Podolsk sewing machines are considered household and served well during the Soviet era. Now they are outdated, but there are craftsmen who continue to use them. To understand the issue, it is worth considering the history, types of models, main characteristics, common types of breakdowns.

Story

The Podolsk sewing machine has a rich history. In the twentieth century, Singer models were actively sold. The Podolsk enterprise also produced its own models, but initially they were not in great demand. In 1994, it was possible to conclude an important contract with the Singer company. By this time, there were three popular models.

Types and characteristics

The following models from the catalogue are among the most common sewing machines "Podolsk":

- "Podolsk 2m".

- "Podolsk 132".

- "Podolsk 142".

They are famous for their high performance and the best materials. Lightweight lubrication is provided and there is adjustment. The following are attributed to important characteristics:

- stitch length;

- dimensions;

- weight of the machine;

- platform dimensions;

- presentation of material;

- flywheel type.

"Podolsk 2m"

This is an ideal machine for home sewing. It works with wool and silk fabrics. The products are durable, and breakages occur extremely rarely.

Specifications:

- platform 371 x 178 mm;

- stitch length 4 mm;

- execution - manual;

- device weight 11.5 kg;

- maximum speed 1200.

Having looked at the general instructions, it becomes clear that the flywheel rotates in one direction. In order not to get confused in the shuttle device, do not completely disassemble the kit. It is recommended to set the foot in the open position.

Attention! It is prohibited to install anything on the thread winding element. This could be a spool of thread or a piece of fabric.

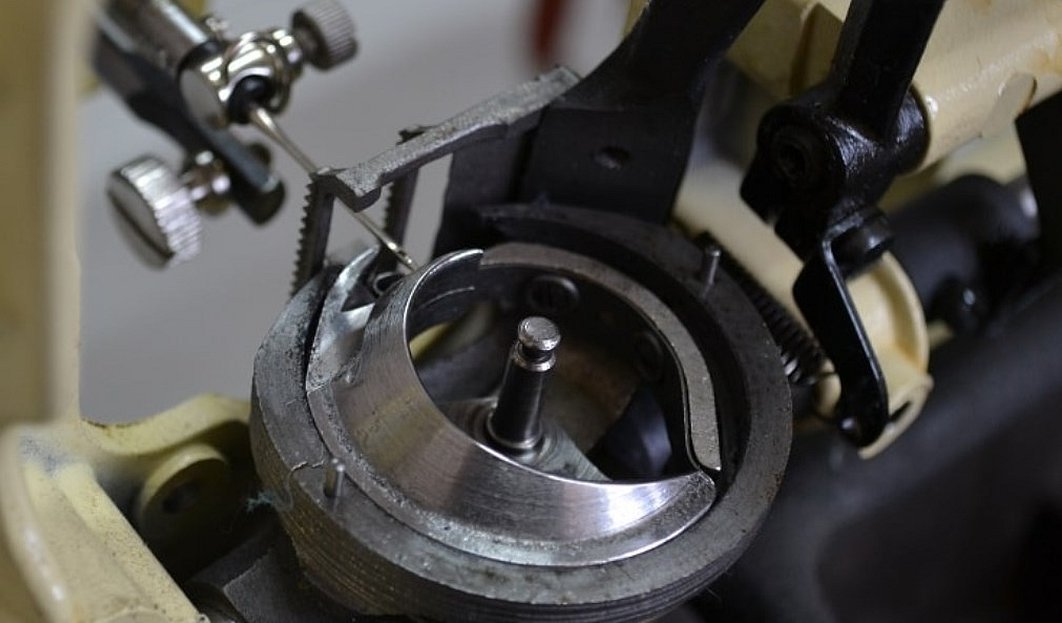

The model is suitable for sewing with a two-thread stitch. To make a stitch, not only the needle, shuttle, but also the thread take-up are used. Bobbins are offered in different options. There are elements with caps, as well as without them.

The winding principle should be considered separately. The main element in this process is the bobbin. It rotates due to the hinge mechanism. A person will not have to make significant efforts, the main thing is to watch the thread tension.

Important! A common mistake made by beginners is not fully releasing the flywheel. It should be open to minimize wear on parts.

"Podolsk 132"

The peculiarity of this machine lies in the following parameters:

- voltage 220 volts;

- needle numbers 70-110;

- stitch length 4 mm;

- head size 290 x 178 x 412 mm;

- maximum frequency 1000 revolutions;

- foot size 4.5 mm;

- zigzag width 5 mm.

When using a sewing machine, the flywheel must not be rotated in the opposite direction. If it is necessary to move the fabric, this is done only on the needle. The head must be lowered. Beginners often try to push the material by force. As a result, the needle breaks and will have to be replaced.

The product comes with needles, brushes, lamps, a threader and additional feet. For safety reasons, it is important to monitor the serviceability of the power cords. If the lamp fails, the part must be replaced. Before this procedure, the plug is removed.

Advice! When working, do not keep your hands near moving parts of the machine.

A common problem is the breakage of the shuttle. The belt has to be adjusted periodically. To start working, it is better to read the instructions and check the main units. There are features for threading the upper thread, since it is necessary to adjust the presser foot.

The spool of thread is installed on top. If it needs to be replaced, it is important to remove the bobbin case. The easiest way to do a straight line is to adjust its length and direction. The regulator with teeth is located on the side of the machine.

"Podolsk 142"

The presented household machine is suitable for household use. It is used on synthetic, woolen, cotton fabrics. You can make a straight or zigzag stitch.

Specifications:

- stitch length 4 mm;

- sleeve extension 170 mm;

- foot lift 6 mm;

- cabinet dimensions 570 x 430 x 780 mm;

- weight 39 kg.

The product comes with a set of needles, a pin, a lamp and a manual. To prepare for work, it is worth checking the body and inspecting the main units. Due to design features, the friction screw often suffers. The flywheel or bobbin may fail. It makes sense to adjust the tension of the foot during work.

Setting up the sewing machine "Podolsk"

The manual sewing machine "Podolsk" is easy to set up, you just need to get to know the device a little.

Main nodes:

- stand,

- regulators,

- fastenings,

- thread guide,

- paw,

- drive,

- plate,

- nightstand,

- fabric engine,

- coil,

- flywheel latch,

- case cover,

- lever.

During the setup, it is necessary to adhere to the rules. The regulator is debugged, it is necessary to look at the instructions. Modern models have wheels, but here everything is done manually. The parts must be rearranged, the spring displacement is taken into account. This is how the winding and bobbin are adjusted. A plan is provided for the thread advancement:

- bending of the ears,

- regulator release,

- lever pull,

- clamping the ears.

To tighten the thread, you will have to use several mechanisms on the panel. Without a tool, a screw and a shuttle are used. The element cannot be used without a washer, it affects the screw. The test on the material occurs after the thread is loosened.

Important! If the loops are visible, it means that you have overdone the pressure.

It is good if the knots are not palpable. The mechanisms with paws are adjusted separately. A spring mechanism is used inside the body. The regulator allows you to adjust its tension. During the process, it is necessary to find the golden mean. To do this, the convergence is adjusted, it is necessary to create minimal pressure on the plate. If you overdo it, the seam will be shifted and will not look nice.

The most common causes of car breakdowns

Podolsk sewing machines break down for various reasons:

- thread breakage,

- needle breakage,

- winder failure,

- coil deformation.

If we consider thread breakage, it occurs due to poor quality of the material. Threading should be done according to the instructions. If the spring inside the bobbin weakens, you will have to change it. Sometimes the problem lies in the small screw. There are serrations at the end, they should not be ground down.

When a bad stitch is observed, experts blame the regulator, it is necessary to take it for repair. If the washer on it jumps off, uneven winding of the thread occurs. Poor advancement along the fabric occurs for several reasons. It can be a rack or a bar. The mechanism does not press the material or presses it too much.

Above we have considered Podolsk sewing machines, which have a rich history. There are interesting models, you can get acquainted with the characteristics. There are features of machine settings, it is necessary to know the common causes of breakdowns.