Clean air and drinking water are a natural human need, so filter materials are used everywhere. But the scope of application of filters is not limited to air and water. Many industries cannot do without filter fabrics of various types.

What kind of "beast" is this?

In various industries, there is often a need for cleaning. Liquids, air, and gas need to be cleaned from small particles and sediment. It is for this purpose that various filter fabrics are produced.

For each specific case, it is necessary to select the fabric taking into account the cell size and fiber composition. The filter fabric must meet the following parameters:

- avoid contact with elements of the working environment;

- ensure the separation of contaminants and impurities from a liquid or gas.

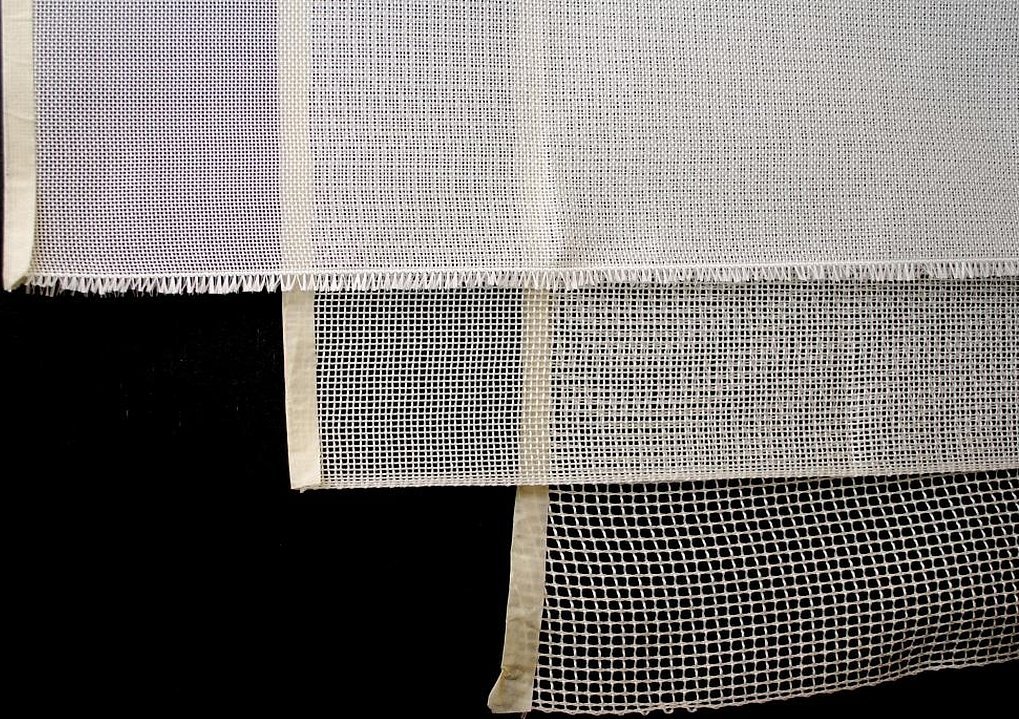

The ability to retain impurities on the surface depends on the weaving method of the fabric, the thickness of the threads and its density. High density and significant thickness of the threads in combination with strong weaving will provide high filtering capabilities of the material. All fabric filters belong to the group of porous filter materials.

Production of filter materials

The diversity of filter materials is due not only to the dynamic development of textile production, but also to the modernization of systems for cleaning the environment from harmful emissions.

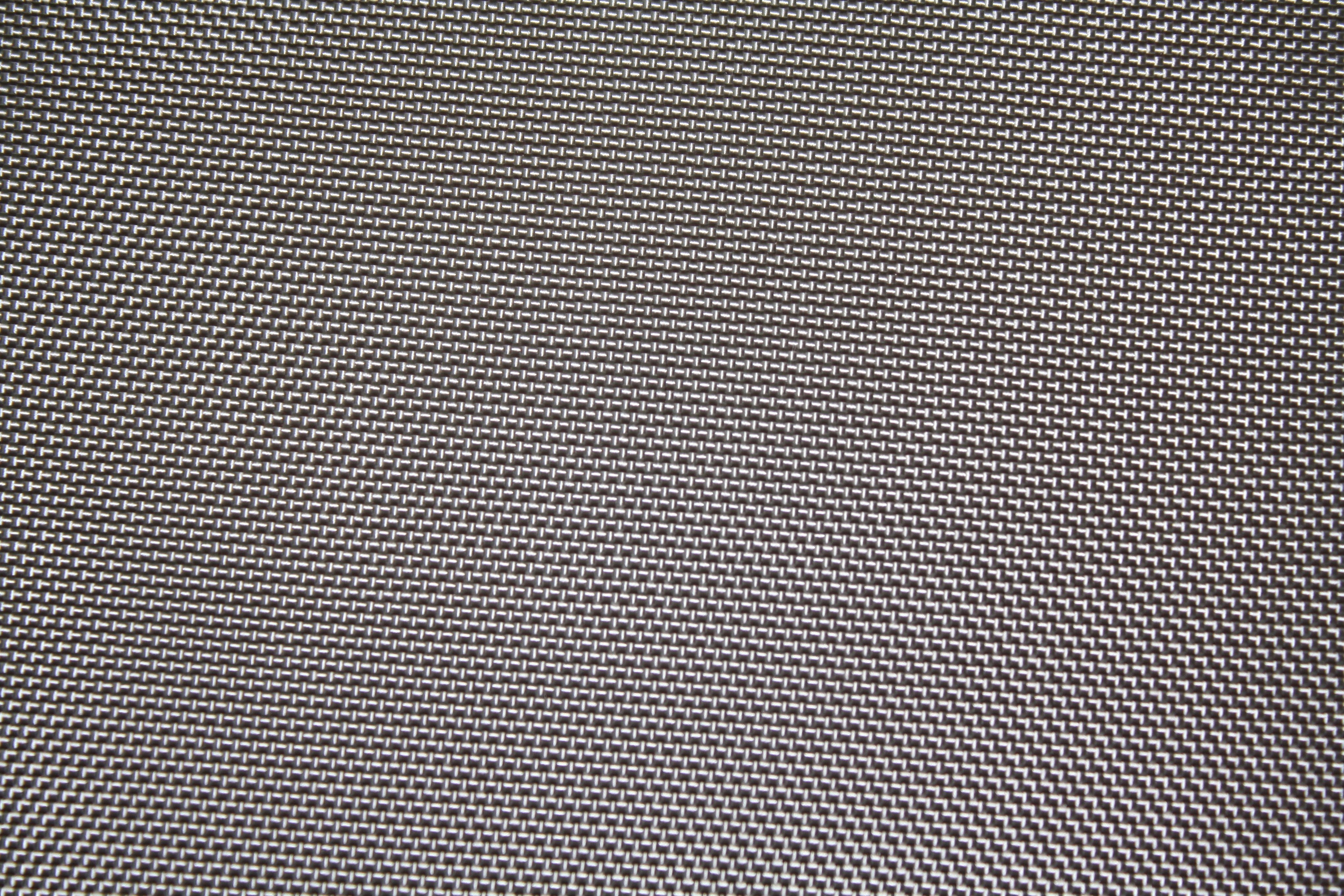

Filter fabrics are made from natural or synthetic fibers with a diameter of 10-30 microns, twisted into threads with a diameter of up to 0.5 mm. The distance between the threads is usually 100-200 microns. The weft and warp threads form a mesh, which can additionally be intertwined with pile. Contaminated air, liquid or gas, passing between the threads, is cleaned, leaving a sediment on the surface of the material. The presence of pile improves the filtering capacity of the fabric. The principle of the filter resembles a sieve - it passes through itself purified air, liquid, oil, retaining various contaminants on the surface.

Important! The fabric comes into working condition after several cycles of contamination-cleaning. After some time, a residual dust layer forms on the fabric, which forms an additional filter. As a result of the continuous filtration process, this layer, together with the resistance of the fabric, is stabilized and preserved. When dust gets stuck in the pores of the fabric, moisture condenses on the surface or becomes oily, the resistance of the fabric increases.

Types of materials

There are several types of filter materials, which differ in the origin of the fibers:

Natural

Cotton filters - belting and filter-embroidered fabric. Both materials are made from cotton fibers, but differ in density and weaving method. Belting is a more durable material with a density of 900 g/m2, filter-embroidered fabric is less dense, with an indicator of 490 g/m2.

Serpyanka - is made from cotton or flax fibers. It is characterized by a large cell size and high porosity, and looks like gauze.

Artificial and synthetic

Polyamide fabric canvas - made from nylon fibers with clear diagonal rows.

Polyester fabric - available in various modifications: raw, with fleece, heat-treated. Lavsan filter fabric belongs to this group. It is characterized by high strength, resistance to sunlight and mold microorganisms. Another variety of this group is the FilTek roll air filter, created by thermal bonding of fibers at a temperature of over 100°C.

Needle-punched non-woven fabric is a popular ventilation filter in the automotive industry. The raw material for the fabric is polyester, which is considered a safe material not only for humans but also for the environment. It is not subject to combustion and does not decompose, and is produced in rolls.

Glass fabric is a durable and wear-resistant material that is also used as insulation. Depending on the number of threads, it can be of simple or leno weave.

Polypropylene fabric canvas - has high chemical resistance and impact resistance.

All types of fabric differ in density. The minimum value is for polyester fabric - 300 g / m2, the maximum value is for polyester raw material with one-sided pile - 970 g / m2. New types of weaving and modern raw materials for filters allow to increase the productivity of devices, reducing the hydraulic pressure in the cleaning system.

Scope of application

The area of application directly depends on the raw materials used in the fabric and the filter’s inherent characteristics of resistance to chemical reagents.

Industrial application

Non-woven needle-punched materials are widely used in the automobile industry and for wastewater filtration. They trap dirt and harmful substances, preventing them from entering the external environment. They provide good ventilation of the car interior and cooling systems.

Cotton fabrics are used in the chemical industry and non-ferrous metallurgy for cleaning solutions.

In the mining industry, polyamide fabrics are used to clean iron ore from impurities.

Important! Air filter fabric is widely used for air purification in supply ventilation and air conditioning systems.

Filter fabric for ventilation is used in openings of electrical cabinets and as a pre-filter in a multi-stage air purification system, as well as for filling cassette filters of various brands.

Polyester filter fabric is widely used in the oil industry for dust collection in rubber production, and in the chemical industry for cleaning color pigments and in the manufacture of detergents.

Food industry

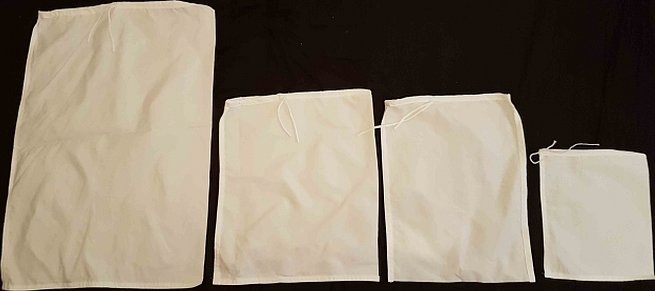

Filters made of natural materials are ideal for the food industry - belting and filter-cotton, as well as serpyanka. Milk is filtered through them to separate whey during the production of cheeses and fermented milk products. Syrups of various consistencies are passed through them. Natural fibers should not be exposed to acids and alkalis, the operating temperature should not exceed 80 °C.

Also used is a neutral to microorganisms cloth - milk lavsan. With its help whey, butter and milk are filtered.

Household use

In everyday life, filters, in addition to water filters, are used for kitchen hoods and vacuum cleaners.

Important! In kitchen hoods, synthetic padding, acrylic or non-woven fabric are used for grease filters. They are most often disposable. After washing, it becomes thinner and loses its cleaning properties.

For vacuum cleaners, fabric bags are most often reusable, sewn from polyamide synthetic fibers, or disposable - from filter paper. Both materials allow air to pass through well, while retaining dust.

Non-woven air filter for vacuum cleaner and air conditioner retains pollen, allergens, mold.

Medical filters

In medicine, fabric filters are used to purify air and gases, as well as to make respirators and pharmacological solutions.

Pros and cons

Each variety has its own characteristics, but in general, filter fabric has the following advantages:

- does not wrinkle;

- has a long service life;

- traps dust, gas and other particles;

- do not react chemically with acids and alkalis;

- does not decompose under the influence of harmful microorganisms.

The disadvantages include the following properties:

- there is no universal type of fabric, each type has its own filtering capacity;

- There is a temperature limitation for using the material;

- Natural materials have low strength.

Despite the above-mentioned disadvantages, it is still possible to choose the right fabric by selecting the material according to the required parameters. This may be the required degree and speed of cleaning, maximum temperature of use and pressure.