Not every person knows the name Cordura. This high-tech fabric is great for travel, active recreation, tourism and sports. Those who have ever used products made of this material know how to distinguish the original from the analogue.

What is Cordura

Cordura fabric is a dense nylon fabric. Wear-resistant and versatile.

Cordura is a premium textile that has been in use for over 70 years. Originally created by DuPont, it was used for the military in World War II because it was durable and resistant to mechanical damage.

Initially, cordura fabric was classified as a companion to viscose, and its intended purpose was to supplement tire production. Oddly enough, the initial classification only revealed one side of cordura and was known as a strong, resistant fiber.

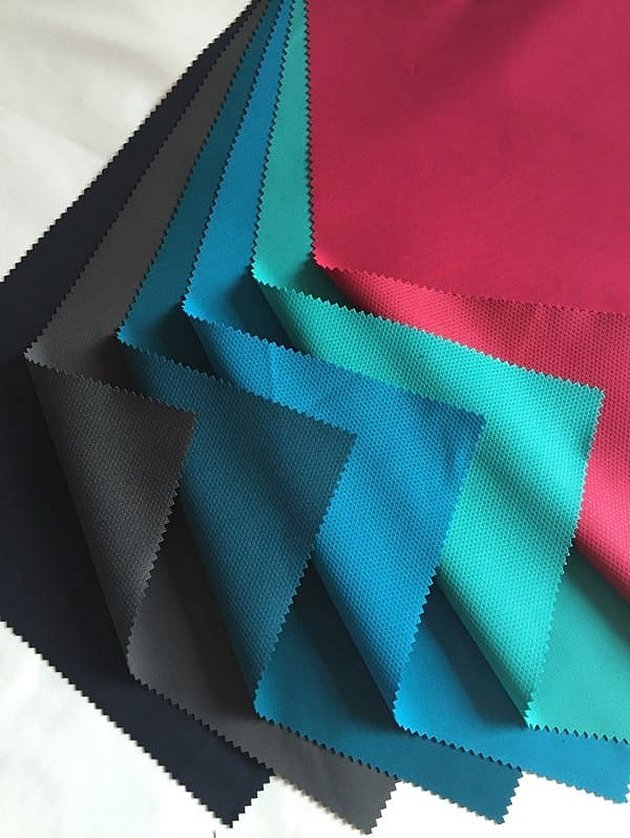

After discovering alternative uses, Cordura took root in the nylon family. After 1977, those who made the interesting material learned to dye it.

History of origin

The universal material was invented and patented in the department of the DuPont company. This company developed the whole range of strong threads from polyamide. The thread for cordura is prepared from hot coal tar in combination with water and alcohol. The fabric fiber has a twisted thread, which provides it with strength.

Technology of obtaining

Cordura fabric is made from nylon, which in turn is a well-known synthetic polymer.

It was invented by Wallace Carothers and first came to public attention in October 1938. Soon after its introduction, it was used to make parachutes, ropes, and tents during World War II, as well as nylon stockings and toothbrushes.

It is a strong synthetic fiber that resists mechanical damage and cracks. But nylon alone is not enough to create a truly versatile material. So monomers (the chemical building blocks that make up polymers) began to be used in production. They are combined into one chain to form a long formula through a condensation polymerization reaction.

If we talk about the description of the fabric, it is nylon 6-6 monomers. They are adipic acid and hexamethylenediamine, and the two molecules are combined to create a polyurethane polymer and water (H2O) is produced as a by-product.

The polymer chain can consist of more than 20,000 monomer units linked together through an amide group, which contains a nitrogen atom.

Composition, varieties and properties

All woven fabrics are made up of various combinations of yarns and weaving methods. Most of the technical jargon refers to yarn. Nylon, polyester, cotton, or any combination of these fibers make up a versatile material. Cordura, as we know, is made using nylon 6.6.

The "D" of this fabric means 1000D. This is a unit of yarn weight, measuring how much weight is in a gram of fabric. So 1000D will weigh 1000 grams for a length of 9000 meters. In turn, 500D will weigh 500 grams.

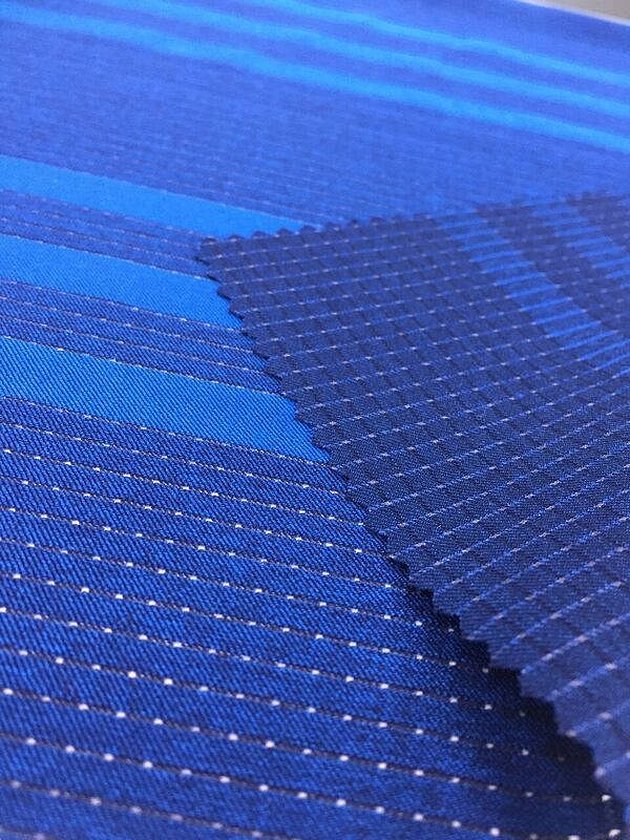

From classic air-jet textured nylon fabrics to today's ultra lightweight polyester nylon and high tenacity fabrics, Cordura fabrics are available in a wide range including:

- Ultra lightweight ripstop nylon fabrics;

- Nylon/cotton blends for workwear and denim;

- Textured nylon;

- Lightweight nylon packaging fabrics;

- Textured nylon or polyester fabrics;

- Ballistic coated heavy weight nylon fabrics.

How to distinguish from fakes

You can distinguish the material from a fake by the external tweed. The fake is hard and has an unpleasant surface, which forms a roughness when rubbed. The original material has a silky shine, and on the reverse side it is matte, even a little rough. The original material itself does not have the property of stretching, and when wet it can stretch no more than 2%.

Areas of application of the material

Given the fabric's original characteristics, it was originally a product of viscose used in World War II tires. After the war, DuPont developed nylon, which became a major component of tire production. In the mid-1970s, a process for dyeing nylon fabric was developed, and the name was revived and applied to a classic line of nylon fabrics. Used in everything from school bags to soldiers' boots, the material is now ubiquitous, making a huge impact on the world for over 50 years.

Cordura what is it? It is a viscose fabric. As production developed, it became the prototype of nylon. Thus, its area of application reached another level

Since Cordura is a synthetic material, it has high-strength fibers that stretch well and withstand long-term wear. It is very abrasive and in most cases very water-repellent.

Complex and intricate matter - versatile, works well for a variety of things including:

- Workwear. Suitable for working in difficult environments - no matter the conditions, it will remain just as durable.

- It makes excellent tents/outdoor shelters - this type of fabric is waterproof and windproof.

- This material makes great jackets. Ballistic nylon is great for motorcycles and tactical jackets.

- Bags: The material is so strong that it is used to create luggage bags.

Care of products

So what is cordura fabric? The material is very easy to use. General care instructions are as follows:

- Clothes: Wash at low temperature using mild detergent.

- Drapery/backpacks/luggage. To care for the products, do not use aggressive detergents.

Important! Do not wash this fabric with bleach or chlorine-containing substances.

Advantages and disadvantages of cordura

Cordura material is simply a hybrid, a hard nylon blend. It is used in the production of backpacks, soft luggage.

Best known, corduroy fabric comes in several iterations, including nylon, poly, and cotton hybrids. Cordura is used in everything from military uniforms to bike bags and caving suits.

White Cordura fabric has a tight weave, but is still lightweight and breathable. It has excellent resistance to abrasion in extreme conditions, and newer versions have increased softness, making them comfortable, as well as stylish and functional. Built under efficient technologies, the fibers of the fabric are more durable than regular ones. So, it is not surprising that the material is much stronger than cotton and has three times the durability of standard polyester.

There are many large companies in the market that use cordura fabric to produce various types of products. The material can also be used to sew clothing for motorcyclists, sportsmen and as recreational equipment. It is suitable for sewing clothing for law enforcement, as well as upholstery of a car or aircraft.

Reviews

Andrey, 35: “I am an experienced fisherman, and for my hobby I need the right equipment, a suit. For as long as I can remember, I have been picky about choosing it. Once I was offered to try out a suit, a special one. At that time, I did not know that it was made of cordura. I decided to test it — and I was right. Especially for winter fishing. It is comfortable — not hot, not cold. It does not require special care. The suit is more than 5 years old, and it is still the same.”

Semyon, 27: “I work as a gunner at a gas station. We were given a suit made of cordura. The material is really very comfortable, just what you need in winter. I often had to shovel snow. And the work itself can be in the rain and strong wind. In general, it passed all the tests. I am happy with the suit, it retained its original appearance and protected me from weather conditions more than once.”

Cordura is a collective name for various types of textiles. These types of fabric have one important characteristic in common; they are capable of carrying heavy loads. Originally started by DuPont in 1929, the project was intended for the front. The nylon-type material produced a super-powerful ballistic effect, and was designed to be resistant to any kind of abrasion, scuffing, and tearing. The material was also used by the military during World War II, in the development of tires.

The most important feature of this substance is its resistance to abrasive loads. This means that it is resistant to abrasion.