The chemical industry is developing every day, so humanity receives various unique materials for its life. They are used to manufacture products for various purposes. PVC is quite unique in terms of application and physical characteristics. It is especially worth highlighting from the line of products made of polyvinyl chloride - PVC fabric, which is a composite and predominantly two-layer fabric.

This fabric uses a strong mesh of lavsan, nylon or capron thread as a base, a mesh of lavsan thread, which is coated with PVC and elastic plasticizers (mainly vinyl polymers). Thanks to this, the fabric becomes durable and very strong. The material is often used to make boats for recreation and fishing, awnings, advertising products, etc.

Methods of making PVC fabric or PVC awning

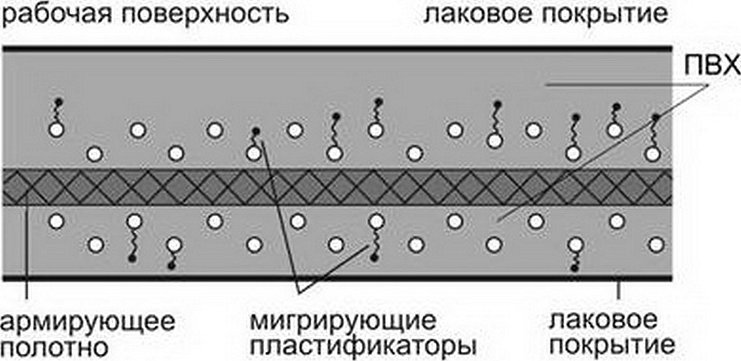

The main methods of producing PVC fabric are lamination and casting. In the first case, a PVC film is applied to a prepared base (polyester, nylon or lavsan mesh). This method is considered simple, inexpensive and less labor-intensive, so it is the most common. The second method is based on the inclusion of polyvinyl chloride in the existing base by melting. It is expensive and is used less often, although the fabrics obtained in this way are reliable, and they delaminate less often even from severe frosts and mechanical impacts.

In addition, a layer of varnish is often applied to polyvinyl chloride fabric and various additives are included in its composition, this allows to increase the operational properties of the material and protect it from ultraviolet radiation. In addition, varnish allows to practically eliminate the adhesion of dirt to the canvas. When varnishing, it is densely coated on both sides with acrylic or Teflon varnish.

Inclusion of plasticizers in the composition of the canvas allows to increase its strength, make it lighter and less waterproof. Addition of polyurethane to the composition of the material allows to make it elastic and resistant to abrasion.

Important! When choosing PVC fabric, you need to pay attention to the products of well-known manufacturers, this will allow you to avoid buying low-quality material. Accordingly, the money will be spent usefully.

Main characteristics

- density - from 200 to 1500 g/m²;

- strength up to 4000 N/5 cm;

- the interlacing of threads in the base of the material can have different ratios (the most common options are: 6×6; 7×7; 8×8; 9×9; 12×12).

- tensile strength - from 700 to 850 kg/m;

- temperature range - from +75 to -30˚С (frost-resistant fabrics up to -50-60˚С).

- service life - up to 15 years.

When choosing a dense, it is necessary to take into account all its properties, because the quality of the product or structure made from it will depend on this. At the same time, it is not rational to buy a canvas with high characteristics, for example, for a regular canopy.

Types of fabrics

PVC fabric comes in the following types:

- Air-holding (for boat manufacturing).

- Antistatic coated fabrics for the oil and gas industry.

- Fabrics for storing water in agriculture, for fire extinguishing, etc.

- Material for the construction of various outdoor canopies, tents and other structures.

- Material for car awnings.

- Fabrics for the production of sports and play equipment (gymnastic mats, swimming mattresses, pools, etc.).

- Material for architectural objects and structures.

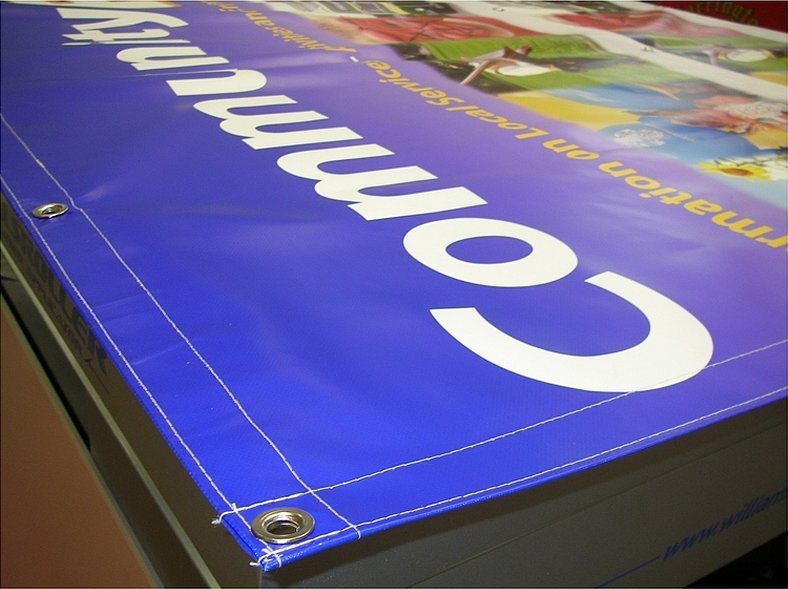

- Canvases for the production of advertising structures.

In this case, the material can be:

- one-sided;

- bilateral;

- reinforced (more durable and safer);

- unreinforced (for example, simple film used to make children's swimming rings, etc.).

- multilayered;

- single-layer.

On average, a roll of material costs 100-25,000 rubles, and the price depends on the type of material. For example, banner products cost 25,000 rubles, since high requirements are imposed on them.*

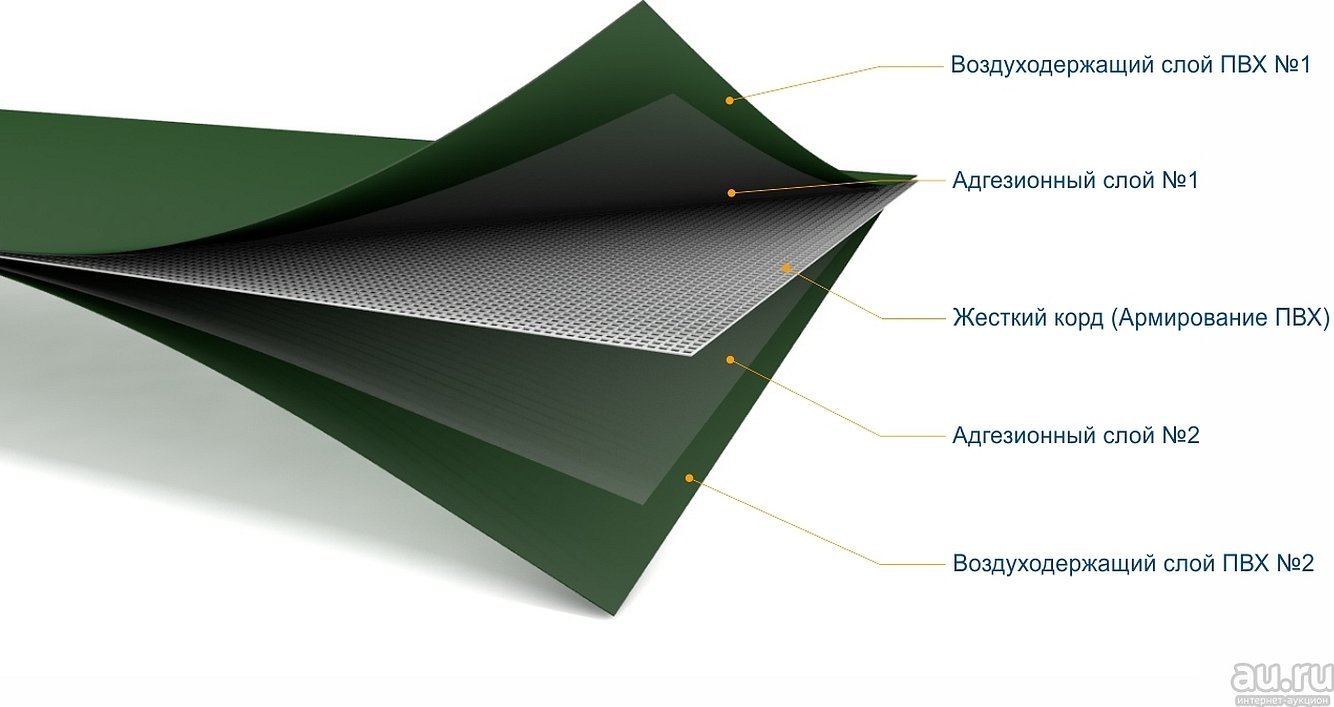

Reinforced PVC

This material has a multilayer structure, based on a strong cord (synthetic polyester material) coated on both sides with polyvinyl chloride. Due to this, it is considered ideal for the manufacture of boats, awnings and other responsible products.

The multilayer structure of reinforced PVC fabric consists of:

- Top layer of PVC;

- Adhesive layer (responsible for adhesion of polyvinyl chloride to the base);

- Cord (base);

- Second layer of adhesive;

- Bottom layer of PVC.

PVC-reinforced fabric is characterized by increased resistance to friction and mechanical damage, water resistance and resistance to temperature changes. This makes it more durable and in demand in the production of various high-quality products (boats, sporting goods, awnings, etc.).

When choosing a material, its density is mainly taken into account, since the strength of the product made from the fabric will depend on this. The quality of the material can even be assessed by touch, for this purpose almost every product is equipped with a piece of PVC fabric (this patch is intended, for example, for boat repair).

Please note! Reinforced PVC is used in the most critical structures and demanding products. This is due to the fact that such a coating is very strong, wear-resistant and durable.

Scope of application

PVC fabrics are used for the production of:

- boats;

- awnings (for railway cars, cars, boats and yachts);

- canopies;

- canopies;

- advertising banners;

- container roofs;

- industrial curtains and hangars;

- shelters for drilling rigs;

- field storage facilities for agricultural products and building materials;

- canopies to protect work areas from precipitation (snow, wind or rain);

It is also widely used as a waterproofing material, in the construction of temporary warehouses. In addition, it is used in the construction of tents, pavilions, summer cafes, trade tents, gazebos, garden awnings and livestock complexes. Various curtains are also made from it.

Sports and children's equipment (mats, tatami, play complexes, etc.), inflatable attractions and sleds of the tube type are also made from PVC fabrics. In this case, the highest quality, durable and wear-resistant material is chosen.

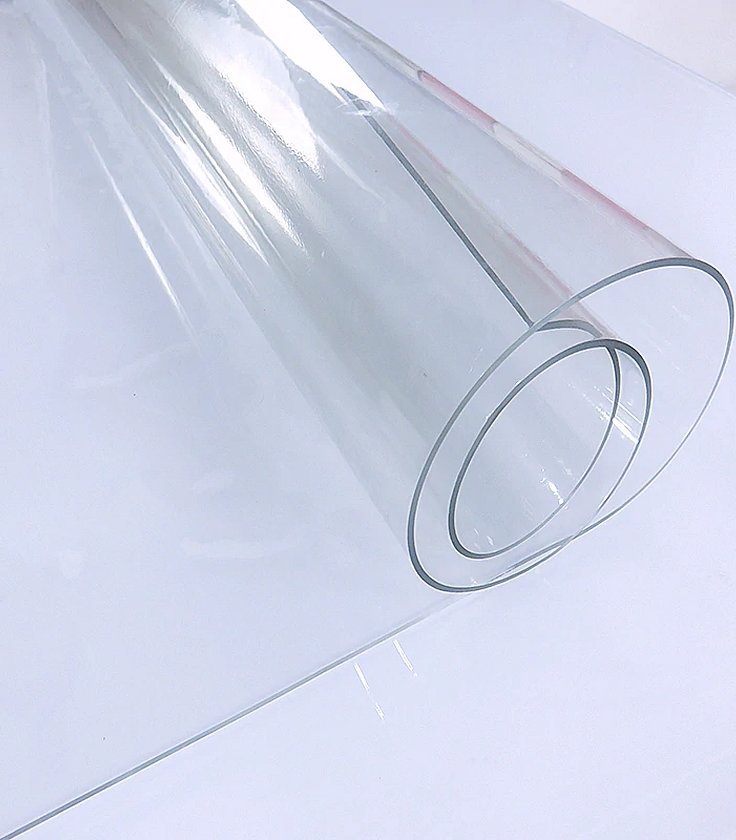

Curtains, drapes, windows, etc. are made from transparent material.

Features of operation

During the operation of PVC fabric products it is necessary to:

- Follow the care instructions (to do this, you must carefully read the instructions that manufacturers provide with any product).

- Curtains, mattresses, and raincoats made of PVC cannot be washed in a washing machine.

- It is prohibited to use caustic chlorine-containing substances and solvents to wash products made from PVC fabrics.

- The material should be washed and cleaned using warm soapy water, a sponge or a soft brush. To do this, the surface of the fabric is treated with a soap solution, then wait 5-10 minutes for it to soak the material well. Then the surface is treated with a sponge or brush, after which the soap solution is washed off with warm water. If necessary, the procedure is repeated. This is especially true for window material.

- Heavy dirt cannot be removed with soap solution, so you need to use special detergents. For example, you can use Nerta, Cleanol, etc. After treating the material with detergent, you also need to wait 5-10 minutes, after which the product can be cleaned and washed.

- PVC products need to be dried well after getting wet so that they do not rot or become moldy.

- It is necessary to carefully roll the items so that strong folds do not form on the material.

- PVC products are dangerous to burn.

Important! If the operating conditions are met, the characteristics of the PVC awning fabric will remain unchanged throughout its entire service life.

Advantages of PVC fabric

The main advantages of PVC fabric are:

- Durability (especially tear strength). Therefore, this awning material surpasses other textile materials, including tarpaulin.

- Excellent water-repellent properties.

- Resistance to decay.

- Oil resistance.

- Fire resistance.

- Resistance to aggressive environments and substances.

- Does not deform due to temperature changes.

- It practically does not fade in the sun.

- Does not require special care.

- Large selection of colors.

- Frost resistance.

- Can be stitched, glued and welded.

- Ideal for digital printing.

- Resistance to contamination.

- Varnished material is a good base for self-adhesive films.

- Long service life.

Due to such a large number of advantages, PVC fabrics are irreplaceable in everyday life, on vacation, in construction and industry. For example, today you can see a tarpaulin truck on almost any road.

Due to its unique performance properties, PVC fabrics are widely used in many areas of human activity. The wide variety of this material allows us to meet the needs of people, industry and construction. With proper use and proper care, awning fabric will serve flawlessly for many years. In terms of price/quality ratio, PVC fabrics are superior to many other similar materials. This makes them affordable for everyone. For example, Oxford fabric has good characteristics and is inexpensive.

When choosing a suitable material, you should always consider its characteristics, performance properties and area of application. This will allow you to choose the best material option for any specific case.

*Prices are valid as of July 2019.