The needle is one of the most important parts of a sewing machine. The quality of the stitch depends on how correctly it is selected and installed. It is important to consider the existence of different types of needles designed to solve specific problems. Knowing how to insert a needle into a sewing machine and the ability to do this will allow you to get even and flawless stitches.

How does a needle work?

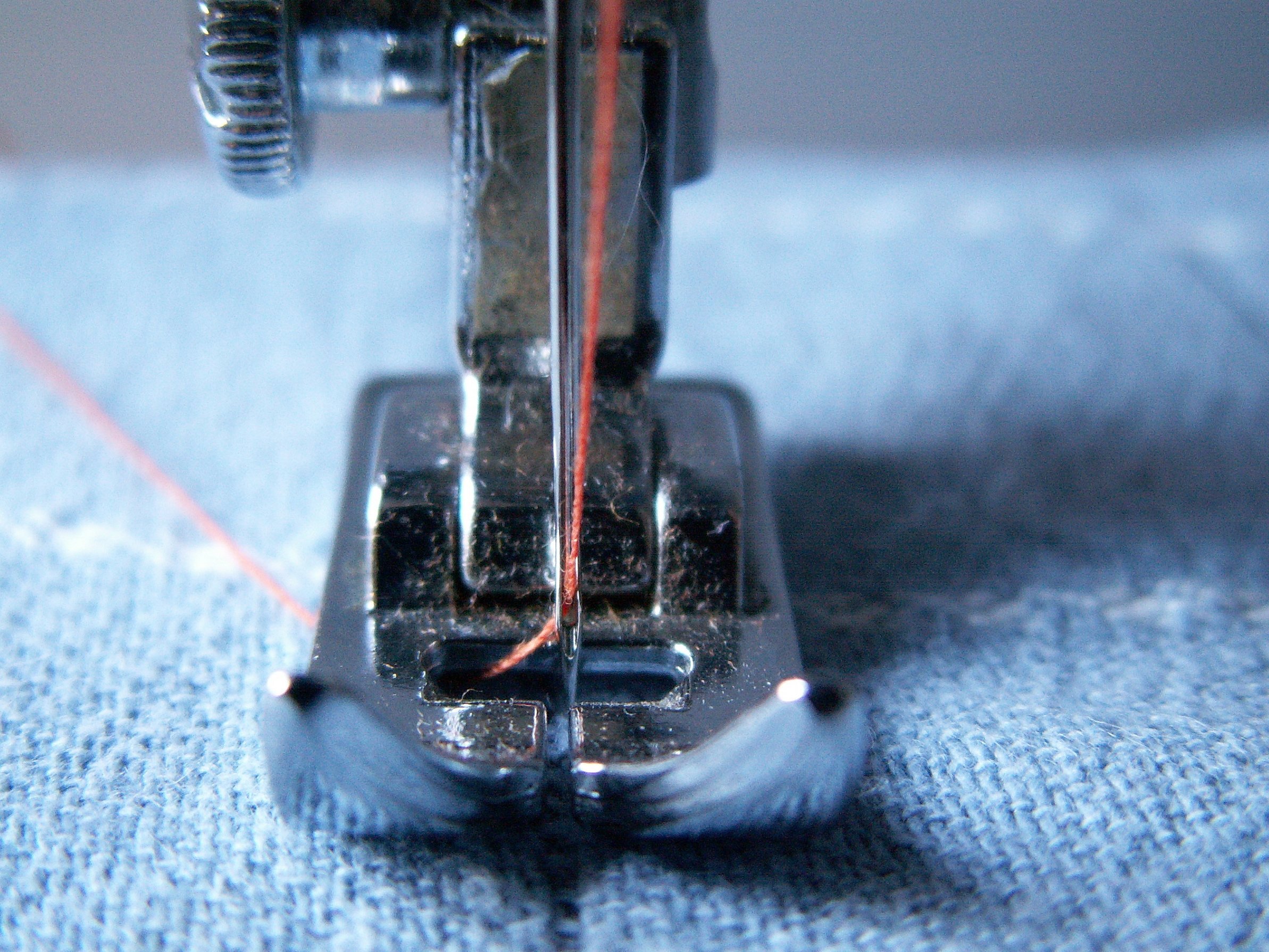

At the beginning of the movement, the needle with the threaded thread moves downwards. When it reaches the fabric, it pierces it. In the extreme position at the bottom, the needle presses the thread, which passes through both grooves - long and short.

When the return movement occurs, the part that is in the large groove does not experience friction and remains relatively free. Where the thread passes through the short groove, it is under pressure between the fabric and the needle. As a result, due to friction, it slows down. Due to this, a loop is formed, which is picked up by the shuttle. Thus, a stitch is formed.

Types of needles for household sewing machines

There are different types of needles intended for use on sewing machines.

Here is a description of the most common options:

- The most common is the universal variety. It is suitable for working with most types of fabric and can be used to perform many types of stitches.

- For taffeta or silk, microtex type needles are used.

- If the fabric is thick (for example, jeans or burlap), then you need to use stronger needles with a special coating to work with it.

- When working with knitwear, varieties with a rounded tip are used.

- When stitching leather, needles are used whose tip resembles a blade.

- When working solo, one that has blades can be used.

Some models use twin needles. Embroidery needles are used for finishing garments.

How to choose the right needle

The correct choice of this part for replacement will ensure high-quality operation of the machine. To do this, you need to know what fabric you need to find it for.

Important! For delicate fabrics, thinner needles are needed. When working, the punctures will be thin and unnoticeable. If you plan to work with leather, fur or other dense material, it is important that the needle is sharp and easily cuts through the fabric.

When choosing what to replace, you need to take into account the shape of the tip, the type of thread used and the length of the needle.

Different manufacturers mark their needles with Latin letters followed by two or three numbers.

The following are examples of the notations used:

- "H" means that this needle is universal. It has a rounded tip. With such a needle you can work with almost all fabrics, except for the coarsest and densest ones.

- "HJ" means that it has a sharp edge. This type is suitable for working with thick fabrics: twill, denim, canvas or leather.

- The "HM" marking is placed on microtex needles. The tip is very thin and sharp. This option is used if you need to change the needle for working with various thin, delicate and capricious fabrics: taffeta, lace, silk or satin.

There are also many other types of sewing needles. Before changing yours, you need to determine which type is best for you.

Purpose and types of feet for sewing machines

The presence of a foot in a sewing machine helps to make the seamstress's work more qualitative and comfortable. This unit will be useful if the stitch is made along the edge of the fabric.

The work uses different types of feet:

- The walking motion is designed to ensure the advancement of the fabric without the risk of shifting the layers relative to each other.

- The knitwear foot takes into account its elasticity and stretchability. It allows skipping stitches and thread breakage when working with this material.

- Overlock allows you to work with the edges of the fabric without allowing them to fray or tighten.

- Attaching a foot designed for creating blind stitches will allow you to create such seams.

- There are devices that are designed to sew on zippers.

- A foot made of Teflon should be used if you need to work with rubber, leather and other heavy materials.

- The snail-type device allows you to create a narrow hem along the edge of the fabric.

- There are feet whose purpose is to sew on buttons, fasteners or hooks.

- There are special devices that are installed for darning and embroidery.

- The zigzag foot allows you to make not only straight stitches, but also zigzag stitches.

- There are some that, when installed, allow you to trim the edge with bias tape.

This list does not exhaust all the varieties available.

Machine needle device

It looks like a metal rod, the shape of which resembles a cylinder. The needle is usually made of stainless steel with a titanium or nickel coating. It is made in such a way that it does not bend or break.

The top part is called the shank. This is the thickest part of the needle. Along the middle and bottom there is a long groove. The thread in it does not experience friction when the needle pierces the fabric. At the bottom there is the point, and just above it is the eye of the needle. On the opposite side from the long groove there is a short groove. The thread passing along it sags when the needle rises, the shuttle picks up the loop and forms a stitch. When the needle is in the last stage of lifting, it tightens the stitch. After this, the fabric moves and the process described here is repeated again.

Installing a double needle

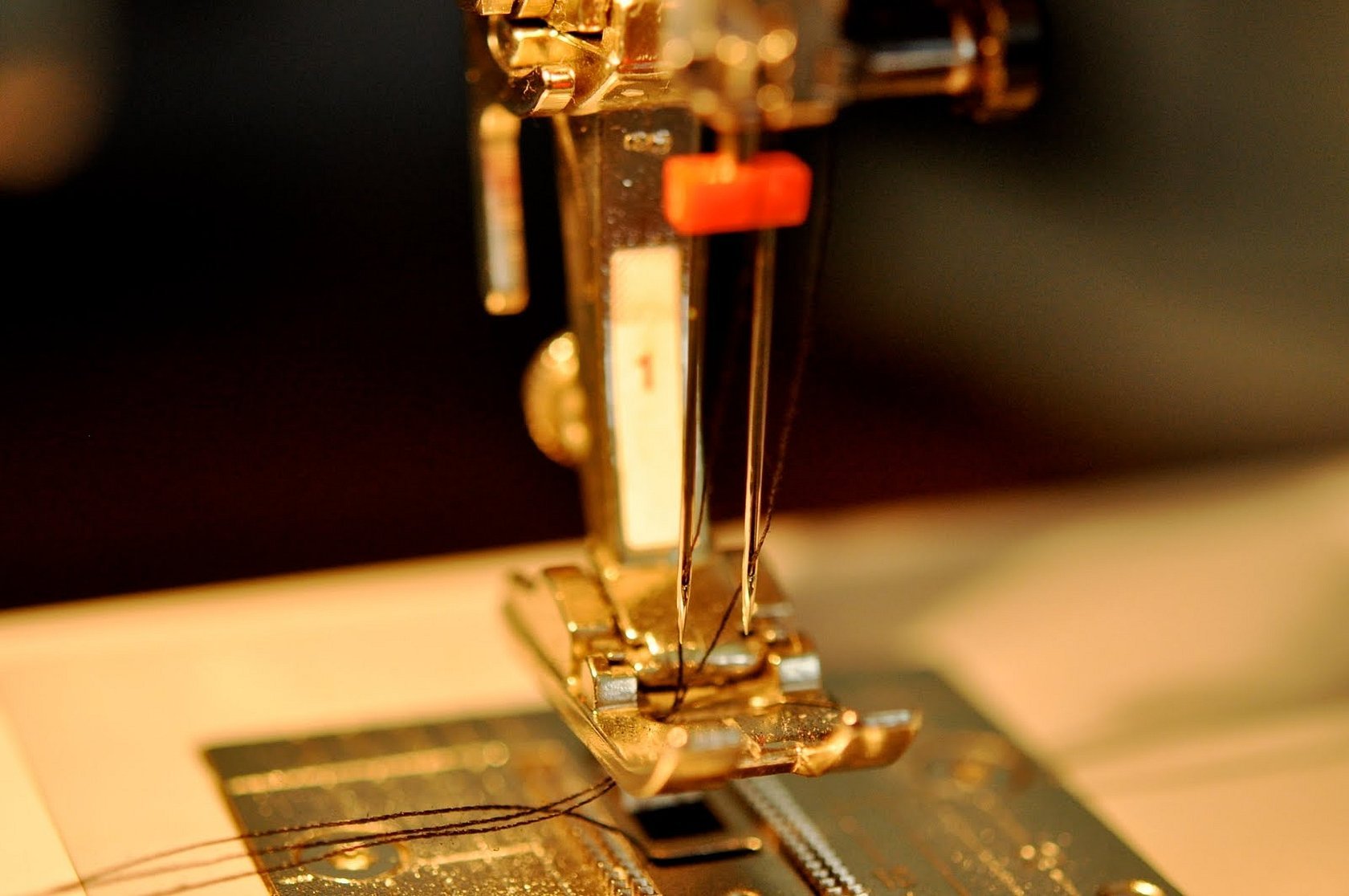

Not all models are suitable for this type of needle. With a twin needle, you can sew two parallel lines with different threads.

In order to install a twin needle, it is not necessary for the sewing machine to have a second needle holder.

Below is a description of how to properly insert a needle into a sewing machine:

- You need to unscrew the mounting screw and remove the holder.

- When inserting the twin needle, turn the flat side away from you and place it in the holder.

- Using a screwdriver, turn the screw until it stops and fix the needle.

When threading, it is necessary to take into account that in this case there are some peculiarities. To do everything correctly, you need to do the following. The lower thread is threaded into the shuttle in the same way as for the universal needle, but now its tension should be slightly weakened.

The upper threads must be taken together and threaded into the thread guides in this way. However, before manual threading into the needles, they are separated and inserted into them separately.

Checking the quality of installation

You need to be careful about how to insert the needle into the sewing machine correctly. You need to be sure that it is done correctly.

Important! To check, you need to try what stitches you get. If they are even and have the same size, then the needle is installed correctly, otherwise it is necessary to make adjustments. To do this, you need to do the following:

- The machine must be disconnected from the mains.

- Use a screwdriver to loosen the holder screw.

- Carefully align the needle.

- If the thread breaks during the stitching process, it must be turned around its axis.

After the adjustment, you need to check again what stitches are produced. If they are even, this means that the needle is now installed correctly and does not need to be replaced.

Consequences of incorrect needle placement

For the sewing machine to work properly, it is necessary to replace the needle accurately and carefully. For example, the gap with the shuttle provided by the manufacturer in the Singer machine is 0.05 mm.

If a needle with an unsuitable shank is used, it will be skewed and the needle will not enter the hole of the needle holder, but will hit it. This will not only ruin the sewing, but can also lead to tearing of the fabric.

It is possible that an incorrectly installed needle will pass through the hole and hit the shuttle as it moves.

As a result, not only the needle plate may be damaged, but also the needle or shuttle may break and they will have to be replaced.

In order for the seams to be of high quality, it is important to carefully select and install the needle. After that, it is necessary to check how correctly this was done.