Manufacturers use natural wood cellulose as the source material for viscose. It is considered one of the most common artificial materials. There are many opinions: what kind of fabric is viscose - artificial or natural? More on that below.

- History of origin and production process

- Characteristics and properties

- Is viscose a synthetic or natural fabric?

- Properties of viscose, does it stretch or not

- Types of viscose fibers

- How to choose fabric

- How to sew viscose items and care for them?

- Rules for caring for viscose fabric

- How to wash viscose

- How to iron viscose products?

- Viscose or polyester: which is better

- Advantages and disadvantages of viscose fabric

- Advantages

- Main disadvantages of the material

History of origin and production process

In 1664, British physicist Robert Hooke worked on obtaining natural fabric from wood raw materials. There were not enough technical capabilities to implement this process. Therefore, the idea had to be abandoned.

In 1855, George Audemars developed a technology for producing viscose by hand. He dipped a thin needle into a sticky mass of rubber, crushed wood, alcohol and ether. This is how the threads were to be formed and extracted. It was a long and laborious process that had no continuation. The material was easily flammable, so it again turned out to be unviable. Only 30 years later, the French chemist Count Guillier de Chardonnet managed to develop a new technology for producing viscose material.

He patented his invention and founded a company to produce it. The material was shiny and fragile, easily flammable. The scientist continued to improve the technology of fabric production. In 1889, new types of threads were introduced. In 1892, British chemists Charles Frederick Cross, Edward John Beaven and Clayton Beadle developed a technology for producing viscose.

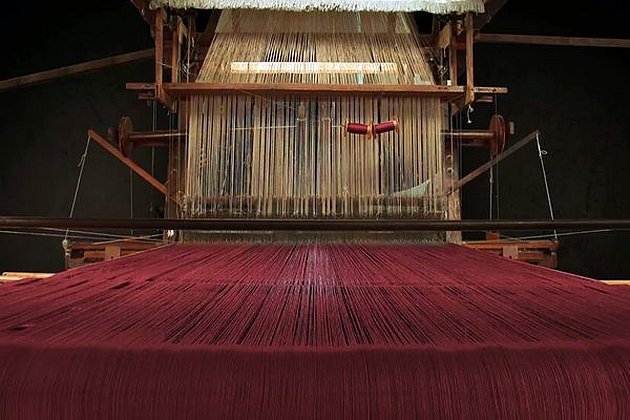

Viscose manufacturing technology:

- Grind the cellulose and boil it in a container with calcium hydrosulfite salt.

- Remove water. Leave humidity at 6-8%.

- Remove impurities by heating a solution of sodium hydroxide - alkali. This results in the formation of alkali cellulose.

- The raw material is kept until it matures. The molecular weight of the original cellulose wood will decrease.

- Treat the raw material with carbon disulfide. Add alkali solution, stir. The result will be a viscose solution containing 85% water.

- Leave the solution for several days to mature and obtain viscosity.

- To produce the material, a wet method is used. The solution is passed through spinnerets. It is directed into precipitation tanks filled with acid.

- The resulting raw material is used to produce long threads that are wound onto bobbins.

This is a traditional method of production. But today there are more modern technological processes. However, many manufacturers have not yet improved their production.

Characteristics and properties

The characteristics of the material are affected by its manufacturing technology. Therefore, the material has different appearances. It can be: glossy and matte, textured and smooth, light and dense material.

Is viscose a synthetic or natural fabric?

Consumers are interested in the question: is viscose synthetic or natural fabric? To understand this issue, we must first clarify that a person produces non-natural material using synthetics. To produce natural material, natural raw materials are used. For example, from sheep wool or silkworm threads. And to produce viscose, wood and special chemical solutions are used.

What is viscose and what does it consist of? It is generally accepted that fabric based on natural raw materials is a natural material.

Properties of viscose, does it stretch or not

The following properties of viscose can be distinguished:

- The material is soft and pleasant to the touch. The folds and drapes look beautiful in sewing products.

- Hygroscopic - absorbs moisture well and allows air to pass through.

- Dry material has a high degree of strength, while wet 100% viscose has a weak degree. To increase strength and wear resistance, manufacturers add chemical additives to the raw material.

The disadvantages, as well as the advantages, in the fabric are compensated by various protective additives. Cotton added to viscose makes the fabric dense, increases its service life. The question "does viscose wrinkle or not?" is easy to answer. The material is strong with an oily shine. Windbreakers and jackets are sewn from it. It is used as a lining material.

Many people are interested in: what kind of fabric is microviscose? If polyester is present in viscose, the fabric does not wrinkle and retains a beautiful appearance. The addition of elastane gives elasticity to the material, which allows the fabric to stretch well.

Types of viscose fibers

The Latin name for viscose is viscosus, which means sticky. Depending on the manufacturing method, thread types are divided into the following:

- Textile. It is used for making garments or home textiles.

- Cord. This is a stronger and thicker thread, compared to textile. Military uniforms and construction jackets and trousers are sewn from cord fabric.

- Staple. Thick and strong thread used for making jackets, fur and carpets.

Today, with the help of technological innovations and ongoing experiments, new types of fabric are appearing on the textile industry market:

- Tencel (lyocell). Eucalyptus wood is used for production. Silky, soft surface, and the appearance resembles cotton fabric.

- Modal. This is a new generation of viscose material. It has a high absorption capacity, as it consists of 100% cellulose raw materials. Viscose knitwear is used to make underwear, sportswear, towels, and children's goods.

- Cupra. It is made from cellulose with the addition of cotton threads. The raw material is kept in a copper-ammonia salt solution. As a result, the material can be compared to silk fabric. Not only does it look like silk, but its quality is also similar. Therefore, cupra is the most expensive viscose material.

- Acetate. The material is obtained from cellulose waste (acetyl cellulose). The finished fabric is thin, with a slight shine. There are several advantages: it has low wrinkling, dries quickly when moistened, and is durable when deformed. In addition to its positive qualities, the material has its disadvantages: it absorbs moisture poorly, melts at high temperatures, and holes appear when exposed to aggressive solutions. The material resembles silk in appearance. It is used as a lining material. It is available in a variety of colors.

How to choose fabric

Viscose is an unusual material. Its origin is considered natural and synthetic. Processed wood shavings are subject to chemical treatment during fabric production. It makes sense to choose viscose for sewing products. It has hypoallergenic, hygroscopic, breathable, hygienic qualities. The material fits beautifully into folds, is easy to drape, and has an affordable price.

For your information! Viscose has one interesting feature and quality that distinguishes it from other types of fabric. When wet, it turns into a dense, hard material. After drying, it becomes pleasantly tactile.

How to sew viscose items and care for them?

Before making a product, the question arises: what kind of material is viscose and how will it behave when sewing? Every craftswoman should know what threads and needles are used to sew the material, what should be done if the parts shift or slide? The main thing is that such material needs to be decatized. Before cutting, the fabric should be moistened, as it “shrinks”.

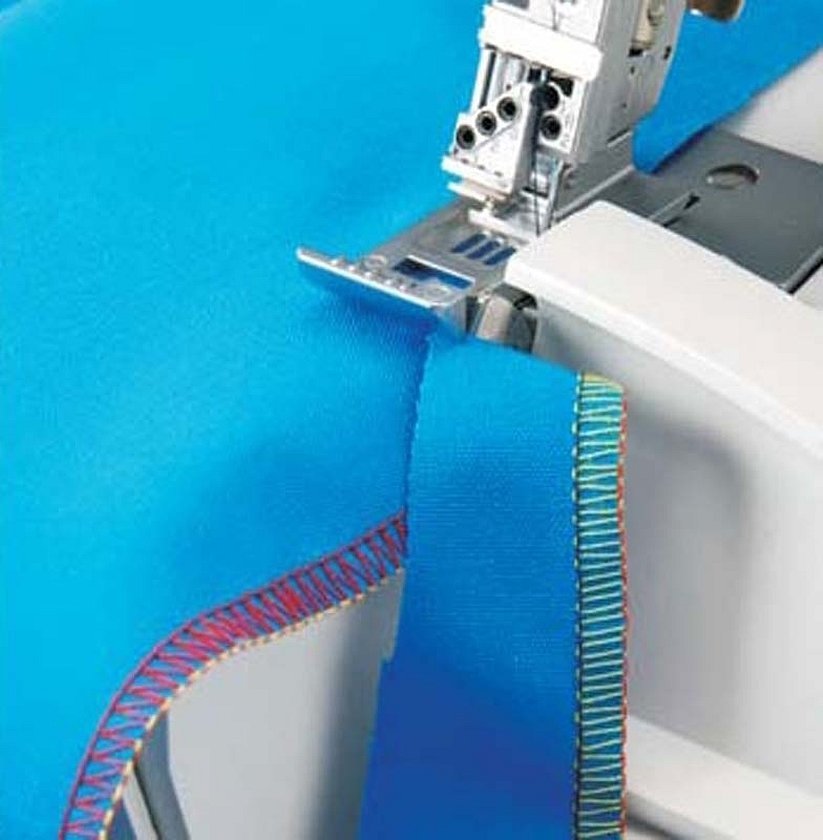

Basic recommendations for sewing viscose products:

- Experts recommend using synthetic threads No. 80. They are durable, do not tear when the fabric is stretched, and the stitching is even and beautiful.

- A needle with a fine spherical sharpening of the tip No. 70 or No. 80 is used. And lycra is sewn with a needle with a normal spherical sharpening of the tip. To get a beautiful stitch, viscose threads No. 40 are needed. For sewing spandex, craftswomen use acrylic or viscose threads No. 40.

- After cutting the fabric, the edges will fray, so you need to increase the seam allowances and finish by hand with a buttonhole stitch or overlock.

Rules for caring for viscose fabric

In order for sewing products to retain their aesthetic appearance for a long time, they need to be properly cared for. This is a delicate fabric that does not require rough handling. Dry cleaning is allowed for the care of viscose products.

How to wash viscose

When washing, please follow these recommendations:

- use delicate mode;

- water temperature not higher than 40℃;

- Do not use wringing to avoid creasing the fabric.

Important! The garment should look beautiful and not lose its shape, so it is better to hand wash and dry it in a straightened form.

How to iron viscose products?

Ironing rules:

- iron from the wrong side using the "silk" setting;

- the iron temperature should not exceed 150℃;

- Iron through a slightly damp cotton cloth.

If you iron the fabric from the front side, it will leave marks from the iron. They will differ from other areas of the product. And the high temperature of the iron can melt the material.

Viscose or polyester: which is better

The large selection of sewing materials confuses fashionistas. From all the variety, you need to choose a material that will not stretch or deform in the product when worn, but will be pleasant and comfortable.

Description of the main qualities is presented in the table.

| Name | Polyester | Viscose |

| Content | The material is made of polyester | It contains wood pulp that is processed using chemical processes. |

| Appearance | It has an unnatural shine | It has the shine of natural silk |

| Tactility | Hard | Soft |

| Usage | For sewing all products | For sewing almost all products |

| Strength | High strength and abrasion resistant. | High percentage of strength. Does not tear. |

| Ignition | Melts | Burning is even |

| Washing, cleaning | Boiling and washing at 100℃ are possible | Wash up to 95℃, dry cleaning recommended, fades. Threads are prone to drying out and breaking. |

| Ironing | Up to 150℃ from the reverse side | Up to 150℃ from the reverse side |

If we compare the structure of fabrics, then for the summer period, products made of viscose are better suited. In the cold period, it will be more comfortable in clothes made of synthetics. This is the only option for sewing outer garments.

What is viscose? The structure of viscose allows it to be used for sewing underwear, and for the production of sportswear, it is better to choose synthetics. We can conclude that fabrics with different qualities cannot replace each other.

Advantages and disadvantages of viscose fabric

Viscose is synthesized from plant material (wood cellulose) artificially. It has long been firmly established in everyday life. Modern viscose: what kind of fabric is it, natural or not, what qualities does it have?

Advantages

Main advantages:

- It is a comfortable fabric to wear;

- the material is heat-labile: cool in summer and warm in winter;

- modern technological processes make it possible to produce textiles that have something in common with silk, linen or cotton;

- does not become electrified;

- good sorption qualities (the material is evenly colored);

Please note! The material is tactile and does not cause irritation. Compared to cotton and linen garments, the weight of viscose garments is much lighter. This fabric is used to sew not only everyday but also festive outfits.

Main disadvantages of the material

They can be considered conditional. For example, wet material has low strength, but at the same time it is easy to care for. At the same time, its integrity is preserved. Viscose can stretch if polyester substances are added to the raw material. The fabric will have a tightening effect. Products made of such fabric are suitable for slender representatives of the fair sex with curvy shapes. With a properly selected outfit, you can hide problem areas of the figure.

The fabric has bright shades, a matte or glossy surface. It is easy to test: if you set fire to a small piece of material, you can smell a distinct smell of burnt paper.