Footer - what kind of fabric is it, what are its properties and what does it look like? These questions are of interest to beginning seamstresses. Every person has items made of this fabric in their closet. Different types of material are used to sew children's clothes, tracksuits, and outerwear.

History of origin

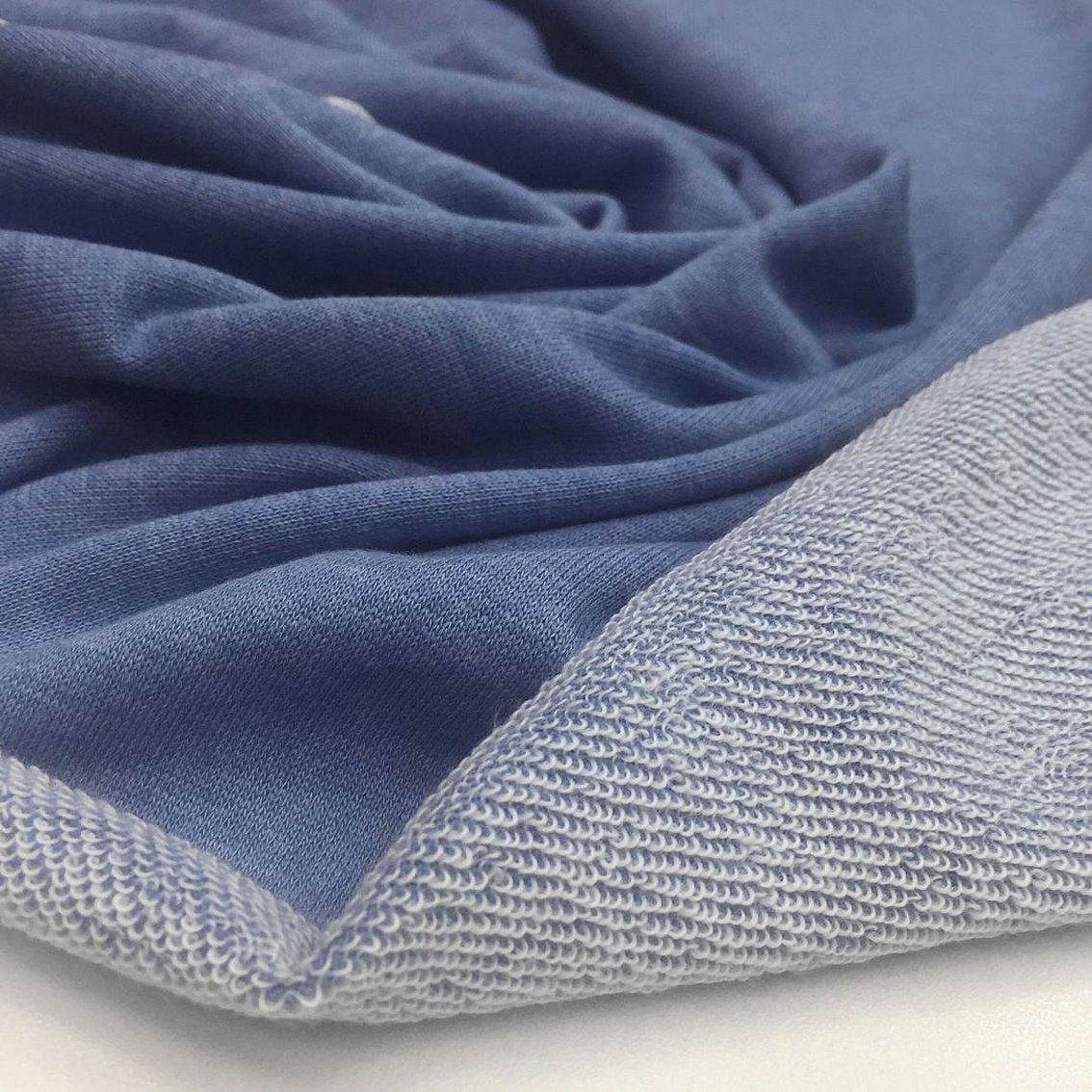

Footer is a knitted fabric with a fleece on the back side and a smooth, pleasant to the touch front surface. The material with special properties began to be produced in the middle of the 20th century. Double-sided fabric with a soft fleecy or looped textured back side is called "footer".

The name of the fabric is literally understood in German as "lining". The name directly indicates not the main quality of the fabric, but the pile on the back side.

The first manufacturing country that launched the mass production of footer is unknown. It could have been the USSR, India, Egypt. Cotton knitwear was created near raw material bases, where cotton was grown.

Composition and production

Footer fabric - what is it, composition and types of double-sided manufactory? The technology of creating footer consists of an unusual way of interlacing threads. The front side of the fabric is smooth, similar to a jersey smooth surface. A small rib is clearly visible on it. And the pile on the inside is created by footer threads attached to the fabric with loop broaches.

The properties and type of footer fabric are determined by its composition; it can be made from pure natural raw materials or with the use of synthetic additives:

- Cotton. It has high hygroscopicity, does not cause allergies. The fabric is soft, gentle to the touch.

- Cotton + wool fiber. The fabric is used for sewing warm clothes.

- Cotton + polyester or lycra. Synthetics are added to make the material wear-resistant.

Fabric properties, advantages and disadvantages

Fleece materials are made in the same way as smooth knitwear.

Note! Some modifications have been made to the production technology. Threads are woven in from the inside using a drawing method, creating a pile surface.

This fabric has many advantages:

- does not cause allergies;

- pleasant to the touch;

- does not cause irritation when in contact with the body;

- absorbs moisture well;

- allows air to pass through, allowing the body to breathe in clothes made of footer;

- knitted fabric is elastic, clothes made from it fit the figure and do not restrict movement;

- natural fiber footer retains heat well due to the brushed back side;

- has increased wear resistance.

The disadvantages of natural-based materials include the following:

- rapid destruction of fibers under the influence of ultraviolet rays;

- natural fabrics shrink after washing;

- When washing in hot water, the fabric is damaged.

To give the fabric special properties, up to 10% synthetic fiber is added to its composition. Fleece with artificial threads has special qualities:

- Lycra gives the fabric shine and stretch;

- Artificial viscose allows you to get rid of shrinkage.

Synthetic additives give the fabric the following qualities:

- brightness;

- wear resistance;

- wrinkle resistance.

Important! Cotton footer with added wool is used for sewing outerwear. It is warm, but also shrinks a lot, and loses its shape with frequent washing. After treatment with special chemical compounds, a fire-resistant effect appears.

Types and Applications

All types of footer are divided into three classes:

- Single-thread. Thin material, soft to the touch with a velvety back side. This type of material is made from natural fiber without synthetic additives. Single-thread thin delicate material is used for sewing children's clothing.

- Two-thread. Two-thread footer - what kind of fabric is it? Two threads are woven into the fabric from the inside using a drawing method. Medium-density material is used to produce children's clothing and underwear. Two-thread footer with the addition of lycra is popular due to its attractive appearance and elasticity. Consumers asking in the store what kind of two-thread footer fabric is, will be offered several types of material that are externally different from each other. The back side will be common to all options.

Two-thread is often produced by manufacturers in the form of a tube so that underwear made from it does not have seams on the sides.

- Three-thread. It has a long pile, the fabric is thick and warm. This class of footer may contain natural wool fibers, artificial additives of elastane, polyester, viscose. The content of impurities reaches 20%. The high-density material is suitable for making outerwear. There are two ways to form a pile. In the first, loops are formed by stretch threads from the inside. The result is a three-thread looped footer. In the second case, a special machine with special needles passes through the back threads, securing them on the back side. At the end of the technological process, a three-thread footer with a pile is obtained.

Depending on the fiber used for production, knitwear is divided into the following groups:

- Penye (PE). Made from long cotton fibers. The result is a high-quality fabric. Used for sewing clothes for babies.

To give the fabric a decorative appearance, lycra is added to its composition.

- Ring. Medium-length cotton fibers are used for its production. The finished knitwear has a slight "fluff".

- Openend (O/E). Inexpensive material made from low-quality raw materials. It is characterized by fluffiness, which manufacturers eliminate by treating the finished fabric with special chemical compounds.

Recommendations for purchase

Products made from footer are easy to recognize. They are determined by the special characteristics of the fabric: a smooth outer side and a fleece back. The label indicates the composition of the material. If natural fibers were used to produce knitwear, the finished item may shrink after washing. In this case, you should not buy a product that fits tightly.

Note! Material with a small percentage of synthetics has better wear resistance, but poorly absorbs moisture. In it, a person experiences an unpleasant sensation in the warm season, the so-called "steam effect".

Care of footer products

Clothes made from footer will look attractive for a long time if you follow these rules:

- They are ironed by placing them inside out on a terry towel and setting the iron to the “cotton” or “silk” mode, depending on the density and composition.

- Wash in warm water, for thin children's items select a temperature of 40 degrees on the washing machine display, and for thick items 60°C.

- Do not boil.

- Wash using “soft” washing powders and gels.

- Dry on a hanger indoors or outside in the shade.

Knitted cotton fabric is in demand due to the comfort that the skin feels when in contact with the surface of the fabric and the aesthetic appearance of products made from it.

Precautions when washing

The only serious drawback of natural fabrics is that they shrink greatly after contact with hot water. To avoid this, finished items are soaked and washed in warm water. Then wrung out without twisting, allowed to drain and then hung on a dryer. Knitwear should not be dried in the open sun, on a central heating radiator, or near a stove.

Important! Purchased fabric, consisting of natural fiber, is soaked in warm water before cutting. Preliminary decatization allows to avoid shrinkage of the product.

What is sewn from footer?

Sewing factories use double-sided footer material to produce the following:

- thin and soft clothes for babies;

- children's knitwear;

- special clothing for sports;

- sports pants, jackets;

- pajamas;

- housecoats;

- summer coats;

- sweaters;

- hoodie.

It is impossible to answer the question of what else is sewn from footer. Designers use this fabric to create all types and groups of clothing, combining this material with lace, denim, applique and leather inserts. Youth clothing made of footer with a thematic image printed in typography looks interesting.

Retail price per meter of fabric

The price of the material depends on its quality, density and special qualities, such as fire resistance, increased hygroscopicity.

Knitted footer fabric with two threads is sold at retail from 850 rubles, viscose two threads can be purchased for 700-800 rubles.

The material is sold in the form of a sheet with a width of 150 to 180 cm, and a pipe with a width of 6.5 to 80 cm.

The latter is used for sewing seamless products. The price per linear meter depends on the fiber consumption and the quality of the fabric. The narrowest two-thread footer costs from 60 rubles per meter.

Comparison with other materials

The advantages of the material are obvious. Clothes made of natural cotton and synthetic additives do not need to be ironed as often as linen items. Knitted items fit the figure perfectly, do not restrict movement. Underwear and pajamas from this manufactory are pleasant to the touch, do not irritate the skin.

Previously, it was believed that the material was not suitable for making evening and business suits. Some types of footer, containing lycra, are used by fashion gurus to create clothes suitable for family celebrations, special occasions, and going out.

Customer Reviews

Consumers evaluate footer fabric only positively:

Lopatin S.A. (Gigant settlement, Salsky district, Rostov region)

"I bought a double-thread lining, they made warm underwear for me for airsoft. It turned out to be a great thing. The special structure of the fabric allows you to keep warm well. The material corresponds to the description given by the manufacturer. Before that, I did not know what footer was."

Dudinets L.A.

"I bought my grandson a sweatshirt and pants made of three-thread fleece. The child likes it, the clothes do not restrict his movements. Before, I was puzzled, what kind of fabric is loop fleece. Now I will recommend it to all my friends."

Fleece is a modern fabric with unique properties.

Note! Depending on the yarn composition, the finished material is used for sewing things for babies, warm clothes, underwear, evening dresses. The material requires special care. Gentle washing, proper ironing and drying will ensure durability of footer products.