There is often a need to connect different fabrics with each other or with other types of materials. This also applies to everyday life and home handicrafts. For such work, special adhesives are needed, which differ in properties and characteristics from ordinary ones. This is an excellent alternative to needles and threads, which does not leave any marks on the work surface. Even under the influence of external factors, the materials retain their strength. Everyone will understand how to glue fabric to fabric thanks to this material.

- How to choose glue for handicrafts?

- Rubber compounds

- PVA compositions

- Casein adhesive mixture

- Hot melt glue

- Moment glue

- Fabric glue "liquid thread"

- Adhesive tape

- Brands and prices

- Instructions: How to make fabric glue yourself?

- Features of using different compositions

- How to glue fabric to fabric at home?

- How to remove glue from fabric?

How to choose glue for handicrafts?

When choosing a suitable composition, several important characteristics must be taken into account at once:

- The purpose of the source materials themselves.

- Method of further use of the product.

- The nature of the work with fabric, for example, creating an applique or something else.

Important. If we are talking about outerwear details, then such qualities as resistance to chemicals and moisture, the ability to withstand serious temperature changes become relevant. Liquid threads and transparent adhesives are just such materials.

It is necessary to maintain resistance to fading, absence of harmful substances that can cause harm to health. Hot melt adhesive for fabric must also meet similar requirements.

There are also nuances in materials intended only for handicrafts, the implementation of any creative ideas. This also applies to waterproof transparent fabric glue.

Rubber compounds

This option is ideal in the following situations:

- High-quality clothing repairs.

- Gluing the inner elements of the suit.

- Other works with fabric, during which it is not desirable to leave traces. Aerosol composition in this case will also become an indispensable assistant.

These are materials made of synthetic or natural rubber, with the addition of so-called vulcanizing agents. The main thing is to buy compounds that are definitely non-toxic. And the packaging should not be too big. The best option is compounds for rubber and fabric. They should be applied to the surface in a thin layer.

Please noteThe treated parts will press against each other when the composition dries.

PVA compositions

Instant glue for fabric, or PVA, is often used by those who need to connect pieces of fabric. When choosing real professional compositions, the quality of work will really be high. Such materials have the following advantages over their analogues:

- Resistant to washing, even with the use of aggressive detergents.

- Doesn't spread.

- No smell, including when the surface is treated with an iron.

- No stains on the surface after treatment. The moisture-resistant composition preserves the appearance of the coating.

- Transparency of the composition. This is a great option for those who are interested in how to glue fabrics to wood.

Please noteWhen making crafts, such qualities become especially important if the conditions are at home.

Casein adhesive mixture

Plywood and cardboard, woodworking are the main areas where this material can be found most often. This fabric glue improves the internal structure of the wood due to its original properties. The product is of natural origin, does not dissolve in water. The main elements are as follows:

- Calcium caseinate.

- Nitrates.

- Inorganic phosphates, which also form a waterproof layer together with other components.

Please note. In weak mixtures of alkali and salt, the product changes its structure, although under other conditions it remains the same. One of the options if the buyer is interested in how to glue glass to fabric.

Hot melt glue

They are sold as glue sticks or in powder form. In the latter case, the composition must be diluted with water until it acquires certain properties. Hot melt glue provides the following characteristics:

- The reliability of the seam is the main condition.

- Environmentally friendly.

- No stains, including when the surface is ironed.

- High degree of adhesion compared to Moment glue for fabric.

Moment glue

The range of this glue is constantly expanding. The manufacturer does everything possible to improve the quality, creating not only universal compositions, but also options with a narrow specialization. Most compositions have approximately the same properties and advantages:

- Frost and heat resistance. An important indicator if someone is interested in how to glue fabric to fabric.

- Resistance to solvents, including oils and gasoline. This allows for gluing various materials.

- A structure that can be transparent or opaque.

- Water resistance. The materials are suitable even for gluing objects that are constantly in contact with water. In this case, gluing will not be difficult.

- No cracking or bursting of the adhesive seam, even with long-term and active use. Also one of the answers to the question of how to glue fabrics.

- Initial curing in a short period. The product can be used in normal scenarios after a day or at least 24 hours. Or you can stick something else.

Please note. You should pay closer attention to the information about the composition on the packaging.

Some varieties include metal chips, which makes the material conductive after treatment with PVA glue for fabric.

Fabric glue "liquid thread"

Such compositions have found wide application in the sphere of home handicrafts. Especially - when there is a need to combine different materials with each other. Suitable for gluing various elements, including:

- felt;

- felt;

- coconut thread;

- spider web fabric;

- patches;

- applications that can be glued without any problems;

- fringe;

- rhinestones, etc. It is easy to work with PVC.

Precision of application, uniformity of composition distribution are the main advantages of such compositions. Additional properties include adhesion to other materials and transparency.

Please note. This type of glue dries very quickly, and the material itself does not suffer under its influence. Even for beginners, the material is quite suitable, they can easily cope with liquid fabric for clothing repair.

Adhesive tape

This is a light type of translucent glue, designed for processing fabrics. They are often used to create high-quality outerwear, they are indispensable assistants for sewing. The width of the strips is from 0.5 to 5 centimeters, at the choice of buyers. Or they are sold in rolls up to 90 cm wide. Sometimes this rule is used for glue for fabric without traces of waterproof.

There are regular adhesive tapes and those that have a paper base. The latter type is characterized by a mesh texture. It is convenient to use when working with knitted fabrics, glued to the surface with a special iron.

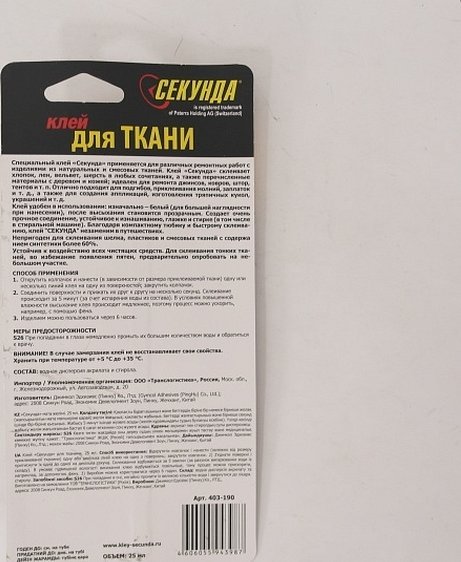

Brands and prices

60-80 rubles is the average price for one unit of glue, which will be relevant specifically for the textile industry.* It is better to contact representatives of specialized supermarkets to choose a suitable option. This increases the likelihood of buying the original, and not a fake fabric glue.

In the case of decoupage and other similar works, you can pay attention to the following manufacturers:

- DECOLA.

- Mod Podge Fabric.

- JAVANA. This composition is also allowed to be used for processing plastic.

Such adhesive compositions retain their properties even when hand washed using various detergents.

Please note. It is not recommended to dilute the compositions with water even for the sake of economy, because this will only worsen the characteristics of the item itself and the composition. Polyethylene is no exception to the rule.

Instructions: How to make fabric glue yourself?

Some types of homemade glue are practically no different in properties from industrial analogues, and the purchase and creation of the composition is cheaper. To create the material, it is enough to prepare water and glue, in the amount of 250 milliliters. The material is not synthetic, natural.

Preparation requires compliance with the following rules:

- The glue and water are thoroughly mixed inside the container and shaken well.

- The result is a substance that is covered with a matte film when applied to the surface of the product. It literally takes a second before the finished result is obtained.

Interesting. Adding water-based acrylic varnish to the mixture will allow you to get a glossy rather than matte film. After drying, in this case, the composition becomes transparent.

Dextrin glue for fabrics and other materials can also be produced at home. In this case, the procedure is described as follows:

- Fill the enamel container with starch. One hand can be free.

- The mixture is placed in a drying cabinet for 2 hours. The room should be heated to a temperature of 160 degrees above zero.

- After this, the result is dextrin itself.

The dried starch is added to boiling water in a 1:1 ratio. Everything needs to be thoroughly mixed until the additive dissolves in the water. The bases can be attached to each other later.

After preparation, it is recommended to use such compositions immediately, because they tend to harden quickly.

Casein glue is another type that is easy to make yourself. To do this, take casein and water in a 2:1 ratio. First, fill a special container with casein, then add water in a trickle. Stir the mixture constantly to create a homogeneous mixture. Such mixtures also harden, so it is recommended to use them as quickly as possible after preparation. You can glue any materials, including fabrics.

Important. There are some additional difficulties associated with the production of casein. The main material for this material is low-fat cottage cheese, milk. But it is better to buy ready-made varieties of casein, this will simplify the life of home craftsmen.

Features of using different compositions

The reliability of the glue seam depends on the type of textile composition currently used. Each type of composition has its own characteristics that must be taken into account.

- Nitrocellulose. Suitable for combining leather and fabric. Or for other complex types of material.

- Butadiene-styrene. This is an elastic material that retains its properties even under constant exposure to ultraviolet rays. It successfully resists the effects of water, extremely high and low temperatures.

- Perchlorovinyl. It is best combined with leather and vinyl, rubber. It is more widespread among shoe manufacturers.

- Hot-melt adhesive. Absolutely safe for humans composition. Colorless material, resistant to water and chemically active substances.

- Nairite, with neoprene as a base. Waterproof composition, with a transparent structure. Allows you to get strong seams regardless of the type of fabric that is being processed.

- Polyurethane. Better suited for materials with higher density.

- Rubber and latex. Combined with foam rubber, leather, fabrics of various types. Can be used even on declicate structures, since they do not harm the surface.

- PVA is a universal glue, including for handicrafts.

How to glue fabric to fabric at home?

The correct use of the adhesive largely determines how reliable the finished product will be. Familiarize yourself with the precautions and instructions in advance to avoid unpleasant effects.

Please note. Double-sided coating, long drying time are typical for rubber compounds. If large-area sheets are glued together, it is necessary to press the surface with a large load. After that, the material is left to dry for several hours.

Perchlorovinyl adhesives are applied in two layers. The first layer should be evenly distributed over the surface, then left for a while. The second layer goes on top. After that, the necessary elements are fastened together.

Nitrocellulose compounds are distributed in one layer, after which the parts are immediately glued together. Only large items are placed under a load when necessary.

Both surfaces to be bonded are treated with PVA glue. It is better to use additional weights to enhance the bond.

Please note. Special heating guns are used when it is necessary to apply silicone adhesives, sold in the form of rods. The composition is distributed pointwise, or in the form of a special thread. The composition is liquid, but not flowing. It hardens quickly, although there is still some time to adjust the position of the parts.

Durable fabrics require sufficiently reliable, waterproof materials. The compositions are first distributed over a degreased surface. The glue is applied in two layers, everything is degreased with glue or acetone. After this, the connection is fixed for as long as possible. Things can be used after a day. No help is needed during the work, everything is done independently.

How to remove glue from fabric?

The main thing is to immediately determine what kind of fabric is used. After that, making a decision will not be difficult. Some methods are suitable for some materials, and for others - destructive.

- low temperatures;

- high temperatures;

- soap and water;

- fat;

- acetone or nail polish remover;

- white;

- petrol;

- table vinegar;

- dimexide.

These are just some solutions, there are other folk remedies. If there are doubts, it is better to first take a small piece of fabric and try the substance on it. Only after that can you proceed with further work. But it is better to trust the cleaning of things to professionals, who will certainly cope with such work without problems.

*Prices are valid as of July 2019.