Among the range of textile products manufactured, fabric occupies a special place in sewing high-quality clothing. The quantity, type, and color range of the product are varied. But the most important criterion for choosing fabric for clothing is the natural origin of the material.

- What is the material?

- A little history of origin

- Features of production

- Description of fabric: composition, properties, characteristics

- Types

- Printed

- Polished

- Plain painted

- Embossed

- Scope of application

- What is sewn from chintz?

- What you need to know about chintz when sewing any products

- Features of chintz care

- Pros and cons

What is the material?

It is for this reason that when sewing diapers for newborns, underwear for adults, preference is given to calico. Not everyone knows what calico is. But every housewife knows that the fabric itself and products sewn from it are distinguished by pleasant tactile sensations when in contact with the body, and the material is made from natural raw materials.

Chintz is a light-textured fabric made from cotton. Chintz fabric is:

- Monochrome - plain dyed;

- Printed - with a print or design.

Only a person closely connected with textile production knows what kind of material calico is - a seamstress, cutter, spinner and weaver. It is such a person who can give an exact answer to the question: "What does calico look like?" the one who will be able to determine the composition and quality of the material by touch.

Please note! The basis of production is a harsh, unprocessed material - calico.

A little history of origin

The history of the fabric began in the 11th century - it was during this period that Indian craftsmen first began to use this material. From Sanskrit, the fabric is translated as "motley". Traders brought printed cotton to Egypt and other countries. In the 17th century, the fabric first appeared on the territory of Europe. The Europeans liked the fabric so much that it was decided to establish its production in France.

It was in the country of wine and fashion that the first cotton workshop was opened, where local craftsmen mastered production and copied the original pattern. The emigration of Indian craftsmen to France contributed to the improvement of fabric dyeing - the Indians taught Europeans how to obtain a durable color for fabric and revealed the secrets of dyeing.

Note! Independent production of fabric was also carried out in Great Britain. In this country, import of material from India was repeatedly prohibited, since the fabric produced in local factories was of poor quality and inferior to products from India.

1780 — calico is produced in Ivanovo, called the "calico kingdom". There is a calico museum in this city, the theme of the expositions of which is the history of the material, fashion trends in the manufacture of products. The museum's collection is thousands of samples, homespun cloth. From the beginning of the USSR, calico was very popular. It was very difficult and expensive to get good fabric at that time. It is for this reason that grandmothers and great-grandmothers saved money for a long time to buy a good piece of material for sewing an outfit. Calico and brocade could be bought from a peddler and that's all.

Features of production

The basis of the production of modern material is a fabric semi-finished product (calico). The material is obtained from thick cotton threads. The yarn is not bleached, the fabric remains unchanged, with a natural gray shade.

Further, the following are produced from the matter:

- Chintz;

- Muslin;

- Madapolam

- Dermantin;

Manufacturing stages:

- Collection of raw materials;

- Seed cleaning, sorting;

- Yarn of threads from pre-combed and prepared fiber;

- Weaving on equipment;

- Dyeing of finished material.

Not every fabric produced in this way can be called calico, this adjective is given only to natural fabrics. You can determine whether calico is a natural material by the smell of the burnt thread. If cotton is used in production, the thread, when set on fire, forms ash with a specific smell of burnt paper.

Important! Before calico is produced, the fibre goes through a series of dyeing and finishing operations. The initial result is a non-uniform material, the final result is a lightweight fibre with a density characteristic of 100 g/m2.

The material has a plain weave. With this method of interlacing the warp and weft threads ("one through one"), a double-sided fabric is obtained. The front and back sides will differ if the fiber has a pattern.

Description of fabric: composition, properties, characteristics

Chintz fabric description combines a number of undeniable qualities. The fabric is reliable and safe, so it is widely used for the production of children's clothing, bed linen.

The fabric is thin and delicate. It is obtained by plain weaving of warp and weft threads. The raw material for production is cotton. It is widely used for sewing:

- Bedding;

- Shirts for men;

- Models of summer clothes for women and children;

- Clothes for babies, newborns. The properties of chintz predetermined the use of the material for sewing clothes for the little ones.

Calico is a similar material in structure. Calico and chintz, what is the difference? Calico is a cotton fabric, as is calico. They differ in structure, properties, appearance.

Calico is a dense cotton fabric in which the longitudinal and transverse threads overlap each other every 2 weaves.

| Sign | Chintz | Calico |

|---|---|---|

| Softness | Softer than calico, used for sewing clothes for newborns | |

| Scope of application | Wider than calico | |

| Density | Thicker than chintz | |

| Durability of use | Prone to wear and tear | Has been used for a long time |

| Tendency to shrink | Does not shrink | Gives shrinkage |

Another material that is often confused with chintz is satin. The main difference from satin is the cost. Satin is an expensive material that has a shine, resembles silk in structure, is soft and delicate.

Types

There are no special differences between the varieties of chintz. But it is necessary and important to know the features of each type of fabric. This will help you to correctly purchase the fabric for sewing this or that product.

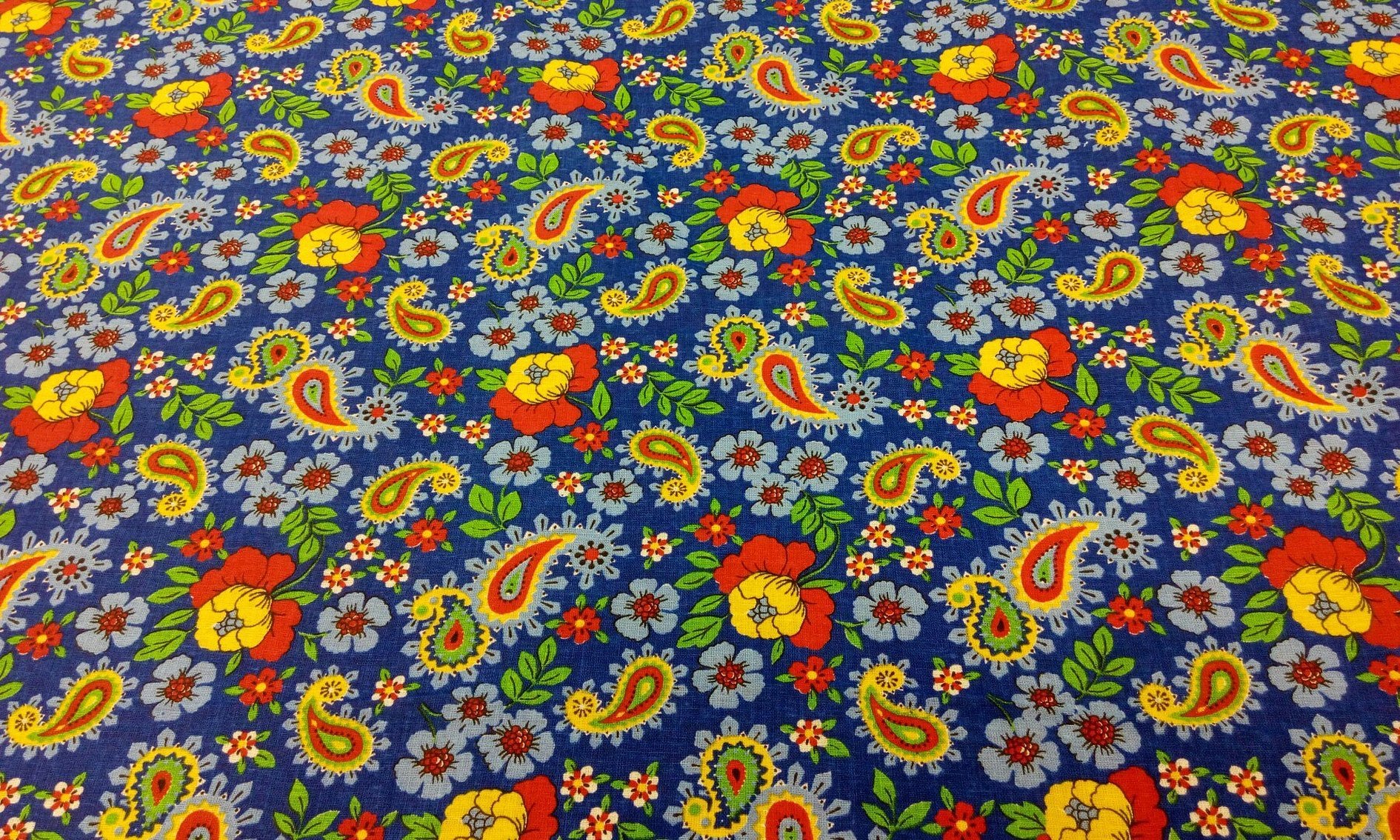

Printed

"Grandma's" chintz. Has a sloppy, factory texture. Pattern applied over finished fabric.

Polished

It has a good degree of durability. The most wear-resistant type. The material is rough, hard. The fabric is applicable for sewing curtains for the kitchen, furniture upholstery.

Plain painted

The material is widely used, it is not difficult to find in stores. The fabric is thin. It is used for bed linen, sewing pajamas, shirts. The only requirement is washing at 60 degrees. Plain-dyed fabric is able to retain its color range for a long time, and the use of plain fabric will allow you to make unique items. Thus, red chintz is obtained.

Embossed

It is obtained by hot stamping. This method is applicable in the production of high-quality wallpaper, expensive tablecloths, which are widely used in various stylistic design of premises.

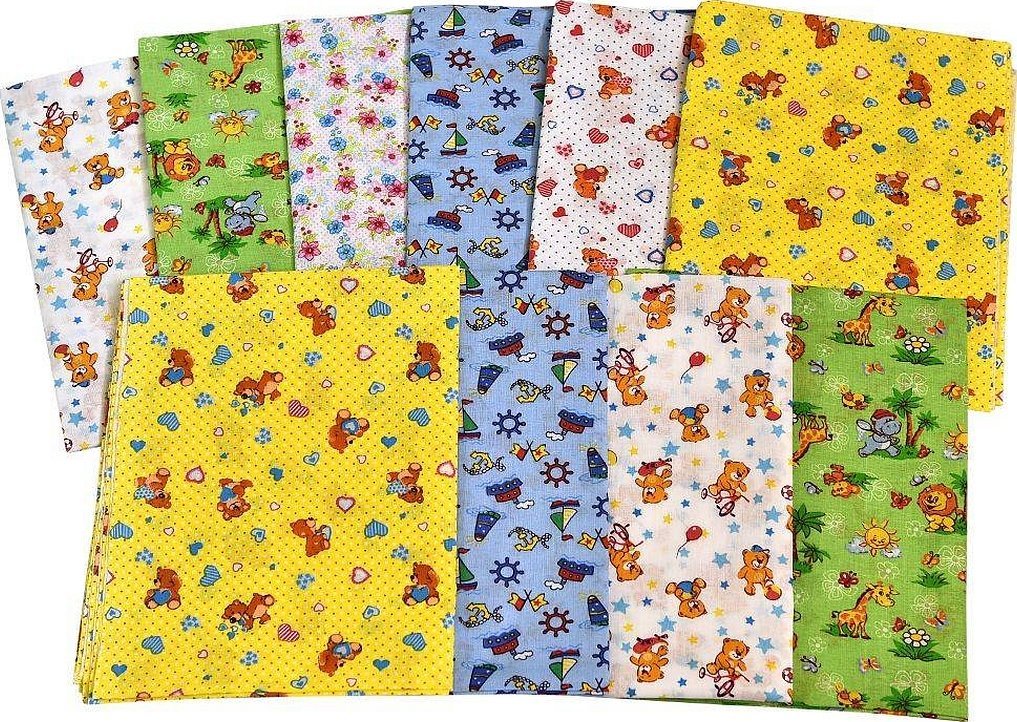

In addition to the above types, white calico has found its application. The material is bleached, and drawings are applied to it. The fiber is used in sewing dresses, dressing gowns, diapers, scarves, and shirts.

Scope of application

The material is available (can be purchased everywhere), is lightweight, and looks presentable. The material is used in many areas of the textile industry - sewing clothes, sewing bedding sets. The product is easy to care for - it is not demanding in care, but requires careful handling. Even an inexperienced craftswoman can sew a thing from calico fabric.

What is sewn from chintz?

The following are sewn from the material:

- Women's and children's clothing for summer (dresses, sundresses, skirts, blouses);

- Shirts;

- Home clothes, underwear, pajamas, nightgowns, dressing gowns;

- Kitchen textiles;

- Curtains;

- Diapers, swimming fin;

- Chair covers;

- Bedding.

What you need to know about chintz when sewing any products

Before sewing clothes, you should take into account the characteristics of the material - it does not stretch, it comes in different widths - all this is immediately thought out and reflected when cutting out a particular product.

The material does not require ironing. After washing, after drying, you need to shake the material and perform several smoothing movements - there will be no creases or creases on the fabric.

Features of chintz care

Easy to care for: can be washed by hand or in a washing machine.

Care instructions.

- Before use, the item is hand washed in cold water. This softens the fabric and protects the color from fading;

- The fabric is washed only with cotton. When washed with synthetics, it becomes rougher;

- The items are washed inside out;

- A gentle type of SMS, with a minimum of bleaching components to preserve color;

- Before ironing, moisten with water and treat with steam - this way you can smooth out creases faster;

- The product is dried in a straightened state, outside in the shade.

Pros and cons

Advantages:

- Environmentally friendly - natural fiber without synthetic additives;

- Bright color. Does not fade or shed during use;

- Safety - no allergies, itchy skin, redness when wearing;

- Easy to care for. Not demanding in care;

- Hygroscopicity and air permeability - absorbs moisture, does not allow water vapor to remain on the skin, allows air flow;

- Affordable price;

- A wide range of products and areas of their application;

- Easy to process.

Flaws:

- Short life - prone to mechanical damage and abrasion;

- If the dyeing is of poor quality, the fabric will fade. It is recommended to wash the product separately for the first time;

- When exposed to high temperatures, the fiber is destroyed;

- Shrinks and wrinkles (iron required).

Smart and light calico is available to many. In the abundance of presented designs, this material has found wide application in textile production: everything is sewn from it, from children's dresses to pillowcases and duvet covers. Careful attitude to products made of calico allows to smooth out its shortcomings.

http://youtu.be/LGDSlGKstWc