A printer for printing on fabric is being looked at for home and business. The devices are supplied by various companies. Manufacturers offer models for domestic and industrial use, the type and characteristics are taken into account. Everything depends on the tasks and financial capabilities.

- Features of textile printers

- The principle of operation of a textile printer for fabric

- What fabrics can be printed on?

- The type of fabric is an important criterion when choosing a device

- What digital fabric printing technologies exist?

- Laser ceramic printers

- Laser engraving machines

- Impact engraving machines

- Screen printing machines

- Which printer to choose for fabric for home use

Features of textile printers

If we consider a stencil machine, it includes the following elements:

- Printed hand.

- Desktop.

- Catcher.

- Spring element.

- Support disk.

- Support stand.

- Upper disc.

Interesting! There are complex modifications with adjustable frame position. Modern equipment has a lowerable frame. Supports are made of various materials, there are models for 1, 2, 3 posts.

The principle of operation of a textile printer for fabric

The fabric printer works on the principle of fixing the print using a heating element.

Main stages:

- Exposure.

- Image transfer.

- Pinning the image.

First of all, check the presence of paint in the cartridge, it should flow into the drum. Any contamination will impair the roller's passability, the image will not be clear. The metal shaft should be in close contact with the fabric.

The process of printing the image is called exposure, the actions are controlled by the control board. To fix the image, it is necessary to heat the surface. The pressure roller is controlled by a sensor, in some installations a cooling system is additionally provided.

What fabrics can be printed on?

The machine for applying a pattern to fabric is not capable of working with different materials, so it is recommended to familiarize yourself with the classification. Manufacturers offer to consider natural as well as synthetic fabrics. They differ in texture, have individual density, other features (elasticity, water-repellent properties, etc.).

Main types:

- felt or felt;

- footer;

- hockey net;

- sandwich;

- ribana;

- prima;

- peak;

- false mesh;

- biflex.

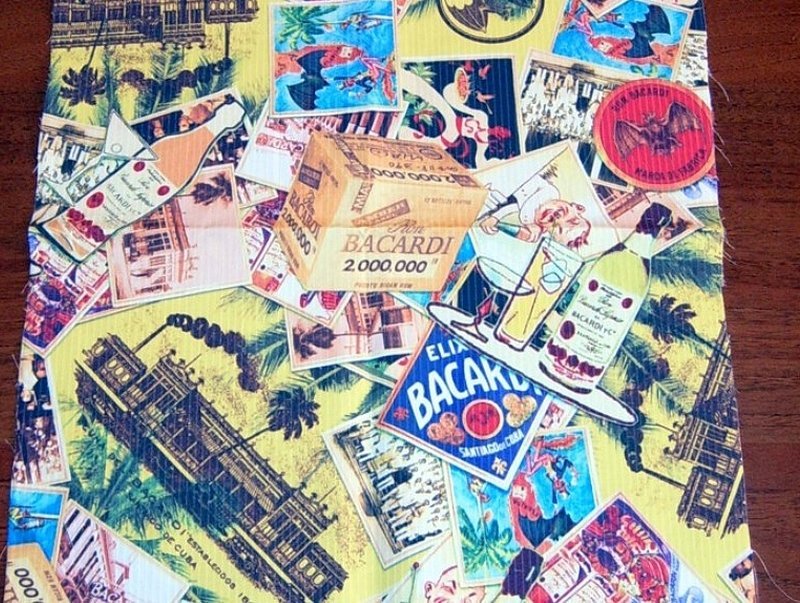

The type of fabric is an important criterion when choosing a device

If we consider biflex, it is declared to have a high density - from 170 grams per square meter. It is not so often found in stores, since it is in demand among athletes. Biflex is also used for printing on swimming trunks and swimsuits. Often, gymnastics suits are produced. The fabric is considered more suitable for screen printing.

False mesh is found with a density of 135 grams per square meter. It is used to make T-shirts and T-shirts. The material is in demand for screen printing. Pique has a low density and is used to make shirts and polo shirts.

Important! The material is absolutely not suitable for laser ceramic printers; it is used only on engraving machines.

Sports jersey is suitable for printing on underwear or T-shirts, it has a density of 130 grams per square meter. The material is applicable for screen printing.

What digital fabric printing technologies exist?

If we consider printing companies, we can find laser ceramic printers, as well as engraving machines. Not all equipment is suitable for home use, there are professional installations that require a setup technician.

Direct inkjet printing is well known and is used for working with signs and billboards. Plotters are sold in various types:

- thermal jet;

- piezoelectric.

A certain type of ink is suitable for the equipment, the user pays attention to the dyes. Piezoelectric technology has proven itself not so long ago. Synthetic fabrics are often used as a material. The operating principle is based on ultraviolet exposure.

The direct printing method is interesting because it can work with natural fabrics. The dye penetrates deeply into the texture of the material and colors it. The principle of operation of indirect printers is based on thermal sublimation. This type of digital printing is suitable for applying a mirror image.

Interesting! For printing, a special carrier is required (it is called thermal transfer). A high-temperature sole is used to fix the image.

Laser ceramic printers

Ceramic printers look compact and are mainly manufactured by Xerox.

Key Features:

- high reliability;

- wide color rendition;

- simple technological process;

- working with different types of fabrics;

- Suitable for advertising products.

If you look closely at the devices, you will notice that they differ in design. There are compact inkjet models, they differ in the kit, the characteristics are also taken into account:

- Print format.

- Weight.

- Dimensions.

- Seals.

- Support for operational pages.

- Print speed.

- Maximum resolution.

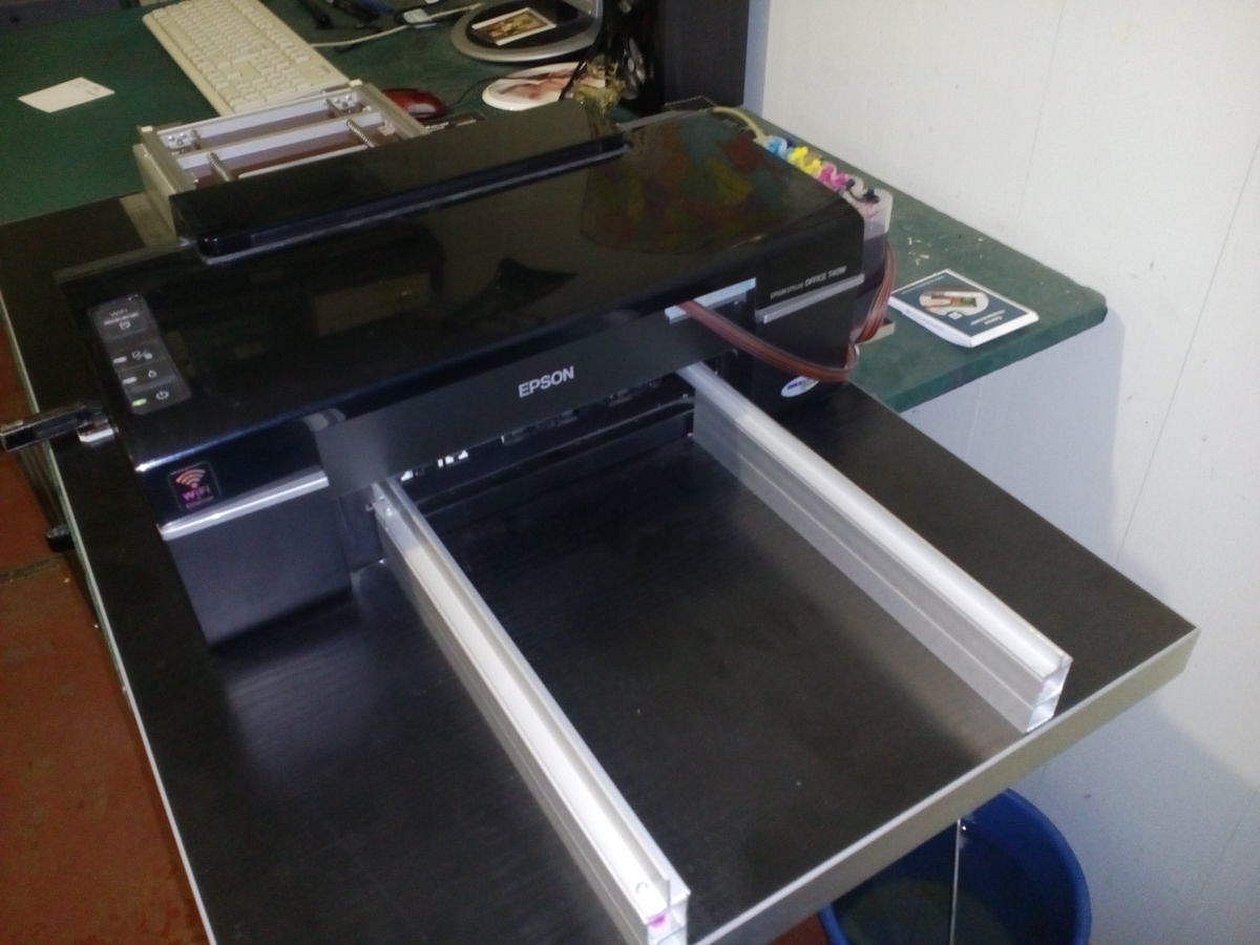

Laser engraving machines

The fabric printing machine of this type can be sold with or without a control panel. According to the design, the models are supplied with a cast or dismountable frame. There are products with a movable and fixed roller mechanism.

Key Features:

- high print speed;

- versatility;

- high resolution;

- ease of control;

- durability of the machine.

Desktop models are more like 3D printers. Modern installations accept plastic, paper, and rubber in addition to fabric. When selecting an installation, the following parameters are assessed:

- Power.

- Printing accuracy.

- Acceptable fabric thickness.

- Connection interface.

- Dimensions.

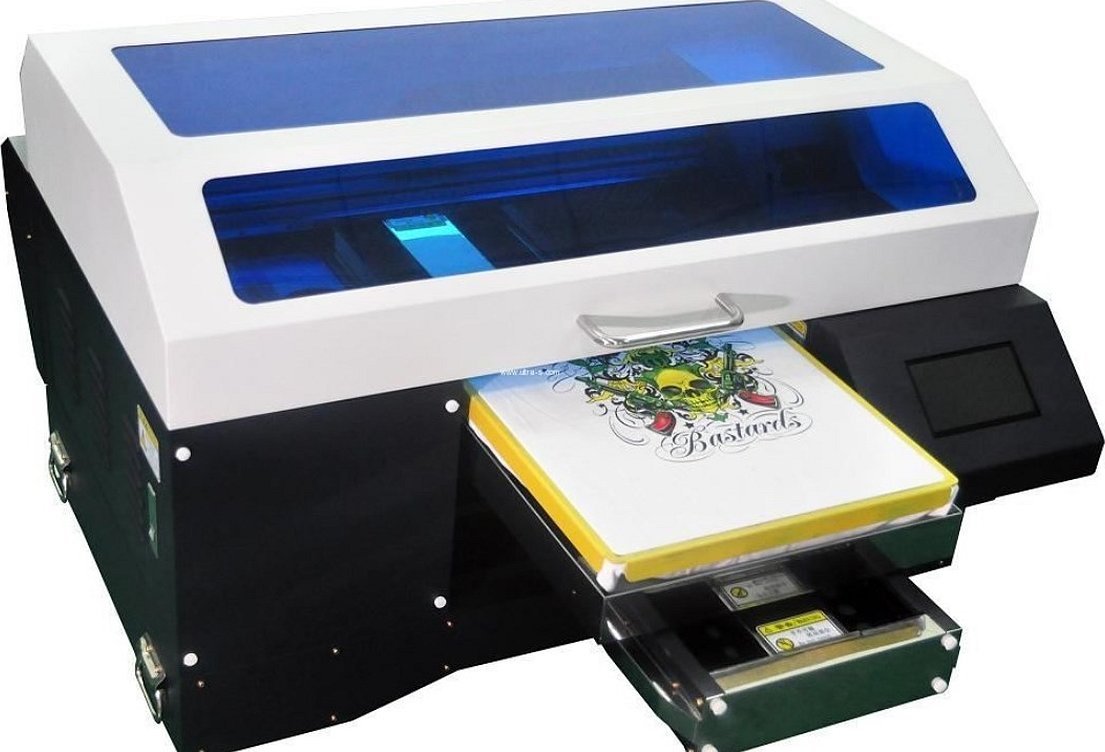

Impact engraving machines

Printing equipment for applying a pattern to fabric of the impact-engraving type is supplied with a control unit. Desktop and floor modifications are provided. Impact-engraving units are in demand at printing enterprises. In addition to fabric, they are approved for working with glass and plastic.

Existing species:

- Classic machine.

- Tablet version.

- Universal models.

If we consider a classic installation, three-coordinate models are considered widespread. There are devices with a lightweight frame and a wide stand. Impact heads, as a rule, are supplied with a suspension. Stabilizers are rarely used in machines, so they are distinguished by their mobility.

The universal version is equipped with a protective drive and is fully automatic. The presented equipment is suitable for printing on different types of fabric. Models of increased power with an asynchronous motor remain in demand. When selecting equipment, the consumer pays attention to the accuracy of operation and the size of the unit.

The last category includes the flatbed type and its feature is the use of a wide working area. The installation is completely controlled from the computer, and it is better to create the image in Adobe Photoshop. Before printing, it is important to decide on the size, as well as the mode (fast printing, high accuracy).

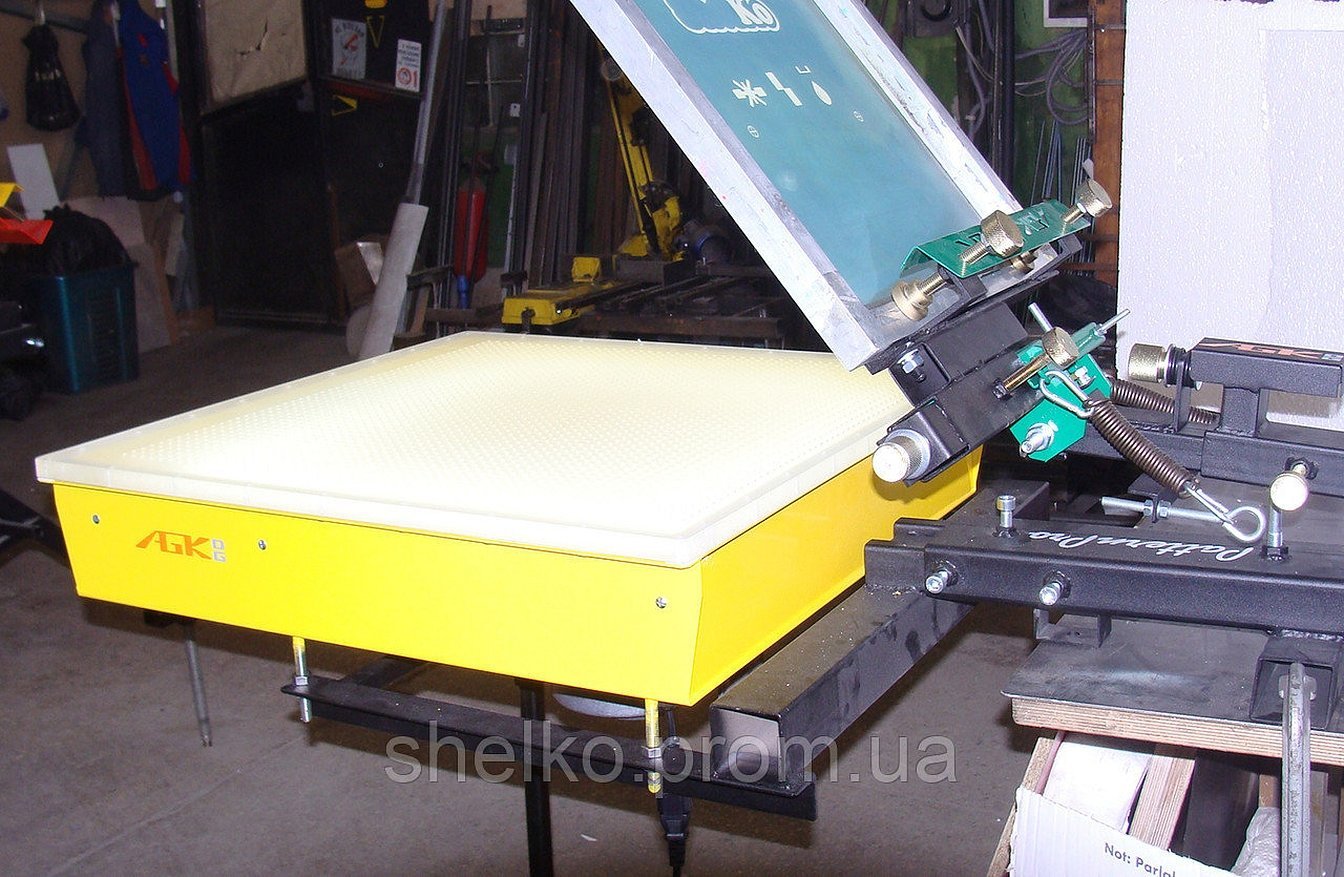

Screen printing machines

Screen printing is suitable if there is a simple image (1, 2 colors). There are interesting carousel models on the market that have the following features:

- wide table;

- different types of fabric are allowed;

- micro adjustment of bearings;

- additional handle for adjustment.

The units look bulky and require forms to operate. The printing unit rotates, so skilled personnel are needed for operation. The advantages include high precision of operation, the image looks contrasting and pleases with bright colors. If necessary, other materials can be used instead of fabric:

- paper;

- PVC film.

The most common are single-color options. As for printing standards, the following types are found:

- 40×50 cm;

- 50×70 cm;

- 41×56 cm.

Manual machines are worth mentioning separately. Printex is considered one of the leaders in the production of these units. The company supplies models of various formats. The technology of the units is similar to the "Americans", they are made with aluminum tables, and thermal rubber is used. Side clamps are used to fix the frames.

Interesting! If something needs to be adjusted, no special tool is used (everything is done manually).

Which printer to choose for fabric for home use

There are no conditions for placing a large machine at home. Therefore, textile printers of the sublimation type remain in demand. They are compact, as in the case of industrial units, desktop and floor models are sold. The difficulty is that the printing is initially carried out on sublimation paper, and then transferred to the fabric.

However, practice has shown that high quality printing can be achieved at home. Plus, you can work with different types of fabrics, natural and synthetic materials are allowed.

Since modern equipment with new technologies is produced, the quality of printing is constantly improving. Consumers are interested in choosing high-quality laser ceramic, as well as engraving machines. If there is no confidence in the quality of the selected material, it is recommended to look for universal models.