The fabric leatherette appeared and became popular at the beginning of the 20th century and still holds its positions. Leatherette - what is it and how to use it is below in the article.

Dermatin or dermantine: what is correct

Words that come from other languages often give rise to disputes. Dermantin or dermantin? Adults and schoolchildren think about this.

Derma is the original word from which the name of leatherette appeared. Translated from Latin, this word means "skin". As a test word, you should remember "derma". Since there is no letter "n" in these variations, it will be written correctly as dermatin, but it is often used as a pronunciation of dermantin.

The word itself is a dictionary word, so remember it. At the same time, the material is periodically called both dermantin and dermantin on the Internet. Despite the fact that the name dermantin is incorrect, it is much more familiar to the ear.

Dermatin: what is it and what is it made of

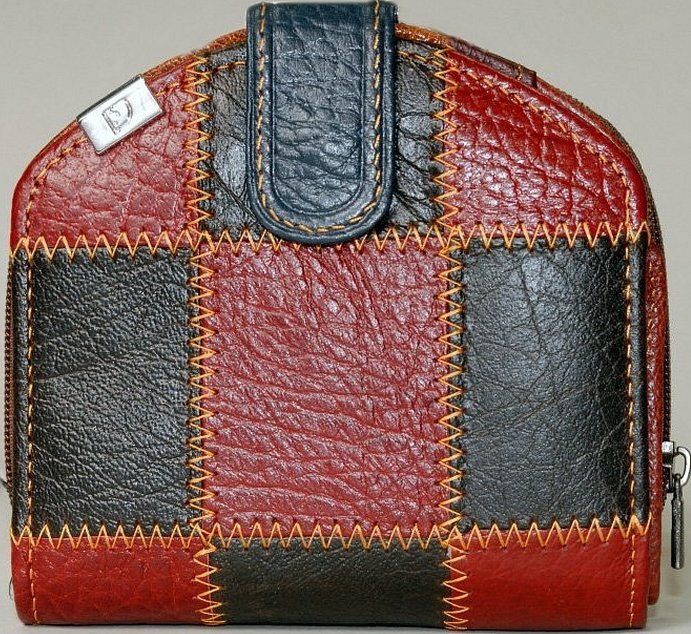

Dermantin is a leather substitute. The material is classified as an artificial type of leather. The fabric was widely used in the USSR and is still popular today.

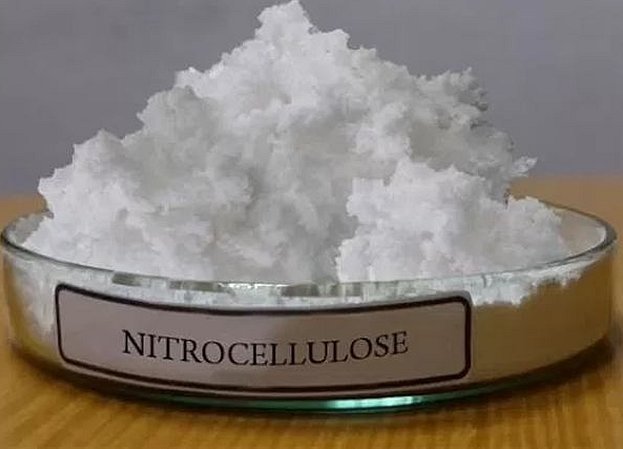

What is leatherette made of? The material is made of cotton, and the top layer is coated with nitrocellulose. For a beautiful appearance, the fabric is maximally adjusted to natural leather. The nitrocellulose coating can be applied on one or both sides.

Later, nitrocellulose was replaced by amido leather or vinyl leather. These substances improved the quality of leatherette and allowed for a wider range of shades. The range of manufactured products also became more diverse.

For your information! The first versions of artificial leather were produced in Europe. Rubber was used as a base.

Production highlights:

- Fabric base production. This is one of the important stages, which is the key to the quality of the future material. If production is poorly controlled, elasticity and strength suffer at this stage. The finished material will crack, tear and be highly creasable. The base can be made of cotton fabric, cardboard or paper. The paper base has low moisture resistance and strength. However, if the base is not strong, special compounds can be used to increase strength and durability.

- Coating of the material. Dispersion, melt or solution are the main methods for applying the coating. The polymer coating must be uniform, and at the same time adhere firmly to the base, otherwise it may peel off. Thin coatings are applied to the paper base, which can be superficial and through. There are various methods of application. The industry uses a large number of equipment for this process.

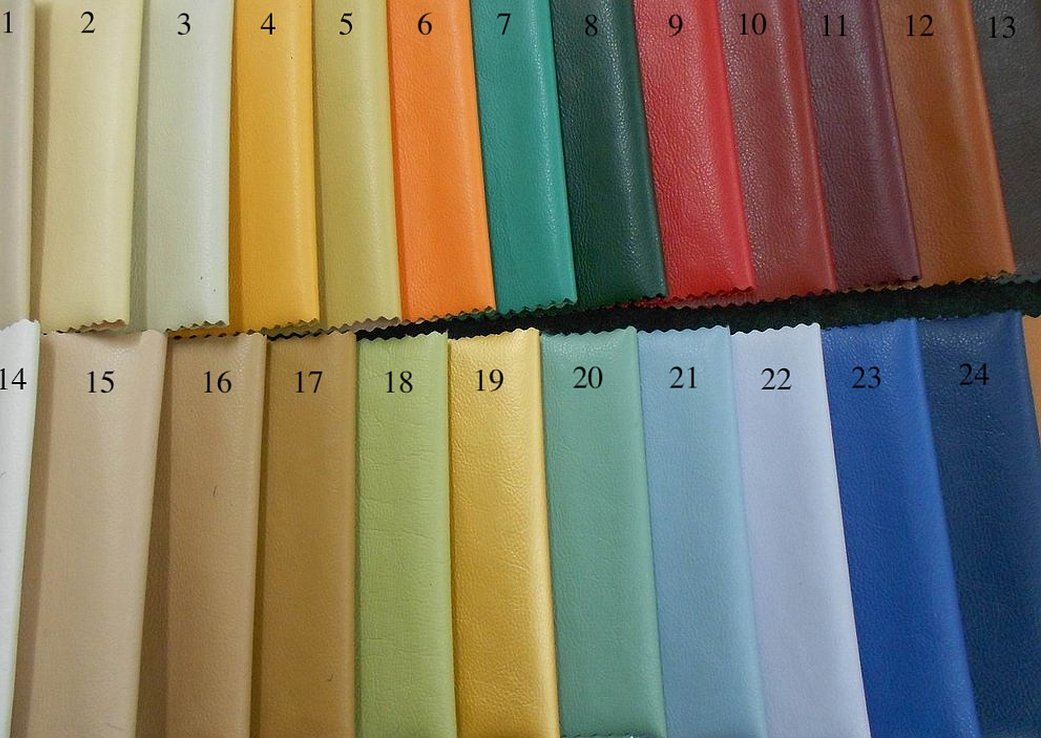

- Finishing stage. At this stage, the material is given a shade and design, the external finishing appearance is determined. You can get fabric with a pattern or any color. Most often, the pattern is applied by printing.

- Test checks are the final stage. The fabric undergoes deformation and stretching tests. Attention is paid to environmental influences, such as temperature. If the test results are positive, the material is allowed for sale.

Production has advanced so much that substances can be added to the composition that improve the porosity of the fabric, capable of changing the basic properties of the material. This is done by mechanical and chemical methods. As a result, it is possible to distinguish between the formed closed or open pores, the size of which may vary.

Varieties

The leatherette material varies in density:

- Monolithic. This type of fabric is dense. In the production process, a solution of polyvinyl chloride is used, which is applied to the finished base. This type of leatherette is more expensive. The scope of application is wide and extends to upholstery and covering of objects where a denser texture is required.

- Perforated - not a very dense type of leatherette. It is made by applying a perforated coating and embossing the layers. It is believed that this type of material is hypoallergenic. It can have different textures. It is used to make clothes.

Important! Perforated “young” leatherette is commonly called eco-leather or stretch leather.

Having heard the name monolithic or perforated leatherette, you should know that this is the same name for types that differ in density.

Leatherette is also sorted by technology, composition and coating. It can be porous, single-layer, multi-layer, with or without a base.

In addition, there are differences in the type of polymer coating.

Advantages and disadvantages

One of the main advantages is the low cost, because this material was released as an imitation of leather specifically. At the same time, not everyone will be able to distinguish a leather analogue from the original. Another plus is a beautiful appearance and a pleasant surface. Furniture manufacturers include texture among the positive qualities. At the same time, the fabric is durable and has various shades.

The fabric is environmentally friendly, safe to use. It does not lose its qualities at high or low temperatures, and is moisture resistant.

Anyone who knows what leatherette is will note that this fabric does not require special care.

Important! You can wipe the surface with a damp cloth or sponge. It is permissible to use special compositions for leatherette care.

There are also many disadvantages. First of all, it is a synthetic type of fabric. Artificial leather does not breathe. Due to the weak air supply, long-term contact with the material will be uncomfortable.

Another disadvantage is low resistance to abrasion, so it becomes unusable much faster than natural leather. At temperatures below -25°C, it cracks and breaks. It is easily flammable. It easily yields to pressure from sharp objects.

How to distinguish genuine leather from dermantin

Unscrupulous manufacturers have learned to make leatherette that is difficult to distinguish from natural leatherette. Since the price difference is significant, it is important to learn how to distinguish. Even official stores are sometimes cunning.

Differences:

- Thermal qualities. Despite the fact that leatherette is a "people's favorite", it does not have heat-exchange qualities like real leather. Eco-leather will not be able to protect from cold or heat. Natural leather is elastic and does not cause discomfort when worn.

- Wrinkling. Despite its chic appearance, it is impossible to fake the properties of artificial canvas. The material is not as elastic and cracks faster than the original.

If you have any doubts in the store about whether the product being offered is natural or not, you should:

- Drop a few drops of water on the outer layer. If it is absorbed and the area darkens, the seller offers a real leather product. Leatherette does not have the property of absorbing water, it will remain on the surface.

- Squeeze a piece of fabric into your fist and see if it will crumple or not. After releasing the pressure, the natural leather will immediately take its shape.

- Check the cuts and thickness of the material. You should know that leatherette is thinner than genuine leather. At the same time, the edges of the latter are not as processed and polished.

- Apply the product to the body and wait 30 seconds. The leather material heats up quickly, while the leatherette will remain at its temperature.

- You can smell the product. You shouldn't rely on this quality alone, manufacturers know how to fake leather smells.

- Inspect the paint. Genuine leather is dyed evenly.

Important! Do not set fire to the product. Although natural oil does not burn, the manufacturer may treat the product with a flammable compound. In this case, you will still have to pay for the product.

Regardless of the chosen fabric, leatherette can be safely used in the household. This unique material is really useful everywhere: for upholstery of furniture or sewing a new skirt. Moreover, it has plenty of advantages.