Grosgrain tape - what is it? Probably, many people in sewing and handicraft stores have often come across this material and asked themselves this question. How does it differ from ordinary tape or braid? The answers to the above questions are well known to those who are seriously engaged in handicrafts.

Grosgrain tape is a narrow strip of fabric with characteristic ribs along its entire length. Both sides of the fabric are identical. Unlike other ribbons, it can perform not only decorative functions, but also more important tasks. The technology of manufacturing grosgrain tape is also of interest, but - everything in order.

How is rep tape produced?

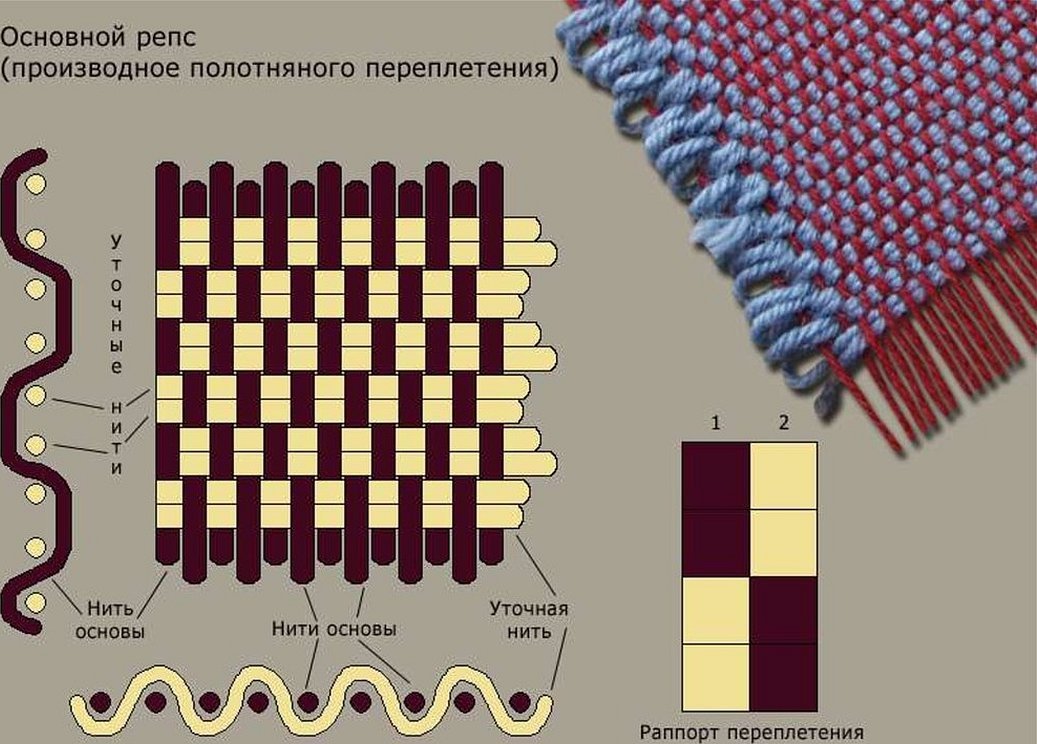

Rep tapes are made on a loom in textile factories using a method of interlacing threads that is a derivative of plain weave. In it, the fabric is constructed from two threads (warp) and weft.

The peculiarity of rep weaving is the lengthening of single overlaps of two, three or more threads in the weft direction. In other words, in the warp of rep, the thread passes not through one, but through two or three wefts. Due to this method, a relief rib is achieved.

The strength and pattern of the material depend on the angle of crossing. If the warp threads in the tape are made significantly thicker than the weft threads, it is called false rep. Due to this, a greater relief of the tape surface is achieved.

Fabric composition

Initially, rep ribbons were made exclusively from twisted silk fiber. It was a very expensive material, which only nobles and aristocrats could afford. Now rep ribbons, which contain only silk, can be found in large textile stores.

To reduce cost and increase durability, cotton, silk and wool fibers are used today with synthetic yarn. Products are now available everywhere.

Some factories of ribbon-weaving products prefer to use polyester for production - an artificial material with high density. But rep ribbons made from this material are of low quality and lack demand in the market.

Properties and characteristics

The composition and features of the production technology of rep tapes determine their characteristics and properties. Due to the rigid ribbed structure, the product holds its shape perfectly, absorbs and lets air through. The longitudinal rib even “stretches” the silhouette and makes the body part visually smaller, the waist slimmer. The material is also characterized by wear resistance, strength, and high density.

The tape fabric practically does not wrinkle and is easy to care for. They are highly hygroscopic, allowing the body to breathe and are extremely comfortable to wear.

Characteristic parameters of rep tape

The classification and further use of the rep tape is determined by its parameters:

- The width ranges from 5 to 50 mm. Particular demand is noted for products measuring 25 and 40 mm. These are the ones most often used by needlewomen for sewing.

- The shape is a seemingly stable parameter, but in rare cases there are models with perforations that resemble lace patterns.

- Colors today can be varied, but the most popular are considered to be classic options—shades of blue, black, beige.

- Stiffness is a parameter determined by the density of the threads. The product can be hard, soft and medium-stiff. Light options are used to decorate albums, diaries, and hard ones are used to decorate clothes and shoes.

Scope of application

People who are not involved in creating something beautiful with their own hands involuntarily ask the question: "What is rep tape used for? Where can it be used now?" Of course, the material cannot be called too fashionable, but the range of its use is quite large:

- Design of outerwear. Tapes can be used to sew additional overlays on a sewing machine. It is the overlays that provide the necessary qualities of appearance and give the product additional rigidity, fixing the given shape.

- Decorating bags, shoes and other items. Durable, highly rigid ribbons go well with leather, thick cloth and other rigid materials.

- Making headwear. The product is often used as an auxiliary element when decorating hats, veils. Bows, flowers and other similar items can be sewn from it.

- Creation of historical interiors and images. Rep stripes are used to decorate theater curtains, historical costumes. They allow you to create voluminous sleeves, stand-up collars, typical of the heroes of the last century.

- Decorating men's and women's clothing - blouses, summer suits, dresses, skirts. With the help of rep ribbons, designers embody the boldest decisions on the canvas, using them as inserts.

Rep ribbons deserve special attention in handicrafts. They can be used to create original decorations. These can be postcards, book covers, hairpins, photo albums. The interior is decorated with decorative flowers, snowflakes, stars. Ribbons are also used to decorate pillows and boxes. Weaving skills help craftswomen make lampshades, intricate bracelets and belts.

Please note! Rep souvenirs look interesting. For New Year, you can give voluminous Christmas trees, cards with flowers and animals for birthdays.

If you buy a product with a pattern, you can easily decorate a gift, a bouquet and a cake or an entire room for a festive event. Glasses, mugs, napkins, pillows, champagne bottles decorated in a single style with grosgrain ribbon are in demand now.

Analyzing all the above-mentioned areas, we can conclude that grosgrain ribbons are very popular, especially in the production of various decorations, fakes and decorative elements.

Processing of tapes

Fabrics made of synthetic and natural fabrics often fray at the edges. Rep ribbons are no exception. Over time, they gradually wear out and begin to fray at the edges. To prevent fraying, you can initially treat the edges of the product.

There are several options for processing tapes:

Method 1 - clear varnish

Using sharp fabric scissors, cut off the required amount of material. The edges are cut at an angle of 45 degrees, or in the shape of the English letter "V". Next, you need to select a transparent varnish. It is advisable to use proven and high-quality brands so that the varnish lasts a long time and reliably.

Take a brush, dip it in varnish, remove excess transparent liquid on the neck of the bottle. Apply a thin layer of varnish to the edges. First process one side, then the other.

For greater effect, it is recommended to apply a 2nd layer. During work, try not to leave a thick layer of varnish on the tape and not to go beyond the edges. If the rules are not followed, the tape may darken and look wet and untidy.

Please note! For best results, it is recommended to test the varnish on a separate piece of fabric to ensure that it will not damage the fabric when applied.

Method 2 - specialized tool

If the buyer plans to use the tape to decorate clothing or other items that will be washed frequently, it is better to immediately purchase an anti-fraying liquid or spray.

The specialized product must be applied according to the instructions. It is usually sold in textile stores. In extreme cases, if you cannot find it, you can order it online on websites.

Method 3 - glue

If you can’t find a specialized product or, unfortunately, it’s too expensive (the cost of liquids and sprays against fabric unravelling starts at 500 rubles), you can use regular transparent glue.*

The application technology is similar to that of transparent varnish. First, the edges are cut with sharp scissors. Then take a cotton swab and dip it in glue. The excess is removed with a paper towel.

Using a cotton swab, run it along each edge of the grosgrain ribbon on both sides.

Important! The product must be kept suspended until the glue is completely dry.

Method 4 - fire

The option is suitable for ribbons made of wool, synthetics or silk. Cotton fabric cannot be melted. Any lit candle will do for the procedure. It is advisable to place it next to the sink.

The edges are cut with scissors. The sharper they are, the better. Take the edges in your hands with your thumb and index finger. It is necessary to hold the ribbon in such a way that it is fixed in one position. It is advisable to keep your hand away from the edges.

The tape is brought to the fire. In most cases, this is enough for the edges of the fabric to melt. If the desired effect is not observed, it is necessary to bring the edges a little closer to the candle. With quick but steady movements, move across the fire.

Next, the canvas needs to be supported in your hands for about a minute to cool down. The result is checked with your hand - the edges should be firm to the touch.

Grosgrain ribbon is a versatile material for sewing and handicrafts that will last for many years. With it, any needlewoman can turn her bold ideas into reality. And most importantly, the material is freely available and very inexpensive.

*Prices are valid for August 2019