Fabric products with bright patterns have always been in great demand. Sublimation printing is now a very common service that allows you to make a product eye-catching and attractive. Stylish, bright and durable patterns on products appear thanks to special equipment.

The concept of sublimation

The process of applying a photographic image using special equipment under the influence of high temperatures is called sublimation. As a result, the image becomes an integral part of the product at the molecular level, the image is bright, rich and resistant to external influences. Sublimation can most often be found on souvenir products.

Please note! To achieve maximum results and color rendering, it is best to choose white fabric.

The essence of the process and technology

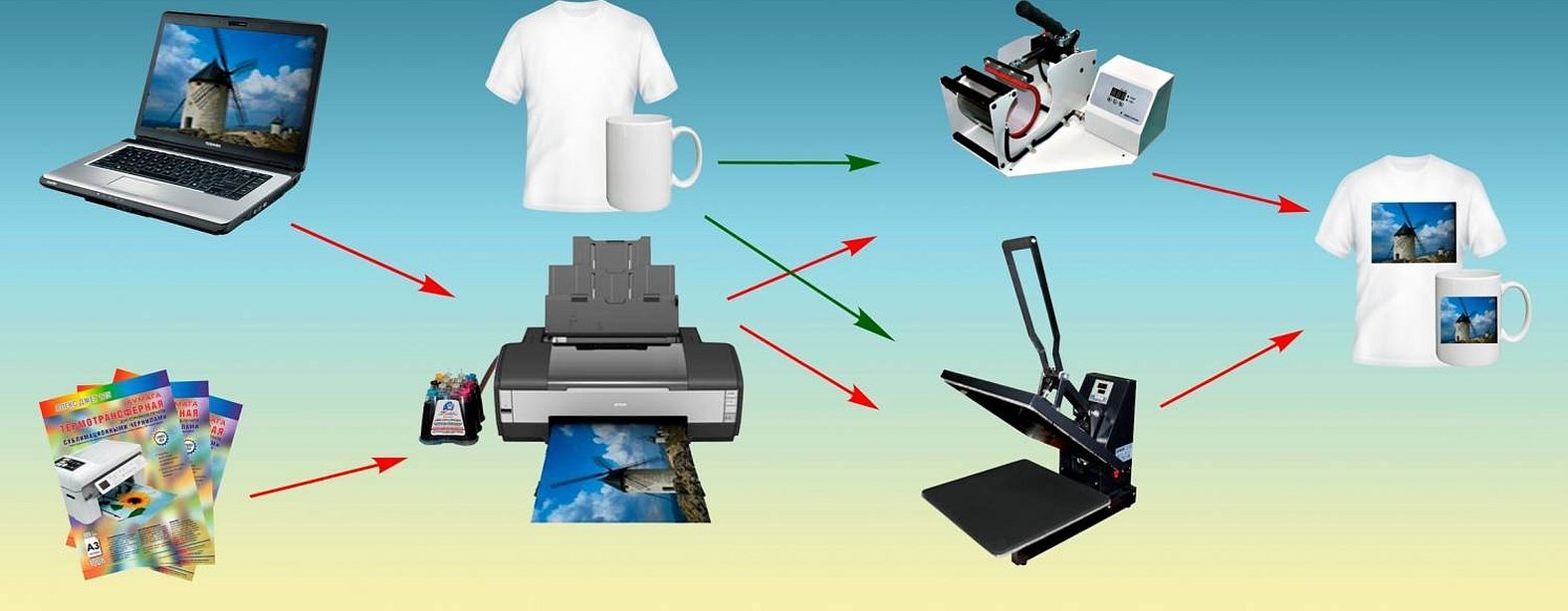

The essence of the sublimation printing process or sublimation is that the paint, which is previously applied to the paper, evaporates as a result of exposure to high temperatures and, without damaging the structure of the fabric, penetrates the product. As a result of this process, the colorful image is transferred to the finished product.

The sublimation process takes place in several stages. First, the image is printed in mirror image on special paper that does not absorb ink. Then the image is transferred from the paper to the canvas. The paper and material are applied face to face and placed in a special press with specific barometric and temperature conditions. As a result of the impact, the paint passes into a gaseous state and is impregnated into the material.

After the process is complete, the finished product is removed from the press. It is important that the paper is removed from the workpiece immediately after removal. Otherwise, the drawing may become blurred and unclear.

What surfaces is it suitable for?

Not suitable for all materials. Preference is most often given to fabrics with knitted and textile weave, which contain at least 50% polyester.

Textile weaving

The most common types of fabrics with textile weave for sublimation are the following:

- Satin is a fabric with a smooth glossy surface. The material is wear-resistant and is perfect for sublimation.

- Blackout - consists of three layers, the two outer ones are suitable for sublimation. The material is used for sewing blackout curtains.

- Backlight - used for the production of lampshades, outdoor advertising and interior design. On it, sublimation looks bright and does not lose clarity for a long time.

- Gabardine - the material is used for sewing bags, tableware, outerwear and workwear. The sublimation pattern remains on it for a long time.

- Satin is a fabric with a glossy surface made of cotton or synthetic thread. It is used for sewing bed linen and flags.

Also, chiffon, craft chiffon, charmus, taffeta, oxford, deshine and others can be used for sublimation printing on fabric.

Fabrics with knitted weave

It is possible to sublimate fabric if it has a knitted weave. In this case, it is best to give preference to the following options:

- Biflex is an elastic fabric with a silky structure. It does not deform or fade, and is used for sewing swimsuits and stage costumes.

- Prime is a synthetic fabric with two face sides. It is used to make underwear, T-shirts and tracksuits, on which logos and company images are applied using sublimation.

- Ribane is an elastic fabric used for sublimation when sewing turtlenecks.

- Sandwich - children's clothing, T-shirts, tank tops and dresses are made from it.

Also, materials with knitted weave for sublimation printing include hockey net, fleece, footer and felt. When choosing an option for sublimation, experts recommend giving preference to light shades, since when transferring an image to a dark material, it is significantly distorted.

What is the difference between sublimation printing and other printing

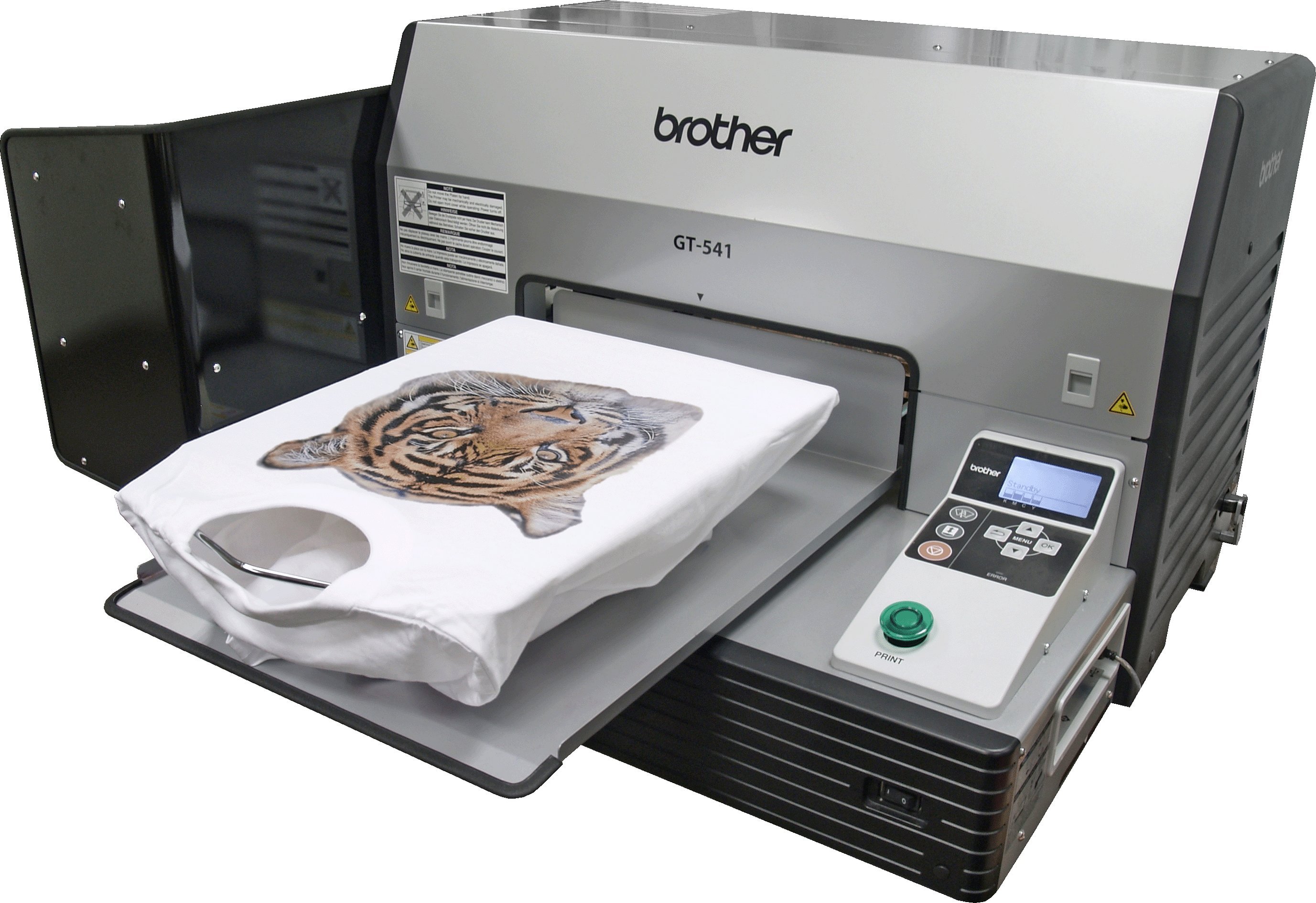

Direct, screen, thermal transfer and sublimation printing are used in the process of applying a pattern to a base. All varieties have their own characteristics. Screen printing involves pushing paint through a stencil. Thermal transfer printing is distinguished by the fact that the image is transferred to the product using a paper or film carrier. The peculiarity of direct printing is that the process occurs using a printer and polymerized paints, which are applied directly to the product.

Please note! Sublimation printing on fabric is considered to be technologically simpler and provides good results on synthetic fabrics.

Also, for example, screen printing cannot boast of accurate color rendering compared to sublimation.

Cost of sublimation printing on fabric

Today you can often find products with sublimation, printing on fabric has become very popular. In addition to the finished product, many companies offer services for applying a pattern to canvas. In this case, you can get a product with absolutely any pattern, the required brightness. The only condition for execution is that the sublimation fabric must be composite or synthetic.

The cost of applying an image to fabric using the sublimation method varies depending on the print run and material. When ordering up to 15 square meters, the cost is on average about 500 rubles per meter*. If the footage is large, the price will be lower.

Advantages and disadvantages

The sublimation method on fabric has many undeniable advantages. The main advantages include:

- affordable cost;

- resistance of the pattern to deformation even with frequent washing;

- resistance to sunlight;

- precision in rendering the finest lines;

- creation of multi-color prints;

- the ability to transfer any design, even a photograph, onto fabric;

- environmental friendliness;

- color saturation.

Despite the fact that sublimation has many advantages and is in great demand, it also has some disadvantages. These include:

- During the technological process, the specified climatic conditions must be observed;

- high image quality can only be achieved when printing on a light fabric base;

- Printing is only possible on fabrics that contain at least 50% synthetic fibers.

Having a clear idea of sublimation, what it is on fabric and how to achieve the maximum result, you can achieve high quality. This method of applying a pattern is preferable when the fabric composition is more than 50% synthetic.

Sublimation on fabric makes it possible to implement almost any idea, both for decoration and for advertising. This method is especially popular for the production of flags that flutter in the wind. After all, in this case, it is important that the pattern is transparent. This result can be achieved using sublimation. The most important thing is that all the conditions for applying the pattern in this way are met. In this case, the product will definitely become unique and attractive, and the pattern will last for a long time.

*Prices are valid as of July 2019