An impermeable cotton fabric, the surface of which is distinguished by its extreme smoothness, is called moleskin. The material, unique in its properties, became known at the beginning of the last century thanks to English weavers. Since then, reliable work clothes for employees of specialized enterprises have been made from it.

What is moleskin

The fabric is made from dense and thick cotton fiber, which is distinguished by a special weave. After production, the material undergoes mercerization (short-term treatment of the fabric with a concentrated solution of caustic soda, followed by washing it with hot and cold water), which gives it a smooth and beautiful surface.

Please note! Initially, moleskin material was made only from cotton and had a black tint.

Nowadays, moleskin contains synthetic threads, which make it much thicker with the same strength indicators. The fabric also has a variety of colors.

The main advantages of moleskine:

- high strength;

- ease of care;

- high wear resistance;

- resistance to aggressive substances and fire;

- excellent air permeability;

- absence of electrification;

- ability to retain dust particles;

- the ability to evaporate moisture from the skin surface.

As for the disadvantages, despite its dense structure, the textile is characterized by excessive friability. In addition, it is not very convenient to sew, and is difficult to pierce with a needle. In some cases, the fabric is cut through at the puncture sites. Also, moleskin is a material that is not recommended to be washed in hot water, as it can "shrink".

During production, depending on the impregnations used, moleskin is produced in several grades.

History of production and use

Moleskin fabric appeared in Russia in the 19th century. Before that time, the production process was carried out only in England. Excessively dense versions of the material had a specific name - "devil's skin". After its appearance on the market, the textile was used to create special and military uniforms, as well as a base for artificial leather. Therefore, moleskin was often used to make book bindings and shoe uppers.

The production of moleskin material is embodied in reality from thick cotton fabric. This is carried out by the method of reinforced satin weaving. Its essence lies in the fact that additional overlaps are intertwined between two warp and weft threads.

Until the 1950s, the "devil's skin" fabric was only available in one shade, but later it was dyed in rich shades and used to sew ski clothing. At that time, it was an ideal option, as moleskin retained heat and prevented moisture from penetrating. But with the advent of synthetic membrane fabrics, the popularity of "devil's skin" began to decline rapidly. This was explained by its high hygroscopicity, which prevented moisture from being removed from the body. That is why sportswear is not made from this fabric in the modern world. But this did not prevent moleskin from gaining immense popularity around the world.

Modern moleskin differs significantly from its original. Now, thinner, super-strong threads are used in production together with synthetic fibers. Special solutions, which the finished product is impregnated with, make it as safe as possible. In addition, modern material is created taking into account that clothes made from it will subsequently be used in difficult production conditions.

Due to the versatility of the textile, not only winter items are sewn from it, but also summer ones. The reasonable price makes it accessible and in demand among buyers.

Properties and characteristics

Increased fiber density is considered the main characteristic of the moleskin material. This feature allows clothes made from this textile to provide reliable protection of the human body from all kinds of dirt.

Important! Thanks to the special weave of the threads, the finished product has a very smooth surface. It ensures that large particles roll off the front side of the suits. Also, moleskin fabric can be impregnated with different compounds to give it special properties and indicators.

On the reverse side, the material has a slight pile. It is created by napping the finished fabric. The fibers of individual threads are pulled out onto the surface of the textile. It is this feature that improves the heat-protective properties and increases the wear resistance of the product, and also makes the reverse side softer.

Moleskin is most often a plain-dyed fabric of one color, which does not fade for a long time, wears out little and does not lose its shape at all. Unfortunately, not everyone knows what moleskin is. Some people think that such a dense material does not allow the body to breathe. This opinion is wrong, since it has a cotton base, thanks to which the suit will not be hot even in rooms with high temperatures.

"Devil's skin" has the following unique properties:

- ease of care;

- environmental friendliness;

- high wear resistance;

- mechanical strength;

- dustproof.

Scope of application

Sewing work clothes for people whose professional activities are related to hazardous production is recognized as the main area of use of moleskin material. Products made from this fabric are indispensable for:

- nuclear power plants;

- metallurgical and chemical plants;

- medical institutions;

- public utilities.

Since its inception and up to now, fire-resistant material has been used to create items for work in hazardous conditions. But despite this, the fabric is also used to sew spectacular exhibits that are presented at fashion shows. Such clothing, in addition to an attractive and aesthetic appearance, is highly wear-resistant.

What is moleskine made of?

Workwear for those whose professional activities involve exposure to high concentrations of dust, various contaminants and open fire was the first use of moleskin fabric.

The "devil's skin" fabric became extremely popular at the beginning of the last century. This super-strong material is used to make suits for workers in cement, flour mills and other factories with high dust levels.

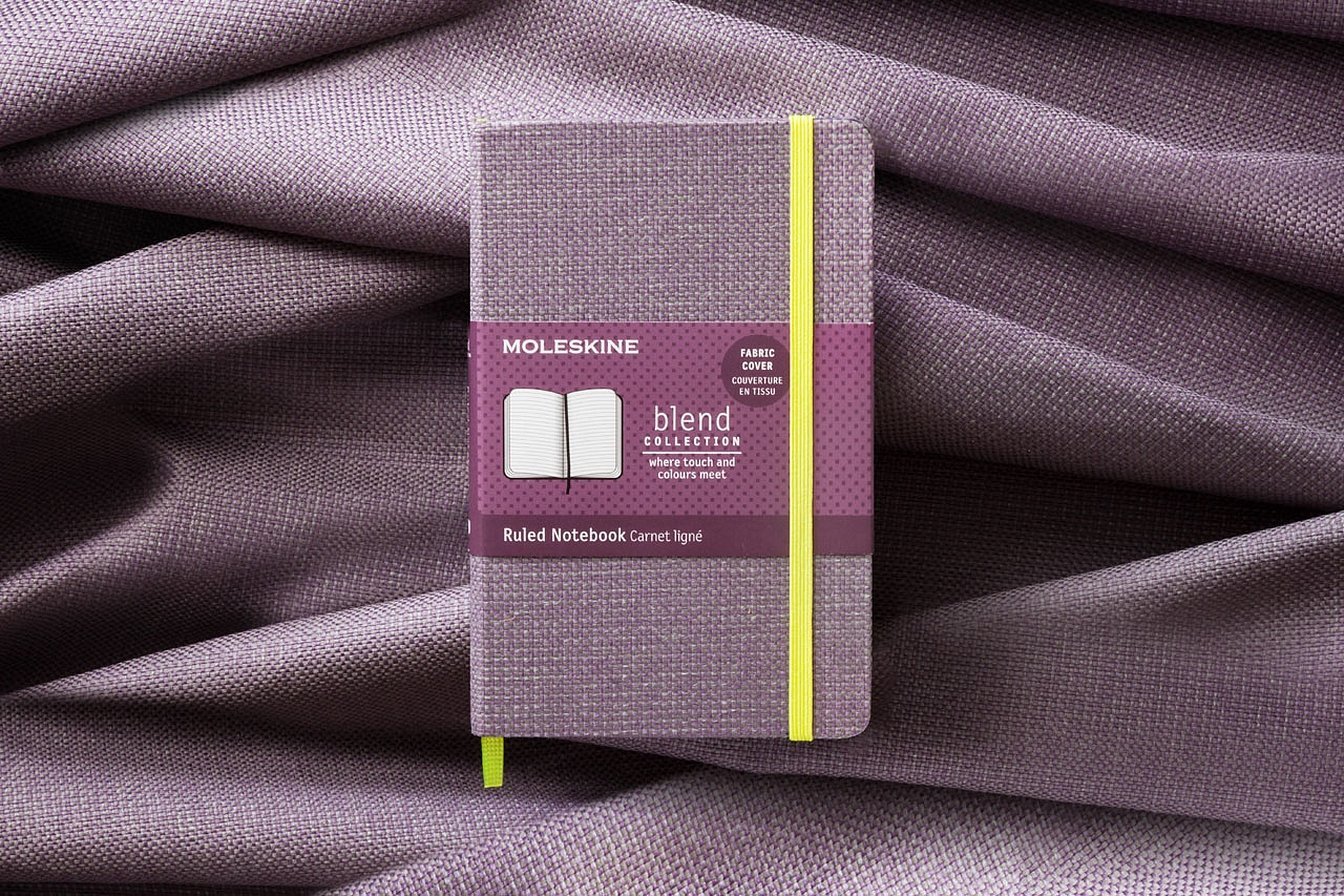

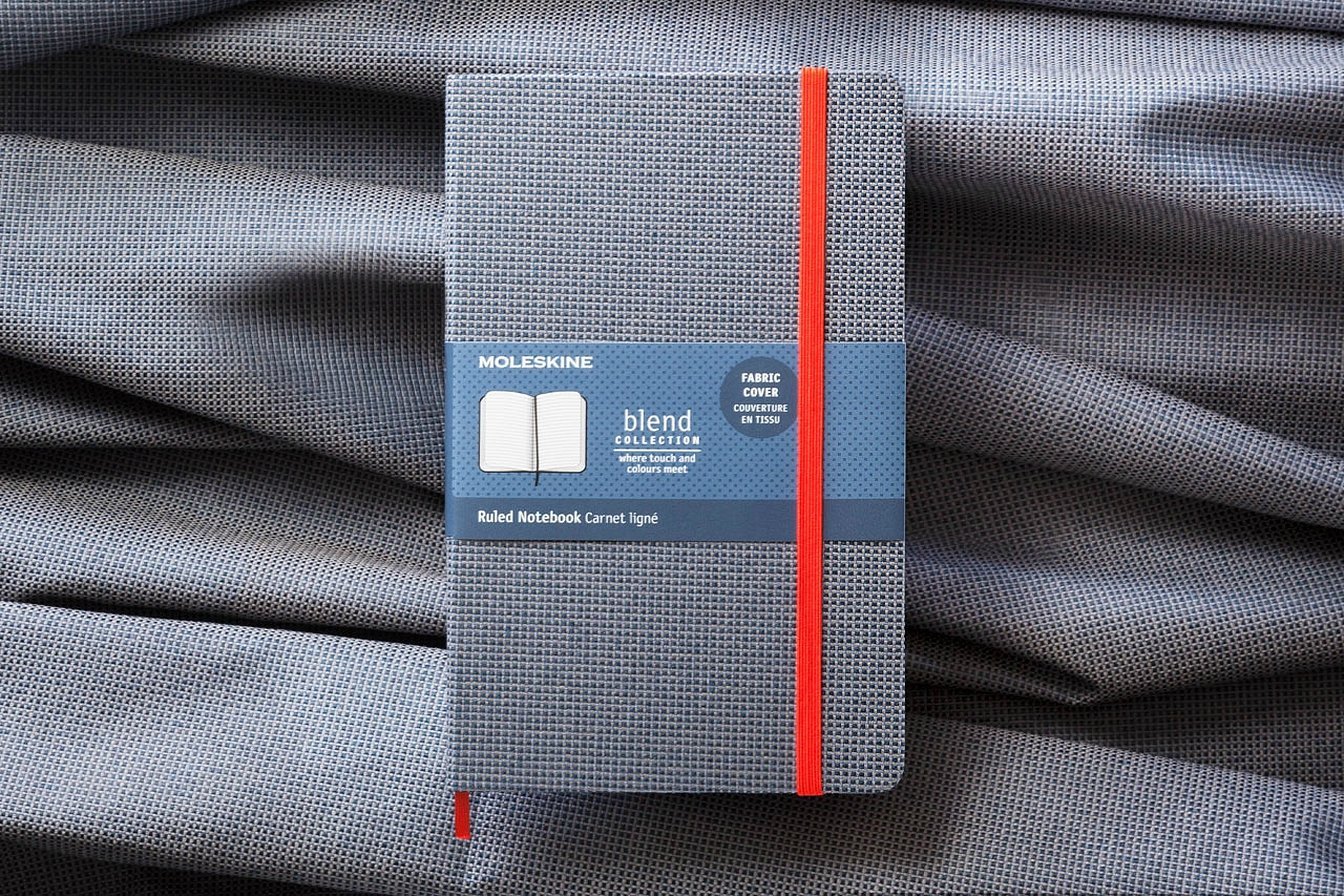

The material is used in sewing military uniforms, and it is also used to make the base for artificial leather, bindings for notebooks and other printed materials, and dustproof covers.

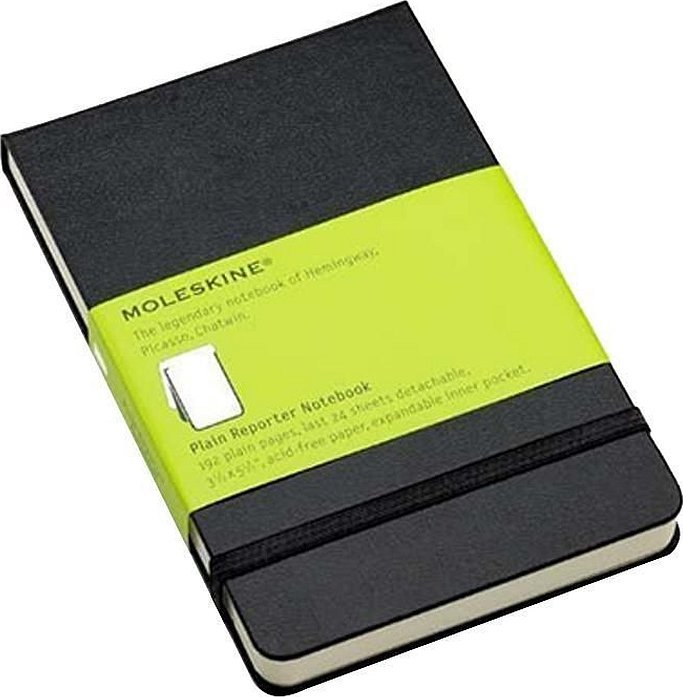

Please note! The famous brand Moleskine specializes in the production of notebooks and other stationery products that are in great demand all over the world.

High-quality moleskin is used to sew elegant raincoats, coats and jackets, and to create shirts and trousers. This is done by some European brands, such as Balmain and Incotex. During sewing, the textile is mixed with synthetic additives, resulting in a comfortable and lightweight material, which is used to create sports collections. The fabric is in demand in the production of the upper part of shoes.

They buy clothes made of this material for personal use. In it, you can always feel safe, even in close proximity to fire or harmful substances.

Very easy to care for

When encountering a product made of moleskin fabric for the first time, not everyone knows what it is and how to care for it. However, caring for the material will not cause difficulties even for those who encounter it for the first time.

When clothes get dirty, you can shake them out or vacuum them. Washing should be done at a water temperature of no more than 60 degrees. After washing, the textiles may change slightly in size. It is prohibited to use bleach. If the fabric is impregnated, then dry cleaning is best. When ironing, the surface temperature of the iron should not exceed 150 degrees.

Based on the characteristics and properties, we can conclude that moleskin fabric is an inexpensive and extremely reliable material. Despite the fact that it is not distinguished by brightness and sophistication, it is used in the most complex industries, as well as at home. It is products made from this textile that can provide comfort and safety regardless of where you are.