The sewing machine is the main sewing tool for both professional seamstresses and homemakers for personal needs. It happens that it "refuses" to work. And this article explains why the sewing machine does not sew.

Malfunctions in the performance of basic functions are a sign of a failure of the settings or a breakdown of the unit. Complex repairs and adjustments should be performed by a specialist, some malfunctions can be eliminated independently - by cleaning, lubricating parts, replacing the needle or changing the thread tension.

- Classification of faults by signs

- Common problems

- Why the needle does not rise and the presser foot does not lower

- The needle breaks

- The shuttle is faulty or its adjustment is disturbed

- If the sewing machine breaks the threads

- If the sewing machine does not feed the fabric well

- If the output is a bad line

- If your sewing machine skips stitches

- The drive belt is loose

- Poor quality sewing stitching

- Malfunction prevention

Classification of faults by signs

Any malfunctions in the operation of sewing machines are divided into three main groups:

- irregularities in the stitch formation process - skipping stitches, uneven length, breakage of the upper or lower thread and similar faults;

- improper stitching - material pulling together, looping, “slanted” stitching or, conversely, stitching that is too straight when processing the edges of the fabric;

- malfunctions in the operation of the machine's mechanisms and devices - extraneous knocking, increased noise during operation, heavy running, broken or jammed needle.

Important! When independently adjusting the correct operation of the sewing machine, you should rely on the instructions for working with it. Attempts to independently disassemble this or that unit will most likely lead to its breakdown. It is better to entrust this work to a master.

Common problems

It is usually possible to determine which mechanism has failed and why the sewing machine does not sew correctly by external signs. However, before looking for problems in the operation of the sewing unit, you should make sure that it is used correctly and the seamstress has the skills to do so. For example, old-style sewing machines are practically not suitable for sewing knitwear, and pulling the material too tightly during operation leads to breakage of the needle.

Why the needle does not rise and the presser foot does not lower

The main reasons why a sewing machine is jammed (neither the needle nor the presser foot move):

- disturbances in the coordination of the needle bar and shuttle device;

- long-term lack of lubrication of units and parts, the appearance of rust on their surface, due to which it is no longer smooth.

In machines with an electric drive, when the belt tension is weak, the motor hums, but the sewing machine does not sew - the needle does not move. In modern models such as "Janom", the needle lift button does not work if the bobbin winder is in the wrong position.

The needle breaks

Common reasons for a simple needle breakage during machine operation:

- the upper thread is too tight, especially if it is very strong (approximately enough so that when the foot is lowered, the thread can be pulled through by hand with some effort);

- the needle is not inserted into the needle bar completely, all the way, so with each stitch it hits the shuttle;

- mismatch of thin needle with thick tissue;

- poor fastening of the foot (due to its movements, the needle gets caught in it);

- needle defects (usually bent);

- displacement of the needle bar due to loosening of its fastening;

- incorrect execution of work techniques - too much pulling of the fabric from under the needle, incorrectly threaded thread.

Please note! The most common reason for needle breakage is its incorrect installation in the needle driver.

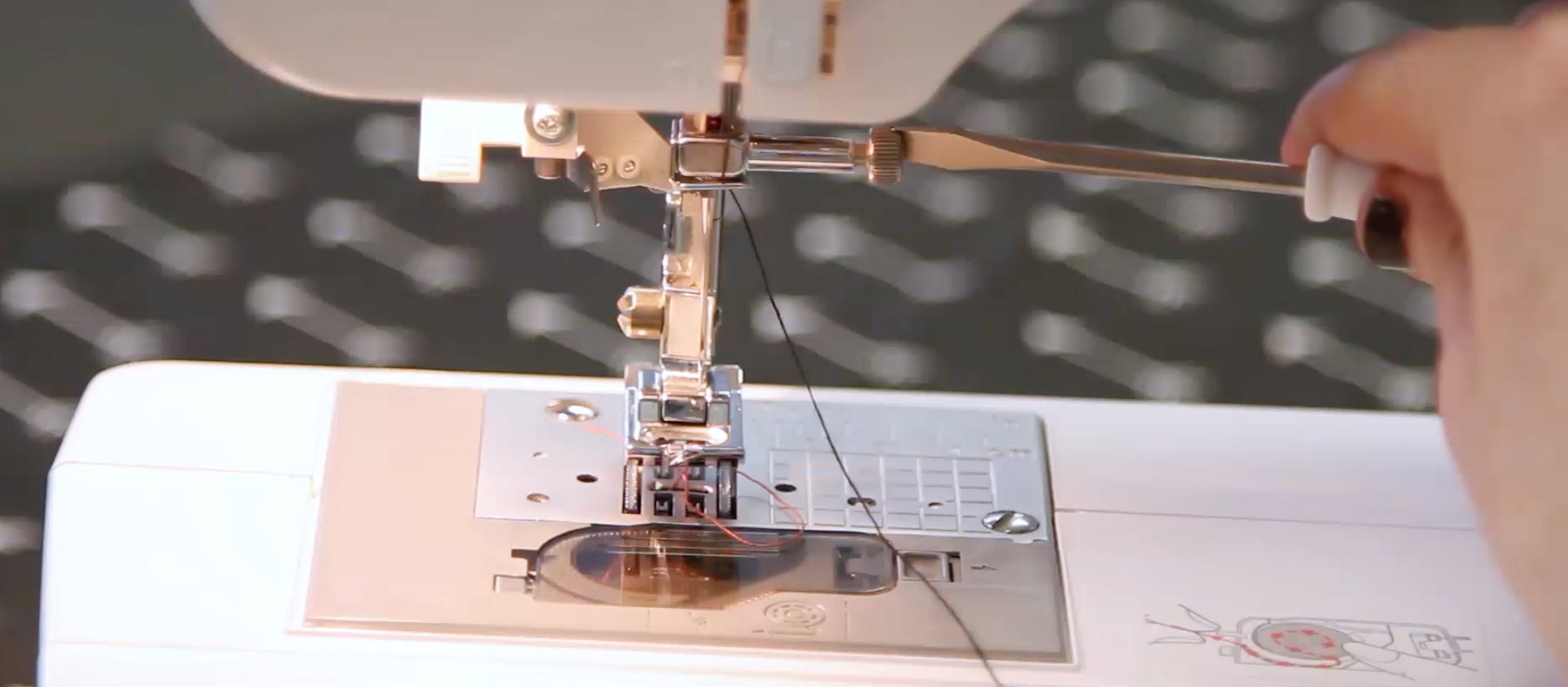

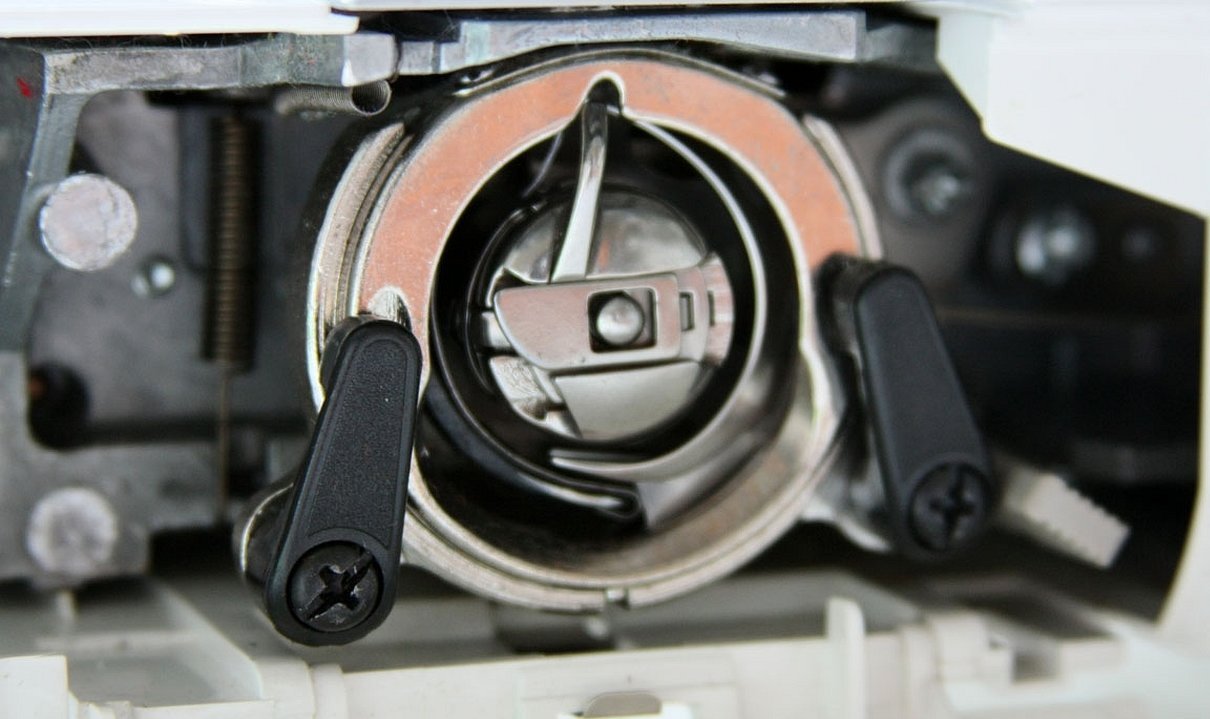

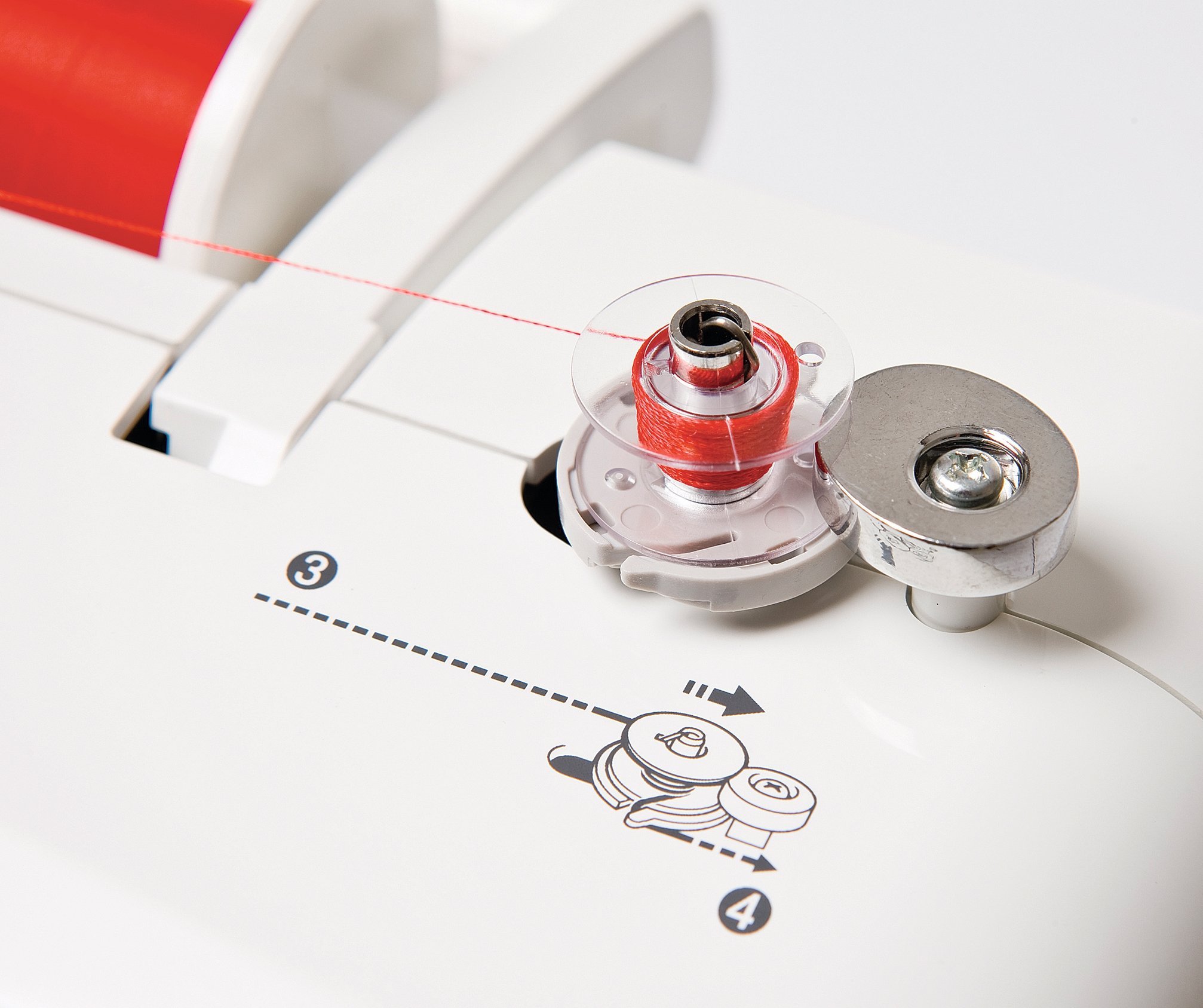

The shuttle is faulty or its adjustment is disturbed

Incorrect adjustment of the shuttle device results in the distance between it and the needle in its lower position being greater or less than the norm (2 mm). In this case, it does not have time to drop the thread or catch it ‒ the machine begins to skip stitches or loop in the seam.

If the sewing machine breaks the threads

There are many reasons why the upper thread breaks. The main one is that the thread is strongly pinched between the tension regulator washers. Some additional reasons are:

- the needle touching the hole in the needle plate, the sole of the foot or the latch of the bobbin case (most often occurs in old-style Singer or Podolsk machines);

- insufficient upper thread tension;

- the needle size does not match the thickness of the material (the needle is too thin);

- needle defect;

- malfunction of the tension regulator.

The lower thread may break because it is clamped in the bobbin by the cap's leaf spring, tangled in it, or the bobbin simply has not been lubricated for a long time.

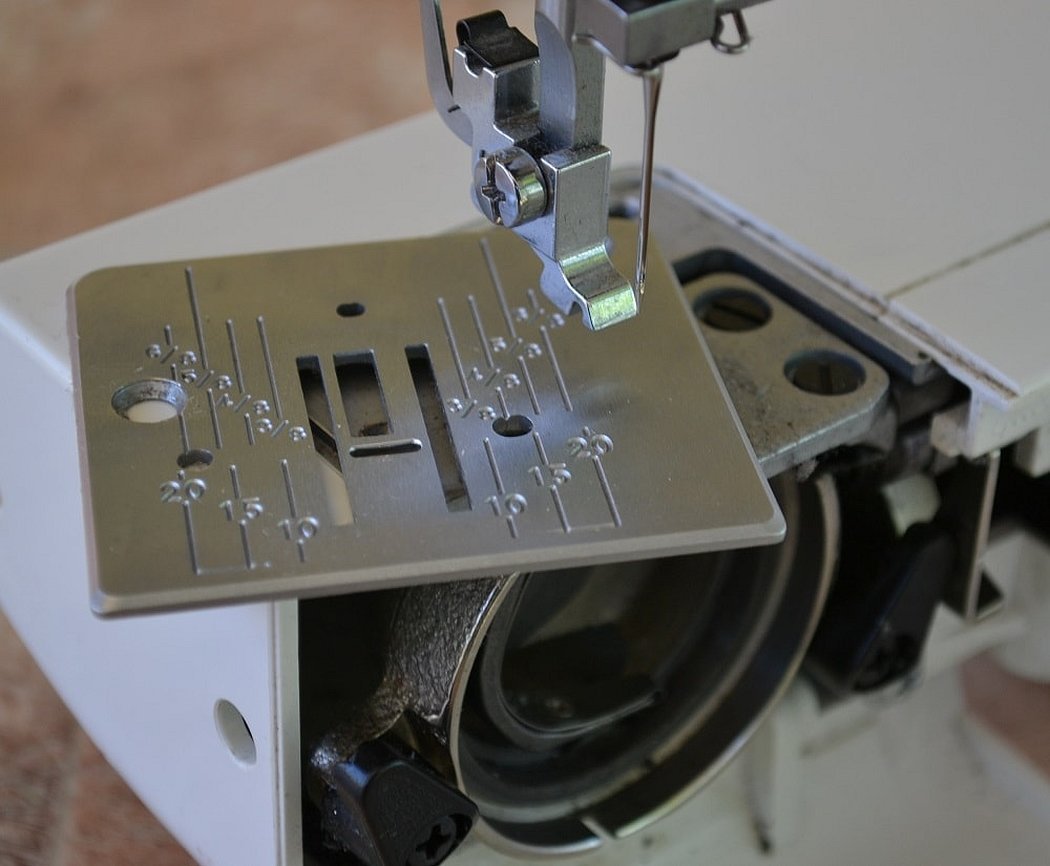

If the sewing machine does not feed the fabric well

Poor tissue advancement is usually caused by:

- the sole of the foot is tilted, which means it does not press the material with its entire surface;

- dulling of the rack teeth;

- incorrect installation of the rail (for example, in embroidery mode).

Please note! Trying to force the fabric under the needle may damage the fabric and break the needle.

If the output is a bad line

Oblique uneven stitches are usually caused by:

- loosening the screws securing the conveyor;

- choosing the wrong thread (they come in different twists);

- general misalignment of the machine.

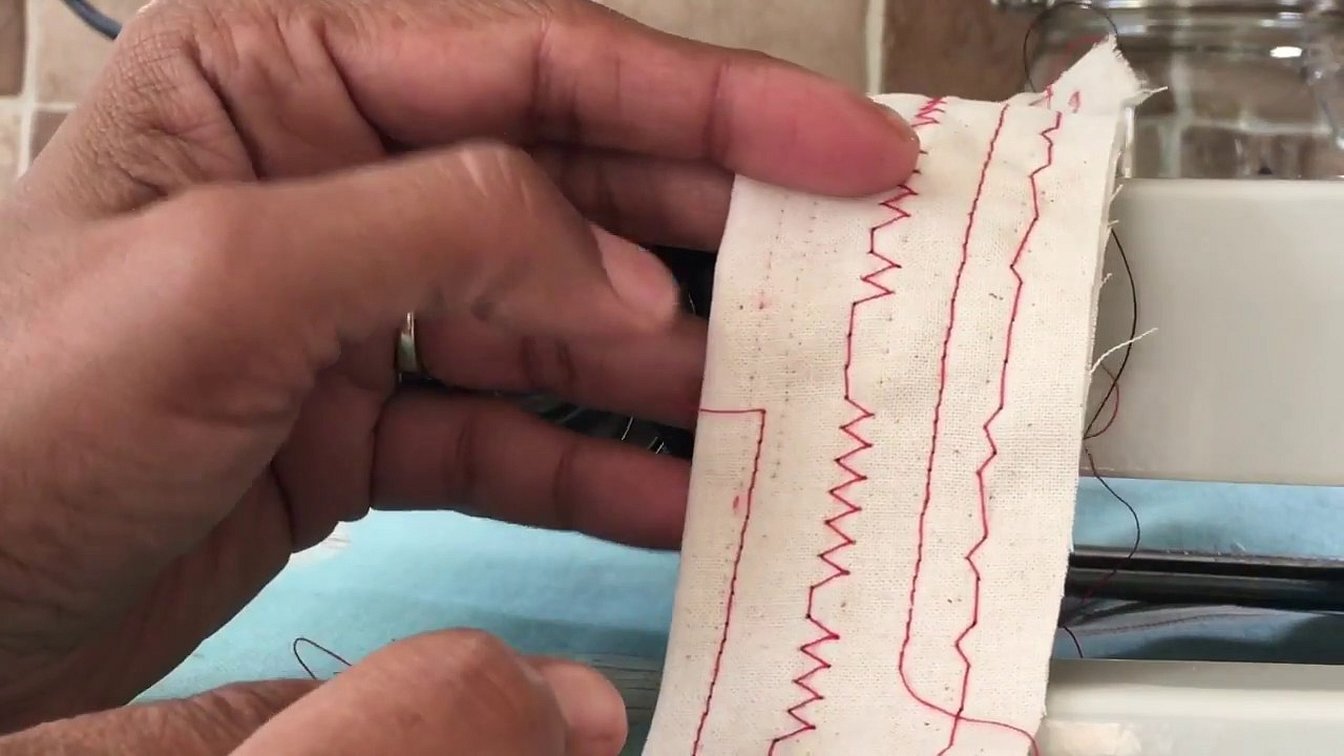

Problems with zigzag stitch:

- the seam pulls the fabric together - this problem often occurs in older machines when working with thin fabrics and cannot be adjusted;

- the stitches are uneven in size - the main gear needs to be replaced due to the wear of its teeth.

If your sewing machine skips stitches

First of all, you should check the needle. Replace the old, curved one with a new one.

When sewing with silk threads, you can first try turning the spool over to change the direction of the twist. If these simple steps do not help, the reason is a serious imbalance of the machine.

The drive belt is loose

The drive belt of a foot or electric drive can slip due to weak tension. In this case, the pulley turns, but the sewing machine does not sew. In general, the looser the belt is tensioned (but enough so that the pulley does not slip), the easier the machine will operate.

Poor quality sewing stitching

If the upper thread loops, the top stitch remains straight, but the bottom stitch is all looped. The reasons for this are:

- weak upper thread tension (increased with tension regulator);

- the needle size does not match the thread size;

- clogging of the upper thread tension regulator with dust and fibers;

- excessive lower thread tension (adjustable in the bobbin);

- breakage or wear of the leaf spring in the bobbin cap (a new one is required).

If the bottom thread is looping:

- the threads in the bobbin are wound unevenly (when winding manually);

- the lower thread is too loose or the upper thread is too tight;

- There are defects in the bobbin (it may be worth replacing it with a new one).

Malfunction prevention

The main reason for sewing machine breakdowns is failure to comply with the rules of their operation: sewing thick and coarse fabrics on "beloshveyki", improper threading or selection of needles, etc.

Old mechanical machines need regular lubrication, at least once every six months. Modern models often do not require lubrication. It can only harm the super-slippery artificial polymers that replace metal, for example, in models from Brother or Janome.

The subtleties of machine maintenance are specified in the instructions for it. Careful implementation of them will help you use the debugged sewing mechanism for a long time and effectively.