The sewing machine class 1022 is still popular with owners of medium and small productions. Old units still work and are capable of processing very dense materials. The difference between machines of different modifications is not very large. But each of them is still successful to a greater or lesser extent.

- Technical characteristics of the sewing machine class 1022

- The structure and operation of the sewing machine class 1022

- Operating instructions for sewing machine class 1022

- Adjusting tension, upper and lower threads

- Operating procedure for sewing machine class 1022

- Making and repairing shoes, sewing with your own hands

- Repair and adjustment of sewing machine class 1022 - replacement of shuttle

- Setting up the shuttle and needle operation parameters

- Maintenance and lubrication of the sewing machine class 22

- List of typical faults

- Why is a 22 class sewing machine considered better than a 1022M

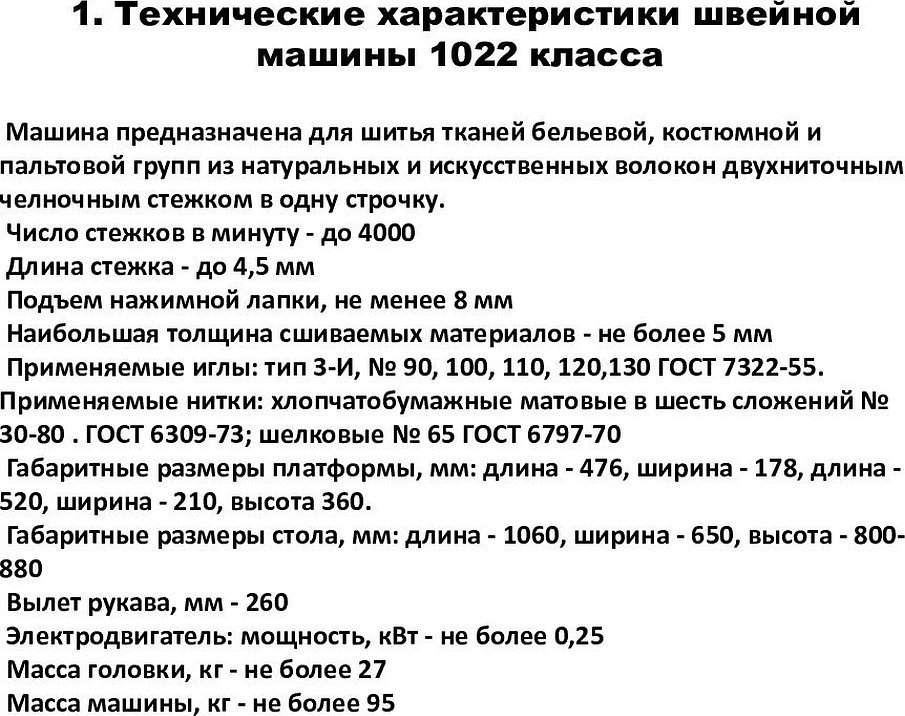

Technical characteristics of the sewing machine class 1022

The sewing machine of class 1022 belongs to the category of industrial-purpose devices. It is capable of processing leather, coat fabrics, and performing complex operations that professionals use when creating clothing.

The technical characteristics differ significantly from those of household models. The 1022 machine makes 4,000 stitches per minute with a length of 4.5 mm. The presser foot is raised by 8 millimeters. The fabric that the machine can process should not be thicker than 5 millimeters. Silk and cotton threads are used. The machine weighs up to 95 kilograms. The power of the unit is up to 0.25 kW. Despite the year of manufacture, older units are more popular.

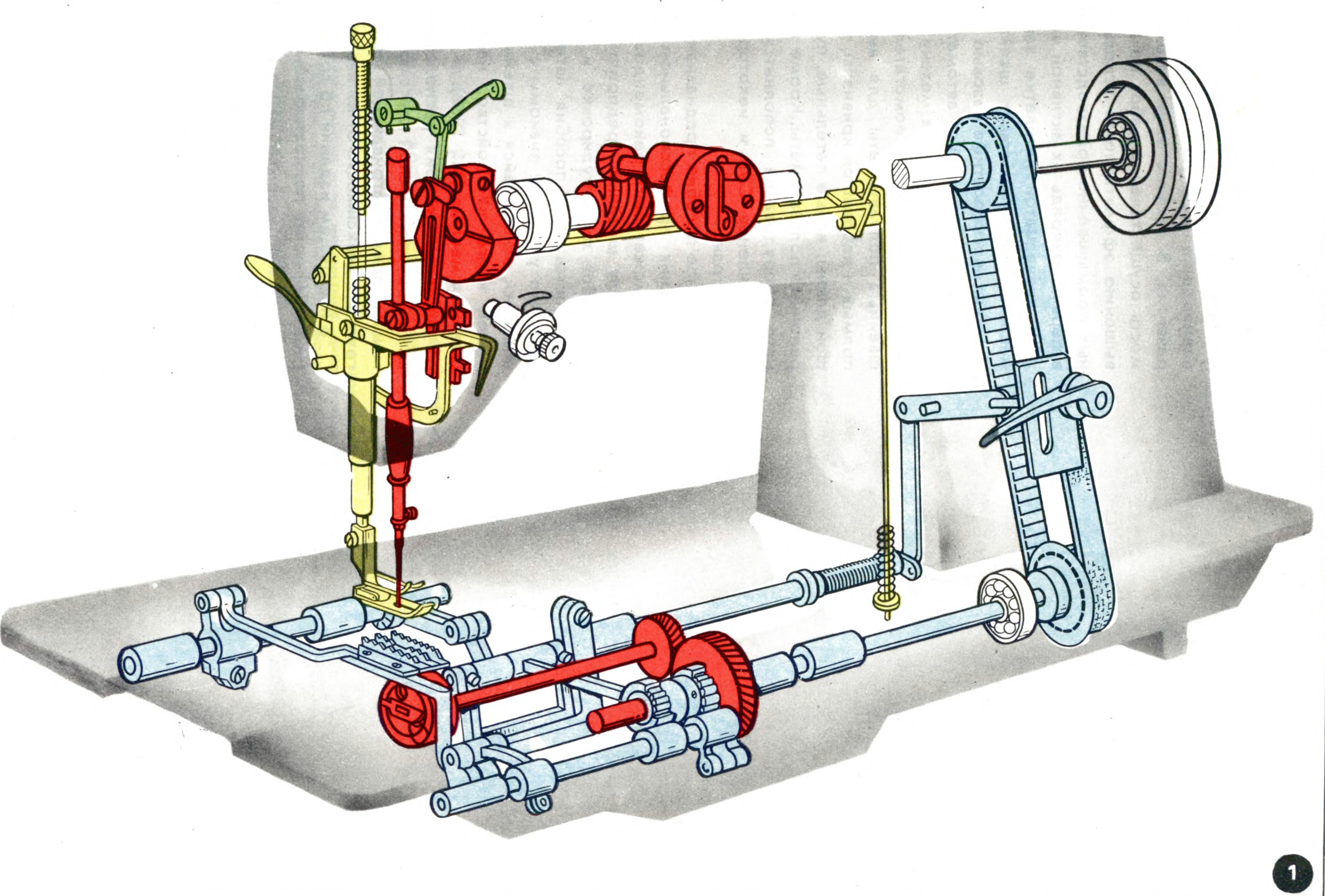

The structure and operation of the sewing machine class 1022

According to the description in the manual, the main ones are the barrel and control mechanisms. A switch and a pedal are provided. There is a place for installing spools, threads, and an oil collector. The advantage of the machine is that there is a box for scissors, threads, needles, an awl and other devices. The material is fed from you and back, a lever is used to change the direction.

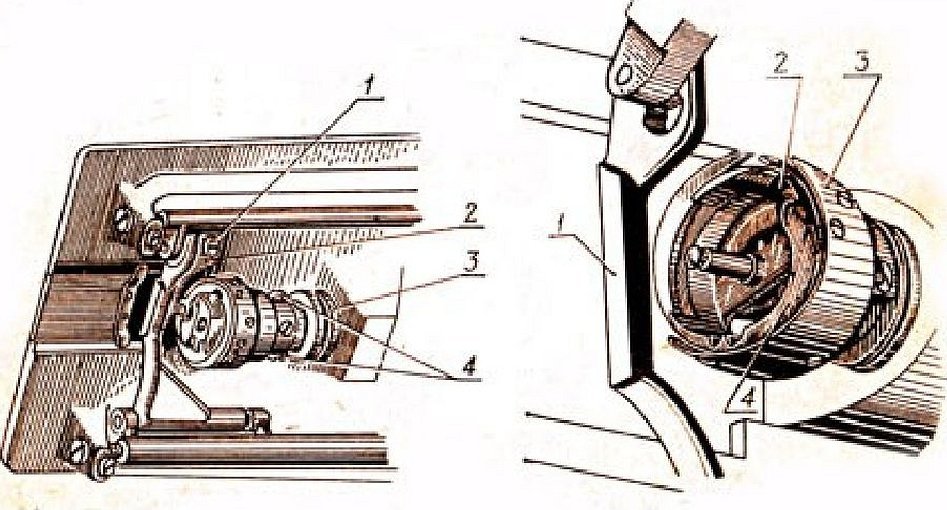

The use of the machine is simplified by the presence of sliding bearings in the sleeve. There is a thread take-up and a needle bar in front. The flywheel is located on the edge. The presser foot presses the fabric to the needle plate. There is an auxiliary lever for this. Manual adjustment is not excluded.

Operating instructions for sewing machine class 1022

The instructions contain rules for beginners and reminders for experienced needlewomen. What is recommended to remember:

- turn the flywheel only in the direction indicated;

- always leave the fabric under the presser foot;

- do not pull the material while the machine is running;

- sew only with a correctly threaded bobbin;

- periodically remove dirt, monitor the amount of lubricant;

- use only approved needles and select them depending on the type of fabric;

- monitor the belt tension.

Do not violate the sequence of filling the device and working with it. Failure to comply with the operating conditions will lead to rapid breakdown.

Important! There are modifications of 1022M, which are intended for edging medium and heavy fabrics.

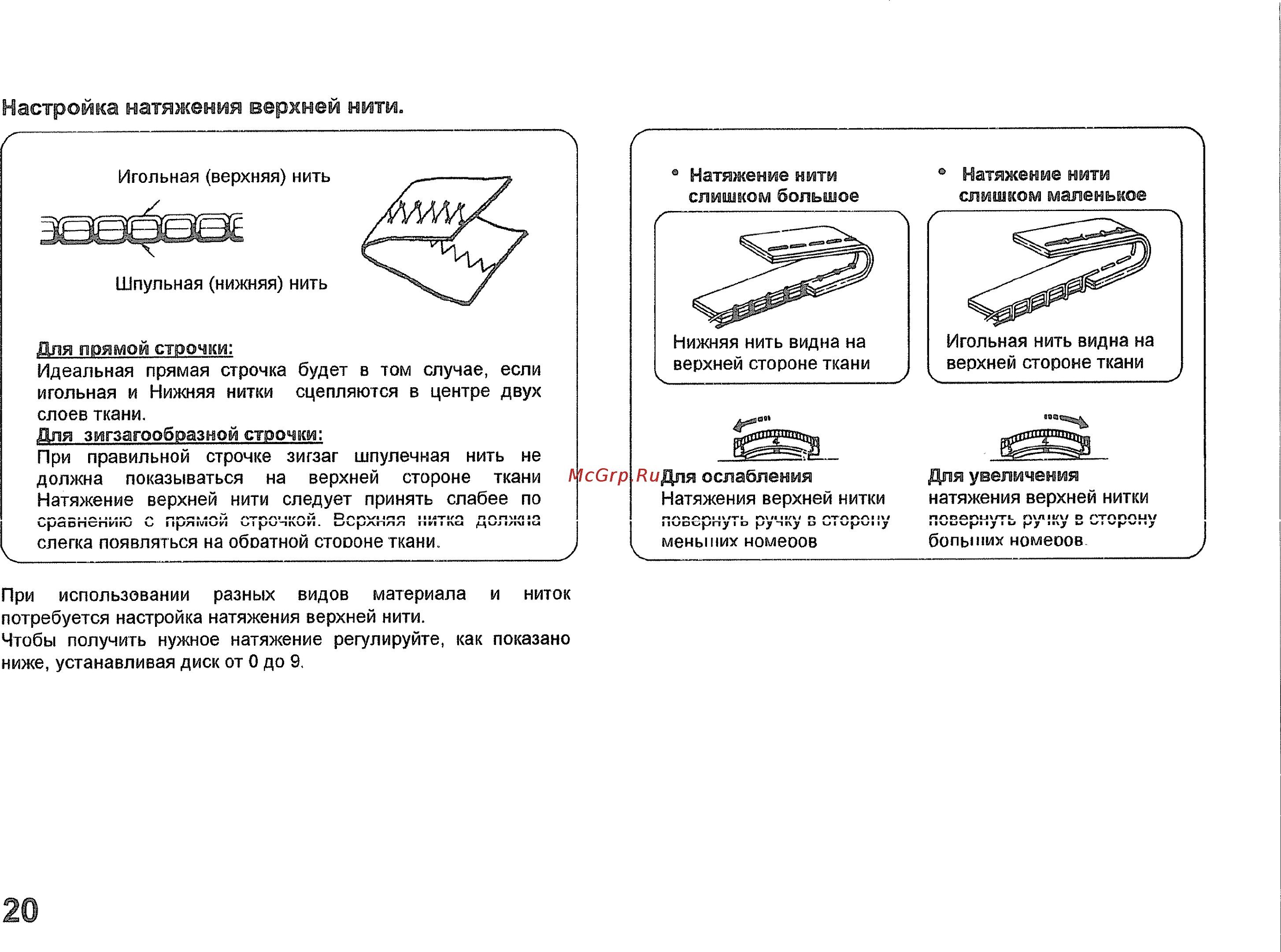

Adjusting tension, upper and lower threads

Machine tension adjustment is done according to the same scheme. If the upper thread is adjusted incorrectly, the lines will be uneven and unsightly. To reduce the tension, turn the regulator to the decrease mark. It is important to periodically check the quality of the lines as they decrease. It is important that the lower thread is not visible from above. If the defect does not go away, it is corrected.

To check the level of the lower tension, you need to hang the shuttle by the thread, it should not unwind it. Otherwise, it is loosened.

Important! For adjustments, it is recommended to always have a screwdriver on hand that will only be used for the machine.

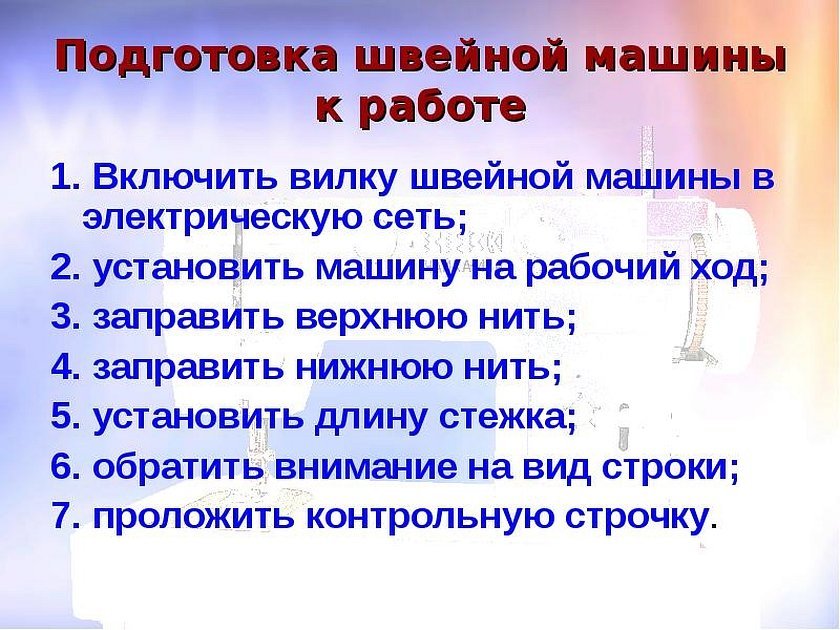

Operating procedure for sewing machine class 1022

Refueling and preparation for work requires following the rules. How to proceed:

- Turn on the drive by pressing "Start".

- Press the pedal.

- Make a line up to 50 centimeters with a reverse stroke.

- Turn off the device.

- Raise the paw.

- Remove material.

- Cut the threads.

It is recommended to use an LED lamp to illuminate the area, it does not distort the shades of materials.

It is important to periodically monitor the quality of the stitching and stitches. And if necessary, adjust the tension, including the needle.

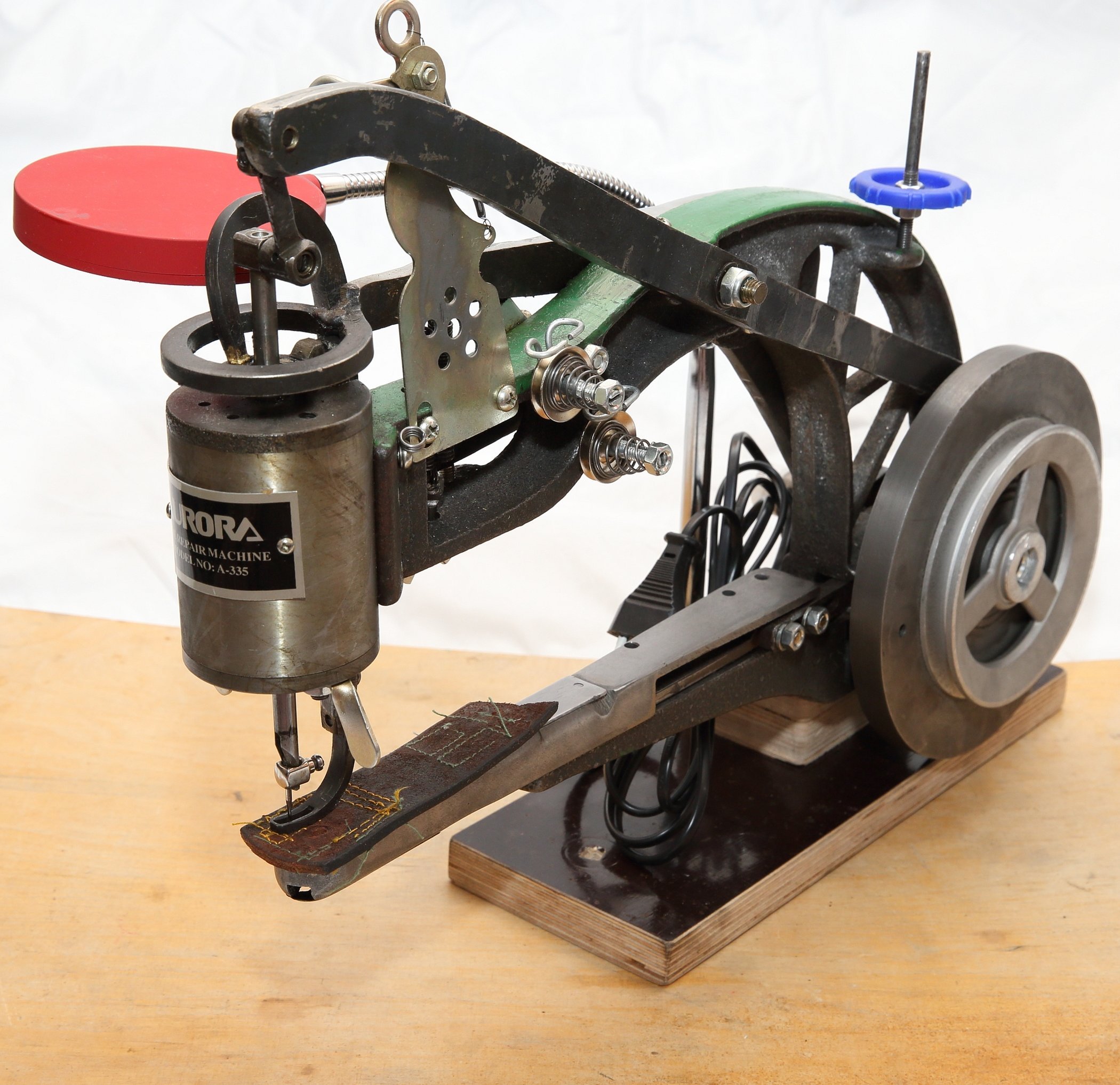

Making and repairing shoes, sewing with your own hands

The device is suitable for sewing heavy fabrics, it can work smoothly even with thick leather. Therefore, devices of this class are often used to repair shoes made of soft materials. At home, it is not recommended to periodically resort to this method of operation. This is easy to explain, because industrial machines cannot be refilled with oil, like household ones. And shuttles in production are changed at best once a year, or even more often. At home, this is not possible. It is also not recommended to try to repair and adjust complex mechanisms on your own.

Important! An industrial unit must be repaired by a specialist.

Repair and adjustment of sewing machine class 1022 - replacement of shuttle

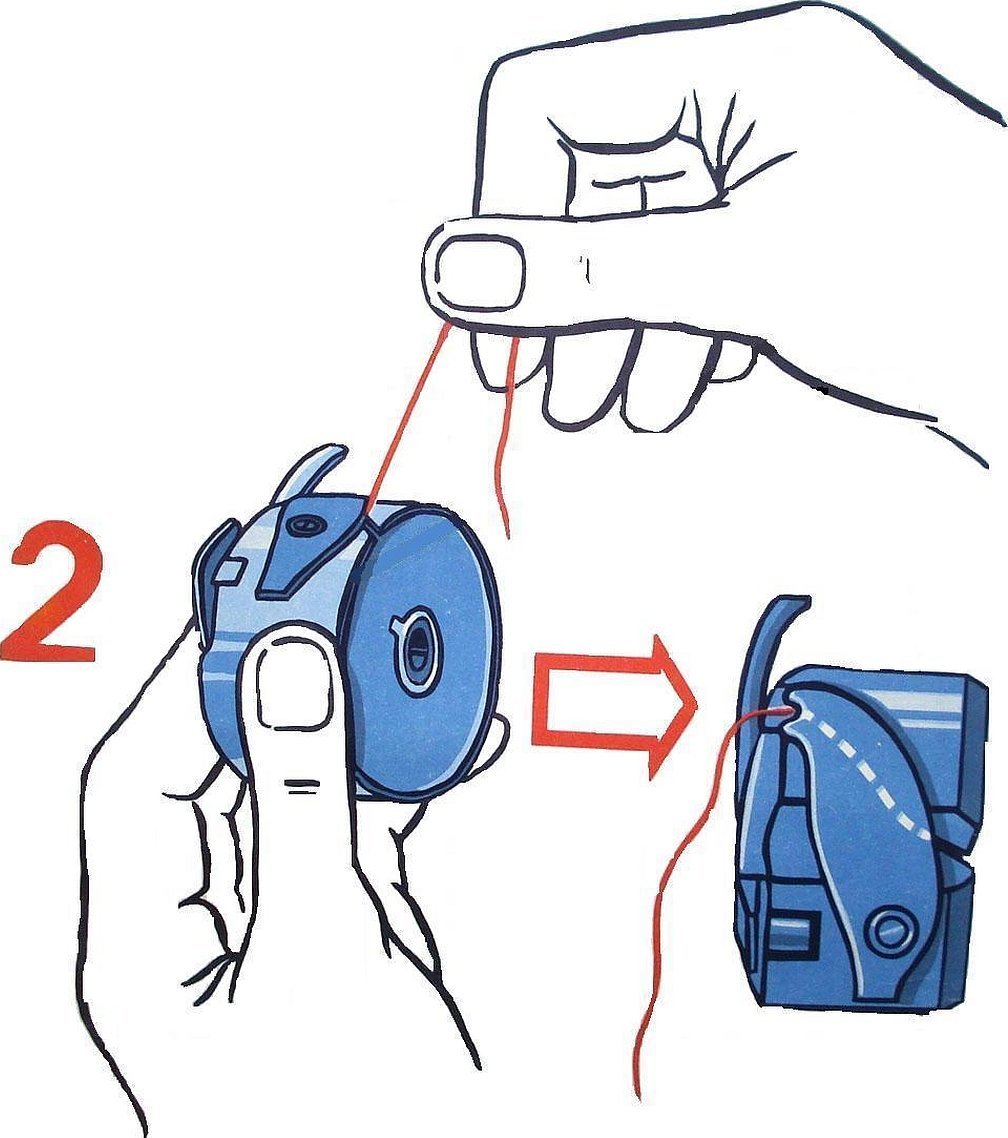

The purpose of class 1022 models is not like that of home devices. Therefore, repairs can be complicated at home. To replace the shuttle, the master removes the foot, plate and motor for the material. And then removes the needle, tilts the main part of the device. Then takes out the cap and bobbin.

Then the specialist loosens 2 screws, turns the flywheel. The next step is to turn the shuttle until the safety catch is lowered, the bobbin holder and remove the shuttle. Then install a new mechanism. After returning all parts to the desired position, the master checks the serviceability, the quality of the stitches, that is, checks the quality of his work.

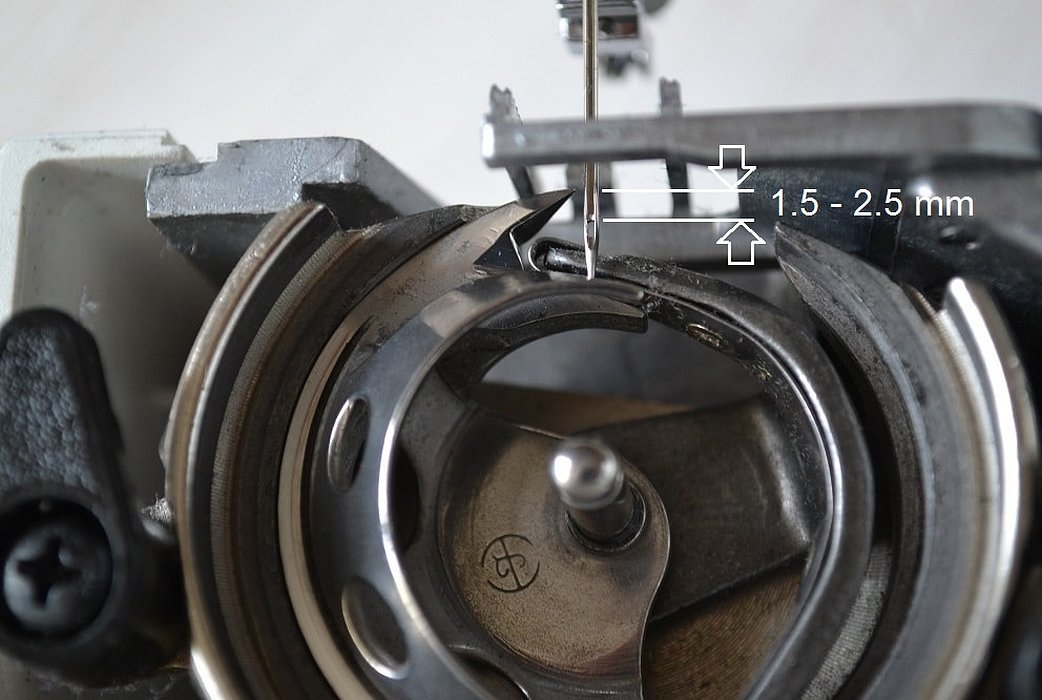

Setting up the shuttle and needle operation parameters

After installation, it is necessary to re-adjust the operating parameters of the mechanisms. It is necessary to put the bobbin holder finger, while maintaining a gap of 0.5 mm. The distance from the finger to the holder should be equal to half a millimeter, while it is necessary to check the thread tension, the indicator should not be more than 60 g. A screw is needed for adjustment.

Next, install the bobbin in the holder, lower the machine head, following the rules. The last step should be installing the fabric motor and needle plate.

Maintenance and lubrication of the sewing machine class 22

Repair and periodic lubrication of parts guarantees smooth operation and production of high-quality products. In addition, it is necessary to clean the mechanisms from dirt and fabric residues. Without oil, the machine works loudly. Most of all, you need to pay attention to the lower part. It is important to apply oil so that it does not get on the fabric later, it will be extremely difficult to wash it off. The substance is easy to distribute with a medical syringe.

To treat gears, buy graphite grease. It is not recommended to apply wick grease, its effectiveness can be disputed. In production, the sewing unit 22 is treated once every 30 days, provided that the operation is not daily.

Important! The main parameter to consider when purchasing a household model is power.

To process the 1022 machine, you need to remove the top cover and use sewing oil. It is extremely difficult to get to the desired unit, this is the main disadvantage of the variation.

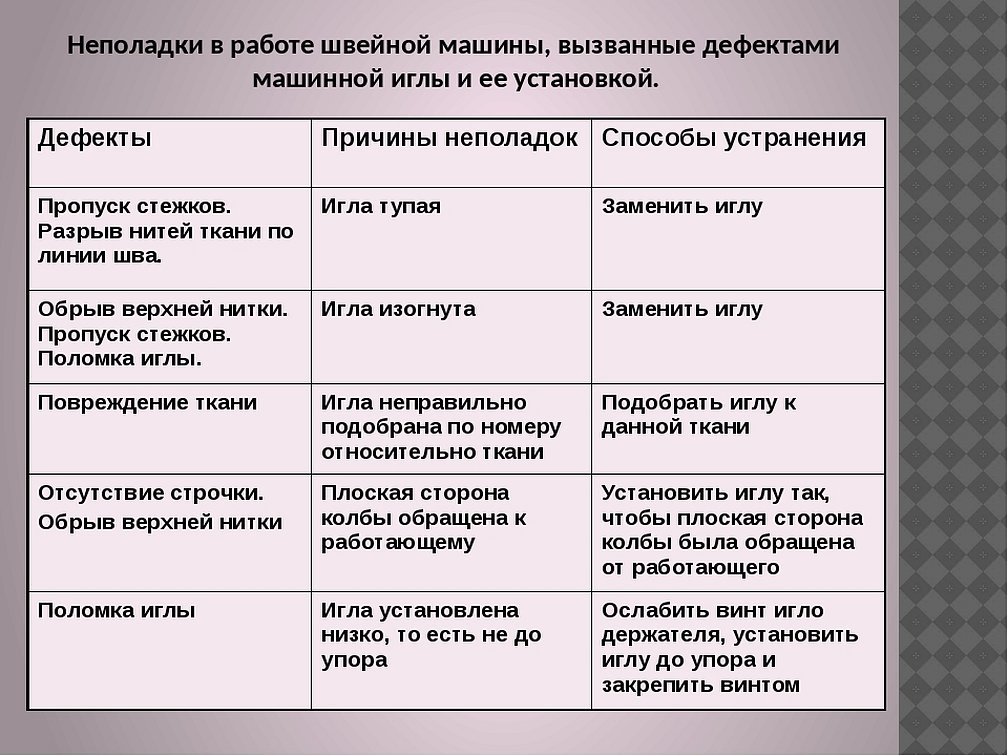

List of typical faults

Industrial machines can work properly for a long time. But sometimes minor faults require repair. They are mainly caused by improper operation. The disadvantage of such sewing units is that it is difficult to find spare parts for them.

Thread breakage often occurs due to the selection of poor-quality material. If this happens, you also need to check the tension, then loosen it. Threads also deteriorate due to poor-quality needles. To avoid problems, it is necessary to replace the needle plate whenever possible, and also polish the burrs that cause threads to break.

Important! There should be no knots in the threads, as they are the cause of poor quality sewing.

Sometimes poor sewing is caused by poor condition of the working surface, dull teeth, bad needles and inappropriate sewing materials. Today, the breakdown of such old machines can become a significant problem, and quality replacement parts are rare.

Why is a 22 class sewing machine considered better than a 1022M

The sewing machine 1022M is inferior to the 22nd models. It can work with leather, rough denim and canvas with high quality and without gaps. The 1022 devices have few differences from similar models. Among the advantages, one can note a more modern design. However, they are inferior to the 22nd class in noise. The 22nd machine does not make noise due to the use of bushings.

Industrial machines are divided into several classes. Small productions still use devices 1022, 22, 1022M. They are not much different and work properly. The difficulty may be in setting up. Class 22 machines produce a noise that is comfortable for the ear, but it is relatively difficult to fill them.