Seamstresses often replace hand tools and devices, familiar to the older generation, with automated sewing machines of various types. Each of them is suitable for a certain type of work and has its own functional features. Previously, no one could even dream of this. Despite such a wide variety, all machines require almost the same care and maintenance measures. This includes lubrication of the main working units with special oil. This is necessary not only to extend the service life of the unit, but also for its impeccable operation.

What is sewing machine oil

Sewing machine oil is a special composition that helps reduce the friction force of parts in the main running units of the device. A layer of such a substance protects the moving parts of the device from wear and prolongs their service life.

If you need to know which lubricant is best to use for a particular machine, where the oil compartment is in devices with an automatic lubrication system, and other points, you should read the equipment operating instructions. It comes with all devices.

Important! It is strictly forbidden to use machine or vegetable oil, as it does not provide proper lubrication, collects dust and has a negative effect on the operation of both individual components and the entire mechanism as a whole.

The quality of oil directly depends on the components from which it is made. Their properties, in turn, are determined by the composition of the primary raw materials. The following types of lubricants are distinguished:

- semi-synthetic. This is a mixture of petroleum and synthetic oils in a certain proportion;

- mineral or petroleum. They are obtained after refining oil. The result is a mixture of high-boiling hydrocarbons;

- synthetic oils. They are produced by synthesizing chemical elements, as a result of which the composition is almost completely free of mineral fats and solvents.

Why do you need oil in a sewing machine?

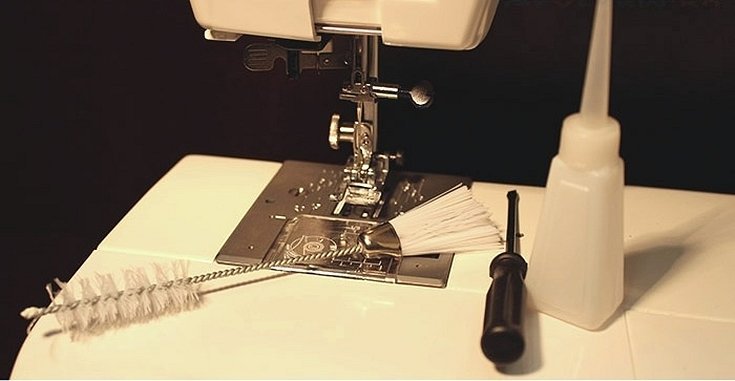

When the machine is carefully maintained and used with care, the likelihood that it will need frequent repairs is reduced. Despite this, after many years of operation, it is still necessary to clean the shuttle device, as well as other moving parts. In most devices, it is necessary to clean the bobbin case, the shuttle mechanism and the shuttle itself. This is done with a coarse hair brush. If you do not clean the mechanics, dust and lint of fabric or threads can accumulate in it, which will interfere with effective work.

In addition to the cleaning process, it is also important to lubricate the running units with special industrial oil. It protects the parts of the device from strong friction and prevents dust and dirt from getting into the units.

Important! In addition, the lubricant provides protection against corrosion. This is achieved by coating parts in places where the metal is worn and more susceptible to rust.

To summarize, we can say that lubricating the machine is intended to prevent its breakdowns. This is achieved by:

- reducing friction of device parts;

- reducing the load on mechanisms;

- protection from dust and larger particles;

- preventing the appearance of rust.

Brands of manufacturers that require lubrication

When repairing and operating sewing equipment, lubrication may be needed for almost all its types:

- hand sewing machines;

- electrical;

- with microprocessor control;

- sewing and embroidery;

- embroidery;

- overlocks;

- carpet lockers;

- industrial sewing machines;

- industrial overlocks;

- hinged units;

- flat seam devices;

- button sewing machines;

- furrier and fastening machines;

- bag-sewing and loop types;

- sleeve machines;

- sewing and column devices.

This means that regardless of the type of device, its functional purpose and characteristics, it must be periodically lubricated and serviced.

Oil for Juki

Many people do not know what oil to use to lubricate a Juki sewing machine. The answer is quite simple. The best treatment is the one that comes with the machine. This is why oil is included in the kit for many machines. You can buy it separately in a specialized store or order it through official representatives of the manufacturer.

If the lubricant was not included in the kit or has run out, you should look for other oils that are suitable in consistency and composition. You can determine what the factory product was made of in the instructions or on its label. If it was not there initially, it will not be difficult to find out about it on the manufacturer's official website.

The substance must also be stored in accordance with established standards: in a sealed transparent jar or a special oiler. The container must be made of high-quality plastic that does not react with the components of the lubricant.

How to choose oil for lubrication

Lubricants for sewing machines are quite viscous in their structure. When too thick a substance is used, there is a risk that the internal parts and mechanisms will not be lubricated properly. And they are the ones that bear the main load. The same can be said about too fluid a consistency: it will not have time to penetrate deeply, and the units will also remain unlubricated. It is for these reasons that the composition should be of medium viscosity. Often the indicator is indicated on the label.

Important! Some sewing equipment does not require lubrication, as it is already initially equipped with an automatic system that is able to independently perform maintenance after a certain time or based on sensor readings.

As already mentioned, the most suitable oil for a particular sewing machine comes with the device. If for some reason it was not there, then you should choose the best quality lubricant. Its cost starts from 100 rubles. It is sold in ordinary plastic bottles.

Lubricant for industrial sewing equipment

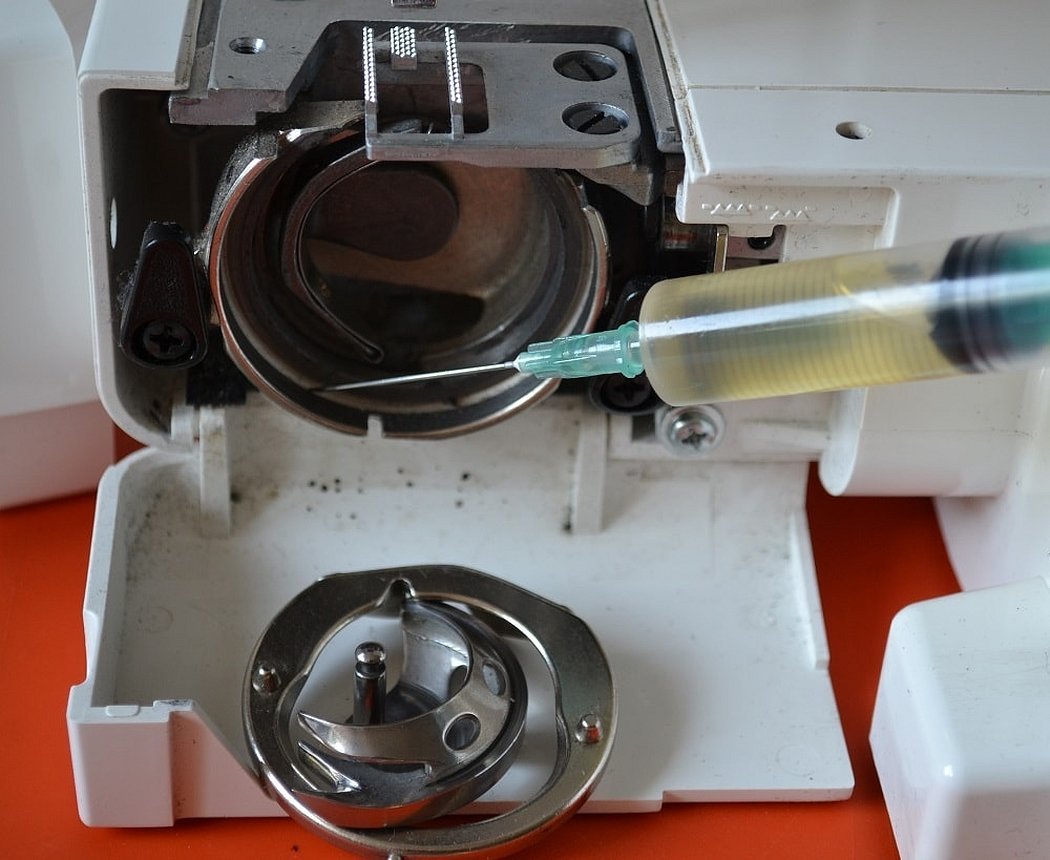

The latest industrial devices have an automatic lubrication system. You only need to look at the oil level from time to time and fill the reservoir if the mark is below the norm.

Some older industrial sewing machines, like household ones, are lubricated using a drip or dry lubrication system. In this case, the main rubbing parts and mechanisms must be processed manually and only by qualified specialists.

Industrial units are usually treated with mineral or synthetic oils. Among the synthetic compounds for sewing mechanisms, silicone ones are in particular demand. This type is used only for certain parts of the device, namely:

- blades and knives;

- motor parts and assemblies;

- plastic and graphite elements.

Treatment should be carried out using a coarse brush and a sprayer.

Features of the lubrication procedure

It is a mistaken belief that when lubricating, you need to apply as much of the composition as possible. This is far from true. Excessive amounts of oil can cause even more accumulation of dust, pieces of thread and pieces of fabric. The mass that forms from lumps of foreign bodies usually accumulates in one place and leads to the breakdown of a certain mechanism.

How Often Should You Lubricate Your Sewing Machine?

There is no universal recommendation for the frequency and method of processing the machine. Everything depends on the regularity of its use and the quality of assembly. If the device is used several times a week, then it will be enough to change the lubricant a couple of times a year. The method of processing is also different everywhere and depends on the structure of the device. Disassembling devices with a vertical and horizontal shuttle, for example, differs, as does the location of the main units in them.

Thus, with high-quality care and compliance with all operating rules, the sewing machine will be able to serve for quite a long time and bring many benefits to its owner.