A sewing machine is a convenient piece of equipment for high-quality and fast sewing of clothes. Why do the pedals of this machine break, how are they arranged and is it possible to repair the electric drive of a sewing machine? More on this below.

- The first models of pedals

- Reasons for failure

- How a sewing machine pedal works

- Features of working with an electric drive model

- Is it possible to make repairs?

- How to Repair a Sewing Machine Pedal Yourself

- Restoring the functionality of the pedal of the sewing machine "Veritas"

- How to disassemble the pedal from a Janome sewing machine

- Podolsk

- Do not leave the pedal unattended when connected to the mains.

- Tips for Buying a Sewing Machine Foot Pedal

The first models of pedals

The first pedals appeared in 1830, when Barthelemy Thimonnier mechanized work with a sewing machine. These were rheostat models. They consisted of a rheostat made with a large number of graphite plates, and closely adjacent to each other. They worked as an on/off switch for the electric drive. Work with the equipment occurs smoothly and gradually. Thanks to them, it was possible to regulate the speed of work and change the voltage indicator supplied to the car drive. As a result, the frequency rotation changed along with the speed of work.

Reasons for failure

At the moment, pedals are mechanical and electric. They often break due to contact oxidation in the connecting plugs or a break in the electric wire inside the cord insulation. Oxidation appears due to a belt that is too tight in the device, a heavy sewing machine, moisture getting inside the structure, dilapidation, twisting and poor connection of contacts. It is easy to fix. You just need to clean the contacts with sandpaper. As for the wire break, you should use a tester to find it and fix the wire.

The wire breaks from inside the insulation process due to various factors. As a rule, as a result of improper use. For example, a wire break occurs if you constantly pull the plug out of the socket by the cord or step on the contact with angular and heavy objects. It is possible to fix a wire break without looking for the place of the break. It is enough to replace the entire wiring. However, replacing the wiring is more expensive than a new sewing machine.

Please note! The cause of the breakdown may be the failure of the electric motor. This often occurs due to overload, unacceptable high or low voltage, a malfunction in the motor assembly, a malfunction in the mechanical machine part, long-term continuous operation of the motor system and increased traction load on the system. Often the motor does not break down, but overheats greatly. This occurs due to the hanging of the brushes and intra-turn short circuit in the motor windings.

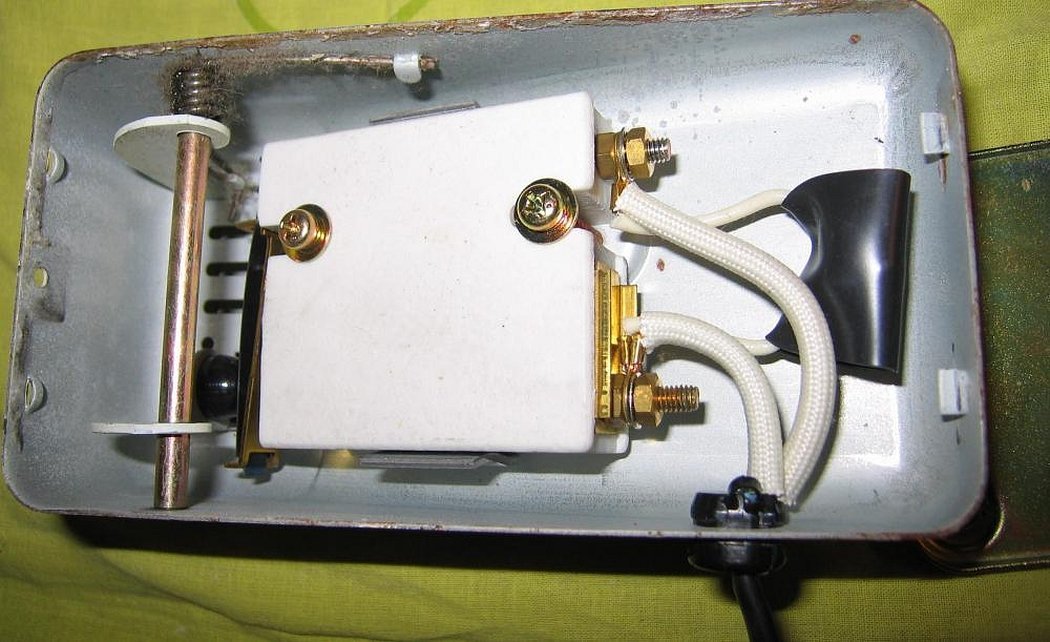

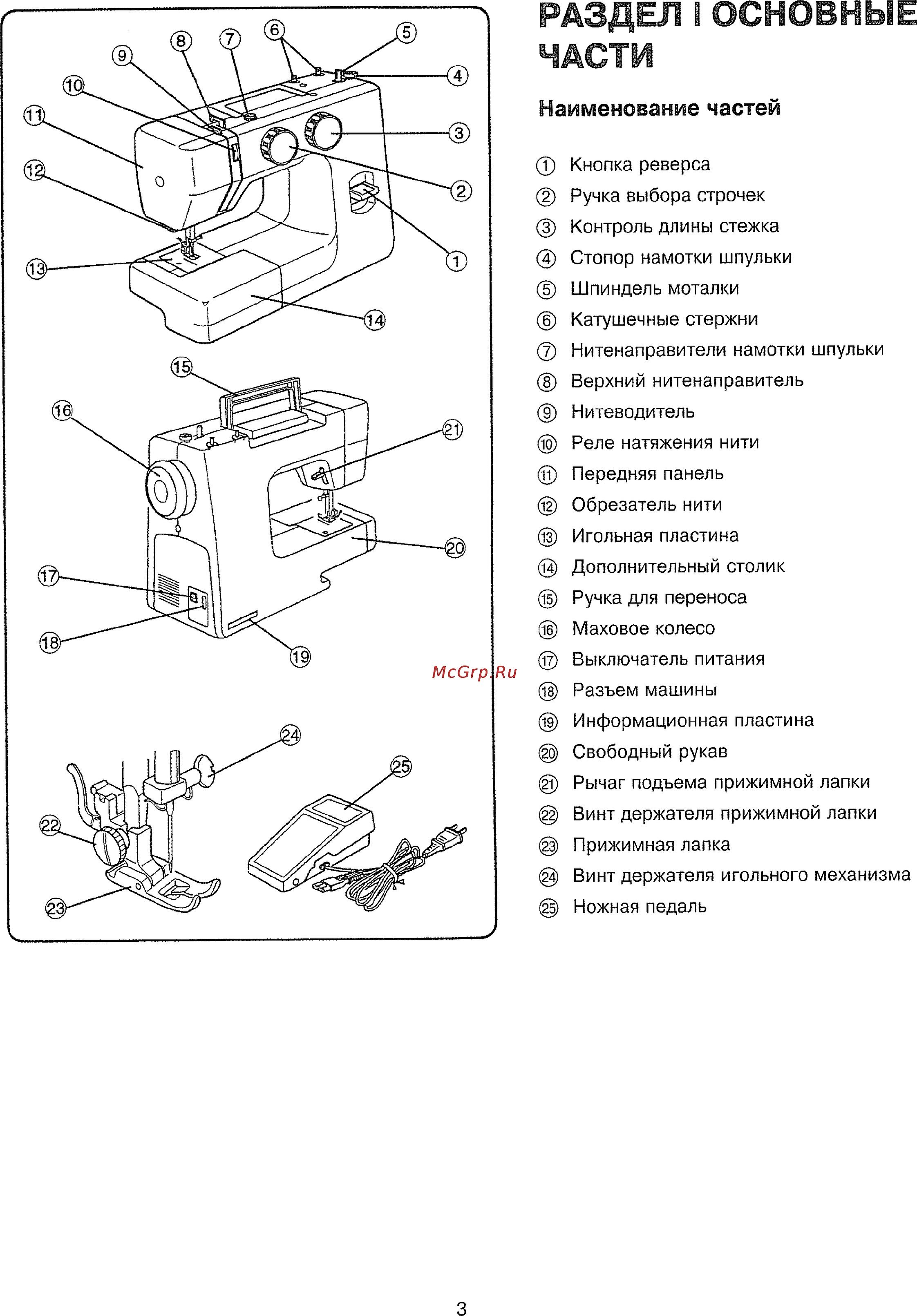

How a sewing machine pedal works

Brother or Singer sewing pedals are very simple. They consist of a switch, a rheostat, graphite round plates, a needle according to the instructions. They work for a long time and fail without any external signs. The main sign indicating a breakdown is a slow rotation, when the pedal must be pressed all the way for stable operation. This is a clear sign for buying a new model. In order not to buy a new machine with pedals, you can adjust the electric drive operation of the device.

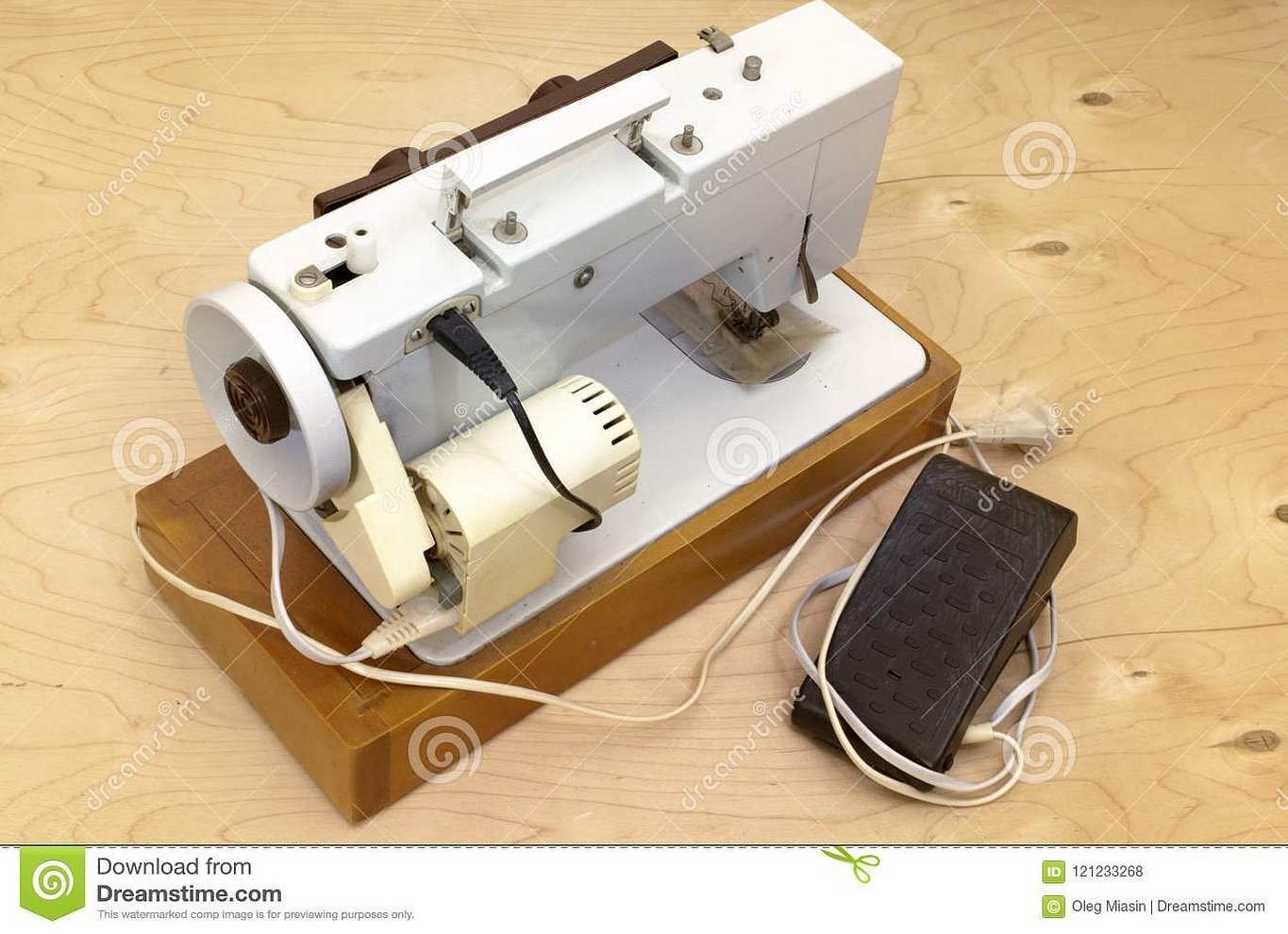

Features of working with an electric drive model

Electric pedals differ from Soviet foot pedals in their plastic case and light weight, plastic case and ease of operation. Inside there is only a small board. Another difference is the installation of the wire directly into the case.

When broken, it is difficult to repair electric drive devices. You will need professional help from an electrician. You will need to find damage to the soldering or torn wiring. Sometimes you need to use a special tester with an oscilloscope in such a case. Electric drive models are capricious. They can suddenly stop and resume their work only with frequent pressing.

Is it possible to make repairs?

Electronic pedals often cannot be repaired even by a repairman. They have a microcircuit with a board inside and therefore it is necessary to use a circuit with testers. You will need to entrust the work to a professional electrician. They stop working immediately and necessarily at the moment when they are especially needed. This happens due to the failure of the main radio component (thyristor).

How to Repair a Sewing Machine Pedal Yourself

You can repair the sewing machine pedal yourself. First, you need to disassemble it. All you need to do is remove the sleeve clamped by the screw by unscrewing the screw.

Please note! Repairs can be made with a rheostat sample. To understand the cause of its malfunction, you need to remove the case. Perhaps, by removing the case, it will be possible to ensure normal operation without calling a technician and buying new parts.

As for the breakdown of the electric motor model, only an electrician can handle it. You cannot repair it yourself. A technician will be able to quickly find the cause and eliminate it. The problem may be in the oxidation of contacts, a broken wire, or a failure of the thyristor, the main radio component. In the penultimate and last cases, as a rule, it is recommended to buy new equipment.

Restoring the functionality of the pedal of the sewing machine "Veritas"

To restore the functionality of the Veritas pedal, you need to find out the cause of the malfunction. If it lies in the rotation frequency of the electric motor shaft, then you can use a carbon resistor, a three-stage discrete resistor. The model is remade from the base and the moving part. To do this, the axis connecting them into a single whole is removed, and then all the parts are removed. Next, the protrusions are removed. Only the tongues are subject to modification. Their height is reduced using a soldering iron. Then a groove is made in them

How to disassemble the pedal from a Janome sewing machine

You can disassemble the USSR pedal by using a flat screwdriver on the side where the thin side of the pedal and the joint of the halves are located. Using the tool, you need to pry the body and separate the halves of the device. It is best to entrust the disassembly of the part to a professional master, since if you do not understand the mechanism of its operation, you can damage the contacts and then all that the user will have to do is buy a new device.

Podolsk

Like other pedals, the Podolsk model consists of a cover push lever and a graphite button, a contact button, a tension bolt, a ceramic body, internal carbon plates, a locking plate, a nut, a capacitor and an electric drive. To get to and inspect the last two Podolsk parts, you need to take a thin screwdriver and unscrew the nuts and tension bolts on the ceramic body of the locking plate. Then adjust the contact electric button, the internal column of carbon plates and start repairing.

Do not leave the pedal unattended when connected to the mains.

After performing the repair yourself, do not leave the sewing pedals plugged into the socket for a long time without supervision. Due to poor rheostat adjustment, the pedals may begin to overheat.

The output plug contacts leading to the electric motor equipment should not have voltage due to the complete disconnection of the electric circuit. Even after the foot is removed from the pedals, a weak current may still remain there. The electric circuit will close and eventually the electric motor will begin to heat up. Then a fire may occur.

Please note! If you cannot check for voltage using a tester, you simply need to not leave the machine connected to the outlet.

Tips for Buying a Sewing Machine Foot Pedal

To buy quality sewing machine pedals, you need to choose models from manufacturers. The shape of the electrical connector of the device must match that of the foot pedals.

It is also important to inspect the wires for integrity to prevent rapid oxidation and combustion.

Preference should be given to those models that have a thick insulating wire. It will be difficult to tear.

It is necessary to select pedals, like a sewing machine, based on the power and available network power in order to avoid overvoltage.

In general, a sewing machine often breaks down due to improper use of the tool. It can be repaired with the help of a master in Podolsk or independently. In order to avoid having to repair the tool, it is important to take into account the above recommendations for buying pedals and not to leave the pedals connected to the network unattended.