Sewing needles experience the greatest load, if compared to other parts. The main thing is to choose a durable and high-quality tool that matches the type of fabric that is most often processed. There are a large number of designs on the modern market, which is why it is easy to get confused. But it is enough to understand the marking and purpose so that the sewing machine needles are selected correctly.

- How do needles differ from each other?

- Numbers on Sewing Machine Needles

- Selecting the right needle and thread for the material

- Special sewing needles for leather

- For denim

- Needles for fine knitwear

- Needles for densely woven materials (microtex)

- Select by device type

- How to choose the right needles for your home sewing machine?

- For industrial sewing machines

- Additional tips for choosing

- Instructions for installing a needle in a sewing machine

How do needles differ from each other?

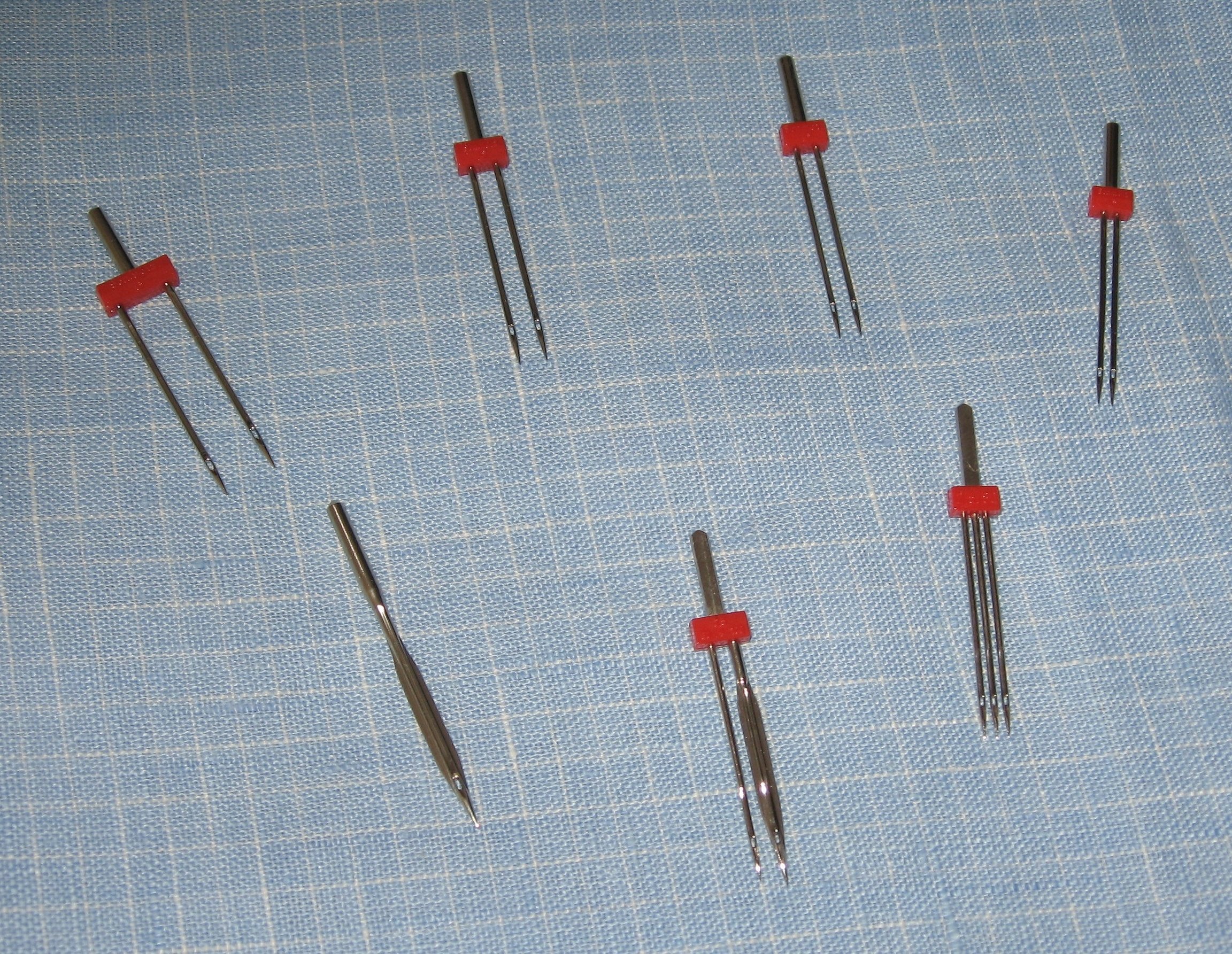

Overlock and for household machines are two large groups that can be initially distinguished. Such parts cannot be considered interchangeable. The size of the eye is the main visible difference. Overlock models are distinguished by an increase in this indicator.

There are also other parameters by which modern devices differ from each other:

- purpose for a specific type of fabric;

- diameter;

- gutter dimensions;

- ear shape;

- flask;

- sharpening. Leather needles for sewing machines can also differ in this indicator.

These qualities directly affect the quality of work. But this is only part of what is visible to the naked eye.

Important. Simply reading the instructions is not enough to get a quality result. You need to know about the markings and classification systems used.

It is advisable to have the needle flask with you when making a purchase.

Interesting. The bulb is the part of the needles that is inserted into a special hole during installation. Manufacturers apply appropriate markings to such parts.

If the flask is lost, you can use the markings from the instructions or other similar accompanying documents. The letters and numbers on the flask from the needles are the main guide for choosing a sewing needle.

In the case of household sewing machines, devices with a flat flask are used. For industrial devices, so-called round shapes are intended, and a standard sewing machine leather needle fits them.

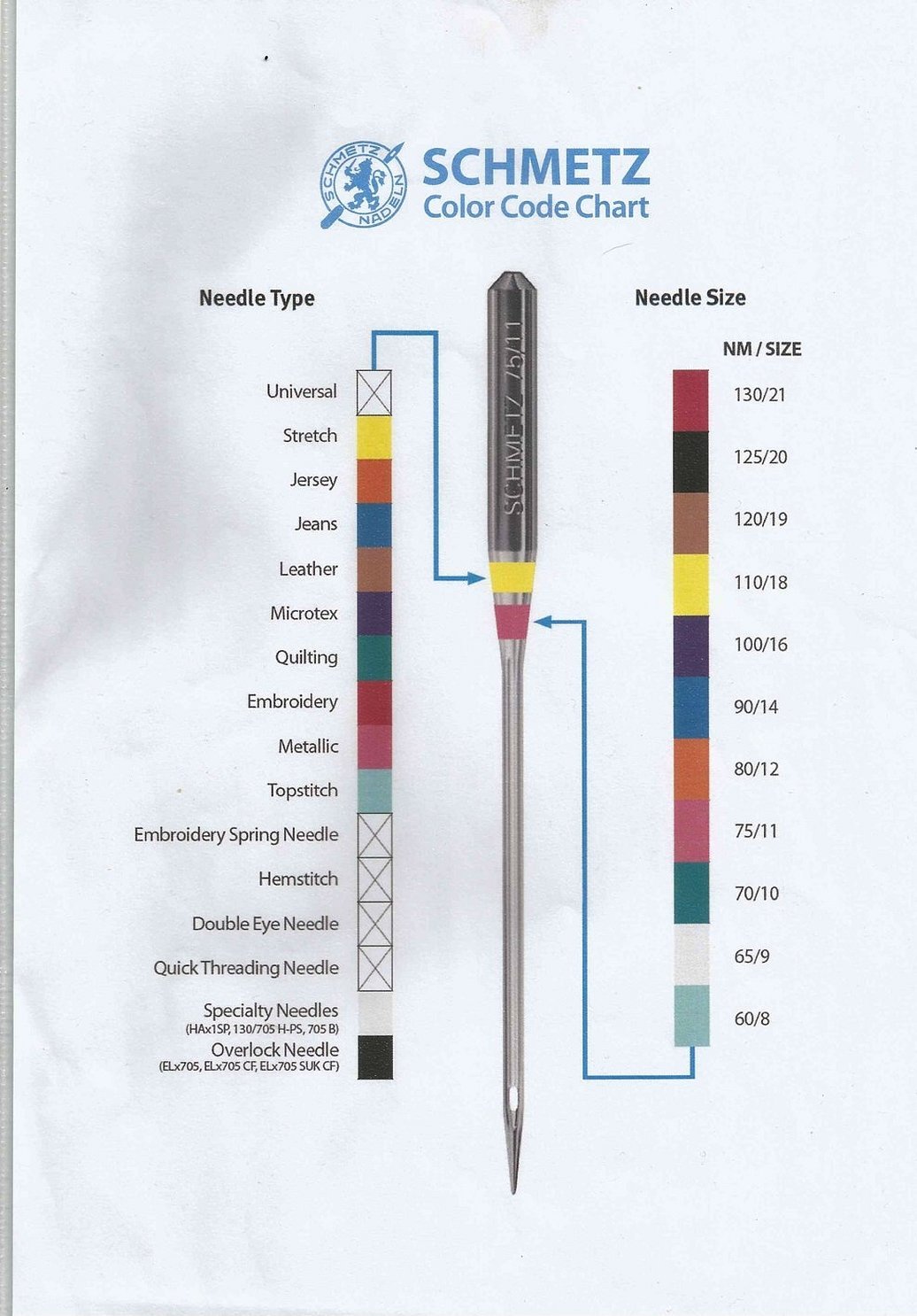

Numbers on Sewing Machine Needles

Typically, the marking for the flask looks something like this: “130/705H”, “HAx1”.

- The size and diameter of the rod are indicated using numbers.

- Units of value are inches or millimeters multiplied by 100.

- For household sewing machines, products marked as 60/8 or 120/19 are sufficient.

Note! The markings correspond to the European or American standard. 200/25 is the marking of the thickest option. The thinnest is 50/5. The first number is a fraction of a millimeter. The second refers to fractions of an inch for knitwear needles for sewing machines.

As for the letters, they also have their own meaning. They determine what a particular tool can be used for.

- Topstitch - needles for decorative stitches.

- H-DRI is a type of triple.

- H-ZWI - double attachments that the machine is supplied with.

- HO - the main purpose will be decorative finishing.

- H-LR and H-LL – for processing leather products.

- H-SUK - round point.

- HQ - quilting.

- H-EM - metallized threads.

- HE — embroidery.

- HS - for elastic fabrics.

- HM - microtex, which implies machine processing.

- Hj - for dense fabrics.

- H — universal device.

The required marking is selected according to the needs of the buyer, as is the microtex needle, for which fabrics it is suitable - it is easy to understand.

Selecting the right needle and thread for the material

You can simply consider what fabric you work with most often. This will simplify the problem of choice.

Special sewing needles for leather

The material requires cutting. Classic piercing only leads to deformations, breaks on the surface of the fabric. The result is the appearance of holes with an irregular shape. The needle begins to break too often. The main thing is to choose tools with a cutting edge. A slight tilt of the stitches to the right or left will be the result of the work if you use the H-LL, H-LR marking.

For denim

The material requires the use of thin needles with maximum strength. The tip is allowed to be slightly rounded. But when crossing the seams on jeans, even the highest quality types of needles for jeans deviate from the axis. Because of this, breakages and omissions occur during work. The needle rod is supplemented with a cross-section of the groove to avoid such negative consequences. Thanks to the number of needles for denim, it is also easy to figure it out.

Needles for fine knitwear

The most important thing is that the fibers remain intact while you work with the material. Therefore, it is recommended to choose needles that meet the following requirements:

- Spherical tip. They have their own classification.

- So that they don’t pierce the threads, but rather push them apart.

- The best options are those marked H-SES, H-SUK, HS. Such markings are used by manufacturers Janome, Microtex, Vector.

Working with such needles, owners will easily form a beautiful stitch, and the density of the fabric will not be disturbed. Thus, it is easier to protect against the appearance of runs, which most spoil the knitted material.

Needles for densely woven materials (microtex)

The following types of marking are suitable:

- HM, also stands for jeans needles for sewing machines.

- HJ.

- HA-1SP.

- HA-1SP. The correct version is easy to recognize.

Note! Usually these are sharp needles with small rounded eyes. The size is selected depending on the parameters of the fabric itself that you are going to work with. The brand is almost irrelevant.

Select by device type

When purchasing, it is recommended to take the following criteria as a guide:

- Manufacturer. Here are just a few of the companies that have become the best - Groz-Beckert, Organ, Scnmertz. If you give preference to well-known companies - you can not worry about the quality. The curvature of the tool, the absence of external defects are the most important parameters checked before starting work.

- Characteristics of the fabric, the use of which is planned. There are special tables containing information on the purpose of each type of tool. Different fabrics require their own shapes, thickness.

- A type of sewing machine. For example, an industrial type. It is better to study the instructions issued for the device in advance. This document also provides recommendations on which tool is best to take in a particular case. When replacing, it is especially important to follow this point, as serious differences are noticeable in the flasks.

How to choose the right needles for your home sewing machine?

Needles in home devices are supplied with flat flasks. Thanks to this, the correct installation of tools and other devices is simplified. Industrial needles should not be used inside home devices. If a curvature is detected, you can try to align it to correct the defect. The tool must be selected correctly.

Important. If the quality of the products is high, they will not bend. Steel or nickel will simply break if attempts to correct the situation are too intense. But this is an indicator that the device is of high quality.

For industrial sewing machines

The main difference from household models is the rounded shape of the tools. The length and purpose are also not the same as those of the analogs presented above. The most famous companies producing needles with the corresponding characteristics are:

- "Organ";

- "Grotz-Beckert";

- "Schmetz".

These companies offer needles for various purposes, including for Singer machines:

- Blind stitch.

- Machines for simulating hand stitching.

- Coverstitch machines.

- Riveting machines, for which their own option will be suitable.

- Button.

- Furriers.

- Erect.

- Embroidery. The product will definitely be of high quality if you choose correctly.

- Overlocks, and so on.

Each device has its own marking, this factor is also paid attention to. Only in this case the needle will last a long time.

Additional tips for choosing

In the case of the tip, there are two main groups of devices:

- For textile group, with rounded end.

- For leather, with blade shape. Weight is not so important.

Only with the right choice of needle can you get a beautiful stitch. In this case, it is easier to avoid various damages to the material. The thinnest type of base will withstand.

Please note. The streamlining of the needle eye together with the external shape lead to the unimpeded passage of the point through the eye. The inner side of the latter remains smooth, which facilitates the movement of any materials. Under such circumstances, interlacing and thread breakage do not occur.

A good loop depends on the shape of the groove. Previously, the main one was the so-called "round groove". But now it is a thing of the past, it is replaced by a device called Pontoon. This is the groove that prevents defects in both the threads and the needles themselves. The French manufacturer adheres to the same rules.

The force with which the needle pierces the fabric depends on the design of the needle rod. The service life is also largely determined by this parameter.

Interesting. The needle holder inside the sewing machine is usually made with a certain diameter. If the size of the flask and the holder do not match, the machine simply cannot be used for its intended purpose.

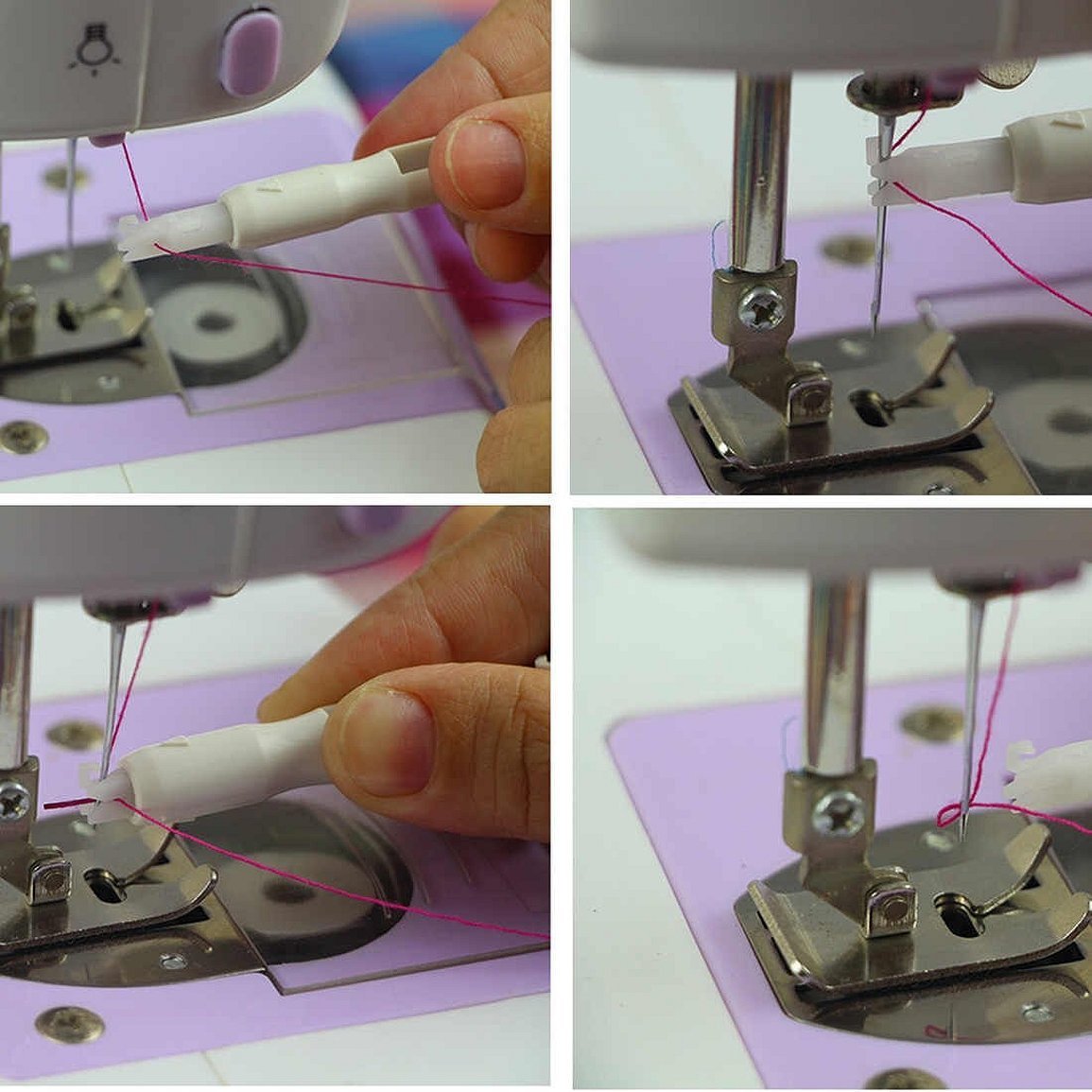

Instructions for installing a needle in a sewing machine

Before installing the part in its place, you need to make sure that there is no curvature. This part can easily slip out of sight if you do not take care of it in advance. You can lay the needles on mirrors or glass. Any gap in this position will be immediately visible when sewing.

The basic rule is that the thread is threaded into the needle from the long groove side. There are several features associated with the operation of the parts:

- In the case of a straight line stroke, the main installation location is usually on the left.

- If the stitch type is “zigzag”, the tool must be installed at the front.

- In the uppermost position, needles are installed in the Podolsk series of devices and other similar machines. The flat part of the thickened flask turns to the right.

It turns out that the long groove will be facing the base of the sleeve. The needle is inserted upwards until it reaches the stop. After that, it is manually secured using a special screw. If the stitching is beautiful and even, without skipping stitches, then the installation was correct.

Please note. The screwdriver that comes with the machine is often used to replace old tools with new ones. The new needle is usually mounted with the flat side facing away from you. First, insert it until it stops, then tighten it with a special screw. The screwdriver is usually 12 cm long.

The needle pierces all the threads along with the fabric when sewing. The thread is placed inside the long groove. Therefore, all the parts easily pass after the main tool. When the needle moves up, approximately the same thing happens. From the side of the short groove, the thread begins to get stuck, as a result of which a loop is formed. The shuttle catches it, and the sewing process continues.

Household models are simpler in this sense, they have a so-called needle driver. The needles are installed in only one position. Things are more complicated when it comes to industrial production. The device will not work if errors are made during installation.

The type of fabric and the number of layers to be sewn largely determine the choice of a particular needle. The best option is often chosen empirically, through personal experiments. After that, it is easier to decide what is best. It is recommended that beginners purchase entire sets suitable for a particular sewing machine. Then, before starting work, it is easier to try out needles with different characteristics. And understand what is better.