The Chaika sewing machine was manufactured by the Podolsk Mechanical Plant, and for many years it was a necessary attribute for most Soviet families. Today, the very popular domestic sewing machine is back with its fans in a high-tech and modern look.

Most residents of Russian cities have seen advertisements for the purchase of old models of "Chaika". However, only a few understand what their real value is, and therefore they are often sold for almost nothing. In reality, the design of the sewing machine "Chaika" does not store and never had in its design expensive metals and alloys.

- Why is there such a demand for Chaika sewing machines now?

- History of the car

- Existing models

- "Chaika-2"

- "Chaika-3"

- "Chaika-132M"

- "Chaika-134A"

- "Chaika-142M"

- Operating instructions for the sewing machine "Chaika"

- How to fill up a Chaika car

- Sewing technology with the Chaika machine

- The order of application of needles

- New models of sewing machines "Chaika"

- How to lubricate a Chaika sewing machine

Why is there such a demand for Chaika sewing machines now?

There is currently a lot of interest in the Chaika due to its high quality and robust construction. Considering that such devices are no longer manufactured, some tailoring professionals buy them for personal use at a good price. Repair shops make a living by buying non-working machines to later remove parts that are no longer manufactured.

An important reason for buying a "Chaika" is undoubtedly their ability to sew the most dense and thick textile products with high quality, which is beyond the capabilities of modern machines. In addition, "Chaika" is purchased as a vintage decoration of prestigious designer studios for the production of clothing items, stage attributes, museum exhibits or for decorating the interior of wealthy homes.

History of the car

In 1900, in Podolsk, Moscow Region, the Singer company built a factory for the production of tailoring machines and equipped it with the most modern equipment. At first, the mechanisms were assembled from foreign-made components. In 1902, the factory began producing its own units. By 1914, the production of units reached over 600 thousand units per year. The machines were in high demand and were sold not only in Russia, but also abroad.

As a result of the October Revolution, the Singer enterprise was nationalized and re-profiled. Machine production was re-established only in 1924 under the Gosshveymashina series.

At the very beginning of the 60s, the plant's designers completed the design and introduced the latest model into mass production. The Chaika sewing machine received the honorary name in honor of the ship on which the USSR cosmonaut Valentina Vladimirovna Tereshkova made her first flight. The peak of Chaika production fell in 1991 - 1,750,000 units. At the end of the 90s, the company stopped producing sewing machines. Nevertheless, even today, Chaikas successfully work in many families not only in Russia, but also in the CIS countries.

Existing models

The model line of "Chaika" is extremely diverse. Despite the fact that it was constantly being improved, but basically they, in essence, did not differ in any way. The basic range of functions did not change. Only the types of electric motors were diverse, from domestic to Japanese, the mechanical drive was made both manual and foot.

General technical data for all modifications of the "Chaika":

- Maximum stitch length is 4.0 mm.

- The maximum zigzag length is 5.5 mm.

- The permissible shift of a line to the right/left from the center is 2.5 mm.

- The maximum thickness of the stitched fabric is 4.5 mm.

- Sleeve extension – 170.0 mm.

- The number of revolutions of the main shaft is 1,000 rpm.

"Chaika-2"

The oldest brand, the release of early copies began in the 30s of the twentieth century. Despite the apparent primitiveness of the model, for a novice seamstress or housewife it was an excellent choice of a unit making simple seams. The validity and durability of its elements and units is confirmed by the era, since some families still have fully working "Chaika-2".

Important! The mechanism is provided with a dismountable central-bobbin shuttle unit, creating an oscillating motion of the shuttle, the movement of which is adjusted relative to the needle. The textile product can be fed in a straight or return direction. The machine is provided with a device for disabling the movement of textiles or a toothed rack during embroidery or darning. The seamstress's workplace on the machine is illuminated by a 15-watt lamp.

Technical specifications:

- Machine with foot-operated mechanism and polished wood cabinet.

- Brand: 115-1-3-0.

- Machine head brand: 115-1.

- The number of revolutions of the main shaft is 1200 rpm.

- The height of the presser foot lift is 7.0 mm.

"Chaika-3"

"Chaika-3" - sewing machine inherited most of the technical solutions of the previous modification. Undoubtedly, minor corrections of the appearance are noticeable. Measures to improve the ease of use were carried out - 2 effective regulators were installed, the weight of the unit was slightly reduced, somewhere by 300 grams by making some structural units from the lightest alloys. In addition to the functionality of the previous modification, it has 10 specialized operating feet, including for sewing on buttons and darning. The stitch length is adjustable.

This household machine 116-2 was produced in 2 configurations. The first with a cabinet, with a foot-type drive and a set of devices. The second configuration with an electric drive, a suitcase and a sewing kit with a light bulb, sewing needles, operating feet, bobbins and a threader.

Types of operations performed by the machine:

- Straight stitch with one or double needle.

- Zigzag stitch with one or double needle.

- Shift of straight and zigzag lines.

- Zigzag edge stitching with right/left shift.

- Butt-stitching of fabric.

- Hemming edges with open/closed cuts.

- Lap seams.

- Production of loops.

- Sewing on buttons, hooks, snaps.

- Applique, Richelieu and darning.

Technical data:

- The maximum thickness of the stitched fabric is 4.50 mm.

- The overall dimensions of the machine are 290 × 178 × 412 mm.

- Needles used: No. 70/90/100/110.

- Threads used: cotton No. 30, 40, 60, 80 and silk No. 65.

- The weight of the machine in the cover is 18.5 kg.

- The weight of the machine with foot drive is 42.5 kg.

"Chaika-132M"

The first electromechanical brand of the model range is "Chaika-132". Production began in the 60s. Almost all samples that can be purchased today were made between 1980 and 1992. This year actually became the year production stopped. The advantage of the configuration is the ability to stitch thick materials: fur fabrics, tapestry and drape materials. In order to free the hands of the seamstress, a foot drive is used in this version.

Combinations of needles and threads when sewing:

- Thin types of silk, cambric – needle No. 70, thread No. 80;

- chintz fabrics, satin, floss, linen textiles – needle No. 80, thread No. 65;

- heavy cotton fabrics, calico, flannel, wool, bed sheet fabric – needle No. 90, thread No. 60;

- woolen suit textiles - needle No. 100, thread No. 50;

- heavy coat textiles – needle No. 110, thread No. 30.

Technical data:

- Number of line options – 4.

- Number of tailoring operations – 23.

- Presser foot lift – up to 6.0 mm.

- The weight of the machine in the case is 13.5 kg.

"Chaika-134A"

The sewing machine "Chaika-134" does not differ from the previous modification in its functions, but it has an improved design. The manufacturer has done a great job of improving ergonomics, geometric design parameters, and the color design of the control handles and lever switches has been improved.

Technical data:

- Number of line types – 4.

- Number of tailoring operations – 23.

- The lifting height of the presser foot is 6.0 mm.

- Machine dimensions: 412 × 178 × 300 mm.

- Case size: 500 × 220 × 340 mm.

Machine delivery set:

- In a table with a foot drive.

- With electric drive on a stand in a case

- On a table with foot and electric drive.

- On a table with an electric drive.

- On a hand-operated table.

- On a stand with manual drive.

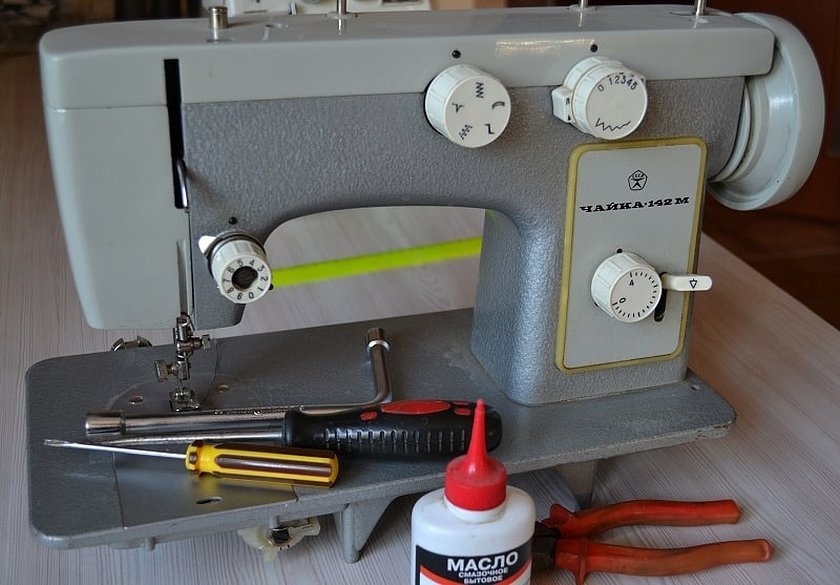

"Chaika-142M"

Without embellishment, today we can say that this is the best modification of the "Chaika" released. The most modernized tool, capable of performing a lot of technological operations. In this configuration there is a thread cutter, a thread tension mechanism, an engine.

It can easily function with sewing linen, silk, wool and cotton fabrics. For decorative seams, there are double needles, basic stitch styles are straight and zigzag.

Technical data of the 142nd model:

- Number of stitch options – 12.

- Number of operations – 23.

- The lifting height of the presser foot is 6.0 mm.

- Machine size: 290 × 178 × 412 mm.

- Case size 500 × 220 × 340 mm.

- The weight of the mechanism in the case is 16.0 kg.

Machine delivery set:

- On the table with foot drive No.: 142M-22, 142M-22-0, 142M-22-1.

- With electric drive on a stand in a case No.: 142M-33

- On the table with foot and electric drive No. No.: 142M-22-33, 142M-22-0-33, 142M-22-1-33.

Operating instructions for the sewing machine "Chaika"

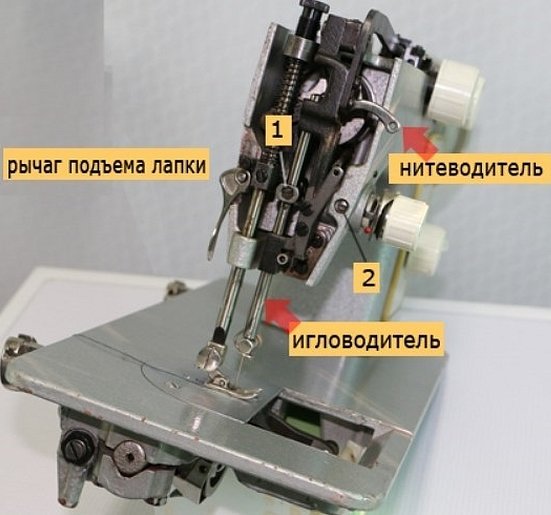

The structure of the "Chaika" of different modifications is practically the same, and therefore the execution of sewing operations and the maintenance procedure are similar for all. Some versions of the "Chaika" have a special device - a copier and a corresponding switching lever for the operation mode. The version of the shuttle module, the threading mechanism and the adjustment of the nodal elements of the units are practically unchanged, except for the setting of the shuttle operating mode.

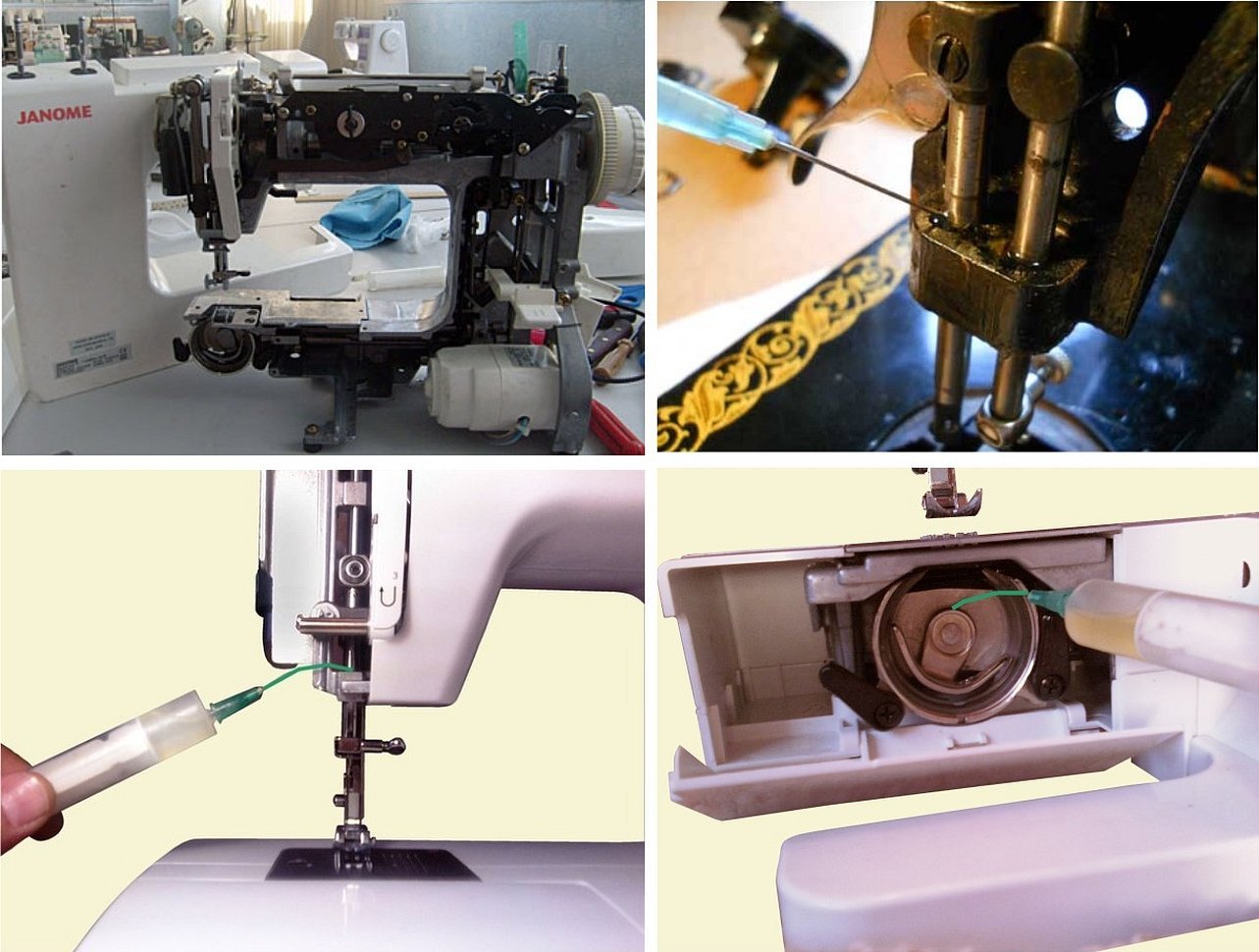

How to fill up a Chaika car

The algorithm for installing the upper thread is the same for most Chaika models, including No. 143:

- The reel rod is lifted out of the sleeve cover until it stops.

- Set the thread take-up lever upwards on the needle, adjusting it by turning the handwheel.

- Raise the presser foot.

- Place the threaded spool on the thread holder.

- First insert the thread into the plate thread guide.

- They launch it through the tensioner washers.

- Then into the upper eye of the tension spring thread.

- Down under the thread tension hook.

- Up through the gap of the thread take-up lever.

- Down into the wire thread guide.

- Then into the needle guide and thread it into the needle.

Algorithm for threading the lower thread:

- Before inserting the lower thread, you need to remove the bobbin case with the bobbin from the shuttle module, for which you need to turn the handwheel to set the needle to the highest position.

- Pull out the sliding plate, then pull the lever and pull out the bobbin case.

- Wind the threads onto the bobbin using a bobbin winder.

- When winding the thread onto the bobbin, the flywheel of the machine must spin idle.

- To do this, you need to release the friction screw.

- The bobbin is placed on the winder in such a way that the spindle spring fits into its groove.

- The coil is placed on the rod.

- The thread from the spool is passed between the tension washers and then a couple of turns are wound manually.

- The winder is pulled towards the flywheel.

- Then rewinding is carried out by turning the flywheel using a drive.

- At the end, the rubber ring of the winder will not contact the flywheel, and winding will be finished. Before removing the bobbin, the winder must be tilted to the left side from the stop.

- The bobbin is inserted into the cap and the thread is pulled out under the spring, leaving an unoccupied end of thread of 100–150 mm in length.

- Insert the bobbin case with thread into the shuttle module. At the same time, the needle is located at the highest level.

Please note! The bobbin cap with the bobbin is placed until it stops on the shuttle module rod. Along with this, the cap pin must sit in the socket completely.

Sewing technology with the Chaika machine

When the bobbin case is installed correctly, the latch should be in a spring-loaded state and when raised, it should try to return to its initial state. Before starting to sew, the lower thread should be placed on the needle plate. To do this, hold its end and turn the flywheel so that the needle goes down into the needle hole, grabs the lower thread from the shuttle and lifts it up. The upper thread pulls the shuttle thread onto the needle plate and places both threads under the presser foot.

The stitch length is set with the handle until the number with the indicator on the body is superimposed.

The opposite direction of fabric movement is achieved by pressing the lever down until it stops. The return feed pitch of more than 2.5 mm will remain unchanged.

The height of the rack is adjusted using a special adjusting device. It is used with the sliding plate released. For thick fabrics it is set to "H", for delicate fabrics - to "Sh", for embroidery and darning - to "V". To switch to zigzag, decorative stitches, you need to set the handle to the desired type of stitch by simply pressing and turning.

The order of application of needles

Thread breakage often occurs with the "Chaika" because the needle is incorrectly selected and installed or a bent needle tip breaks the thread. According to the manufacturer's instructions, only factory-made needles must be installed. In addition, it is necessary to correctly select the needle size based on the thickness of the material and threads.

It is not allowed to use needles with a spherical shank. Needles for the "Seagull" are distinguished by the cut on the shank. For the manufacture of clothes from different fabrics, use the appropriate type of needle, for example, for sewing leather goods it has a tetrahedral point, which will facilitate piercing the leather and contribute to the formation of a loop on the needle when it is captured by the shuttle.

Additional informationIf the thread breaks during the process, you can use a magnifying glass to inspect the position of the needle tip and replace it if necessary.

New models of sewing machines "Chaika"

In contrast to their predecessors, modern CHAYKA machines are high-tech machines that can satisfy the highest demands of both an amateur and an experienced craftsman. Representing a domestic brand, they are manufactured at the production facilities of the world's leading sewing machine companies. The latest model CHAYKA NEW WAVE 4030 deserves special attention - a computerized sewing machine with a horizontally located shuttle and extensive functionality in 100 sewing technological operations.

Craftsmen and amateurs of home sewing appreciate the advantages of this modification: integrated threader, a significant range of stitches, lower conveyor communicator. The width of the zigzag and the duration of the stitch are practically adjusted by buttons on the front panel.

Using the reverse key, it is possible to darn and perform fastening at the end of the line. The complete set of this configuration includes an impressive set of feet: for zippers, for hidden and satin stitches. On the CHAYKA NEW WAVE 877, you can conveniently apply all the jewelry achievements of sewing craftsmanship.

How to lubricate a Chaika sewing machine

Before setting up or repairing the Chaika machine, it is recommended to perform a preventive inspection, cleaning and lubrication of the rubbing units of the unit. For this purpose, disconnect the motor from the voltage, remove the two screws of the top cover. Disconnect the foot, remove the needle and needle plate, the cover of the shuttle module. Disconnect the machine from the support or table.

The shuttle module is disassembled. Then all dirt deposits are removed from the machine, especially in the module section, and absolutely all parts and units that are subject to friction are thoroughly lubricated with special oil. For the operation, a hard, not very large brush is used, and for lubricating the parts, it is very practical to use a general medical disposable syringe. To create easy movement of the mechanisms and prevent wear, all areas marked by the manufacturer in the instructions must be moistened with two drops of lubricating oil I-20/A.

Mandatory places for applying lubricating oil:

- The connecting rod mechanism of the machine.

- Zigzag mechanism.

- Shuttle module.

Today, the production process of the famous "Chaika" machines has been restored. Unlike their predecessors, CHAYKA are progressive technological mechanisms that can implement the highest requirements and needs, they bring benefit and joy to their owners both at home and in production. But the main thing that they inherited from their ancestors is reliability and longevity.