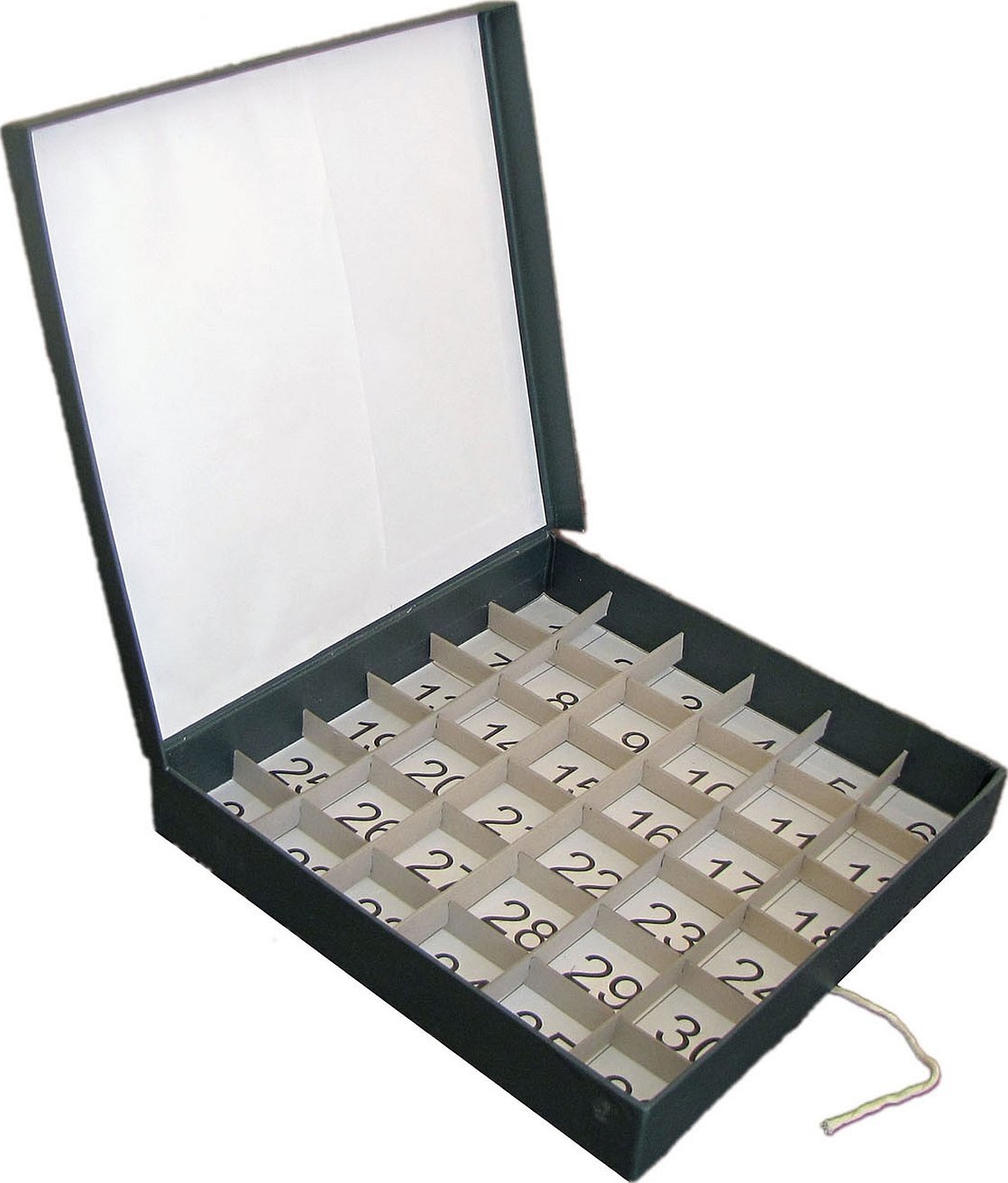

Calico is suitable not only for binding printing houses and albums. It is durable, does not wrinkle and does not fade. Therefore, it is often used to protect windows, namely for sewing curtains, which can be painted in any shades with any patterns. The material is also used to create gift boxes and cases.

Artists draw preliminary sketches on it, and designers print and draw pictures on it to decorate the interior of the room. All this is possible due to the fact that the material is cheap and has a whole range of suitable properties.

Important! To prevent calico products from spoiling and becoming covered with mold and mildew, they should be stored in a well-ventilated area.

Some types of calico are more technical fabrics. In general, the material can be used for the following:

- Restoration of paper products, paintings;

- Strengthening wall geographical maps, diagrams and tables;

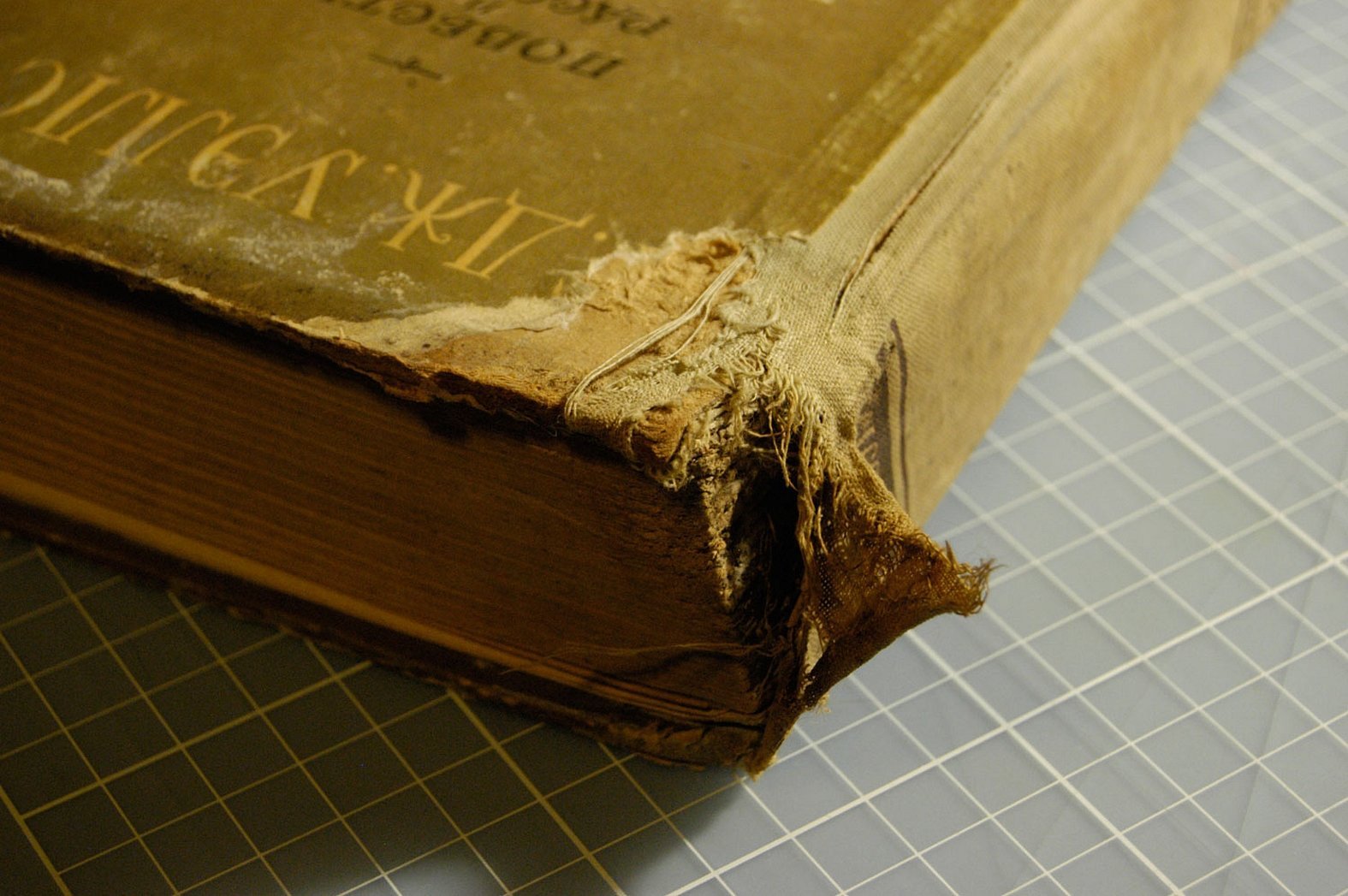

- Book bindings and restoration;

- Production of strips for folders, diaries, notebooks;

- Souvenir boxes;

- Photo printing and reproductions;

- Canvas replacements.

Storage

It is important to understand that when using any type of material and for any purpose, the room must be maintained at an optimal temperature and humidity. This is done to prevent mold and fungi from appearing on the material, which love cotton fabric and settle there, depositing their spores there. By maintaining a temperature of 20 to 25 degrees, as well as constantly ventilating the room, you can ensure that things made of this material and books will be stored for a very long time and will bring many positive emotions to more than one generation of people.

Advantages and disadvantages of calico

The fabric on which hopes for the preservation of books are placed must have properties that distinguish it positively from other materials in terms of density and quality. The fabric must have the following characteristics:

- Density of the fabric;

- No cracking at bending angles;

- Easy and fast perception of twists after gluing the fabric;

- Increased resistance to abrasion, achieved by priming and applying nitrocellulose film;

- Retains color after prolonged exposure to ultraviolet rays from the sun.

Important! The fabric is produced with different primers, textures and colors. It can be embossed with foil or treated with binding dyes.

Nowadays, technology has advanced so much that it is possible to produce fabric of such quality that it will be practically free of drawbacks. The key word is "virtually". Calico is not free of them either. It also has several negative properties:

- The starched coating does not tolerate moisture;

- The material ages quickly under poor conditions and without care;

- The starch coating may crumble;

- Calico is very easily soiled;

- Gets completely wet when gluing old and new books;

- It is a favorable place for the development of mold and fungi in high humidity conditions;

- Its appearance is not distinguished by beauty and sophistication.

Thus, calico is an important and dense, but quite demanding fabric, originally used for bookbinding and restoration of books or albums. Today, the applications of this material have expanded and it has become more popular. Despite its many positive qualities, it also has negative ones, which can be eliminated with careful and proper care and storage.