In the modern world, it is difficult to meet a person who would not know that water-repellent materials exist. In the creation of things for hunting and fishing, tents, clothing for active recreation, ordinary outerwear, you can not do without the use of water-repellent fabrics. A huge number of scientists are working on the latest fabric manufacturing techniques, increasing thermal insulation, the ability to withstand low temperatures, resistance to deformation and getting wet things. This article tells about what waterproof fabric is, how to care for it and which one is better to choose.

Waterproof fabric: name and types

Water-repellent fabric is made of polyester and nylon. The most common types are:

- Taffeta. Made from nylon or polyester, the back is treated with a protective film. This soft, dense material has an increased vapor absorption system, is not damaged by water, does not change color and does not shrink when washed. It is mostly used as a lining fabric. Winter jackets are mainly made from it.

- Taslan. The material is polyamide, it has a special appearance, similar to a small rib, formed due to the rep weave of threads. It is protected from moisture and dirt by milky impregnation. It also removes sweat. A favorite fabric in industry, for making jackets.

- Oxford. Dense, coarse, water-repellent fabric, made using a burlap weave. Very resistant to chemicals, highly durable and heat-resistant.

- Duspo. Of all the waterproof materials, Duspo has a matte surface, which gives things a chic look. It is very popular in the creation of children's multi-season clothing.

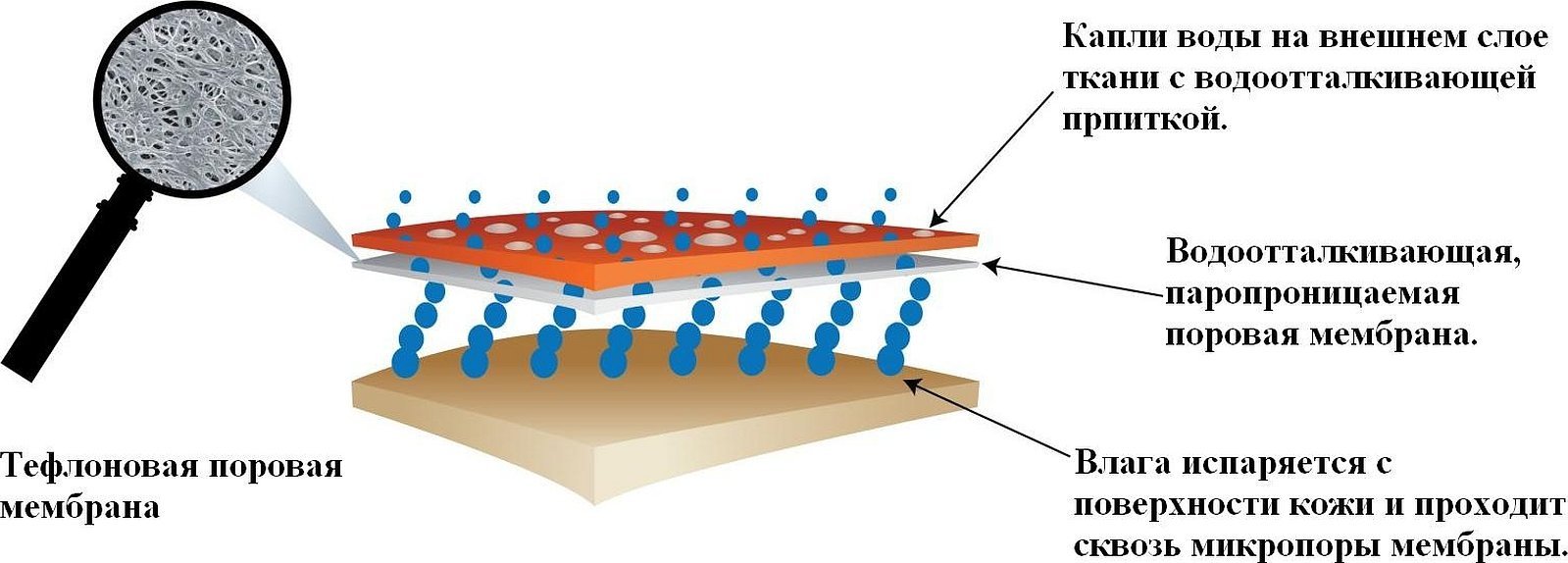

- Membrane. The material is created using new technologies, has complete impermeability and protection from drafts. It is created by spraying a transparent polymer porous mesh onto a synthetic fabric. Items made of the membrane perfectly repel water, do not get wet in the rain, are used in the manufacture of special clothing for rescuers, equipment for mountain sports, etc.

- Acrylic. It tolerates frosts quite well, is resistant to water and dirt. It is made in half with natural and synthetic fabric. Very durable material.

- Tyvek. Lightweight, yet dense, waterproof fabric. It is mainly used to make tents, car covers, and marquees.

- Tarpaulin. Has increased wear resistance and water resistance properties. Has a hydrophobic membrane.

How Waterproof Breathable Fabrics Work

The inner part of the garment made of moisture-resistant fabric becomes waterproof and breathable due to the following technologies:

- Laminates (laminate membranes) are formed when a membrane is attached to the back of the material. In the same way, wallpaper is glued to the surface of the walls - in other words, the membrane (wallpaper) and the material (wall) are the final result - a laminate flooring.

- The coating is a liquid preparation that gives the material waterproof and breathable qualities when applied to the interior. It is like applying paint to a wall.

The outer surface of the products (face material) is treated with a professional water- and dirt-resistant finishing impregnation to protect them from water.

The following are the aspects of impregnation:

- The impregnation only affects the outer part of the product and does not apply to laminates or coatings.

- Its function will be to protect the front part of the material from water penetration and, as a result, from sagging of the material and a feeling of moisture.

- Thanks to the impregnation, moisture collects in drops on the surface of the product and quickly falls off.

- The impregnation does not affect the breathable properties of the material.

- When washing, the effectiveness of the impregnation decreases due to its washing out.

Important! To ensure that the impregnation does not lose its properties, the products need to be cleaned, and the impregnation needs to be renewed occasionally. Special solutions and cleaning agents are used for this purpose.

Purpose and application

To make the fabric water-repellent, special impregnations are used for it. The impregnation itself is needed not for the membrane, but for its front side. Because basically, only the outer layer of things or shoes is exposed to water.

What happens if an unimpregnated product gets wet?

- The moisture absorbed by the threads will fill all the air spaces in the product and create a problem for the free release of steam. The breathability of the fabric will drop sharply - the vapors have nowhere to go and the person will sweat.

- If the material gets wet, the overall thermal conductivity of the clothing layer will increase, meaning it will be cold.

- Wet clothes immediately become heavy.

To avoid such problems, you can use DWR impregnation.

For outdoor furniture

Waterproof fabric for outdoor furniture is made from synthetic threads that are highly durable.

Attention! Acrylic materials have the highest properties, and they feel the same as soft fabrics made of natural threads. In addition, impregnations are always used in production, giving the material water-repellent characteristics and resistance to dirt adhesion. They are mainly used for furniture fabrics in large shopping centers, garden furniture.

For clothes

To create waterproof fabric for clothing, materials that contain 100% polyester with a layer of special impregnation are mainly used.

They are most widely used in the textile industry today.

Synthetic waterproof fabric Oxford is becoming increasingly popular in the production of children's and sportswear, as well as equipment for active recreation.

In the industrial manufacturing process, it is treated with a polyurethane film layer, which makes things waterproof. Both 100% polyester and 100% nylon can be used in production. These materials are resistant to dirt, abrasion and mechanical defects, but nylon items are very cheap and light, and also have high elasticity.

For covers

Mainly used waterproof fabric for Jordan covers. Its surface is thick, smooth with a slight shine and characteristic shimmer. It is quite soft and pleasant to the touch. The material is distinguished by increased dimensional stability: during use, the waterproof fabric does not stretch or shrink after washing.

The milky type with a grey water-repellent coating applied to the back of the product is widely used. In addition, a double waterproof fabric with knitwear inside is also made, which is used in sewing warm clothes.

The versatility of this fabric allows it to be used for sportswear and suits, jackets and down jackets, some shoes, bags, covers and many different things. It can easily be dyed in the most juicy shades, for covers, camouflage and swamp colors are mainly used.

Advantages and disadvantages

Pros and cons of water-repellent fabric:

Such materials have a number of positive qualities, in comparison with other types of textiles:

- Diagonal weave. A special weaving technique allows achieving high water-repellent properties of the fabric.

- High density. The moisture-resistant fabric has a smooth and slippery surface, from which water drops flow freely and do not penetrate deep.

- Versatility, comfort and practicality. Synthetic thread in the fabric structure helps to achieve increased consumer properties: bright color, strength, high durability and long service life of finished items.

Disadvantages of such clothes:

- The most obvious disadvantages are typical for inexpensive materials, which are mostly 100% synthetic. They let water through and are not safe to wear.

- Good membrane clothing is very expensive.

- It can be damaged if washed incorrectly.

- Short-lived.

- For such things you need special thermal underwear.

It is necessary to remember about the care of such fabric. Before using the impregnation, the item must be washed, for this it is necessary to use the following rules:

- First, check the product tag. There may be instructions on it.

- The washing machine must be completely clean, if there are any powder residues, they must be removed with a wet cloth. This is a very important point.

- Use only liquid detergents for membrane materials.

- The washing temperature should not be more than 40 degrees, otherwise the clothes will lose their properties.

- Rinsing is carried out several times until the water becomes clear.

- It is allowed to wring out the product, but at low speed. The machine simply will not be able to wring out the product completely, so when you take it out, it will be very heavy.

Important! Do not use conditioners, stain removers or bleaches, they may damage the integrity of the product. It is recommended to dry at room temperature, in an upright position. Avoid direct sunlight, so as not to damage the structure and properties of the material.

In conclusion, it should be emphasized that things made of waterproof materials are gaining popularity. Previously, these were only suits for fishermen and hunters, now almost everything can be made from such fabric, from outerwear to car covers.