Textiles have played an important role in the life of every person for many centuries. They are used in everyday wear, in everyday life and in industry. Depending on the area of application, fabric may have some special properties. For example, when working with flammable objects, non-flammable fabric (also fireproof or flame-retardant) should be used.

What threats does fireproof fabric protect against?

Fireproof fabric is a specialized fabric. The name speaks for itself. The market is so dynamic that it makes fabrics that are focused on multi-protection, i.e. they save not only from flames. However, there are also those that have more specific properties. So, non-flammable material can protect against:

- thermal effects;

- open flame;

- drops of hot metal;

- electric current;

- mechanical impacts.

Technologists are constantly working on the composition of these fabrics to make them as durable and wear-resistant as possible.

Depending on the type and composition of the fabric, it may not protect against all properties, so it is worth clarifying the scope of application and requirements before purchasing.

Scope of application

Due to its properties, fireproof fabric has a wide range of applications. And if you consider that a special impregnation that gives fire-resistant properties to almost fireproof fabric, then its possibilities are almost limitless:

- hotels. They always have a large number of tourists, from whom you do not know at what moment and what to expect. That is why such material is widely used for carpets, curtains, bedspreads, upholstery on furniture. This effectively allows you to secure the premises;

- living space. Owners of any living space always have a risk of fire. Therefore, in order to protect yourself, you can buy curtains, carpets, tablecloths made of fireproof fabric;

- kindergartens, schools, universities and other places where children and teenagers gather;

- hospitals, clinics, sanatoriums;

- places where people constantly gather: theaters, cinemas, restaurants, etc. Decorations and seat covers are ideally made of fire-resistant fabric;

- high quality furniture upholstery;

- public transport;

- special clothing.

The material is extremely practical and in high demand.

Main characteristics of fire-resistant fabrics

Fireproof fabric has a number of characteristics that no other material can compare with:

- products made from such fabric are hypoallergenic;

- ultraviolet rays have no effect on it;

- due to the impregnation, dust practically does not accumulate (this is especially convenient for curtains);

- the products are not electrified;

- naturally, tissue combustion is excluded;

- things that lie around for a while, don't get moldy or rot;

- the products are easy to care for, do not shrink or wrinkle;

- heat-resistant properties do not disappear over time.

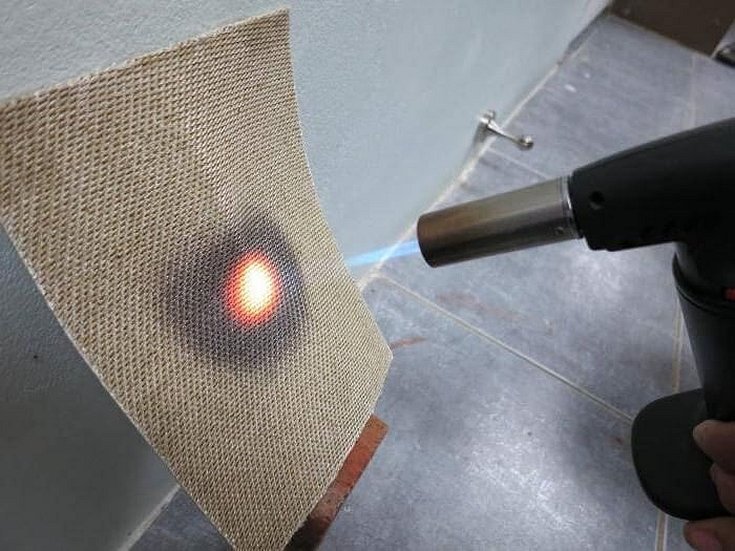

If the product suddenly gets into an open fire, it starts to smolder. Surprisingly, no smoke is produced at all. The next step is that the fire goes out completely and does not spread further.

Each company produces fire-retardant fabrics using its own technology, and the quality of the final product depends on this. There are a number of qualities that are worth paying attention to:

- oxygen index (normal value is about 30);

- heat resistance (indicates how resistant the material is to open fire);

- density (170-350 g/m2).

Products are considered high-quality when they have high protection indicators with a fairly modest density. Dense products are also good-looking, but not always, because they greatly increase the weight of the clothes.

The material usually consists of 100% impregnated cotton, sometimes with the addition of chemical compounds to make the protection more effective. However, additional protection can harm human skin. Good products are initially made of fire-resistant thread.

For example, viscose. In addition to fire-resistant properties, it maintains normal thermal regulation under clothing. Fluorocarbon, fiberglass, silicone coating, or metallized spraying are often used as external finishing.

Types of fabrics

There are 8 popular types of fire-resistant fabric, which differ in the weave of the fibers:

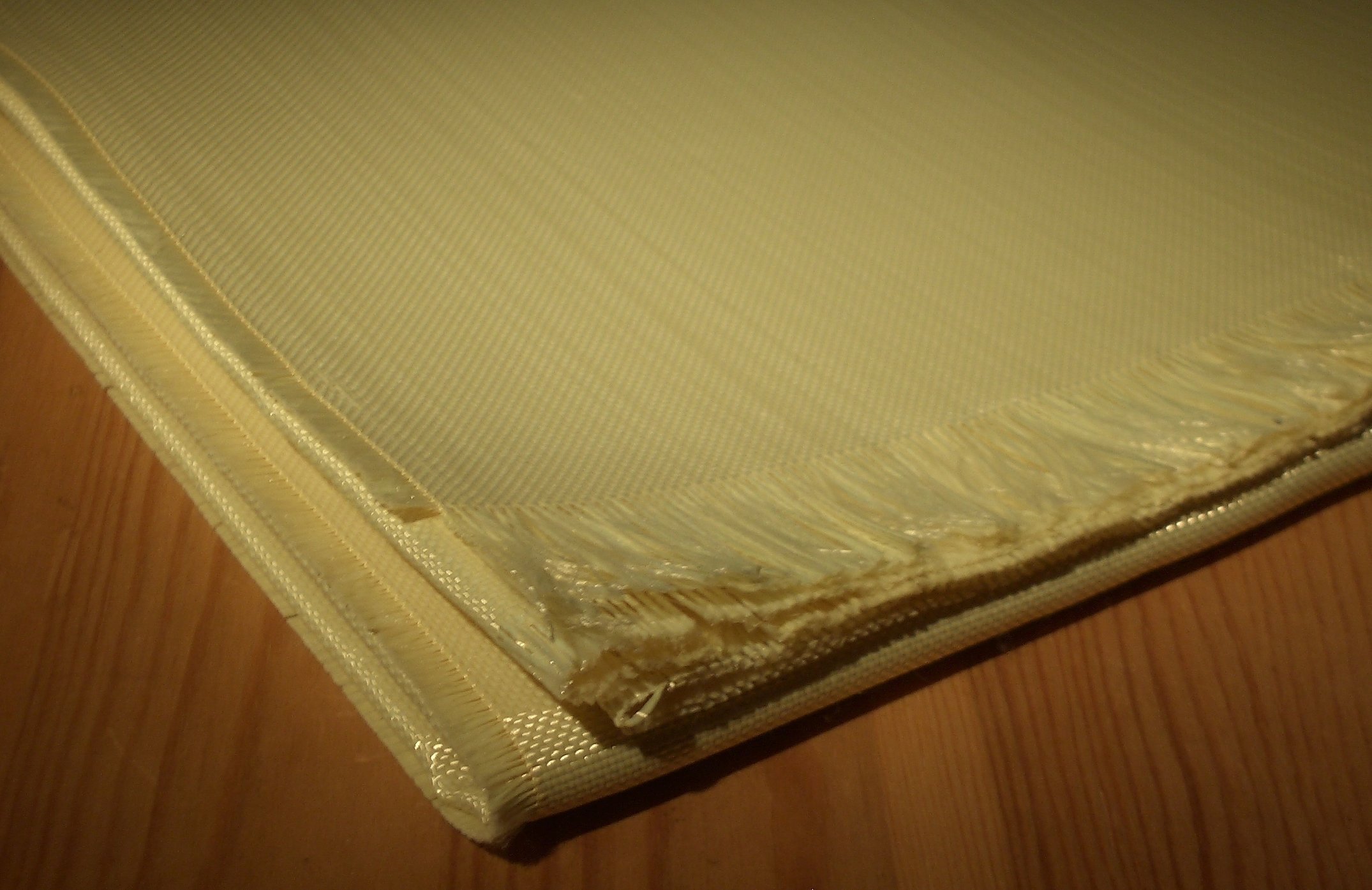

- Fire-retardant cotton fabrics with PA insertion. Fabric with the highest possible protection level, resistant to aggressive effects. Has a special thread weave and is made of long-haired cotton. When exposed to hot metal, the product does not burn through.

- Silica. Similar in composition to quartz fibers. The only difference is a lower content of silicon oxide (up to 95%). The fabric is able to protect against temperatures up to 1200 degrees for a long time. It can even protect against radiation.

- Polyester. Made from polyester threads. Resistant to high temperatures due to phosphorus impregnation. Rapeseed, jacquard, satin, velvet and other fabrics are made from this fiber (depending on the weave). Fabrics made from this material often have a good aesthetic appearance, but at the same time are extremely practical, wear-resistant, hygienic and safe. Clothes made from polyester materials easily allow air to pass through.

- Carbon fibers. As is known, natural fabrics are called so because they are made from natural raw materials containing carbon, oxygen and hydrogen. Oxygen and hydrogen, in turn, are distinguished by their easy flammability, so technologists have developed synthetic non-flammable fibers, which contain only carbon. Today, the fiber is made from viscose and polyacrylonitrile. Such fire-resistant fabric can withstand temperatures up to 370 degrees and is very wear-resistant.

- Multi-protective materials. The option when one material contains all possible properties: protection from flame, ultraviolet radiation, resistance to any thermal effects. It is believed that it is better not to take products from such fabric, but to pay attention to something more narrowly focused.

- Asbestos. Made from silicates containing the finest fibers. Good insulating properties. More common in heat-resistant building materials, not recommended for clothing. Withstands temperatures up to 500 degrees.

- Aramid. Made from polymeric materials. The properties depend on how the benzene rings are connected. Fire-resistant aramid is lightweight, durable and can withstand temperatures up to 370 degrees. Most often used for sewing workwear, military uniforms and thermal insulation products

- Quartz fibers. Natural quartz is heated strongly, stretched and thus fibers are made. The production process is very labor-intensive, but the obtained properties are amazing. The material from this material contains about 99% silicon oxide, so it can withstand temperatures up to 1400 degrees (short periods of time up to 2000 degrees), similar properties have metal devices. Bonus - complete safety for the user.

Fire-resistant coating treatment

Almost any material can be made heat-resistant by means of a fire-resistant impregnation which contains non-flammable chemicals. As a rule, these are fire retardant compounds. They are also often used for wood treatment. This treatment has a significant advantage: it does not last long, but it retains its properties only for a year, then it needs to be renewed.

Another disadvantage is that the product may be coated unevenly, so there may be stains somewhere, and an oily film somewhere else. When washing, the impregnation is gradually washed off, so things after water need to be treated more often than once a year.

The received product must be accompanied by a fire safety certificate.

Advantages and disadvantages of fire-retardant fabrics for curtains

Curtains are one of the most popular products made from fire-retardant fabrics. Therefore, it is important to understand the description of the advantages and disadvantages.

Pros:

- environmentally friendly composition despite chemicals;

- when burning, it does not release carbon monoxide, but slowly smolders until the fire is extinguished;

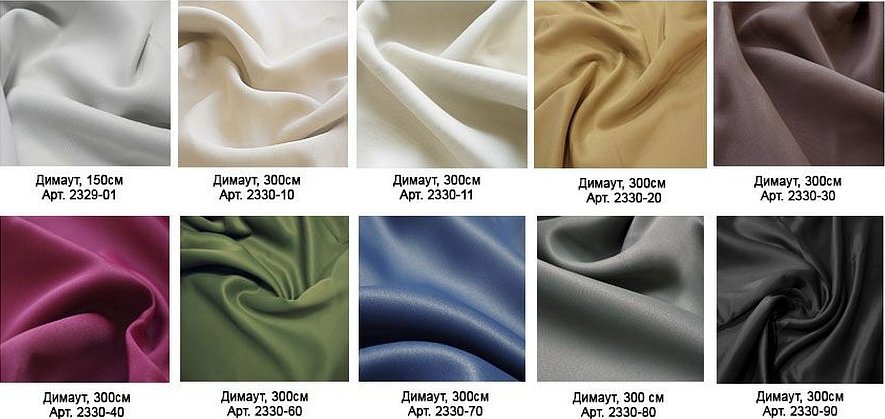

- aesthetic appearance - different fabrics, textures, colors;

- are not affected by ultraviolet rays, which is a huge advantage for curtains that constantly block the sun;

- non-flammable fabrics for curtains have a long service life;

- practicality and wear resistance, do not require constant washing and ironing;

- breathable;

- low cost;

- non-flammability.

Cons:

- Curtains made from impregnation instead of fibers do not last long and are not very reliable, since the impregnation is quickly washed out and the curtains will lose their properties.

To sum it up, it can be said that it will be a very good decision to replace some household items with fireproof ones. This will ensure safety and reliability. Very useful in everyday life: it will save PVC windows, is perfect for making a tent, will help with welding and welding work, and is also suitable as oven mitts.

The fabric can be of different widths. Despite the fact that such a concept as "fire-resistant curtains" is only up to 50 years old - they have gained enormous popularity, both among specialized equipment and in everyday life. Has a lot of manufacturers.