Many people don't know what nylon is. Nylon is one of the basic fabrics that every woman needs. Tights and hosiery immediately come to mind. What else makes this material stand out and what is nylon made of? Details below.

History of creation

Capron is a type of fiber obtained as a result of an experiment by German scientists. Initially, polycaprolactam was derived. In 1938, the first positive results of synthesis appeared, and 5 years later industrial production was established.

Capron fiber had a serious drawback - it was coarse. Because of this, the material was used more as an auxiliary element in production. Then Soviet scientists supplemented the experiment with some developments. This is how this polyamide was synthesized.

Thanks to the discovery, polycaproamide fiber was produced, and then aminocaproic acid was added to it. In Germany, a product with similar characteristics was developed, called perlon. Also in other countries, the fabric is known under the names nylon or dederon.

This is interestingIt will cost several times less to produce nylon than to produce cotton.

Capron or kapron - since we are talking about the reaction of caprolactam, it is correct to say kapron.

What is nylon made of?

The main production process is phenol hydrogenation. The most commonly used formula is the oxidation of isopropylbenzene. Oxidation is made possible by two elements: propylene and benzene. The raw materials are petroleum products, from which caprolactam is produced. In turn, polycaproamide is produced from caprolactam. Then, fibers are made from the product, from which nylon is then obtained. The technical process is aimed at continuous operation.

Obtaining nylon fabric

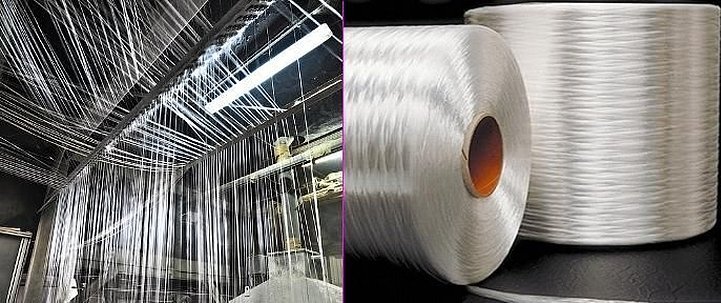

Many people wonder what fibers nylon is. It is of synthetic origin. As a result of caprolactam polymerization, a thick gel is formed. The gel is an explosive substance, therefore, enterprises producing nylon threads are considered high-risk facilities.

Polymerization occurs at a temperature of 270 °C. Threads are pressed through special equipment from the gel. After some time, the threads turn into fiber. Before being handed over to the weavers, the threads are stretched in an industrial manner.

Technologically, there are 2 types. The difference is in the weaving method used during production.

Types of weave:

- linen;

- twill.

In the first case, the product will have greater strength and will be thinner. In the second case, the thickness will be wider, but at the same time, wear resistance will increase.

If you fold the threads several times and twist them, you will get a cord thread.

Nylon: properties and applications

In appearance, capron is a material from transparent to yellowish shade. The material has a slight shine. It is a thin but dense fabric.

Nylon has such properties as strength, wear resistance and lightness. Dirt does not stick to it, does not change under the influence of water, is light and easy to care for. Items made of nylon fiber can be subjected to physical impact. For example, compressed. But when scratched with a sharp object, the fiber is easily damaged.

The composition is not susceptible to pathogenic effects of microorganisms. Nylon fiber does not absorb moisture, but when washed at too high temperatures it can lose shape. The density of nylon can be different. The material cannot burn: it simply melts, forming a resinous substance.

Interesting factAfter its release, it received the “title” of the strongest material, displacing silk from there.

Where is nylon used?

Nylon fabric has a wide application and is widespread in the textile industry. Usually the range of manufactured clothing is expanded by producing mixed fabric. This is achieved by adding other materials to the main fabric tape, such as silk or viscose (raincoat version).

Capron is a polymer used in the production of automobile and sporting goods, such as the well-known tires. Filter fabrics required in production are also produced using capron fabric.

A large number of household goods are made from it. The use of nylon is reflected in the following products: cables, nets, fishing lines, ropes, curtains, tulle and medical supplies. Medical clothing and professional uniforms are also often produced thanks to nylon compositions. The most widespread are nylon tights, accessories, and elements in clothing where it is necessary to make some part of the body transparent.

Additional information. Nowadays, curtains made of nylon fiber are not popular. The main role of the material in the production of curtains is reduced to external finishing.

Care

For nylon, as for any other fabric, proper care is important:

- It is not recommended to wash this type of fabric at high temperatures. A delicate mode is used for washing. Housewives recommend using a temperature of no more than 30 °C. But at 40 °C, nylon items also do not lose their positive qualities.

- Do not use bleach when washing; if necessary, simply soak the item in soapy water.

- Be sure to ensure that the powder dissolves as much as possible.

- The item must be rinsed well, otherwise the product will lose color and brightness.

- The fabric is not spun or ironed. If it is necessary to iron the material, use low temperatures.

- If the item is dusty, it is best to use a vacuum cleaner.

- Avoid contact with sharp objects.

Advantages and disadvantages

In addition to the main characteristics of the fabric, its advantages include elasticity and low cost. It is noteworthy that the material does not rot and is resistant to chemical influences.

Flaws:

- Low environmental friendliness. This is due to the fact that the fabric is difficult to recycle.

- Burnout. The material can quickly fade in the sun.

- Low heat resistance. The material will provide little protection from the cold.

- No hygroscopicity. The fabric is not suitable for wearing in hot weather, as it has low hygienic properties. Such fabric will cause sweating and will not absorb excess moisture.

- The fabric is uncomfortable when worn on the bare skin. When worn in this way, many products can cause discomfort.

- Low resistance to acids.

Thanks to its qualities, nylon is an indispensable material in everyday life. Despite some shortcomings, the release of this unique synthetic fabric has made human life much easier.