Adhesive material refers to auxiliary fabric that facilitates and speeds up the sewing process. With its help, the product acquires an attractive appearance due to the clear contours of the collar and cuffs. The materials have firmly entered into everyday life; sewing outerwear is impossible without them. Adhesive fabric is used to create things from delicate fibers, chiffon. For beginner needlewomen, it will become a real assistant. The material describes the types of adhesive materials.

Types and properties

Advantages of adhesive materials:

- Long service life:

- drapeability;

- the ability to choose double-sided or single-sided adhesive coating;

- durability, self-adhesive fabrics for clothing will not tear;

- flexibility.

Adhesive bases last longer than non-woven ones. When the product is turned inside out, the fabric does not form rigid folds. But all materials differ in density and are divided into 2 main groups - elastic and non-elastic.

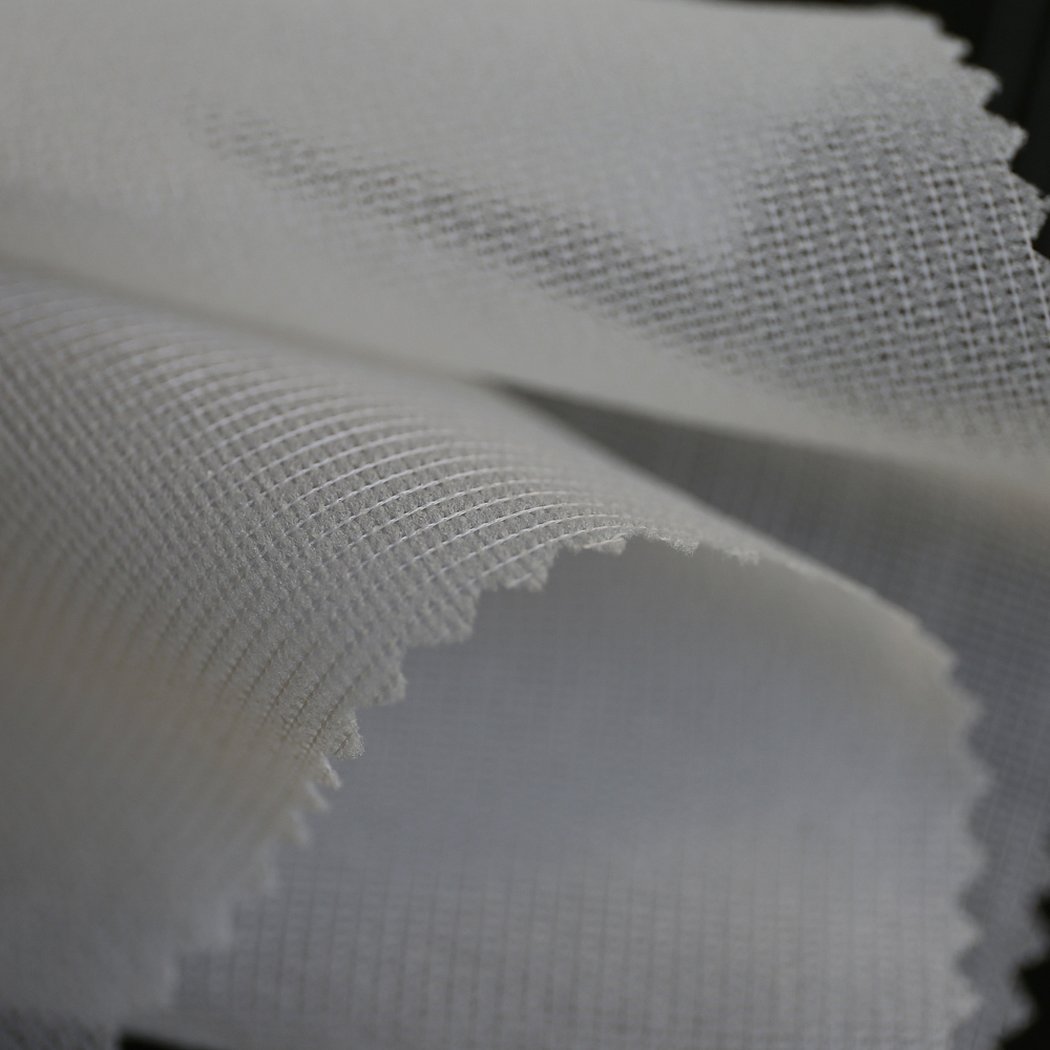

Non-elastic patches are hard and soft. The base is made of cotton or polyester. The fabric does not stretch, it is used to give products strength and shape.

Elastic types are made of thin lint-free knitwear for the second layer of thin fabric, lint-free knitwear for soft items and hard items. Adhesive tape is divided into subtypes: thread-stitched on a base of calico or interlining. It is used to strengthen round parts.

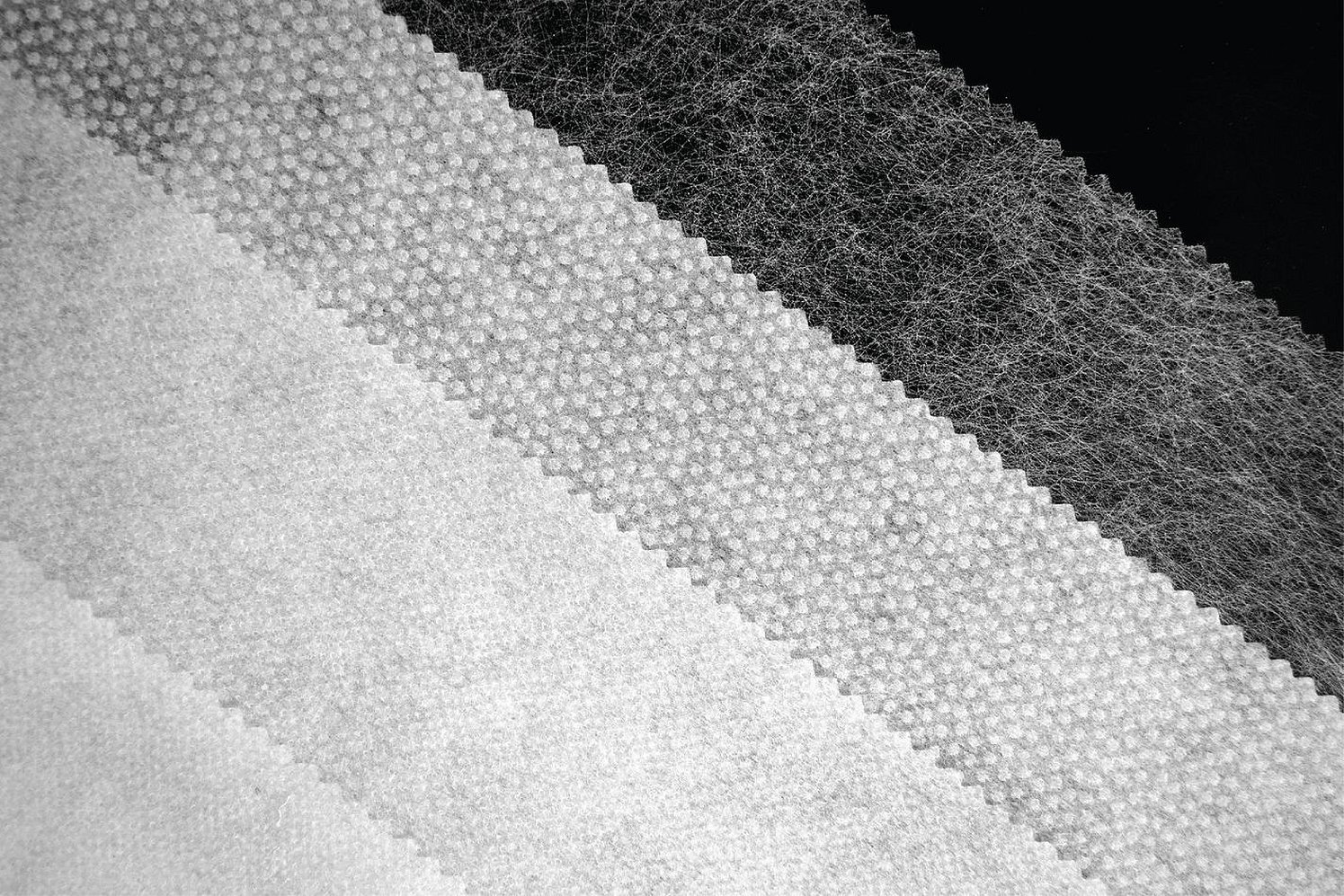

Hot-melt interlining fabrics are textile materials - knitted, non-woven fibers, on one side of which an adhesive dot or strip coating is applied.

Women often ask what is the name of the adhesive tape for fabric with an iron. This is a spider web, which is a non-woven isotropic material that is created from a polymer melt using the aerodynamic molding method. The spider web is produced in the form of strips or a sheet. The material fastens the edges of clothing, acting as hidden seams.

The adhesive thread is a monofilament made of synthetic polymer. The product is designed to fasten the edges of clothing. An adhesive coating is applied to the edge materials. The products are sold as ready-made edges or sheets. Hot-melt edges are necessary to protect the folds of elements from stretching.

The adhesive film is made from a number of polymers. It is used to make appliques, seal thread seams. Flizelin is distinguished by a continuous or point location of glue. The material pro-clamelin allows you to make overlays in the chest, shoulders, for laying in small elements when sewing a coat.

rImportant! Interlining and interlining are sold in the form of a sheet. They are purchased to maintain the shape of an item, for decoration and to add rigidity.

How to choose correctly

When choosing a fabric with an adhesive base, you need to take into account the main rule - the material can be harder than the main one, but in no case denser. It is recommended to test on several samples. Take squares of the main material with a long side of about 15 cm, several pieces of the lining smaller in size. Then duplicate, glue with an iron.

After thermal exposure, the pad becomes harder, but not equally, but to varying degrees. This will be noticeable on the samples. Some colors become darker after gluing. Sometimes the base fabric, its shade changes, protrusions appear on the front side.

Important! It is recommended to check how the main fabric drapes with the interlining on the glue. All samples are folded in half and it is observed which of the options is the most suitable.

If the fabric is dense and thick, then high-density linings are selected for it. For thin materials, it is better to take interlining. When choosing an adhesive lining, it is worth considering the desired rigidity. Depending on the indicator, recommendations are given:

- For sewing blouses, silk and viscose dresses, soft interlining H180 is used.

- When creating blouses and dresses from thick material, choose interlining H200, H250.

- Strong interlining H310 is suitable for sewing linings for coats, suits, wool, denim and trouser fabrics.

- If the owner has chosen interlining, it is better to glue it to a pre-moistened adhesive fabric for clothing repair. This is done to prevent subsequent shrinkage of the item.

- Experts recommend doing a test ironing on a small area of fabric. This will help set the correct temperature, humidity and steam.

- Dublerin cannot be used to fix small parts or elements made of thin, soft material.

Sometimes interlining is replaced with interlining, but it is worth remembering that the thickness of the product will increase.

How to use

It is very difficult to tear off the glued fabric. First, you need to iron the part. This will help soften the adhesive. Then you can tear it off. After that, remove the remaining glue.

If after applying the fabric on the front side a line is visible between the fastened and unfastened section, then the edge of the interlining needs to be fluffed up a little. Students often write essays on this topic with a practical visual part.

How to use for clothing repair

Adhesive material for garments is sprayed with water from a spray bottle. Then it is laid out on a flat surface and left for 30 minutes to dry. If you ignore this action, the fabric will shrink after the first wash. As a result, the clothes will be skewed and unsightly folds will appear on them.

Important! When cutting, you need to pay attention to the direction of the grain line - it should match that of the main fabric. There is no need to make seam allowances, there is no need. Otherwise, the edge will become voluminous and dense.

How to use fabric adhesive tape:

- The purchased part is applied to a specific area of the fabric. It should be placed with the rough side facing the wrong side.

- Then iron with an iron that has been preheated to 100°C.

- If the surface of the treatment is voluminous, then each centimeter of the product must be pressed and held for 5 seconds. During this time, the composition will melt and begin to work.

Brands and prices

The main manufacturers of adhesive products are the following brands:

- Hansel, Kufner, Fulda - Germany;

- Baldin, Koenig - Belgium;

- LanourPicardie - France;

- Wilen - UK.

In Russia, the materials are produced by a company called Mamontovka, located in the Moscow region, and TIM Holding in Krasnoyarsk.

Important! The company, known as the first developer of interlining, also produces adhesive synthetic padding.

The latest technologies make materials of higher quality, namely:

- increase the strength of connections;

- increase shape stability;

- ensure compliance with environmental cleanliness requirements;

- save thermal energy by reducing the temperature and time of the material bonding process.

The Russian market sells products from the Japanese manufacturer "Heimo". This company has been a leader in Japan in the production of adhesive materials since 2009. The company entered the European market, gradually gaining momentum.

The company has achieved trust and status thanks to a combination of unrivaled quality and flexible prices. The company strictly controls the production of materials at every stage. The manufacturer offers customers a wide range of products.

High-tech equipment used in the creation of fabrics has allowed the products to regularly enter the European market. They are purchased at an affordable price in any quantity. The products have received certificates in Russia. It has been tested and concluded that they fully comply with the standards and technical requirements.

Adhesive products from the manufacturer Danelli offer patented materials. They allow you to duplicate fabrics even at 5 degrees. The parts will remain resistant to washing and chemical treatment.

The company produces all types of materials needed for sewing outerwear, blouses, trousers. The popularity of this brand is due to the technology of applying glue to the surface. It is distributed by computer, a clear distance between the points is observed. High quality of gluing with any coatings is guaranteed.

Average cost of materials:

- an applique product measuring 100×50 cm costs 170 rubles*;

- interlining for a collar 260 g/m2, 112 cm wide will cost 360 rubles;

- a spider web on paper 112 cm costs 340 rubles;

- spider web in a roll version, 83 cm long, 112 cm wide - about 5000 rubles;

- interlining 75 grams per square meter, 100 cm wide - 80 rubles.

How to care for adhesive fabric

Care for the material is mainly related to the type of fabric it is glued to. You need to look at the label on each garment. It contains recommendations for washing and ironing.

Washing products with a lining in hot water will not damage the clothes. When ironing, do not place the heated soleplate of the iron on areas that contain glue. If you iron these areas, it will be difficult to remove the residue later.

Adhesive materials are an excellent alternative to simple glue. Self-adhesive fabrics are used in industrial production, and women buy them for home use. It is easy to work with the products - they will stick with a hot iron. The scope of application is wide - as a lining, the fabric will weigh down and insulate the main material, give the clothes shape, rigidity and density. Adhesive models are indispensable when sewing coats, jackets, fur coats, for processing the edges of trousers, skirts, creating hangers, small details.

*The prices indicated are valid as of July 2019.