Beginners who sew ask questions about the shuttle in a sewing machine: what is it, what types exist? When choosing a model, the advantages and disadvantages of each type are considered. It is better to follow the advice of experts.

Shuttle in a sewing machine

A shuttle is a device necessary for sewing with a two-thread stitch. There are different types of options and when choosing, attention is paid to the characteristics. A shuttle for a sewing machine consists of a head, a cap. There are several holes along the contour for passing the thread.

Types of shuttles

The following types of shuttles are considered common:

- pendulum;

- vertical;

- horizontal.

Each of them differs in design.

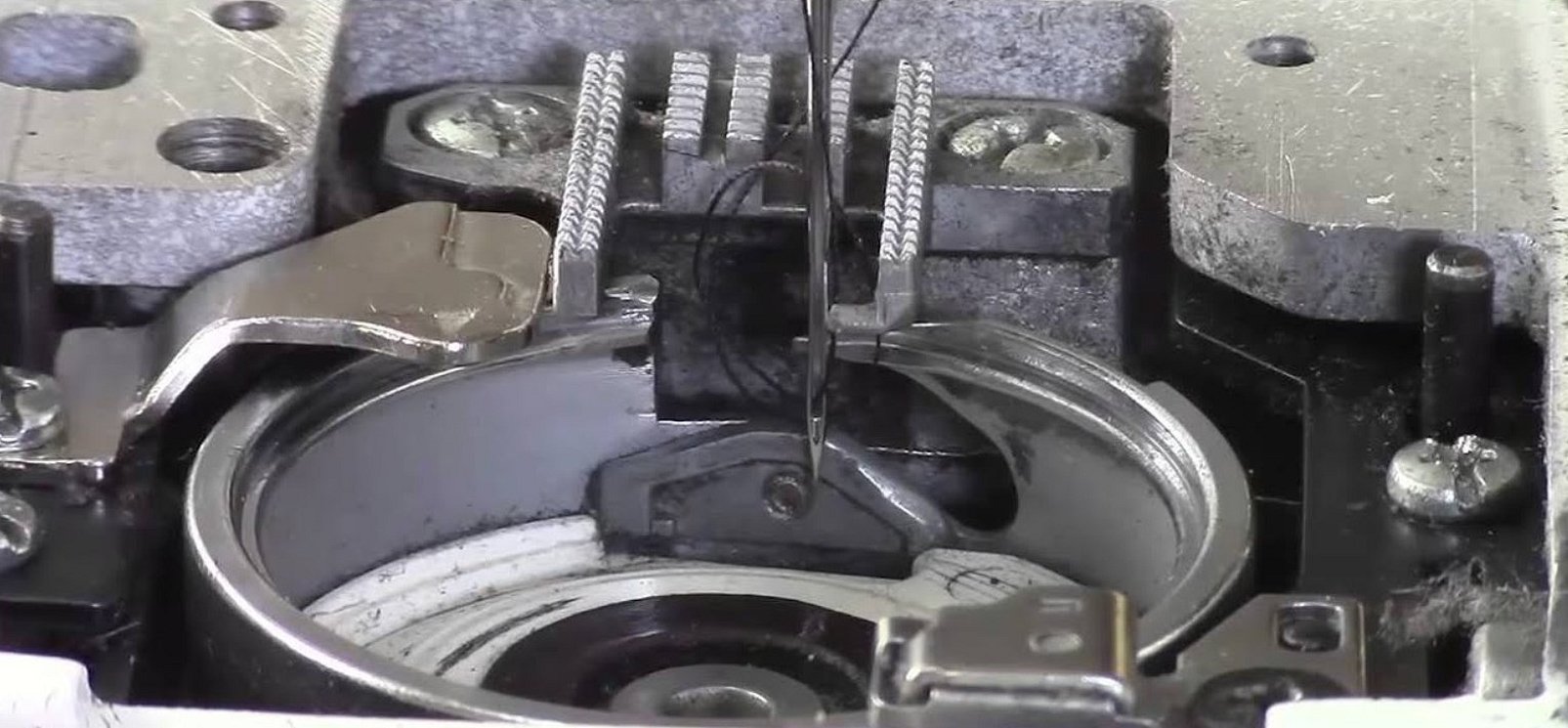

Pendulum shuttle

The presented element is found in economy-class machines. For example, the "Chaika" model uses a shuttle that operates on the pendulum principle. The presented part is also called a swinging one. When the head returns, the thread is captured. The advantage is that the machine is simple in design and the element can be easily replaced.

Interesting! During operation, the pendulum practically does not require frequent inspections. However, in older models it most often required adjustment.

The cap and the rod are fixed, they do not dangle during work. Defects are rarely observed during sewing. When examining the design, gaps in the formation of loops are noticeable. The swinging elements have their own disadvantages:

- low speed;

- high vibration;

- noise;

- limited functionality.

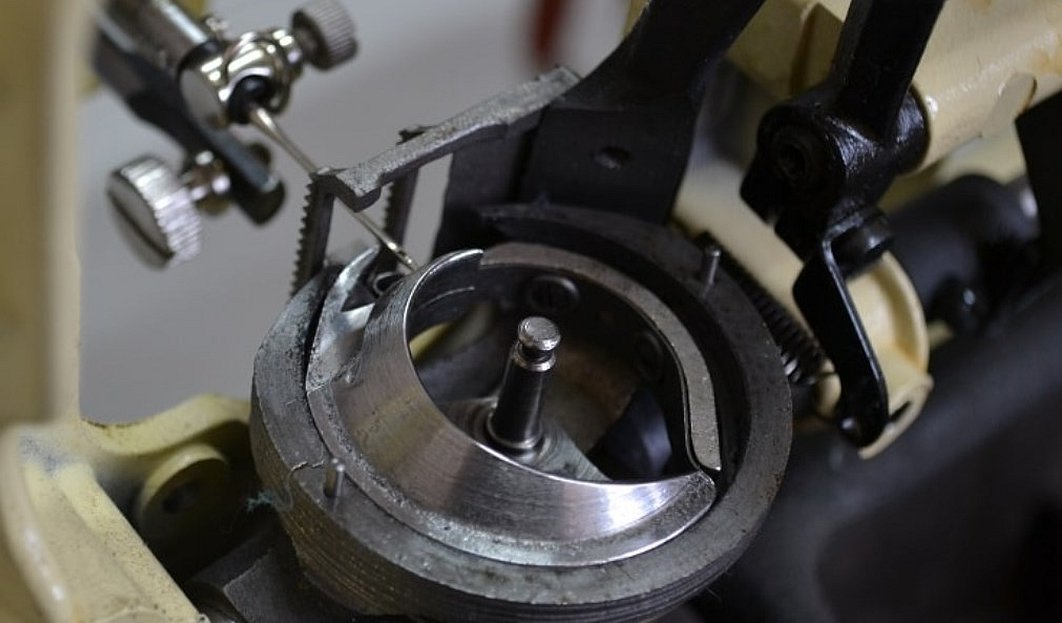

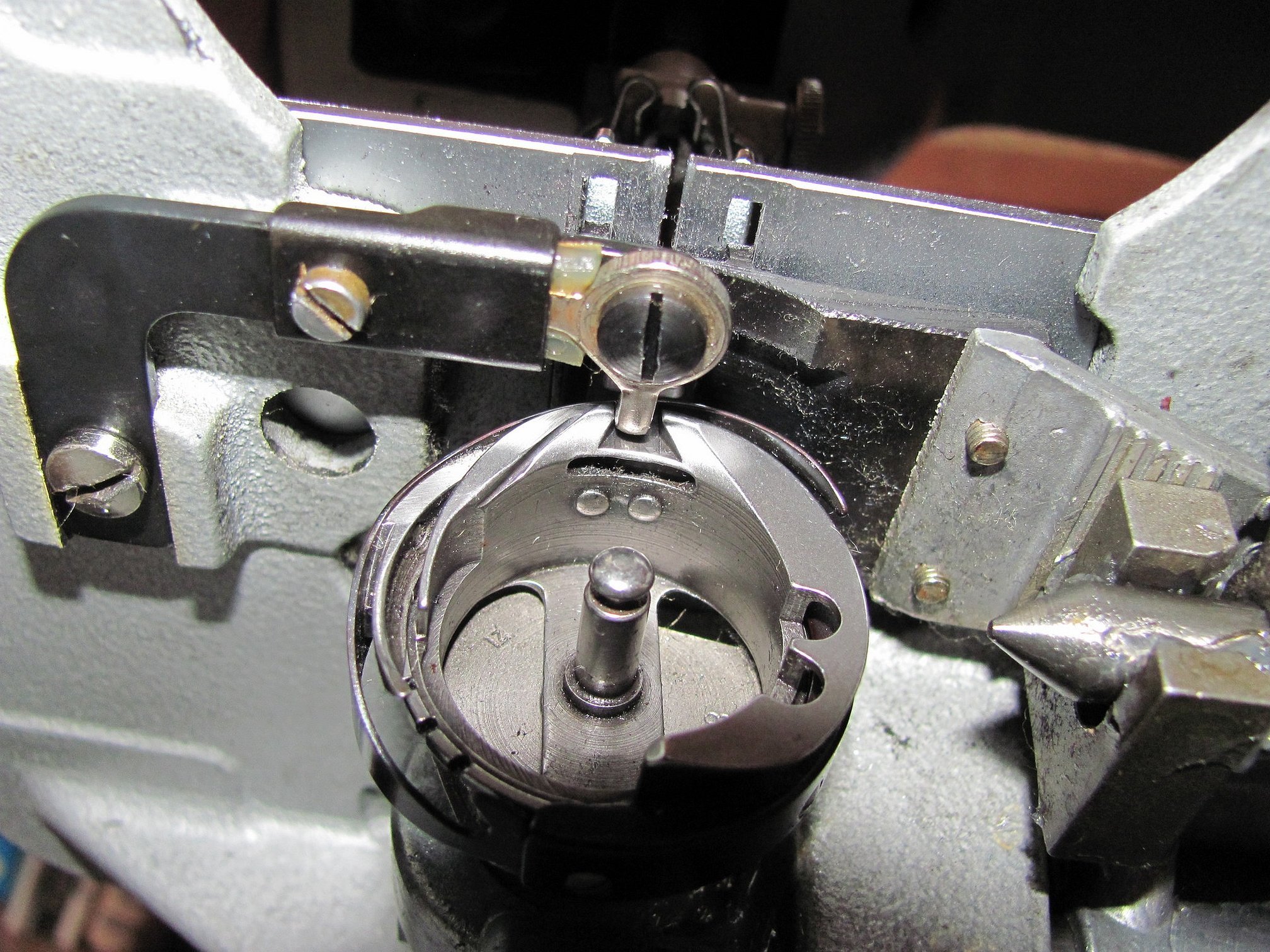

Double-circle vertical shuttle

The vertical element differs from the pendulum. Some experts call it rotary, there are design features. The head is fixed, located in the ring. A semicircular clamp is provided, which can change its position.

Important! The rotary unit is often found in professional models of the highest category. Experts choose it because it provides high sewing speed.

The rotary element of double running is not afraid of wear, can serve for a long time. In fact, an excellent line is provided, you can be proud of the work. Other advantages include the following:

- high strength;

- reliability;

- the ability to work with thin fabric.

The only disadvantage is the high cost.

Horizontal shuttle

The shuttle of this type is located in a horizontal position and visually looks like a plate. There are options with an open and translucent cover. The absence of a cap is another feature. Thus, the thread is always visible and the main advantage suggests itself. During sewing, the master looks at the material and is able to quickly determine the color.

Winding is done on a bobbin. There are elements with plastic or light metal. Some parts of the mechanism are combined, but this is not welcomed in a professional environment. For horizontal shuttles, the type of thread is important, it is recommended to follow the advice of the manufacturers.

Interesting! The bobbin with horizontal elements can be replaced (repairs will not require large investments). But the wear of the head in places requires the intervention of a master.

When contacting a service center, you will have to pay a large sum. When considering machines with horizontal elements, replacement bobbins are most often purchased in advance.

Main advantages:

- slight vibration;

- absence of noise;

- even line;

- no distortion;

- the bobbin can be replaced;

- quick threading;

- suitable for clothes loops;

- the ability to control the electronic unit;

- affordability.

The downside is the long adjustment of the mechanism. The plate needs to be adjusted before sewing and a screw is installed for this purpose. Another problem is the inconvenience, since the bobbin is in a hard-to-reach place.

Choosing a shuttle

The pendulum shuttle is mostly left for beginners. Thus, the masters consider vertical and horizontal elements. The first type will have to be adjusted, but there are many fans of such a mechanism. Even when considering inexpensive machines from the USSR (Podolsk 142, 2M), it is noticeable that they are practical and reliable. During operation, the vertical element does not rotate in a circle and is not subject to wear.

Some will find it difficult to adjust its position, for this purpose the features of a particular manufacturer are taken into account. Breakages are often observed if you maintain a high rotation speed. The shuttle nose is a weak point. When purchasing an element, the number of serrations is checked (the more, the better).

An additional feature is hidden in the work with fabric. During stitching, the needle moves together with the mechanism. The element is bent, plus high loads are allowed. Fans of the Singer technique scold vertical shuttles, although in fact, they can serve for a long time.

Interesting! If the model gets to the master, he checks the rod. Often it is slightly deformed, the fastening is also checked. A working machine is quite functional and convenient.

The situation with the horizontal shuttle looks a little different. This type is considered modern and in demand in household models. Popular companies that use this type of device:

- Brother.

- JANOME.

- MINERVA.

There are several significant differences in design. The mechanism spindle is short. The panel has markings, it is important that they can be easily read. Companies have been reducing production costs in recent years, so options without a cap are supplied. In fact, this is convenient and simple. In practice, gaps are rarely visible, but much depends on the elements.

Thread breakage occurs frequently because the shuttle moves to the side and is not fixed firmly. Singer and Veritas machines are produced with similar mechanisms and provide a high stitch width. Self-adjustment operations are sometimes very complicated. Even modern models require maintenance.

Expert Advice

When choosing a shuttle, it is worth following the advice of experts:

- pendulum elements are suitable for beginners;

- horizontal shuttles break less often;

- With a vertical model you can save thread.

When choosing a shuttle, buyers are guided by the price. The market offers modern models with vertical shuttles. They are capricious in terms of material. However, a high-quality level of sewing is ensured. If you save on machines with a horizontal element, the manufacturer is not responsible for the functionality.

Above are sewing machine shuttles. There are different types of elements, it is necessary to understand the design. When choosing a shuttle, it is better to consider the advice of experts.