Despite the fact that Kevlar fiber was invented many years ago, people still continue to be amazed by its unique properties. The material has revolutionized the field of fabrics that are designed for protection due to its parameters and characteristics.

Kevlar: What is it anyway?

A fabric made of synthetic fiber with a crystalline structure is called Kevlar. The incredible strength of the fabric is provided by the benzene ring, which lies in the cross-section of the crystal. According to its characteristics, the material is stronger and more durable than metal, while it is very thin and light.

Everyone gets to know Kevlar differently, everyone learns what it is from certain life situations. Modern youth are familiar with the material thanks to the game Rast, in which characters are offered to buy armor and ammunition made of it. The older generation associates the fiber with protective clothing and sports equipment.

Briefly about the origin

In the distant 1975, a material called Kevlar was first introduced to the market and immediately began to enjoy huge demand, which is only increasing every day. This unique polymer was obtained in the laboratories of the world-famous DuPont concern. Officially, its creator is considered to be the chemist Stephanie Kwolek.

At that time, it was used for tires as a reinforcing material. Later, it found application in various composite materials, sports equipment, and cable products. Kevlar fabric began to be used for the production of personal protective equipment.

Kevlar fabric production

Having first learned about this material, many people ask the question of what to make Kevlar from. To obtain it, a solution of calcium chloride and methylpyrrolidone is taken. Special reagents are added to it, releasing an unusual substance with the qualities of liquid crystals. The process is carried out at low temperatures.

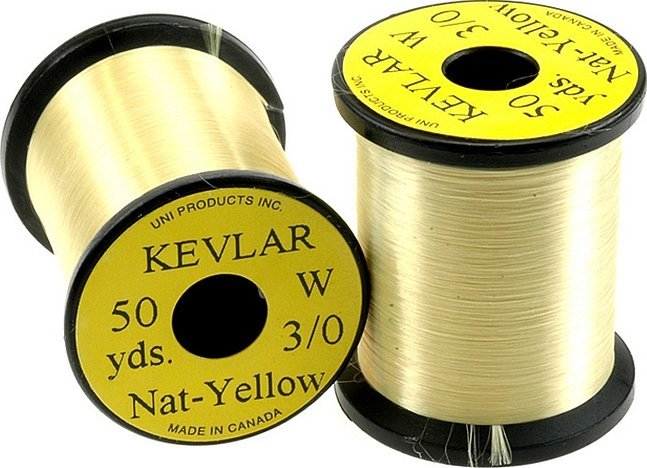

On the outside, the resulting polymer is a crumb or gel that is washed and dried. Then it is passed through spinnerets, as a result of which fibers are formed, then threads are obtained. It is not difficult to guess what Kevlar threads are. The obtained fibers are twisted into threads, which already form the finished product. After this, they are sent a second time to the precipitation bath, washed and dried.

Please note! Since the production of Kevlar involves significant difficulties, including the use of sulfuric acid, the process is very expensive.

Technical characteristics and properties

The technical characteristics and properties of Kevlar are truly unique. The main feature is considered to be high mechanical strength. At the same time, the mass and density are relatively low.

Kevlar is a material with unique resistance to stretching and self-extinguishing ability. At the same time, it does not burn or melt. Only at temperatures above 430 degrees does it begin to decompose. As a result of exposure to high temperatures, not immediately, but after a certain time, it begins to lose its strength.

It is resistant to organic solvents and corrosion, and has a high elastic modulus. Under the influence of low temperatures, it not only does not deteriorate, but on the contrary, becomes stronger. It is resistant to cuts and has low specific electrical conductivity.

Areas of application of Kevlar

Despite its widespread use and demand, not many people know what Kevlar is. Although this high-strength fiber has found a wide variety of applications for many decades.

Kevlar is mainly used in areas where the following characteristics are important:

- wear resistance;

- thermal stability;

- low structural hardness;

- significant lightness;

- good strength at low weight.

Therefore, it is logical that Kevlar fabric is used to make personal protective equipment, various clothing for military personnel and special forces.

Aviation industry

The properties of Kevlar, what kind of material it is, are well known in the aviation industry. It is used in the production of a number of unmanned aerial vehicles to provide protection.

Personal protective equipment

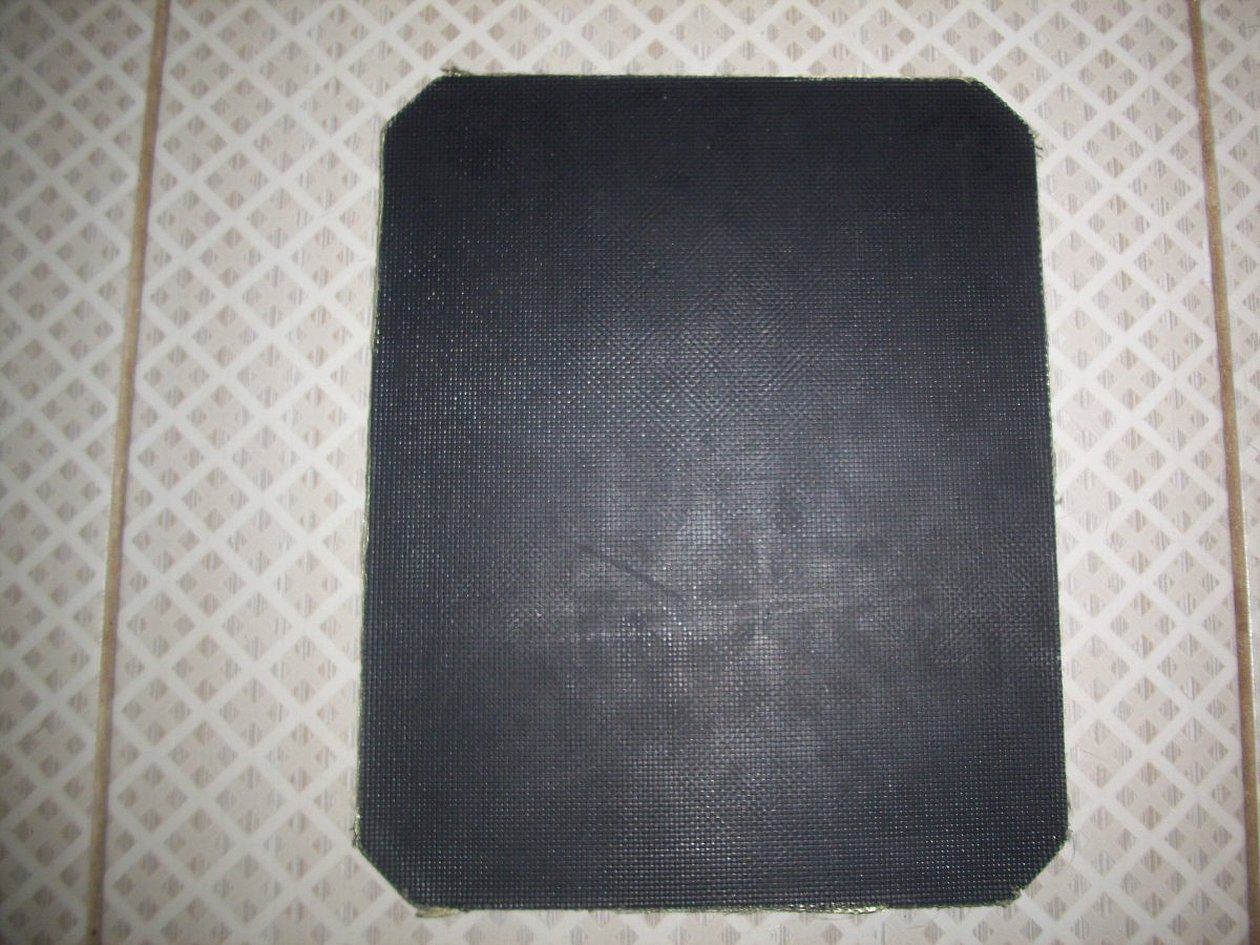

Mechanical properties make Kevlar fibers suitable for the production of personal armor protection. Combat helmets, bulletproof vests, and ballistic masks for face protection are made from it.

Thanks to Kevlar armor, the armed forces of various countries create special bulletproof masks and balaclavas for the crews of armored vehicles. In addition, it is with the help of Kevlar that the armor of the Nimitz-class aircraft carriers is carried out.

Kevlar fiber bulletproof vests are rightfully considered the highest quality. Such armor can provide protection from glancing blows of cold weapons, weaken the impact of bullets, and protect against the penetration and spread of fragments. Protection is provided due to the unique lightness, strength, and relative durability of the material used.

At the same time, when giving preference to Kevlar products, such as bulletproof vests, it should be taken into account that the polymer has certain aspects. Since the armor is soft, it will not be able to protect against a point-blank shot or a penetrating blow with a knife or an awl. For such purposes, special models with special rigid panels are being developed. Another disadvantage is photosensitivity. With constant and prolonged exposure to sunlight, the material begins to gradually deteriorate.

Since Kevlar thread is considered an expensive material, a general "Kevlarization" has not yet occurred. Only economically developed countries can afford to equip their armies and units with tactile products made of this material.

Hand protection

Tactical gloves with Kevlar plate inserts are used to protect hands from damage when colliding with the enemy's teeth, as well as to significantly increase the impact. Such gloves are also called a kind of modern analogue of brass knuckles. Such accessories are in great demand among employees of specialized units, as well as extreme sports enthusiasts, outdoor enthusiasts and street fighters. Such popularity is explained by durability, resistance to moisture and damage, as well as warmth. Hands in such gloves will be fully protected.

Sports equipment

Snowboards, boats, paddles, skis and sports helmets made of Kevlar are lightweight and highly durable. Sports goods made of this material are preferred by both amateurs and professional athletes.

It is this material that helps to minimize vibration transmission, ensure withstanding deformation loads without damage. As a result of the plasticity of the material, products are protected from various serious damages, crushing. In addition, it is completely safe and reliable even under the influence of high impact loads.

Among other things, Kevlar is used for the lining of some bicycle tires. It is what minimizes the risk of punctures. Layers of Kevlar are added to table tennis rackets. This increases the rebound and reduces weight. The material is used to make safe clothing for motorcyclists. It is especially used to replace plastic elements to protect the shoulders and elbows.

Other areas of application

High chemical and mechanical stability indicators, as well as the strength of Kevlar ensure its wide application in various fields. This material is considered one of the most high-tech in the modern world.

Most often it is used for the following purposes:

- As a reinforcing fiber - used to make the material light and strong. It is used to strengthen cables and protect them from breakage and stretching.

- In the process of producing orthopedic prostheses.

- For the production of ropes - products are distinguished by their resistance to corrosion, reliability, low weight, and non-conductivity. Due to these characteristics, ropes are widely used in shipbuilding and mining, replacing steel cables.

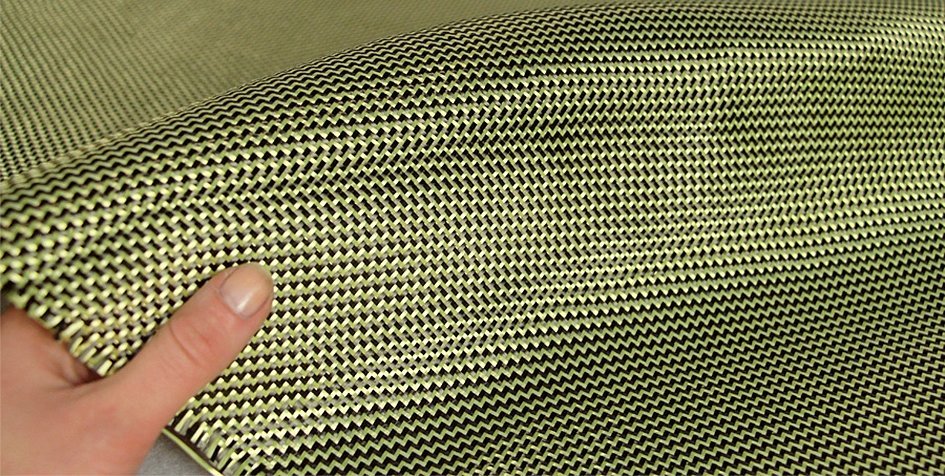

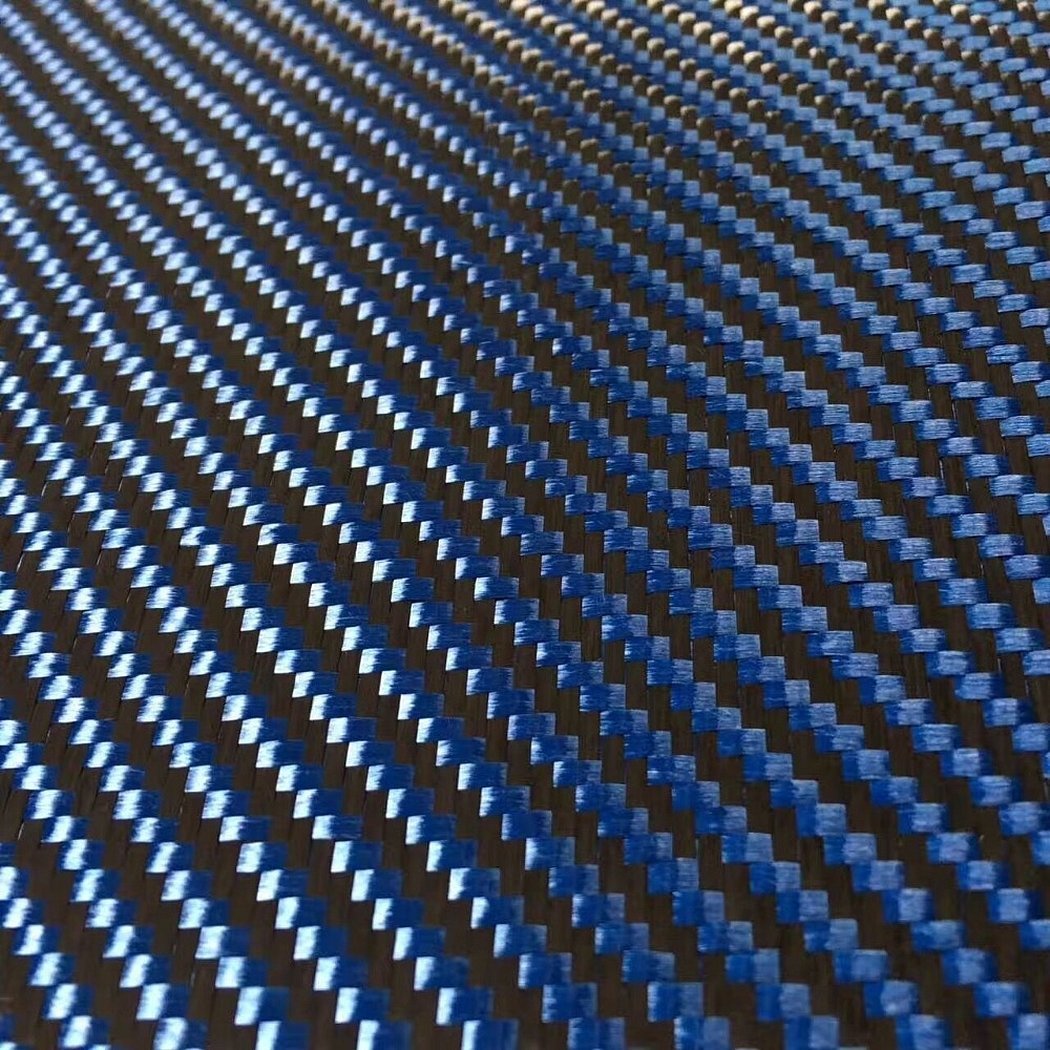

- To obtain a hybrid material called carbon-kevlar, it is used to build boat hulls that are capable of developing significant speeds.

- For the production of the newest super-strong building material called Kevlar concrete - used to make paving slabs, facade stone for walls, monuments, curbs, steps and much more. At the same time, such building materials are quite expensive due to the Kevlar used.

- For the production of fishing line - if a person is engaged in fishing professionally, then he gives preference only to high-quality gear. Also, a Kevlar glove will be indispensable for fishing, especially when catching catfish or pike.

- For the manufacture of crankcase protection - provides a high level of resistance to mechanical damage. It is heat-stable and has a high degree of resistance to chemicals. At the same time, the Kevlar composite is comparatively cheaper.

Kevlar fiber is used in a variety of areas today. It is almost impossible to imagine passive protection without this material, and bulletproof vests and helmets have already saved many lives.