Nowadays, more and more people want to start their own business. This article talks about what fabric production is and what is needed for it.

- What are fabrics made of?

- Production of synthetic padding

- Flax crafts

- Jute production

- Manufacturing of woolen fabrics

- How interlining is made

- How Fleece is Made

- Felt production

- How to make biflex

- How to weave melange

- Cotton, manufacturing methods

- Production of jeans

- Basics of Fabric Production

- Spinning

- Synthetic yarn

- Weaving

- Threads and weaves

- Fabric finishing

- Equipment

- Loom

- Jacquard machine

- Sizing machine

- Rolling machine

- Dyeing line and printing machines

- Washing and measuring machine

- Scraping, cleaning and shaking machines

- Carding and spinning machine

- How to Start a Fabric Manufacturing Business

- Explore the future sales market

- Get funding

- Find a place for production

- Purchase raw materials and equipment for fabric production

- Hire working staff

- Organize advertising for your business

- Look for large buyers of products

- Pros and cons of organizing fabric production

What are fabrics made of?

They are made from natural or synthetic fibers. Below is a description of what fabric is made from.

Production of synthetic padding

Mainly used as a filler, sintepon is made from several layers of synthetic threads.

Flax crafts

Flax flowers are used in the production of linen fabrics. The material is smooth and shiny. Satin and viscose also belong to the subspecies.

Jute production

To understand what this fabric is made of, you need to visit China. That is where the tree from which jute is made is located. It is also very often made from bamboo. A subspecies of burlap is made from it.

Manufacturing of woolen fabrics

The production of felted wool fabric begins with the collection of fur from sheep. It can be either pure or with the addition of silk and other things.

How interlining is made

The production of interlining can be based on glued and non-glued, modified cellulose threads with possible mixing with polyester fibers. The production of PVC fabric is necessary for tents, sails, etc.

How Fleece is Made

What is fleece fabric for clothing made of? It is made of polyester. With the help of professional devices, small loops are created for combing and a large number of breathable pores.

Felt production

This is a double-sided material, made from fine wool. Felt is made by mixing down or synthetics.

How to make biflex

It is made with the addition of lycra, nylon, and microfiber.

Attention! A distinctive feature is softness, the ability to beautifully fit the figure without restricting the gait.

How to weave melange

It is made from ordinary synthetic threads of various shades.

Cotton, manufacturing methods

Cotton is produced from a plant called cotton plant. Threads of different lengths are extracted from its fruits. The production of cotton fabrics is a specialty of India and Belarus. The subspecies include flannel and calico (used to make sweatshirts, T-shirts, and underwear).

Production of jeans

To create it, yarn with long fibers that are very similar to each other is used. They are intertwined, which is how denim threads are obtained.

Basics of Fabric Production

To understand what clothing fabrics are made of, you need to know how to process them using different methods. Fabric production takes place in several stages.

Spinning

The fibers arrive at the production facility in stacks. Then they are unwound and scoured on machines, while simultaneously being cleaned of stones and debris. Rolls are made on a machine.

Attention! Then the roll goes through a carding machine, which has metal needles in it. After carding, we get a tape, which must be aligned on the machine.

Synthetic yarn

A more complex technological system is used for synthetics. A liquid and viscous spinning solution is obtained from the initial materials. It enters the machine, which is needed for processing synthetic threads.

The fibers are produced using special metal nozzles. The mass enters the machine using pumps.

Weaving

The actual process of making materials from yarn is called weaving. The loom for making is operated by weavers. They can use hundreds of looms at once.

Threads and weaves

They produce transverse and grain threads, which are woven differently. Grain threads are woven along the product because they are thinner and stronger. Transverse threads are denser, shorter, and have the ability to stretch.

Fabric finishing

At the end of the work, the product needs to be finished. This helps to improve the quality and properties of the material, gives it a marketable appearance and density. During the production of fabric, during the finishing process, the raw fabric can become smooth and printed.

Types of finishes:

- napping;

- bleaching;

- mercerization;

- scorching;

- boiling.

Equipment

All manipulations must be performed on special devices, which are presented below. The work depends on what the fabric is made of.

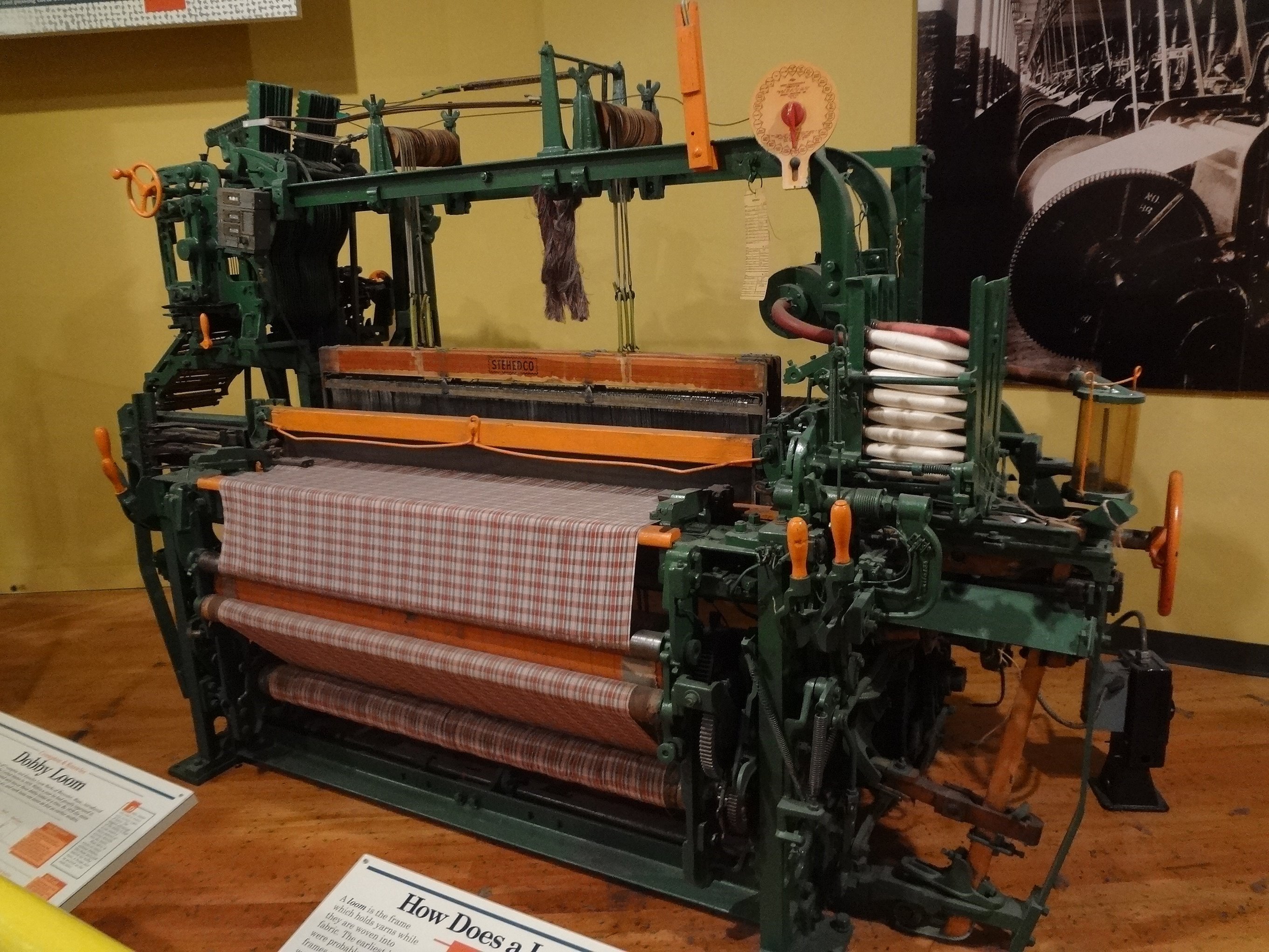

Loom

Almost all the fabric manufacturers known today work by placing a cross thread on the main thread. This is called weaving. This work took place hundreds of years ago. The first machines were wooden and had one function. Today, there are a variety of machines with many operations on the market.

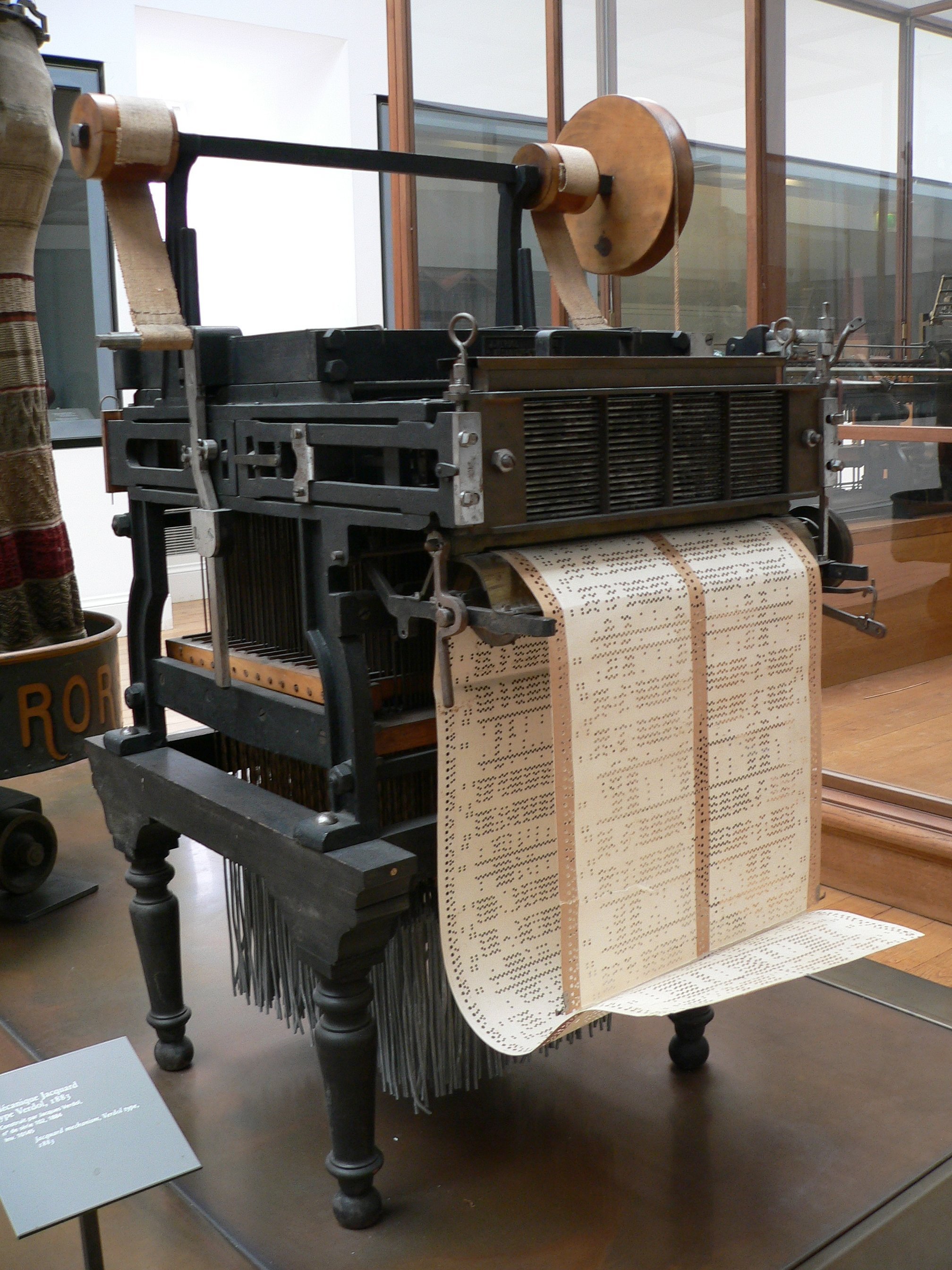

Jacquard machine

It has a loom mechanism and is designed to produce materials with large patterns and ornaments. The loom allows different threads to be moved separately across the plastic surface.

Sizing machine

The work of sizing consists of coating the warp threads and applying glue to the fibers. Sizing will be the most important stage in preparing the warp threads for work. Any mistake can greatly increase the breakage of threads on the machine.

Rolling machine

This device rolls the products into a roll. Rolling occurs when the material is stretched, which causes the webs to stretch. If the stretch is not even, the webs do not match in length.

Dyeing line and printing machines

This device is used to dye canvases.

Washing and measuring machine

This machine is designed to wash and dry the product in the factory. This will be the final stage in the production of the canvas.

Scraping, cleaning and shaking machines

Designed to process flax to obtain shorter pile. These machines loosen short threads.

Carding and spinning machine

The carding machine makes threads from flax, and the spinning machine helps to obtain yarn with the required strength. The spinning machine can be spindle or spindleless.

How to Start a Fabric Manufacturing Business

To get started, you need to draw up a short business plan and calculate approximate expenses and income from the work.

Explore the future sales market

Business experts emphasize that textile production is quite a profitable business. People are interested in both cheap products and more expensive and high-quality ones.

Get funding

Start-up capital is needed in any business.

Options for obtaining:

- Take out a business loan;

- Find investors willing to invest in the project;

- Starting a business with a partner;

- State credit.

Find a place for production

The main factor that influences good business development is location. It should be a well-trafficked place.

Purchase raw materials and equipment for fabric production

The most expensive thing you will have to spend money on is equipment. Sewing machines and lathes are very expensive, and for business you only need high-quality tools.

Hire working staff

To begin with, you can try to work independently, but if the business starts to gain success, then it is necessary to hire responsible workers.

Organize advertising for your business

For a good start, you need advertising. It can be in the form of leaflets, advertising in cinemas and buses.

Look for large buyers of products

To promote your business faster, you need to look for wholesale buyers. This guarantees success in 95%.

Pros and cons of organizing fabric production

Attention! The main disadvantage of the garment industry is the high dependence on materials (up to 55%) and tools.

There is almost no textile industry in our country. But at the same time, there will be a workload for the whole year, and not just for the season.

Due to the rising dollar rate, the number of customers interested in domestic products is increasing. This will be a good time to expand production.

The good thing about own production is that the entrepreneur is his own boss and can control everything.

Opening your own fabric manufacturing business will be difficult for someone who is just starting an entrepreneurial career. You need to know what fabric is made of, what tools are needed for this, etc. But if you avoid all the pitfalls, then success is guaranteed in Russia, since there are few such types of activities at the moment.