During the processing of natural cellulose, viscose threads are obtained. Viscose fiber is a material of artificial origin.

- History of viscose production

- Structure and properties of viscose fiber

- Good and bad properties

- Manufacturing technology

- Core technology

- Technology of obtaining viscose fiber by semi-continuous method

- Other technologies for producing viscose fiber

- Lyocell

- Siblon

- Folding, marking and packaging of fabrics

- How to use

- Modal

- Tencel

- Staple fiber

- Acetate

- Rules for material care

- How to identify viscose in fabric

History of viscose production

In 1892, the technology of viscose fiber was developed. Cellulose was first treated with sodium hydroxide, then with carbon disulfide. The result was an aqueous solution of cellulose, which was passed through a mold into a bath of acid, where the polysaccharide was restored in the form of viscose fiber.

Structure and properties of viscose fiber

Viscose thread, in terms of chemical composition, is represented by hydrated cellulose, which is characterized by good hygroscopicity, interaction with water with the formation of new compounds, esterification and oxidation.

If you look at an enlarged image of viscose fiber, you can see longitudinal lines on the surface of the threads; in cross-section, the fiber has a ribbed shape.

Additional information! The multitude of cross-links in hydrated cellulose contributes to the increased strength of viscose fiber. Viscose threads are not characterized by thermoplasticity, so they can be used at a temperature of 100 to 120 degrees Celsius without losing their mechanical properties. Viscose fiber does not swell in gasoline, benzene and water. It dissolves in organic acids and alkalis. Under the influence of certain microorganisms, viscose fiber is destroyed.

Good and bad properties

Products made of viscose fiber are pleasant and comfortable to wear. The fabric attracts with a variety of colors and a pleasant appearance. In the heat, viscose clothes are not hot, and in winter they are not cold. The fabric is quite strong. It is easy to sew things from viscose. Viscose thread fabric is easy to dye and it retains its color for a long time.

The material wrinkles a lot. Negative properties also include short lifespan when worn for a long time. Viscose material shrinks and deforms a lot when washed. Viscose products lose their original appearance when exposed to high temperatures and sunlight. Viscose fabric is prone to pilling. To improve the quality of the fabric, manufacturers mix viscose threads with other fibers.

Manufacturing technology

Core technology

The technology of viscose fiber production includes two stages:

- Obtaining spinning mass (viscose).

- Thread forming.

The starting material is wood cellulose. First, the polysaccharide is extracted from wood by boiling it in a solution of calcium acid salt with sulfurous acid (formula - Ca(HSO₃)₂) under pressure for twenty-four hours. Then the cellulose is mixed with water, dried and separated into layers. Sulfite cellulose is formed.

Next comes mercerization (treatment with 20% caustic soda) at a temperature of 45 to 60 degrees Celsius. This produces alkaline cellulose. The mixture is squeezed out and crushed. Next, the alkaline cellulose undergoes preliminary maturation (oxidation in air).

The last stage is xanthogenation. Alkaline cellulose is treated with carbon disulfide. The resulting cellulose xanthate is converted into an alkaline solution and after maturation, a viscose thread material is obtained.

Technology of obtaining viscose fiber by semi-continuous method

Based on the semi-continuous method, it is possible to obtain thin viscose fiber.

Additional information! With this technology, viscose fiber is formed using the wet method in a short time.

Other technologies for producing viscose fiber

The following modified fibers are produced on the basis of viscose.

Lyocell

Modification of cellulose in amine oxide is the basis for obtaining lyocell. The advantages of this process are:

- the resulting wet material has increased strength;

- the fiber is compatible with all natural and synthetic threads;

- Lyocell has good and stable color, interesting shine;

- Lyocell products are durable when worn;

- Lyocell is successfully used in the production of fabrics and non-woven materials;

- Lyocell is in high demand among consumers because this material is similar to cotton, but stronger and of higher quality;

- Lyocell absorbs moisture better and feels like silk on the skin.

Disadvantages of the lyocell production process:

- production stages do not always comply with sanitary and hygienic requirements;

- high cost of license;

- high price of lyocell.

Siblon

In the 1970s, scientists in the Soviet Union invented high-modulus viscose threads called siblon. Coniferous wood is used as raw material. The strength of siblon exceeds the strength of viscose by 1.5 times. It absorbs moisture better and is not affected by alkalis. Products made from siblon shrink less and wrinkle less.

Folding, marking and packaging of fabrics

Folding, marking and packaging of fabrics are regulated by GOST 8737-66.

Important! Viscose fabric for the clothing industry is folded in whole pieces. Different pieces of fabric of the same color and article can be assembled for sale.

The length of the cut for sale is from 15 to 60 cm. For sewing factories, the length of the cut should be from 20 to 80 m.

Fabrics that are assembled in pieces must be stamped with information about the manufacturer.

The label must contain the following information:

- manufacturer's name;

- name of fabric and article number;

- name of the standard or technical specifications;

- type and nature of finishing;

- name of chemical threads and their percentage in the fabric;

- color fastness data;

- width of viscose fabric;

- variety;

- length of the canvas in a piece;

- date of manufacture.

Viscose fabric can be packed in:

- paper;

- film;

- cardboard.

How to use

There are several options for using the fabric in question.

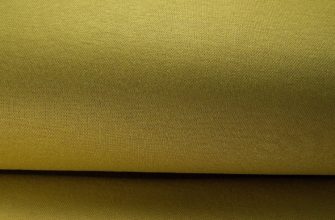

Modal

One of the varieties of viscose is modal. It is neither natural nor synthetic material.

Beech wood is used for its production. Modal gives minimal shrinkage, is resistant to deformation and fading. It is characterized by softness, smoothness, good absorption, so modal has found application in the production of towels, underwear, and robes.

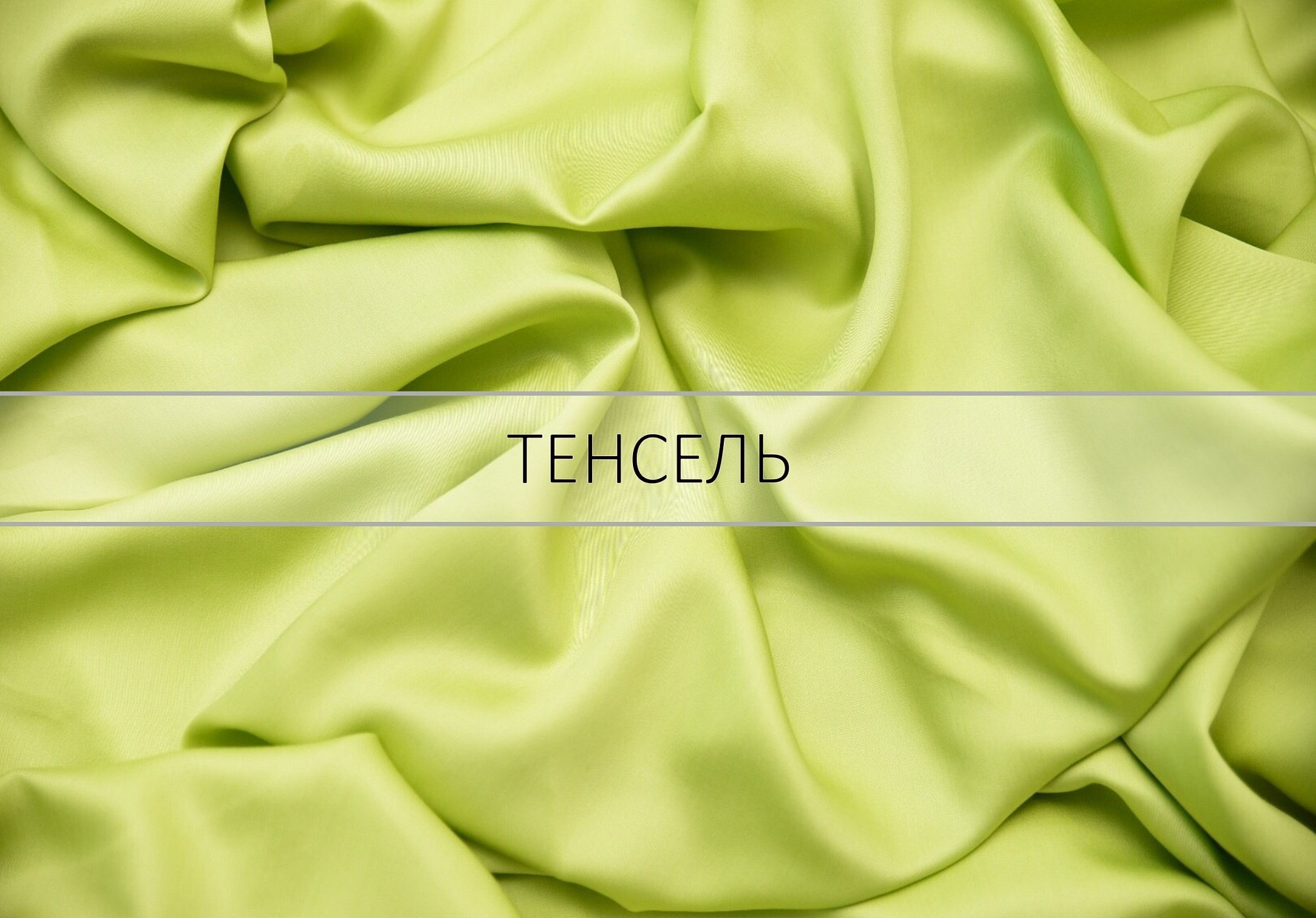

Tencel

Tencel is a modern natural material. Tencel is comparable to cotton in its properties. It resembles silk in appearance. Tencel fabrics are often used to sew various clothes. Tencel fabric consists of lyocell, silk, wool and cotton. Tencel is also often used for ropes. In medicine, it is used to make bandages.

Staple fiber

Staple consists of short threads of the same length, which makes the fabric elastic. Staple products are almost wrinkle-free compared to other viscose fabrics. Staple may contain cotton. Dresses, shirts, and blouses are made from staple fabric. The fabric is inexpensive and of excellent quality. Staple fiber is also used to make yarn.

Acetate

Acetyl cellulose is used to produce these fibers. Acetate fiber is divided into two types: triacetate threads and acetate threads. Outerwear, clothing fabrics, underwear, knitwear, and curtain fabrics are made from acetate fiber. Thanks to acetate, products wrinkle less.

Viscose threads are used in embroidery and in the production of yarn for knitting.

Rules for material care

Viscose fabric products are washed by hand or in a delicate mode at 30 °C. Wringing and drying products on a rope are not allowed. Drying should be done on a flat horizontal surface.

How to identify viscose in fabric

The fabric is comfortable and soft for the body. When burning, it behaves the same way as cotton. The fibers have a bright shine, like silk fabrics. The fabric is easily wrinkled. The strength of viscose fabric when wet is lower than that of cotton.

Viscose fiber has found wide application in many branches of industry, but is mostly used in textile industry. Like all fabrics, it has its positive and negative sides.