Oxford fabric is traditionally used for sewing men's shirts. Due to its high strength, wear resistance, water resistance and durability, it is quite popular among buyers. Now there are a huge number of varieties of this material, so everyone can choose the right fabric.

History of origin

Initially, the fabric consisted of natural fibers (pure cotton), at the end of the 20th century, they began to add admixtures of nylon and polyamide. Over time, they began to create a completely synthetic material, thanks to which it became possible to use it not only for clothing, because the main characteristic of oxford fabric was high strength. A new stage is the creation of special coatings. Thanks to this, the fabric acquired such properties as protection from water, high temperatures and chemical reagents.

Important! At the moment, the Oxford brand produces a wide variety of materials that do not belong to the classic fabric.

Despite the fact that the name of this fabric has an English origin, its homeland is Scotland. Shirts made of this fabric gained the greatest popularity thanks to Oxford students. Today, many students of American universities wear this uniform, thereby demonstrating the prestige of the educational institution. This material is also very popular among office workers, as well as adherents of the preppy style. It is known that the modern through-through button-down shirt fastener first appeared in a polo uniform made of Oxford.

Features and specifications

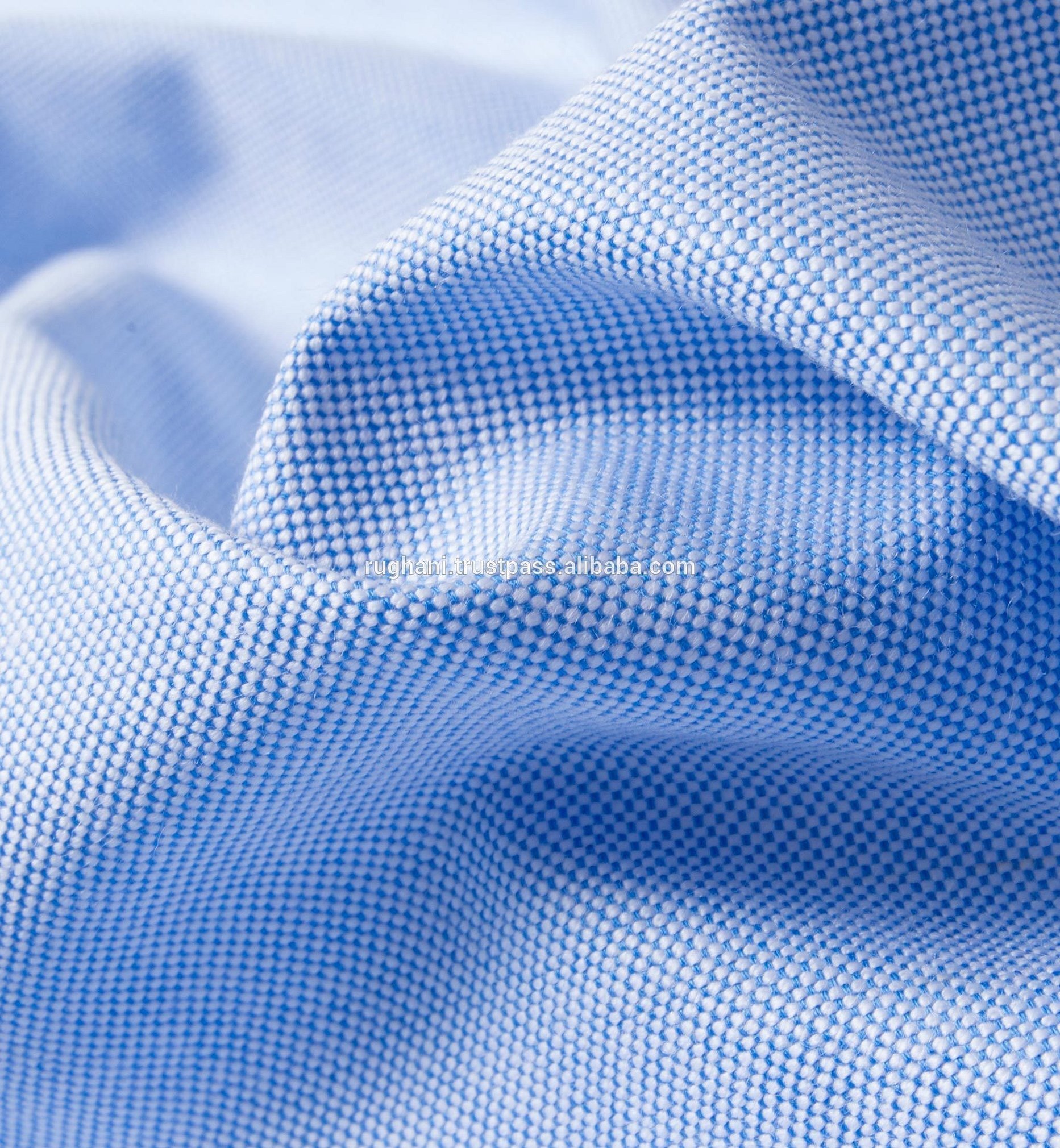

The main characteristic of this material is its relief structure, which is created by a certain method of weaving. The fabric has a special type of weaving - a basket weave or Panama weave (from the English "Basketweave") - the warp and weft threads create a kind of chessboard.

Please note! The main feature of this weave is that, unlike the classic version, the warp and weft threads are not intertwined separately, but in whole groups. Due to this, the fabric has a certain texture.

One should not forget about such characteristics as the composition and thickness of the threads.

These features make up the main properties: strength, moisture resistance and reliable protection from weather conditions.

Types and areas of use

Based on the material, oxford fabric is classified into two types:

- Nylon. It is based on nylon fibers. This fabric has high strength, elasticity, resistance to various damages, abrasion, and chemical exposure. But it can accumulate static electricity, and also does not cope well with high temperatures and light.

- Polyester. Consists of polyester fibers. The material is less durable, but has excellent light and heat resistance, and is also resistant to chemicals.

For your information! The scope of use is directly related to the thickness of the thread used.

The fabric is used for the production of:

- clothes;

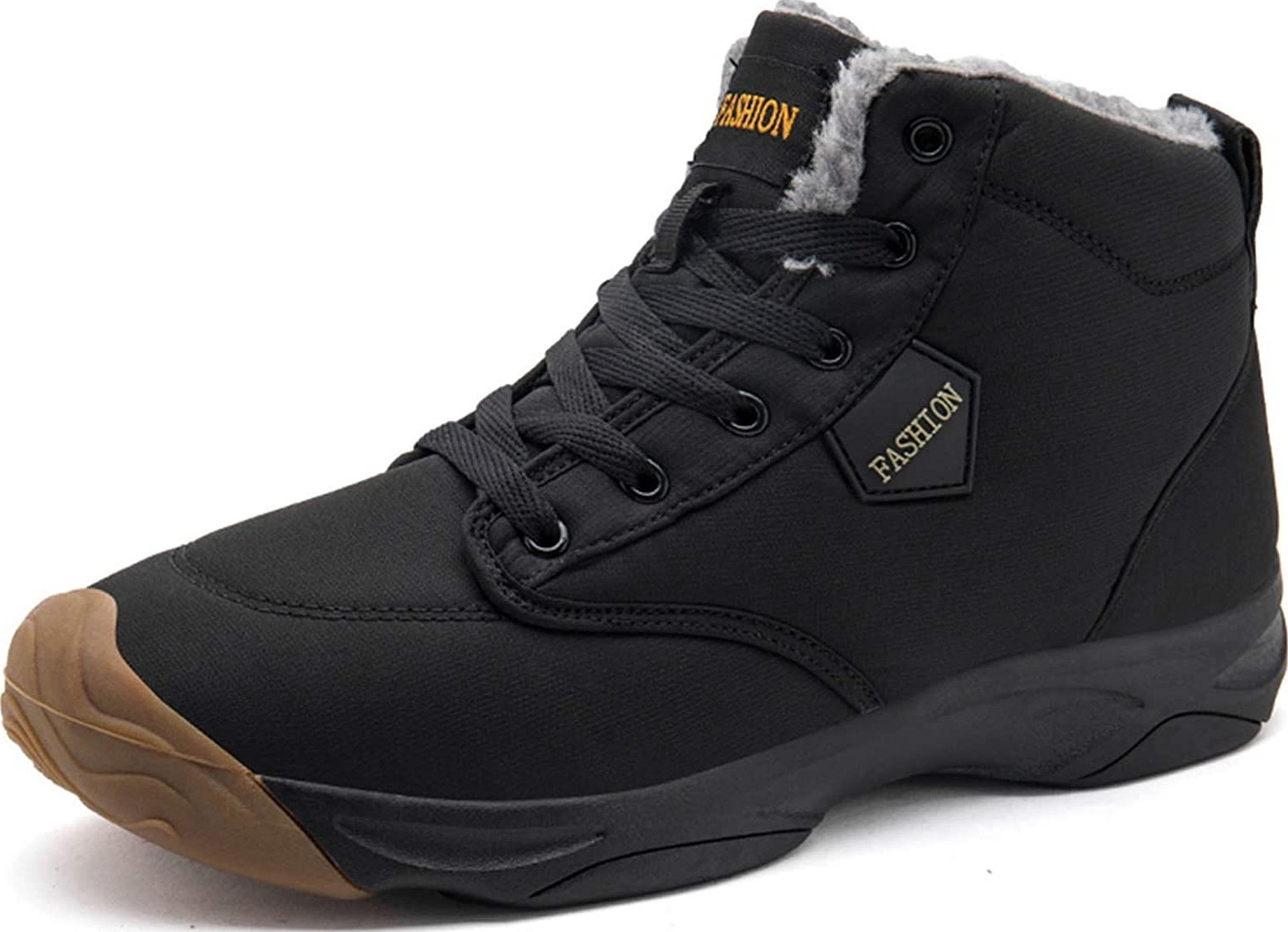

- shoes, bags and backpacks;

- tourist tents and awnings;

- special clothing;

- covers for various vehicles;

- special forces clothing.

Marking

The thickness of the thread is designated in Den (dainir) and determines the density of the fabric. The higher its value, the more pronounced the basket texture of the Oxford.

There are only two types of water-repellent coating:

- PU (polyurethane). Transparent, makes the fabric waterproof and windproof due to its application to the reverse side. It is resistant to organic solvents and skin secretions (sweat, etc.).

- PVC (polyvinyl chloride). Provides complete waterproofness. Has resistance to chemical reagents, has high fire resistance. It is also applied to the back side of the fabric.

According to density, the following types are distinguished:

- 210D. Quite a dense fabric. Widely used in tourism. This material is used to sew clothes for hunters and fishermen, life jackets, raincoats, and also to make shoes. In addition, the uniform of security personnel and law enforcement agencies is most often represented by this variety.

- 240D PU. Distinctive feature - impregnation from polyurethane composition. Used for similar purposes with 210D, but this fabric is more durable and protects well from water and dirt.

- 300D PVC PU. Hard and dense material impregnated with polyvinyl chloride and polyurethane. Shoe and haberdashery production are added to the above-mentioned areas of use.

- 1680D PU. Has the most attractive structure. Covered with polyurethane, has high water resistance and density. Excellent for making covers and curtains.

- 1680D PVC. Covered with polyvinyl chloride, less flexible and frost-resistant, less resistant to folding than 1680D PU, but denser.

Important! The 1680D PVC variety is twice as heavy as 1680D PU.

What is sewn from this fabric?

The fabric is used to make many things: various types of clothing, footwear, haberdashery, fishing, tourism, hunting and recreation equipment, vehicle covers, advertising banners, posters, furniture production, etc. The use of this material is widespread, it is used in all areas of light industry, because the density of the fabric varies from 150D to 1800D. The fabrics can be thin and very dense, hold their shape well and fold comfortably, drape perfectly.

Please note! The color range of Oxford fabric is directly related to the items made from it.

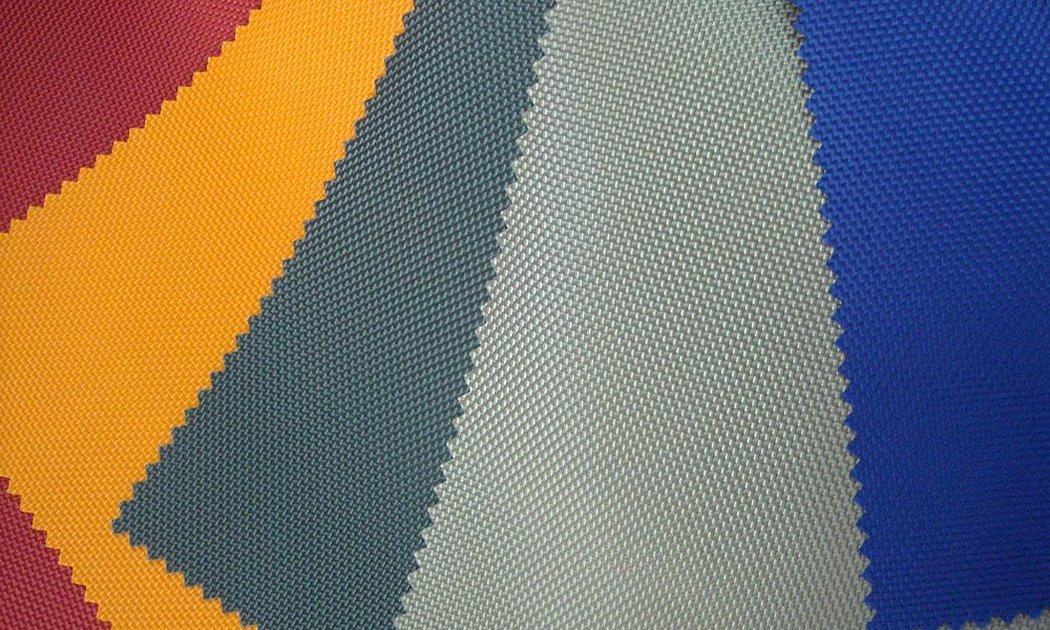

Since the scope of application is quite narrow, this material cannot boast a wide variety of colors. The classic option: black, gray, blue, green and khaki colors. Prints in white-green and white-blue stripes of various shades are very common. Less common are such tones as white, yellow, orange and red. Fabrics with camouflage print and luminescent coating are specially produced, sometimes neon colors are found. The fabric can also be dyed with special paint.

Rules for the care of products made of oxford fabric

Caring for such items is not particularly difficult, because the fabric repels dirt and water. If a small stain is found, it will be enough to simply wipe the area. You can wash in a washing machine or by hand, or take it to a dry cleaner. The permissible water temperature is 30-40 °C. If there is heavy contamination on the surface, such as soil or chemical reagents, then before washing they must be cleaned under a strong stream of running water.

Important! Most varieties of oxford are not afraid of exposure to chemical reagents, so almost any detergent will do, but only in liquid form. It is important to remember that each type of this material has its own impurities, so you should first study the composition.

After washing, you can rinse, wring out and dry the items in the machine, but do this at low temperatures. Iron in the "Synthetics" mode.

Fabrics and products made from them must be stored in a closed place, away from direct sunlight.

Main advantages and disadvantages

Oxford fabric is widely used due to a large number of properties that you will not find in the description of other popular fabrics.

Among these advantages are:

- large selection;

- high strength, which results in the absence of breaks and bends in the material;

- excellent water resistance, dust repellent ability;

- has good heat resistance. The fabric retains its qualities at temperatures from -50 °C to +110 °C;

- withstands exposure to sunlight;

- no special care is required, the material is easy to wash and does not lose color;

- You can buy a piece of fabric quite cheaply (from 160 to 37 thousand rubles per 1 m)*.

However, such a wonderful fabric has its drawbacks:

- poor air exchange. Due to the synthetic composition, items made from this fabric are not suitable for long-term wear and physical activity;

- small choice of colors;

- rustling of material.

Important! The disadvantages of the fabric depend on the original material and the coating used. For example, a fabric made of polyester will not be dense and flexible enough compared to nylon. In turn, unlike the former, the latter is easily burned by sparks.

Despite possible disadvantages, do not forget that oxford fabric has a pleasant and beautiful structure, is durable and wear-resistant. It is very important to choose the right type of fabric for the intended purposes and carefully study its characteristics.

Reviews

Olga, 34, Nizhny Novgorod: "My husband and son are into rock climbing. I sewed gear for them, I have no complaints. It doesn't let moisture or dirt through, it's windproof, the weather conditions of this fabric are absolutely irrelevant! It's easy to wash, he doesn't pay attention to the chemicals in the washing powder. My men are happy!"

Sergey, 43, Kazan: "My friends gave me a whole hunting set for my birthday, all made of oxford fabric. I actively use the jacket, pants and backpack. A super thing! Three years already, and they are like new."

Svetlana, 28, Saratov: "I had a tailor make a jacket, I've been wearing it for the third season. It's warm, windproof, precipitation is not a problem. I'll definitely make more! It's indestructible! The fabric is, of course, thick, you can't wear a T-shirt made from it every day...".

Of course, Oxford will be useful to everyone, regardless of their goals and objectives. Thanks to its excellent characteristics, it is widely used both among professionals working with fabrics and among ordinary people.