Cotton fabrics have been popular for many millennia. The ancient cotton plant and its raw materials were transported along the Silk Road to other countries. Over time, the use of cotton fabrics has decreased by more than half due to the increase in the production of synthetic, artificial polymers. Reducing the cost of goods in industry is in the first place. These circumstances stimulate the production of mixed fabrics in Russia. One of them is polycotton.

Characteristics and composition

Polycotton - what kind of fabric is it? The question arises every time a new material appears on the shelves.

Combination of cotton and synthetic raw materials is used in the production of new textile fabric. The idea of mixing different fibers came in the middle of the 20th century. Combining different properties of fabrics in one copy prompted experiments in the textile industry.

The result of chemical production was implemented to produce a new type of textile fiber. Mandatory components in polycotton composition include natural cotton and synthetic polyester. How safe is it?

Important! The percentage change in the components affects the cost and quality of the material. With an increased content of synthetics, the quality characteristics of the material deteriorate significantly. With a cotton content of 50-65% in the fabric, it is considered a good indicator, and with 15%, the presence is considered more conditional than appropriate.

Cotton fibers used in production are short-wave up to 26 mm, medium length 34 mm and fine-fiber with a length of up to 50 mm. The structure of the raw materials used affects the quality and cost of the finished product.

How the components of the future fabric are mixed. The content of polyester fiber in polycotton is carried out by polymerization of terephthalic acid and ethylene glycol. The polymer compound is used in the production of food films, packaging, and certain types of textile fabrics. Purified polyester is inert and does not pose a danger. Polycotton, its composition, what is this new type of material.

With a cotton content of 50%, the fabric has:

- good appearance and pleasant to the touch;

- hygroscopicity;

- no problems with static electricity;

- minor shrinkage after washing;

- no deformation after multiple washes;

- strength of the canvas with a small thickness;

- requires almost no ironing.

The disadvantages of synthetics increase with their percentage content in the fabric. Decreased hygroscopicity and accumulation of static. The fabric does not breathe and retains moisture.

The main 4 types of material are used with a cotton content of 65, 50, 35 and 15%, and polyester according to GOST - 35, 50, 65 and 15%. The combination of completely different components gave birth to a fabric with the characteristics of both fibers. The first has porosity, environmentally friendly and hypoallergenic qualities, and the second gives the fabric strength, wrinkle resistance, homogeneity and no shrinkage.

Types of material

The widespread use of polycotton has led to the division of the fabric according to the type of application.

- quilted fabric is used for sewing pillows, blankets and mattress covers with fleece, synthetic padding and wool filling;

- bleached is used in hotels, banquet halls and resort complexes;

- Plain dyed, ideal for bed linen.

The use of calico and satin, similar to batiste, for making ordinary clothes is popular not only with the manufacturer. Housewives are happy to hone their skills in making tablecloths of the right size or window curtains of a fancy shape on their own.

A special characteristic is the construction of the fabric - the number of threads per section length. Usually this section is 10 cm. The marking T131; 68*63 will tell the buyer that there are 131 threads, of which 68 are longitudinal and 63 are transverse. The more threads there are on the measured section, the thinner they are and the better the quality of the fabric. T200 is almost never found on the Russian market.

The average density of the fabric is from 80 g/m2 to 146 g/m2. Imported polycotton, in the style of satin-jacquard weaving, is used for furniture upholstery. The high density category is marked T215, and wear resistance is 10 thousand cycles.

Comparison of polycotton and calico

Calico contains 100% cotton, while polycotton contains a maximum of 65%. But each fabric has its own pros and cons. The first shrinks, wrinkles, requires mandatory ironing, and at a density of up to 125% it is a "gauze". A small amount of the second smooths out all the shortcomings, so polycotton with a lower proportion of polyester in its composition is quite competitive with calico.

If we compare the properties of 65% silk and 35% polyester fabric, then in terms of electrostatic qualities it is inferior to natural cotton fabrics, including polycotton. The reduced ability to absorb water and let air through is compensated by the bright colors of synthetic fabrics. Tablecloths in a restaurant and curtains made of this fabric look beautiful due to their silky shine.

The properties of combined fabric are used in the manufacture of products that require waterproofing - jackets, mattresses, tents.

Types of weaves used in the production of polycotton

Simple types of weaving of the main thread and additional ones determine the quality of the fabric.

- Plain weaving involves alternately weaving one thread at a time longitudinally and transversely. Double-sided fabric is similar to the production of chintz, calico, calico and cambric.

- Twill. Shift by one thread with weft covering 2-3 warp threads. The face of the fabric acquires shine on diagonal ribs. It becomes softer, but less durable.

- Satin. 4 warp threads are interwoven with a weft thread with a shift of 2. Soft material, prone to fraying edges.

The type of weaving determines the properties and further purpose of the fabric. The consumer must know what polycotton is.

Polycotton: selection rules

When choosing, pay attention to the cut edge of the fabric, checking for fraying. The thickness of the fabric and the weaving method, to determine the service life of the future product. If the material marking is not indicated, then they are guided by the ability of the fabric to wrinkle - this is how you can determine the cotton content in the finished product. These qualities affect the ability to retain moisture, allow air to pass through and affect the health of the consumer.

Polycotton what kind of fabric and how to correctly identify a fake. If a piece of fabric melts and drips when set on fire, then the synthetic content in such a fabric is maximum. The fire acquires a blue-green hue, as when setting fire to a film. If the usual combustion process occurs, then the presence of cotton makes up at least half of the fabric. Yellow tongues of flame indicate the presence of natural components.

Care instructions

Proper use and cleaning of polycotton products directly affect their service life.

- With a high content of polyester in the composition, the water temperature during washing should not be higher than 40 degrees. Delicate ironing in the "synthetics" mode. Separate washing from other things will be ideal. The use of bleaches is excluded.

- The requirements that apply to other clothing also apply to polymer fabrics - fastening buttons and zippers, washing bed linen inside out and drying under natural conditions.

- If the cotton content is up to 65%, the washing temperature can be up to 70 degrees, and ironing up to 170. Avoid using bleach. If possible, wash separately from colored fabrics.

- It is not recommended to dry in direct sunlight to avoid fading of individual stripes on the canvas.

Important! A wide range of high-quality polycotton is presented on the market. Beautiful appearance, comfortable to wear, budget option of textile material.

Advantages and disadvantages

The main positive qualities of the material are

- ease of care of products;

- hygienic and environmental safety;

- budget cost;

- minimal wrinkling;

- absence of deformation at any period of operation;

Disadvantages include electrostatics, low air permeability and the formation of pellets on the surface during wear. The price per linear meter starts at 80 rubles with a content of 15% natural raw materials and increases to 200 rubles with 50%.

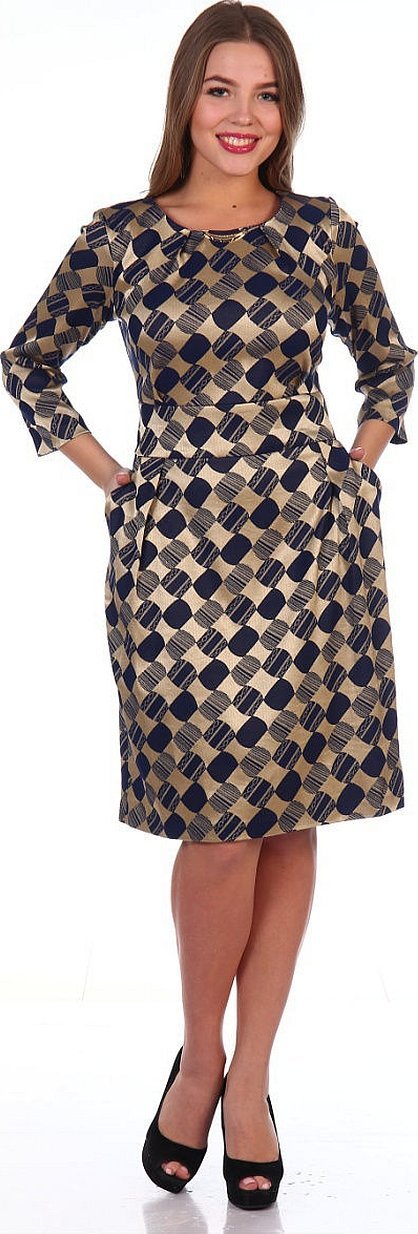

The fabric is widely used for mattress covers, car seats, sewing sportswear and trousers. Dresses and blouses made of polycotton remain bright, without losing color after washing, and bed linen lasts longer than cotton.

Sportswear is usually combined taking into account the advantages and disadvantages of the fabric. The upper part of the suit or jacket is made of a material with a high polyester content to maintain waterproof qualities, and the inner part is lined with a second layer of lightweight fabric with a high cotton content to maintain the natural thermoregulation of the athlete's or child's body. The lining is made of a thin "gauze" type fabric.

Combined material is often used to make work clothes at enterprises. The ability to retain color and shape after multiple washes is successfully used to sew work overalls, jackets, caps, raincoats.

The new type of textile has won the attention of the consumer. About 90% of all combined material on Russian markets is produced in Pakistan. The imported fabric is considered one of the best in terms of density and quality characteristics.