Safety precautions must be observed at any enterprise. This is manifested in passing safety briefings, observing certain norms and rules of conduct at a particular type of enterprise, as well as providing employees with individual and collective protection measures. One of the types of such protection is special clothing and footwear. It can minimize the impact of harmful production factors on a person and protect him from minor mechanical damage, hazardous chemicals, etc. This article will show a pattern for a work overall, men's camouflage, and tell you what nuances are inherent in sewing a uniform and sewing work clothes compared to everyday clothes.

Types of workwear

Work clothes can be classified according to various factors. One of the popular classifications is the division by types of threats, among which are:

- chemical;

- biological;

- radioactive;

- electrical;

- mechanical;

- physical.

The same clothing can provide protection against several types of threats affecting a person. For example, a regular respiratory mask can protect the respiratory tract and lungs from both toxic gases and large and small dust particles.

By type, special clothing can be divided according to the body parts it protects. Among them:

· Respiratory protection. Respirator masks are used for these purposes. They are divided into two types: isolating and filtering. The latter only filter the air and filter out dust and harmful substances, while the latter completely allow the worker to breathe clean air;

- Skin protection. Skin is also affected by chemicals and other factors, including high temperatures, biologically active substances, and mechanical damage. To protect the skin, various types of clothing are used, the properties of which directly depend on the factors to which the worker is exposed. These include: overalls, robes, aprons, gloves, and boots.

- Eye protection. Eyes suffer at work as often as the respiratory system. This is most often manifested by dust, harmful substances or microbes getting into them. Protective elements are: glasses, masks that cover the face completely and special shields.

- Hearing protection. In noisy workplaces, the ears are the first to suffer. This is quite dangerous, since no one will pay attention to it, but over time, hearing begins to deteriorate. To prevent this, earplugs and headphones are used.

Purpose of special clothing

Most workwear is multi-purpose clothing. This means that it can be used in a wide variety of working conditions and protect against a wide variety of harmful factors.

The features that distinguish a uniform from other types of clothing are:

- convenience, allowing you to perform various movements without the fabric interfering with your work;

- functionality, which determines a wide range of applications and the presence of special functions;

- practicality. Work clothes are made of material that washes well, does not get dirty easily and does not require any special care.

Areas of application of special clothing are:

- construction;

- auto repair shops and assembly work;

- light and heavy industry;

- work with welding and electricity;

- farming;

- chemical and biological industry.

Uniform Requirements

The first work clothes were invented for builders in America. They were made of thick and durable denim or jeans. At the seams, such fabric was fastened with decorative threads of contrasting colors.

Interesting! It was from that time that denim fabric became so popular not only among workers, but also among ordinary people.

Features of the cut

Traditional workwear comes in several variations:

- A jumpsuit is a one-piece suit with a straight silhouette. It consists of trousers that are sewn with a jacket. It has no relief details or darts. The jumpsuit fits the waist due to an inserted drawstring.

- Semi-overalls - similar to the simple type, but do not contain a jacket. These are pants to the chest or navel with suspenders and additional fabric.

Materials

As already mentioned, the material for such uniforms should be selected based on the type of production and work, specific factors. The most popular materials are:

- Spunbond is a non-woven fabric on a polymer base. Its advantages include increased strength and poor conductivity of electric current. Spunbond is often used in the light and food industries, as well as in laboratories.

- Twill is a fairly wear-resistant material with diagonal weaving of threads. The fabric allows the worker to be comfortable and provides good heat exchange with the environment.

- Cotton-based blended fabric - has all the advantages of twill.

For some specific types of work, materials with light-reflecting, air-permeable, heat-protective, and fire-resistant characteristics are used.

Additional elements

The functionality of workwear is based on the use of additional elements. These include patch pockets, various sections and flaps.

Important! Spunbond models are made without any additional elements or pockets. It is distinguished by its uniformity and smoothness.

Various fasteners are also often added, which can be made from buttons, zippers or snaps. The fasteners themselves are made at the front or side. Sleeves are often equipped with cuffs, and knees and elbows are protected with additional pads.

Instructions for measuring and cutting with your own hands

If the company does not have the ability to provide workers with ready-made sets of clothing, then it is possible to sew overalls independently.

To cut for an average worker of average build you will need:

- material 3 by 1.5 m;

- zipper length 75 cm;

- zippers 16, 19, 28 cm, one piece each;

- two zippers of cm for pockets;

- Velcro tape 40 x 2 cm;

- two buttons;

- rubber band 80 by 4 cm.

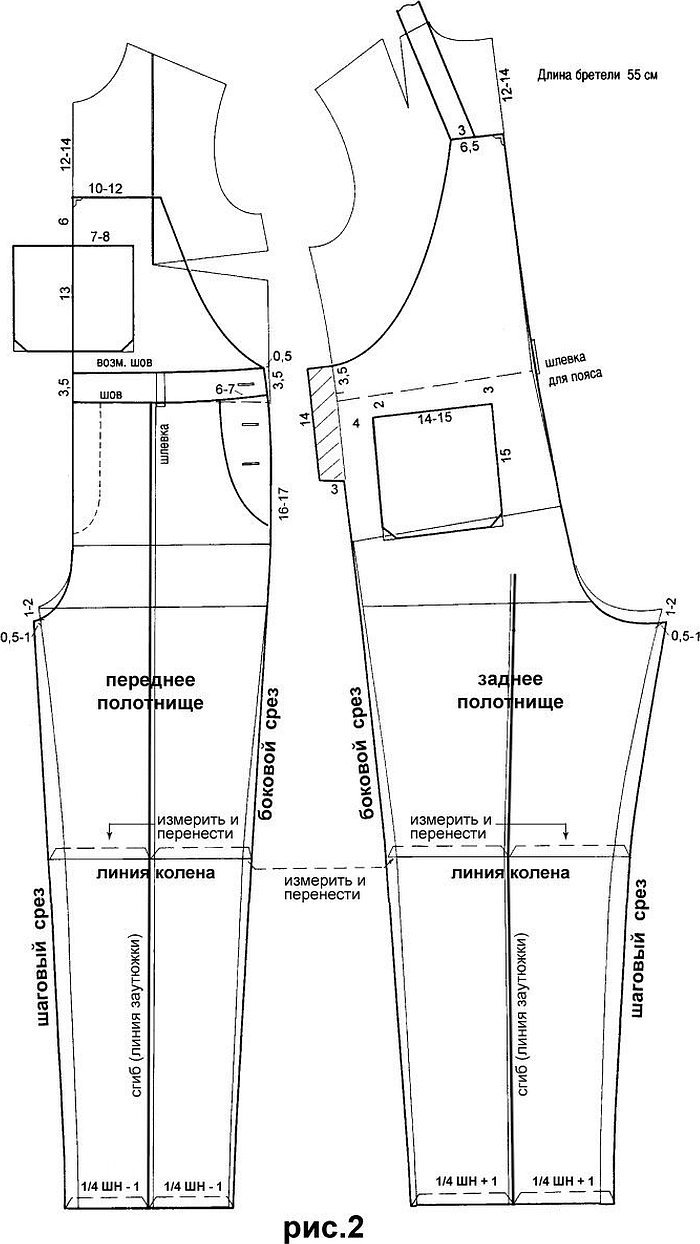

Pattern of men's work overalls

To sew men's work overalls, you can use a ready-made pattern. To do this, you will need to take measurements and transfer them to the pattern:

- height;

- The chest circumference can be determined by passing a tape measure through the middle of the shoulder blades, armpits and the most prominent points of the chest;

- Waist circumference is measured at the narrowest point;

- The hip circumference is measured at the most prominent points of the hips and buttocks. The measuring tape should be parallel to the floor.

After constructing the pattern, it must be transferred to the fabric and the parts cut out of the material. The finished parts of the future clothes must be assembled according to the instructions below:

- make and process pockets with zippers;

- iron the pocket allowances and secure the folds;

- sew the yoke to the back base using double stitching;

- connect the shelf to the back with the same stitch;

- connect the sleeve parts and process them;

- attach elbow reinforcements to the sleeves;

- sew the cuffs on with adhesive tape;

- connect the cuffs to the sleeves;

- sew the sleeves into the armhole;

- attach the collar to the neckline;

- sew the sleeves to the base;

- sew the belt loops to the base and sew them on;

- attach knee pads and sew the back of the trousers;

- connect the seams on the sides of the trousers;

- sew on all pockets;

- connect the jumpsuit together and insert an elastic band to secure it at the waist.

How to tailor work overalls

After long use, clothes wear out and the question arises: how to take in work overalls. Work clothes can be taken in almost all cases. This is not such a complex type of clothing as a coat or jacket, so anyone can handle it. The easiest way to reduce the size of overalls is washing and drying. After these actions, the clothes will become one or several sizes smaller, but over time they will stretch.

In order to take in the clothes, it will be necessary to steam all the seams and darn them. First, you need to measure the size by which you ultimately need to take in the uniform. You should leave allowances for the seams. After all the work, the product is sewn again. Some elements, such as trousers or sleeves, can be shortened in a matter of minutes.

Care instructions

Below are some rules for caring for this type of clothing:

- Work clothes are bought or made for specific types of work, therefore, it is precisely these types of work that need to be performed in them. If this is not observed, then they will lose not only their appearance, but also their protective properties.

- Any fabric requires care, so you need to treat it carefully not only during use, but also during washing and storage.

- All instructions for ironing, steaming, drying and washing work clothes must be followed. Otherwise, even the most unpretentious material can be damaged. Always read the labels on the clothes you buy and follow the care instructions.

Workwear for workers is an important element that no manufacturing company can do without. It is very important that the clothes are selected in accordance with specific types of work and meet all safety measures, because during production work, the company's management is directly responsible for the health of the personnel. If the company does not have the opportunity to purchase ready-made uniforms, then it is possible to order tailoring of workwear from a seamstress.