Among all the variety of textile products, ramie fabric has gained wide popularity.

Ramie plant

Since 2010, the fashion house Corpo Nove has succeeded in producing clothes using this fiber, demonstrating to the whole world a unique collection of clothes made of nettle. It is believed that the first fabric from nettle began to be made in ancient times. And it is no coincidence that more and more people of our time prefer natural fibers to synthetic materials.

Ramie fabric: history of cultivation

Rami fabric what is it? This question can be heard from a layman who has never encountered either the fabric itself or products made from nettle fabric. Usually the phrase "nettle fabric" is alarming.

There are several types of plant materials used in the production of ramie fabric:

- White. (Fig. 1);

- Green (Fig. 1a);

- Nandu.

The plant is classified as a genus of bast fibers. The plant is harvested 6 times a year. It produces a large number of branched roots, is characterized by active growth and productivity for 2 decades. The plant material contains a large content of resins, pectins, the removal of which requires complex and expensive processing processes.

Description of the plant

It is cultivated in China. The leaves are large, serrated, heart-shaped, covered with white fluff, which gives a silvery sheen. The homeland of the green deadnettle is the Malay Peninsula. The plant has smaller leaves, green underneath, the plant is cultivated in tropical conditions.

The plant, which grows in northern climates, is characterized by short and coarse fiber. It is for this reason that the plant, cultivated in temperate latitudes, has found wide application in the manufacture of materials used for domestic purposes. At the same time, the fiber of white nettle and the closely related genus Boehmeria tenacissima has been grown in southern Asia for 5 thousand years. The materials produced from plant raw materials are white and green ramie.

There is a ramie museum in South Korea, where the fabric is called "moshi."

According to historical data, the Chinese used nettles as a raw material for making outerwear - kimonos. Traditional Korean clothing - "hanbok", made of linen, was popular due to its elegance. The fabric combines lightness and silkiness, is similar in many ways to flax, is used in the production of clothing and home textiles.

If plant raw materials are processed incorrectly, the chance of obtaining low-quality fabric increases. Fabric produced in China and India is especially valued. These countries have centuries of experience in growing and processing the plant.

The canvas was brought to Europe by travelers. In the 19th century, large-scale cultivation of nettles began in Europe, and fabric production was organized in some countries. The plant is cultivated and raw materials are produced in the Caucasus. The plant is not grown in the Russian Federation.

Rami in modern clothing production

1980 was a landmark year for the production of clothing from natural fibers. White nettle is not used in textile production due to the high cost of raw materials. Moreover, complex processes are required when processing the plant. Ramie is a unique fiber of natural origin that combines useful properties. The main task of modern clothing production from this plant raw material is to improve the processing of the material, which will affect the popularity of the fabric in the future.

Interesting fact. Korea traditionally holds a festival of fabrics made from Chinese nettle. Over the course of several days, there are demonstrations of products, making souvenirs from the plant, and tasting dishes.

Countries producing Chinese nettle:

- China;

- Brazil;

- Philippines;

- India;

- South Korea;

- Thailand.

Countries importing plant materials:

- Japan;

- Germany;

- France;

- United Kingdom.

Important! Fabric and plant materials are difficult to find on the international market: only a small part of the produced material is available for sale. Most of the fabric is used within the producing countries.

Fiber production

In the Chinese town of Yichun, the material was made by hand. Ramie is called "light" and is compared to "cicada wings", paper, mirror, silk. High-quality fabric obtained from ramie was twisted into a long thread. Then, fabrics were made by hand.

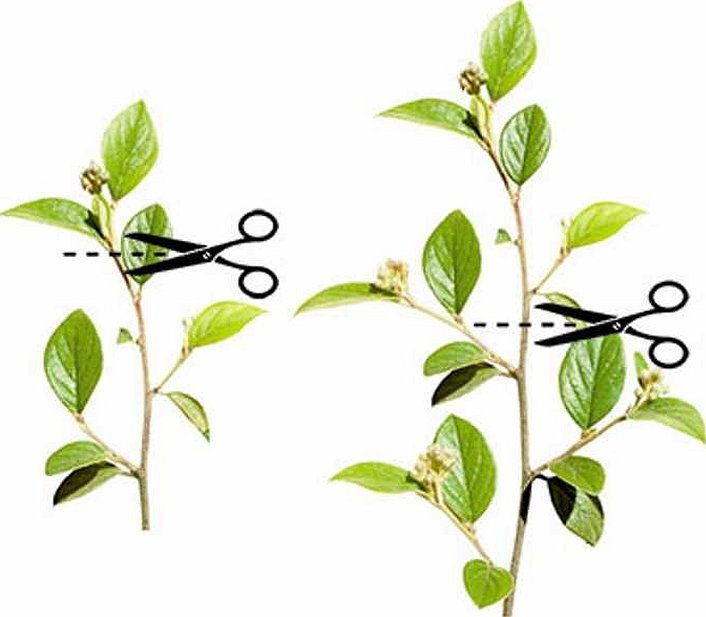

The production of the canvas begins with the collection of plant raw materials. At the time of flowering of the dead nettle, the fiber content in the plant reaches its peak - a favorable time for harvesting. The signal that it is time to harvest the crop is the darkening of the stem. Otherwise, the chance of obtaining low-quality and fragile canvas increases. Late harvesting will reduce the chance of separation of shoots from the fiber. This will lead to large time and material costs, and will reduce the quality indicators of the finished product.

The shoots are cut manually. This reduces the risk of breaking the core. After cutting, the core is disposed of, and the plant material is dried.

The next stage is the removal of resins. The operation is labor-intensive. It is carried out by 2 methods: biological and chemical. Each manufacturer of the canvas uses its own method of processing, which is kept secret.

When processing plant materials, an important and complex stage is separating shoots from plant fibers. The quality of the future material depends on how correctly this stage is carried out. The result of the processing is the finest white cloth with length parameters of 1 m 20 cm.

The burning and stickiness of the material is removed by using chemicals.

Ramie: material composition and properties

The plant's fibers are used to make a fabric similar to linen, but different from it.

Properties:

- Durability. Depends on the conditions of growing the crop and harvesting. Due to this characteristic, it attracts designers and clothing technologists. The tear strength is greater than that of cotton and silk.

- Natural color, shine. Does not lose shine during use;

- Does not rot, is resistant to destruction, to insect attacks. Eliminates chemical treatment of fabric, makes it possible to achieve environmental friendliness of the obtained raw materials.

- Antibacterial. Prevents the proliferation of pathogenic microorganisms. It is actively used in the production of children's clothing and bedding.

Important! Cultivation of the plant helps to reduce soil erosion.

Modern manufacturers take into account the properties of natural fabric when producing it. 100% fabric is not produced. Clothes made from 100% raw materials are rough and wear out quickly. To eliminate the shortcomings, wool, cotton, and flax are added to the finished fabric. As a result, a combined material similar to natural felt is obtained.

Important! Ramie is added to denim as an additive.

Care of products

You can learn how to care for ramie by determining:

- Fabric as an additive (according to clothing labels).

- 100% raw material content.

Washing items made from natural fabric will help to preserve the original color and presentable appearance of the fabric for a long time.

Important: Dry the product and fold it horizontally (the reason is the fragility of the fiber).

Advantages

- Strength: Increases when the fiber gets wet;

- Absorption of moisture and dirt;

- Fast drying;

- Resistance to destruction, exposure to pathogenic microorganisms, insects;

- Resistance to alkaline and acidic environments;

- Quick cleansing

- Resistance to deformation;

- Does not shrink;

- Presence of shine;

- Colour fastness;

- Resistance to temperature fluctuations and increases.

Disadvantages of Chinese nettle fabric

- Abrasion;

- Creasability;

- Rigidity;

- Low degree of elasticity;

- Fiber fragility;

- High cost.

Ramie clothing manufacturers

- "Zara";

- "Mango";

- "Collins".

Combined fabrics are used to make:

- Blouses;

- Business clothes;

- Maternity clothes;

- Clothes for children;

- Shirts;

- Trousers;

- Skirts;

- Dresses.

Clothing with an admixture of natural fiber has a positive effect on the body:

- Normalization of blood pressure;

- Improved blood flow;

- Relief from migraines;

- The clothes are recommended for people with allergic reactions.

Reviews

Marina, Sergiev Posad: "I ordered ramie fabric for a sarafan. I am very pleased. The fabric that arrived was high-quality, bright and breathable. The clothes are worn perfectly, there are no problems with caring for the product. The sarafan still looks bright after a year. Presentable. Thank you for the high-quality fabric."

Regina, Novosibirsk: "I ordered fabric for sewing home textiles. I wanted to do something original and transform the interior of the apartment. I spent a long time choosing the pattern and type of fabric. I settled on ramie, which I do not regret at all."

The product is easy to care for, beautiful and high quality. It perfectly tolerates dry cleaning, all automatic washing modes, high temperatures during washing and ironing, and bleaching.