One of the human traits is the ability to observe nature and improve it. For many centuries, natural leather has been used to create everyday items and clothing. However, due to increased demand and deteriorating environmental conditions, a shortage of natural resources has arisen. Man responded to this challenge by creating artificial leather. What is vinyl leather, what are its characteristics - details are given below.

What is vinyl leather: description

Many people are interested in what vinyl and leather are. The first artificial substitute for genuine leather was rubber, produced on the basis of natural rubber.

Mass production of artificial leather began in the 1930s. With the development of technologies for creating leather substitutes, new polymers began to be used in production along with synthetic rubber.

In modern times, leatherette is a complex material, the components of which provide it with excellent consumer characteristics.

Leatherette is a material on the surface of which a polymer (high-molecular compounds such as rubber and protein) is applied. Polyvinyl chloride (PVC) is mainly used, another term for it is vinyl. This is where the second name of leatherette comes from - vinyl leatherette. Now it becomes clear what it is.

Important! PVC is a universal and safe material: every day people come across products made from it - disposable cups, handrails in public transport, toothbrushes, etc.

Manufacturing process

Artificial leather is divided into categories depending on the polymer used:

- microfiber (MF);

- polyurethane (PU);

- vinyl leather (PVC);

- eco leather, rubber, polyacetate (PA).

Each type has specific production features, but there are always three main stages in the process:

The first stage involves preparing the base of the material, which can be made of fabric, paper, cardboard, and other materials. The quality of the base directly affects the characteristics of the final product. To increase strength and wear resistance, fibrous fabrics are treated with special solutions.

At the second stage, polymers are applied to the base using three methods: melt, solution or dispersion. The homogeneity and reliability of the polymer application also affect the quality of the leatherette. In the process, you can add the necessary properties: plasticizers increase frost resistance or fire resistance, stabilizers help preserve the characteristics of the material, and pigments add color to the product.

For example, to create pores in breathable leatherette, the polymer layer is additionally perforated or foamed using mechanical or chemical action.

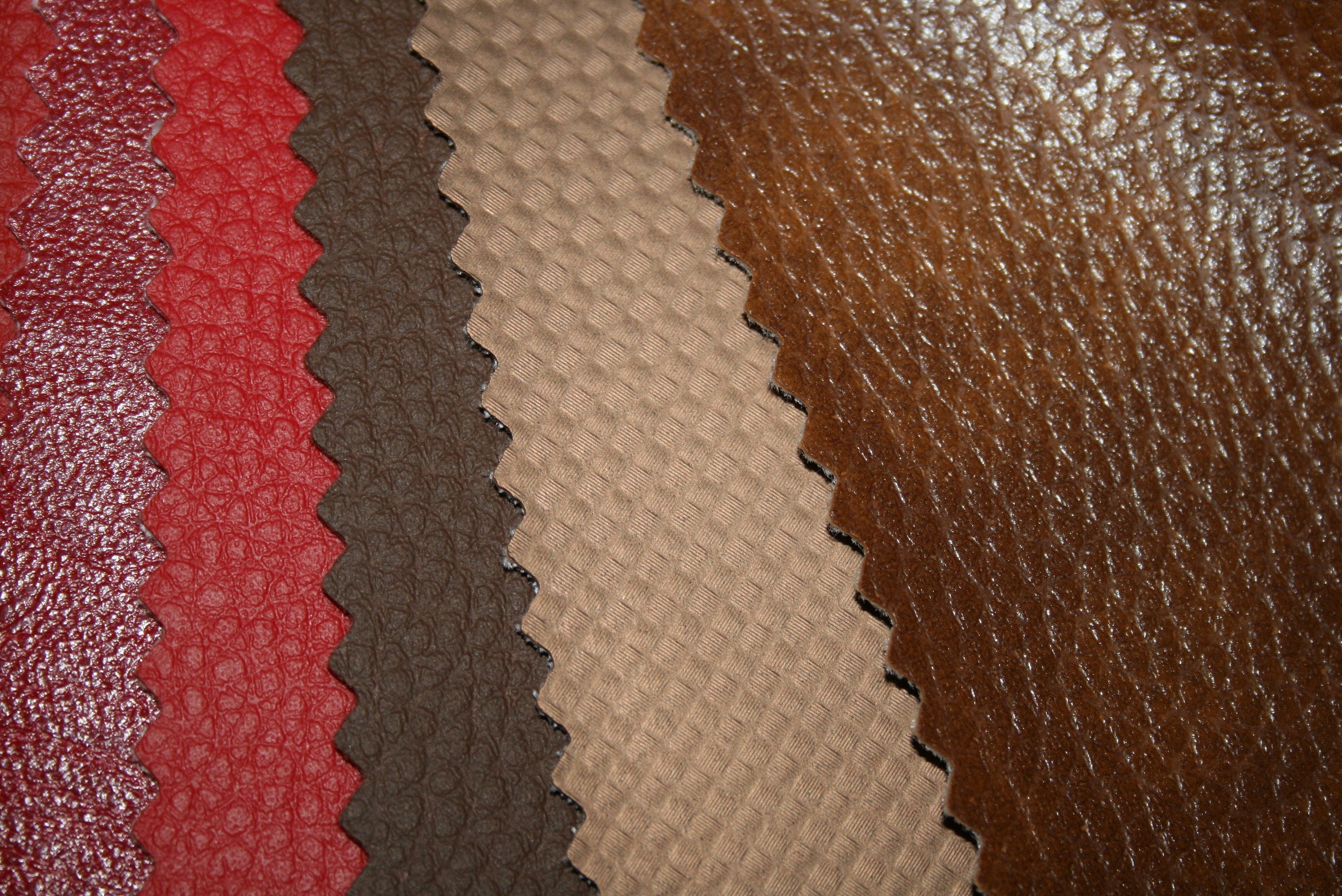

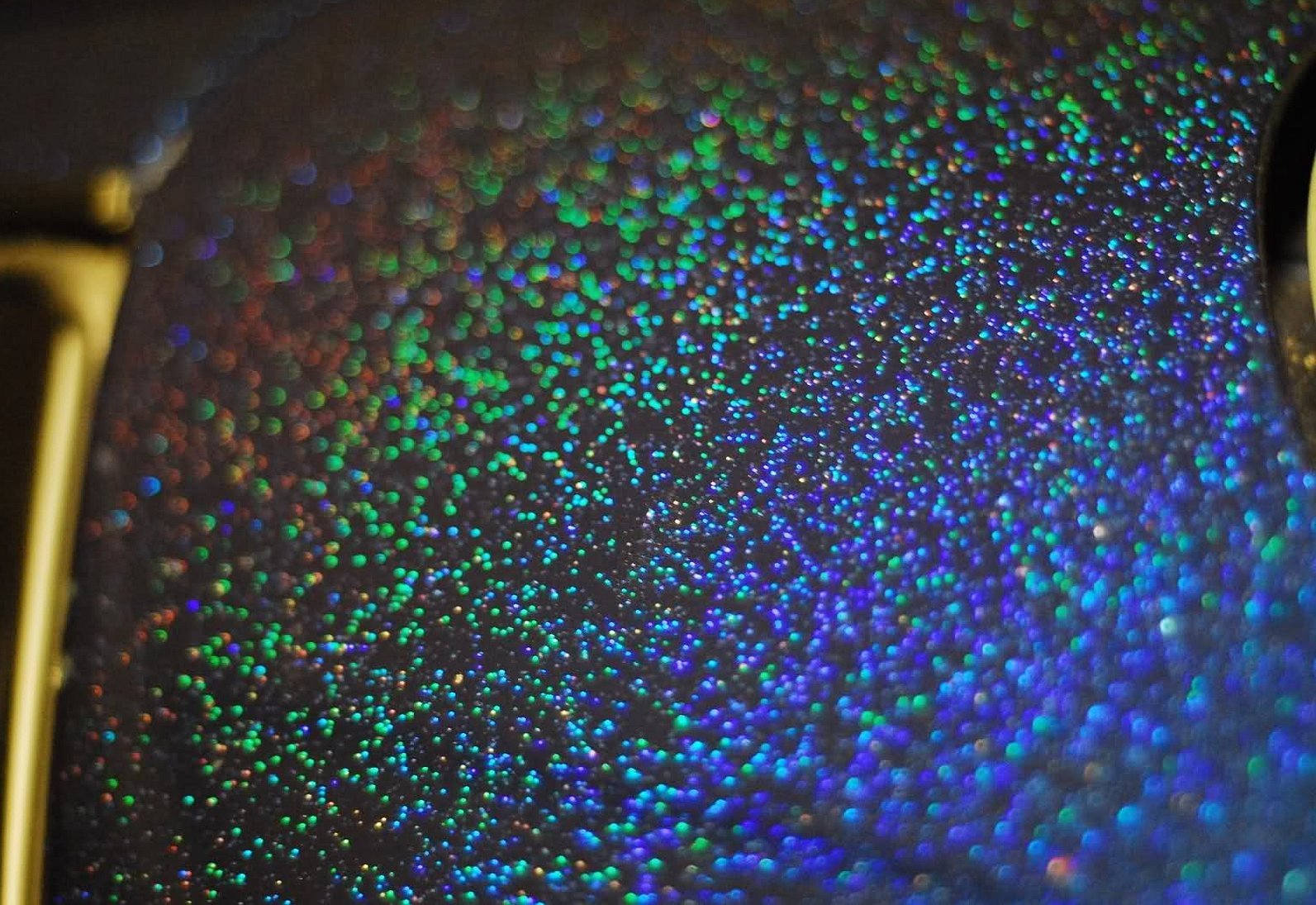

At the third stage, the artificial leather is given its final qualities: it is sanded, varnished, a pattern is applied or embossing is used. The combination of various methods allows creating artificial leather of any texture and color. Whether it is buffalo, dinosaur or crocodile skin, or leather with a chameleon effect - it all depends on the creativity of the designer.

Important! In general, the process of producing vinyl leather cannot be called simple, but its complexity is not comparable to the production of genuine leather, which is reflected in the significant difference in their prices.

Vinyl leather is assessed by the same technical parameters as genuine leather - durability after repeated bending, resistance to scratches, cleaning agents and ultraviolet radiation. Each type of artificial leather undergoes various tests.

The use of modern technologies and high-quality raw materials allows leatherette products to meet strict quality standards.

Properties and characteristics

Artificial leather, regardless of the polymer used, is highly resistant to mechanical damage and negative environmental influences.

In particular:

- It is difficult to damage and combines strength and elasticity.

- In everyday life it is easy to care for and hygienic, does not absorb dyes, liquids and oils.

- It is resistant to mold and has breathable properties.

- Difficult to catch fire, be damaged by chlorine or be scratched.

- In addition, the material does not fade in the sun and retains its original appearance for many years.

What is the difference between leatherette and vinyl leather?

Vinyl leather is a material whose base consists of cotton, knitted fabrics or non-woven bases, onto which polyvinyl chloride and synthetic additives are applied.

This leatherette is widely used in a variety of areas: from footwear and clothing to the production of hangars, awnings, car upholstery, furniture, doors and much more.

The characteristics of the finished product (flexibility, elasticity, strength) depend on the selected base and the amount of impregnations used.

Vinyl leather is durable, easy to care for, does not fade in the sun, and is resistant to mold and microorganisms.

Eco-leather has quality characteristics similar to polyurethane leather (PU is a three-layer material with low-quality genuine leather added to the middle). The main difference with PU is the absence of a second layer. Synthetic fiber or cotton fabric is used as a base.

Eco-leather is used to make sports and casual clothing, fashion shoes, suitcases and accessories. It has also found application in furniture production and the automobile industry.

Please note! The unique feature of this type of artificial leather is its breathable structure and appearance, reminiscent of natural leather. This leatherette is hypoallergenic, durable, moisture-resistant and resistant to ultraviolet radiation, temperature changes and mechanical damage.

Characteristics

The main advantage of artificial leather is its texture. In some cases, products made from this material are difficult to distinguish from those made from genuine leather. Another important aspect is the cost: the difference in price compared to genuine leather can reach two times the value.

In addition, vinyl leather has a number of advantages:

- environmentally friendly - the material does not emit allergens, toxic substances or unpleasant odors;

- durability and high wear resistance;

- air permeability;

- easy to care for and does not absorb dyes, oils or moisture;

- resistance to disinfectants, mold and microorganisms;

- durability - the material is not subject to abrasion, tearing or deformation;

- protection from the effects of ultraviolet radiation.

Important! To maintain the original appearance, it is enough to wipe the product with a damp cloth and soap solution once a week.

Artificial leather also has some disadvantages. It can become deformed if exposed to water for a long time. Some types do not have good air permeability and do not tolerate temperature changes well, while others are highly flammable and have an unpleasant odor, releasing toxic substances when burning.

Thus, we have dealt with the material of vinyl leather. However, technology continues to develop. Chemists have already created a leather substitute that is not inferior in its properties, and sometimes even superior to genuine leather. Perhaps in the future, scientists will be able to eliminate the disadvantages of vinyl leather. And leatherette bags and diaries from haberdashery stores will remain popular.