When working with fabric, you may need various tools that allow you to speed up the process of work and creation of the final textile product. To create ideal and beautiful products or clothes, you cannot do without such sewing accessories as threads, a needle, a sewing machine, ironing boards and presses, glue, etc. Hot scissors are no exception. With their help, you can very quickly and easily do the usual work for a needlewoman.

What types of fabric cutting equipment can we offer?

Conventional scissors, knives and blades can be used as textile cutting equipment, but hot fabric scissors and knives that are heated by electric current due to their special design are much better, especially for some types of fabric and hair cutting.

Electric fabric scissors look like regular ones, but they are plugged into a power outlet. Through a special heating element, the cutting blades are heated to a certain temperature, which can be between 100 and 600 degrees Celsius and adjusted by a thermostat. They are used to seal the edges of the fabric at the place of its cut and for other purposes.

The thermal knife looks like a flat soldering iron. Its operating principle is similar to hot scissors: it, like them, copes better with even and neat cutting of some types of materials. In addition, with its help you can cut out details and figures in the form of stars, houses and animals according to pre-prepared forms and drawings.

Important! This knife can be used not only for cutting textiles, but also plastic and foam rubber. With its help, the seam and cut will be smooth, without defects, and the final product and its edges will not need to be processed additionally.

It is worth paying close attention to heating scissors, since they are the ones most often used in the textile industry and in home processing and cutting of fabrics.

Electric Heating Fabric Cutting Scissors

Electric scissors for fabric materials are used for cutting some synthetic fabrics and textiles such as neuron, polyester, nylon, parachute silk, cordura, polyamides.

Important! Thermal fabric scissors are not suitable for cutting very thin textiles, such as satin or organza. When working with these types of material, the advantage of using the device is lost, since it allows the edges of the fabric to melt rather than crumble. Thin fabric begins to melt excessively.

The main benefit of using this type of scissors is a significant saving of time when working with cutting out the product. Their use will allow you not to process the edges of fabrics and cuts additionally after cutting.

How hot scissors work

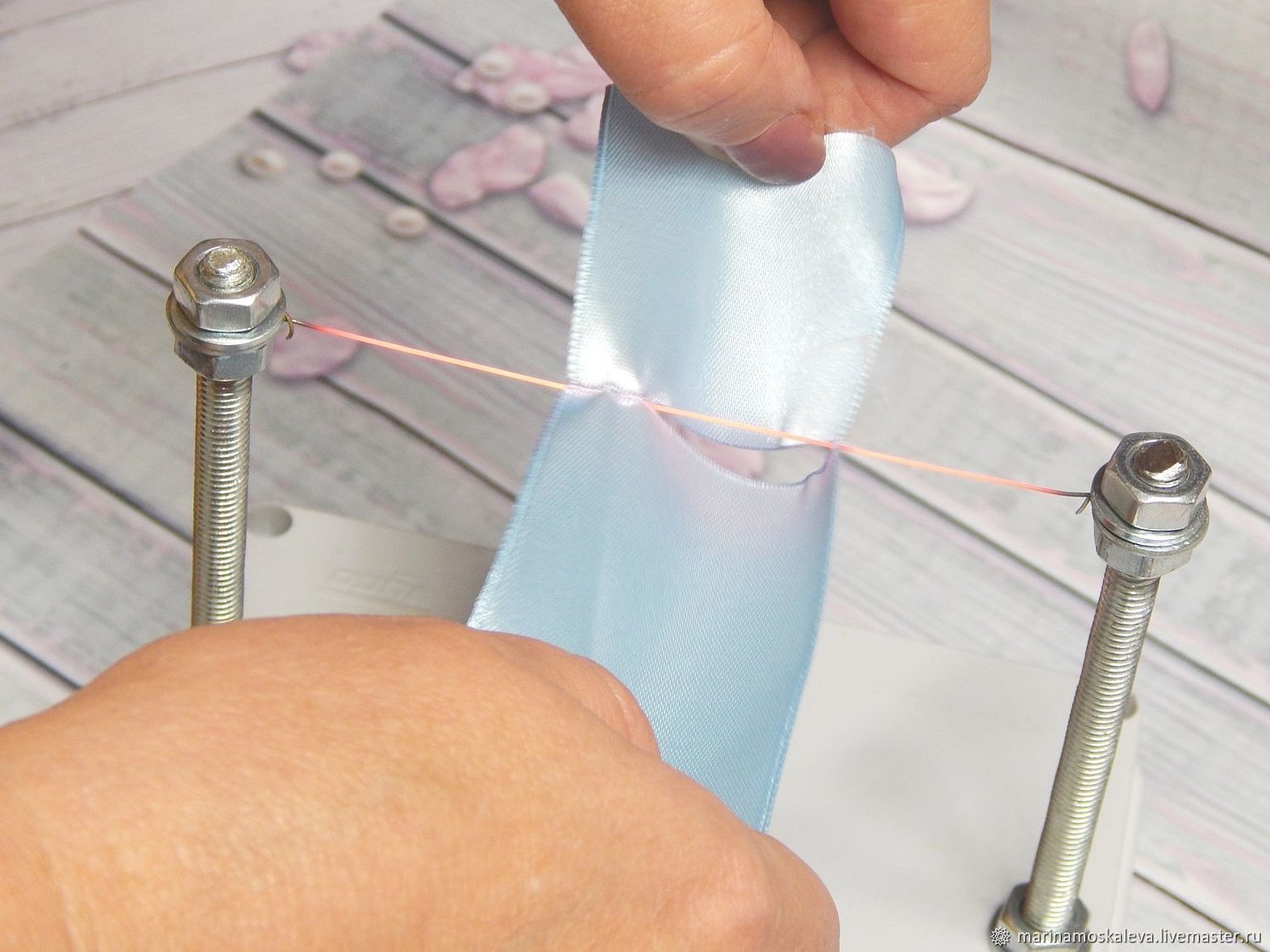

The principle of operation of hot scissors is as follows: when they cut the fabric, its edges are sealed at the cut points due to the high temperature of the blades. If you use regular scissors, you will have to process the edges manually using other improvised means.

The design itself assumes the presence of ordinary sewing scissors, which are connected to the network using a cable and a plug. With the help of a special heating element, the blades of the device will heat up to the desired temperature, which will allow you to work comfortably.

Important! Although the blades heat up to enormous temperatures, your hands remain safe, as any such device is equipped with a heat- and current-insulating handle that prevents burns and electric shocks under various circumstances.

It is also important to understand that cutting fabrics that are not suitable for this purpose is fraught with melted textiles sticking to the blades, the appearance of an unpleasant odor and damage to the fabric, and ultimately the scissors.

Operating rules

When working with such scissors, you need to be careful and accurate, do not neglect safety precautions and reading the instructions for use. The rules for using thermal scissors assume all the same rules as using other electrical appliances. You cannot:

- Leave the device switched on for a long time;

- Touch the blades with your hands when the appliance is plugged in;

- Use them when cutting certain types of materials that are prohibited by official instructions;

- Use scissors without heat-protective handles and covers or if they are damaged;

- Try to fix them yourself.

Important! In addition to personal safety, you should also use the scissors themselves correctly. They are not cheap.

Also, you should not overheat the device or use it in an unstable network.

How to make hot scissors with your own hands

It is possible to make hot scissors for cutting fabric with your own hands at home. If a person has advanced knowledge in electronics, then it is quite possible to make a device from ordinary scissors, thermal materials and a wire with a plug. In any case, it is not safe even if a person is experienced in this matter.

There is a known option, in which the scissors are heated on the stove or elsewhere manually. After that, the corresponding manipulations with the fabric are performed. You can also use a soldering iron, but all these methods have a large number of disadvantages and can ruin the fabric.

There are also scissors that are stored and heated in a holster. They are more often used by hairdressers than by craftsmen. Battery-powered devices are used less often.

Review of electric sewing scissors, except hot ones

In addition to heated electric scissors, there are also mechanical ones. They are multi-purpose and suitable for almost any type of material. With their help, you can quickly and evenly cut fabric from any material. Even the leather of shoes and hats can be cut easily. In addition to cutting fabrics, they are used to cut grass. The most popular company that produces such devices is Bosch.

Important! As a rule, although such devices are mechanical, they make virtually no noise and do not heat up. At the same time, this solution fits well in the hand thanks to the ergonomic handles.

Thus, with the help of sewing tools, you can significantly simplify your life and improve the quality of manufactured products. Using them correctly, you can sew unique decorative elements or clothes, as well as extend their service life.