Rubber fabric has long been used in various industries. From clothing to equipment that is protected by rubber. Modern factories and enterprises have charters and rules that stipulate the need to use protective materials. This article tells about what rubberized fabric is and what functions it has.

How to get rubber-impregnated fabric

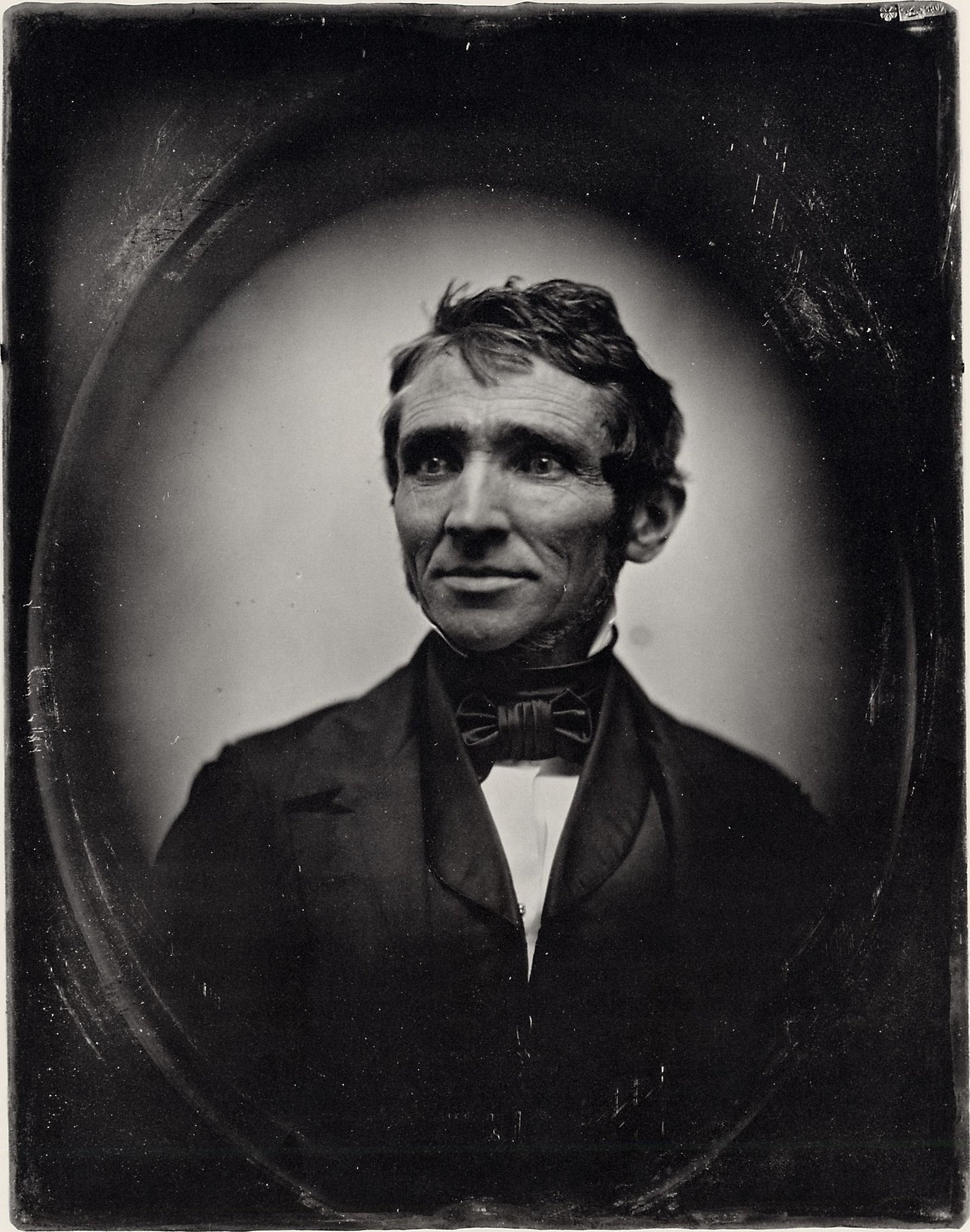

In the 17th century, unusual trees were found in South America. Their sap instantly set in the open air like glue, only stronger. Since then, scientists around the world have been looking for ways to use it.

In England, one scientist mixed the juice of this tree and turpentine, and then began to coat the fabric with this mixture. He discovered that water did not penetrate deep into the fibers. Since then, rubberized items have been produced.

Please note! Natural materials are usually used as a base: thin or thick strong cotton, calico, silk, wool. But sometimes synthetics are used: nylon or capron.

Rubber is applied using the following methods:

- Rubberized device (a thin layer of the composition is applied to the fabric);

- Lubrication;

- Lining on calendars.

When working on a glue spreading machine, rubber glue, which is 90% gasoline, is spread on one side of the material, which then evaporates during work.

The next step is the process of continuous vulcanization and the transition of rubber into rubber. This process was discovered by scientist C. Goodyear in 1845. It was called Vulcan-God of Fire. Its essence lies in the contact of rubber with sulfur and hot processing, after which its molecules merge into a common spatial network. As a result, the strength, hardness and flexibility of the fabric increases, and its plasticity and ability to deteriorate and dissolve in water decreases.

When using rubberized items, avoid contact with sharp objects, because in case of a cut, all its positive properties will be lost. Mechanical defects cannot be sewn up, so professional repairs will be necessary. Contamination can be quickly removed with a soft cloth or sponge soaked in soapy water. After that, soap stains should be removed with a clean cloth. If the product has been stored for a long time and has become very hard, it must be soaked in water with ammonia. Do not clean with gasoline or White spirit.

Types and properties

Such materials can have different densities and thicknesses, depending on where they will be used.

There are single-layer, double-layer and multi-layer. The first are divided into single-sided and double-sided. In others, the fabric base is formed between two layers of rubber. In multi-layer, many layers of rubber, material and felt can be formed.

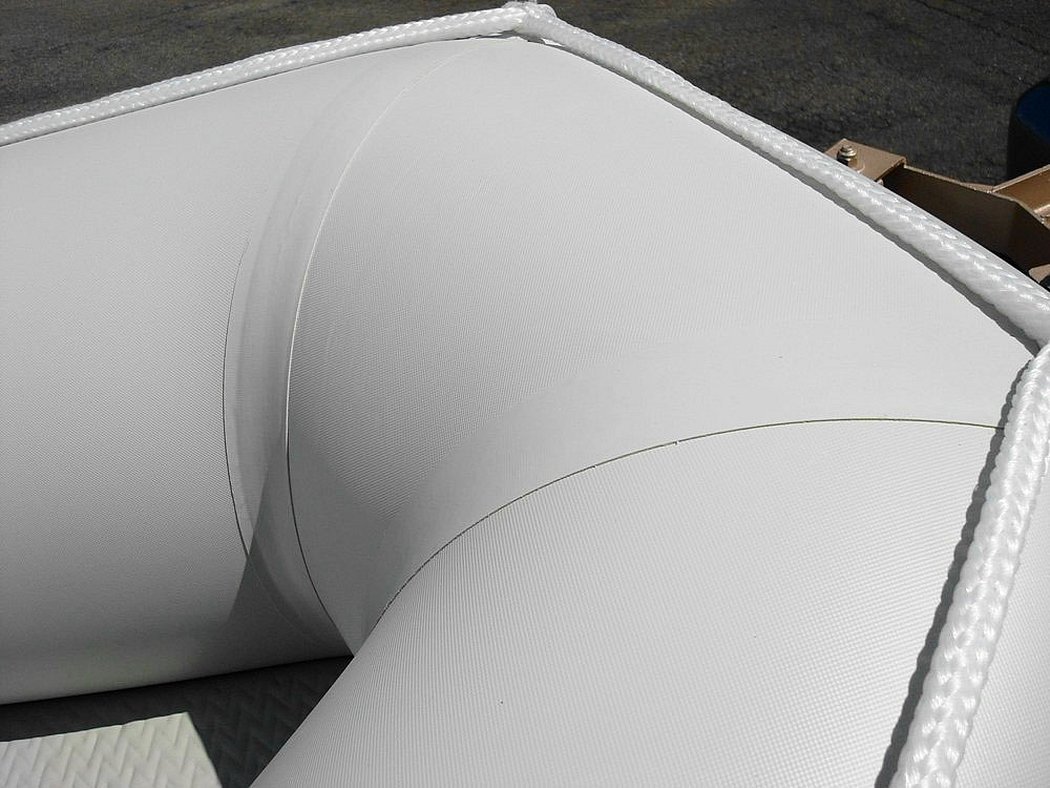

Balloon clothes with a rubberized surface are mainly made of silk or wool. They are comfortable and durable, they have a fairly low gas permeability due to the application of more than 10 layers of glue. They are used to make aerostats, stratospheric balloons. Oil and gas plants use oilcloth fabric to build membranes, containers, curtains, repair wheels, etc. Many special services have equipment rubberized with rubber. Tourist and sports equipment also cannot do without the use of waterproof materials. Inflatable boats, awnings, sleeping bags and tents, backpacks and many other things, including inflatable ones, are made from it.

All such fabrics have a number of properties:

Resistance to damage. Due to the dense base, the material can withstand ruptures and deformations, especially if it contains synthetics;

- Water repellent. The rubber layer repels water drops well;

- Resistance to stretching and abrasion;

- Quite low vapor and gas permeability;

- Resistance to detergents.

The material can withstand river water, various solutions. To increase the resistance to aging from ultraviolet radiation, various color dyes are added to the material, which can absorb sunlight.

Children's waterproof clothing is often made from such materials. But it should only be worn in necessary situations; the rest of the time, the skin should breathe.

Before purchasing or rubberizing a product, you need to look at the density table. For each area of work, you need a suit with certain indicators.

For technical purposes

Rubberized fabric for technical purposes is used in the production of inflatable items - waterproof suits, for equipment, medical products. They combine increased strength, water resistance, resistance to low temperatures and resistance to detergents.

Balloon materials will be the most important type of fabric for technical purposes. They are mainly used for the shells of aerostats, airships and stratospheric balloons. In the creation of balloon products, only strict rules are used in terms of control and systematic laboratory research.

Such rules are prescribed in the technical conditions for cylinder products, which define low gas permeability, low weight and high strength.

Many industrial enterprises, where work is carried out with welding, machine tools and other dangerous equipment, use rubber suits and shoes. This helps to avoid accidents, for example, shavings bouncing off the metal during cutting fall on the suit, and not on the bare hands of the person. It can leave deep scars, so it is better to ruin the suit than to get injured.

Use in clothing.

Why rubberized fabrics are used in clothing.

- Price: this is one of the advantages of the fabric, the price is one of the lowest on the Russian market.

- Practicality: clothes made from such materials can be worn in any weather, and are also very easy to care for.

- Versatility: but, unfortunately, such things cannot be worn every day. They do not allow air to pass through well and a person will sweat constantly.

- Durability: such things are not the most durable; if you don’t fall carefully or catch them on a wooden branch, they can be torn.

It is very convenient to have an oilcloth suit for fishermen or hunters, people involved in active and extreme sports that are exposed to various climate changes (heat, rain, snow). Tents with rubberized fabric are very effective.

These can easily withstand thunderstorms, without the risk of moisture getting inside. But the most popular are boots. They are very comfortable to walk in mud and water. People involved in the field of electricity, according to the rules, must wear only such shoes. So that the discharge does not pass through the body.

Is it possible to rubberize fabric at home?

At home, you can rubberize the fabric using various impregnations. However, you need to choose a high-quality and popular manufacturer so as not to spoil the item. Many companies add various chemicals to the composition, which can be hazardous to health.

Types of impregnations

Type WR

The most common type is WR impregnation, which is applied exclusively to the outer part of the product. The treated material is not susceptible to getting wet, as drops of moisture roll off it.

Also, the material does not become covered with fungus at high humidity, since the protective layer does not allow even small liquid molecules in the form of steam or fog to pass through.

Polyurethane impregnation (PU)

On the contrary, it should be applied inside the product. The item may get wet on top, but the moisture will not be absorbed completely. However, it does not withstand severe frost conditions and at a temperature of -25 it begins to crack and lose its qualities.

DuPont impregnation

It is somewhat similar to WR, but unlike it, it is applied to materials that are used in more severe conditions. This impregnation is more often used for furniture upholstery, tents and jackets. It is mainly used in industrial zones in the Far North.

PD impregnation

Apply to the inside of the product, it not only prevents the fabric from getting wet, but also makes it much stronger. Sometimes it is used in combination with other impregnations and applied. Relatively cheaper than all the above-mentioned compositions. But it is not inferior in quality.

In conclusion, it should be noted that rubberized fabrics are very popular in various fields of activity. You can do this process yourself, but for this it is better to watch various video tutorials. It will be a little cheaper than buying a ready-made thing.