A sewing machine is the main tool of a needlewoman. It should be chosen very carefully, having defined the necessary functions. The appearance should be aesthetically pleasing, and the functionality should fully make you feel like a professional. But not only the quality of the device itself affects the service life, the correct operation of the device is also important. In order for the sewing machine to serve for a long time, it is necessary to service it well: change parts, clean and lubricate, adjust the mechanisms. This article will tell you how to lubricate a sewing machine, why lubrication is needed at all and what lubricants are used for this.

- Why do you need lubrication?

- What you will need for work

- Which oil to choose

- What components need to be lubricated?

- Sequence of disassembling and lubricating the machine

- How to lubricate a Janome sewing machine

- Brother Machine Lubrication

- Singer

- Astralux

- Machines with vertical shuttle

- Machines with horizontal shuttle

- Machines with a rotating rotary shuttle

- How often should I clean and lubricate?

Why do you need lubrication?

A sewing machine is a complex device. When creating a stitch, many mechanisms work simultaneously. If you do not clean and lubricate important components in time, the mechanisms will become clogged and fail. This will lead to thread breakage, creaking, knocking and general noise. In the worst case, the machine will not work and will have to be replaced.

Lubricants are needed for:

- Extending service life and improving overall performance;

- Easier needle movement;

- Reducing noise during operation;

- Preventing thread breakage and fabric damage;

- Easy and quick adjustment of mechanisms.

Important! Old machines need to be lubricated every 90 days, while new ones require inspection every 6 months. If the work intensity is low, you can lubricate the moving parts once a year.

With constant use, it will immediately become noticeable when new oil is needed.

What you will need for work

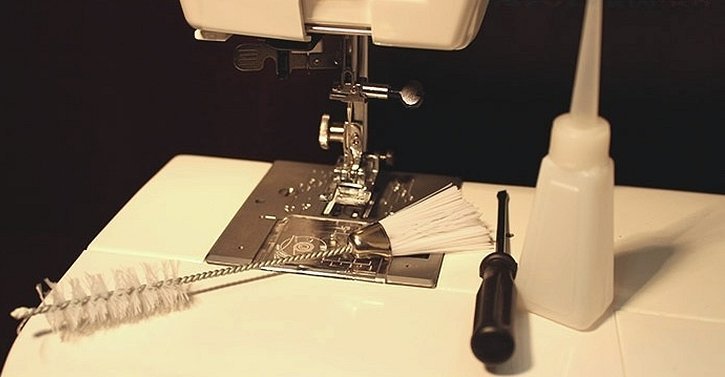

To lubricate the machine correctly, you should prepare everything you need for this. And you may need:

- Machine oil. You can buy it at any hardware store. Even 100 grams of oil will be enough;

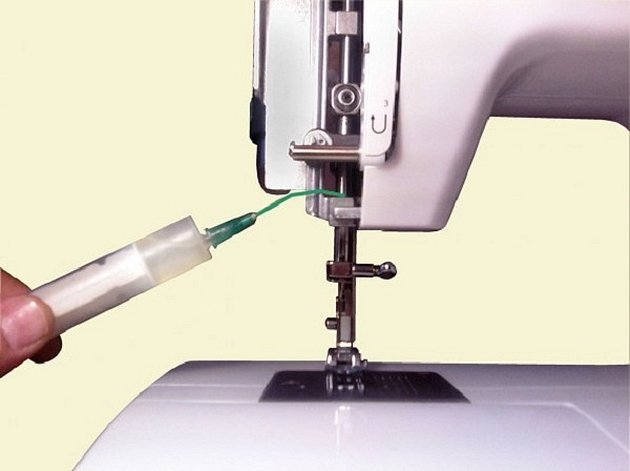

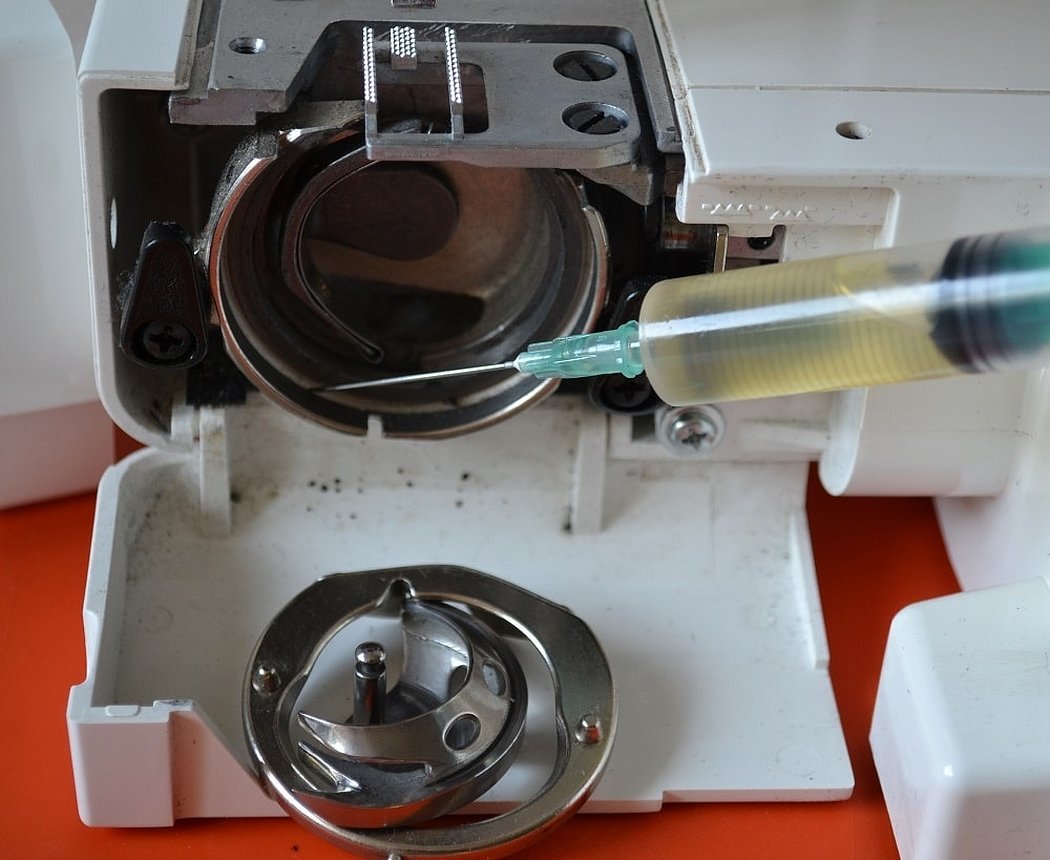

- Medical syringe. It is convenient to lubricate those parts of the machine that are difficult to access without disassembling it;

- Brush. A small brush will do a great job of removing dust, dirt and old oil;

- Screwdriver. You will still have to unscrew some things. On some machines you will need to disassemble the case, and on others - certain parts and covers;

- Napkin or rag. The remains of new and old oil and dust can be safely removed with a napkin;

- Film for surface protection. If the machine has not been cleaned for a long time, it may have a lot of dirt on it, which will end up on the tablecloth or carpet.

Important! This is exactly the set you need to perform high-quality professional cleaning in good faith.

Which oil to choose

Oil for such purposes has a special viscosity index. If it is too viscous and sticky, then the deep parts will not be lubricated properly, and it is on them that almost all the load falls. Too fluid composition will also not bring benefits, since it will not have time to penetrate deep and will simply flow off. This means that the lubricant for the sewing machine should be moderately viscous. Usually this parameter is directly indicated on the box and found out when buying. When working on a high-quality production machine, lubrication may not be needed, since such units have an automatic lubrication system.

The best oil will be the one that came with it. If it is not there, you need to choose a better quality lubricant. You can read the recommendations for choosing on the website of the manufacturer of this machine. In no case should you use vegetable oil: this can lead to serious damage and rapid contamination.

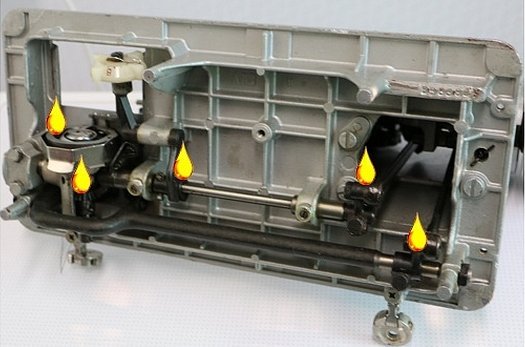

What components need to be lubricated?

It is necessary to determine which working units of the device require lubrication. This is usually indicated in the machine manual. If it is lost, you can find an electronic version on the Internet on the same official website of the manufacturer. You can do it even easier: lubricate all units where there are moving parts. For cleaning and lubrication, you will need a table, from which you must remove all valuables in advance so as not to stain them with oil and dirt.

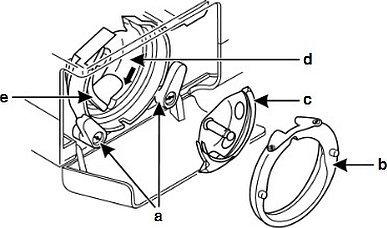

Sequence of disassembling and lubricating the machine

Disassembling the machine is necessary before lubrication. By looking at it, you can immediately determine the elements that can be removed and unscrewed. The general order of work is as follows:

- Remove the cover from the needle bar by unscrewing the screw and pulling the cover out;

- Turn the device over and loosen all the bolts at the bottom;

- Pull the gear shift knob back and remove it;

- Remove the cover from the side without touching the flywheel;

- Unscrew all remaining screws;

- Remove the handle fastener;

- Lower the handle of the presser foot;

- Separate the remains of the plastic housing;

- Remove the shuttle from the holder.

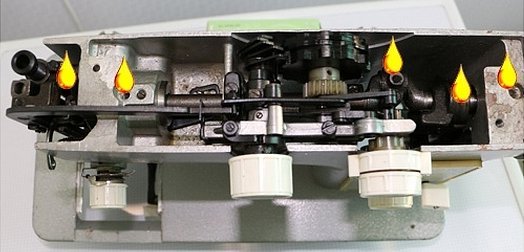

No further disassembly actions are required. All elements can be reached by hand or with a syringe. The further order of lubrication of the units is as follows:

- Place the machine in a position as if it were going to be used for sewing;

- Fill the syringe with lubricating fluid;

- Slowly turn the flywheel counterclockwise;

- Drop oil onto all available parts and their joints, which will begin translational and rotational movements;

- Do not touch plastic parts and gears that have already been lubricated with a special compound under any circumstances, as this may damage them;

- Lubricate the needle bar parts in friction areas;

- Remove excess grease with a napkin or cloth;

- Check the operation of the units by connecting the power supply;

- Assemble the machine and give it a couple of hours to allow the joints to soak in oil;

- Run for a couple of minutes with the presser foot raised.

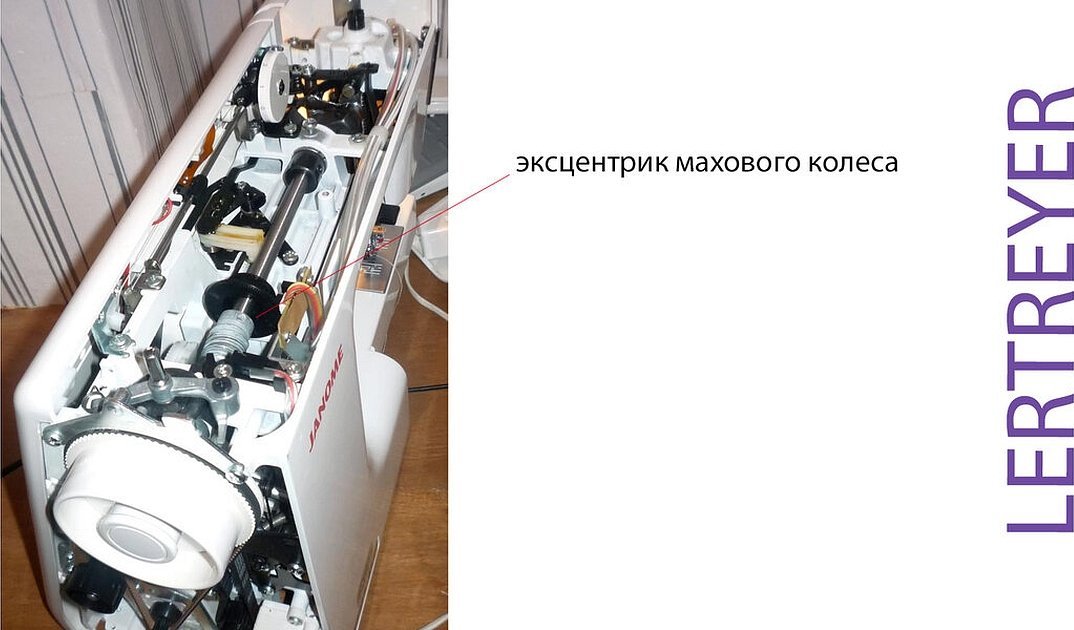

How to lubricate a Janome sewing machine

Janome are popular machines, so the question is relevant. As with any device, they require constant breakdown prevention and lubrication. At least the main units that set the device in motion need to be treated.

Before work, it is important to read the cleaning and operating instructions, examine all the explanatory drawings. It is necessary to remove the cover of the device and pour the lubricant into special holes, and also apply it to the rubbing elements.

Brother Machine Lubrication

No less popular brand of machines. It has its own instructions, but if it is lost, it is important to remember that a couple of drops of oil will be enough for processing. They should be applied only to metal surfaces, avoiding lubricating plastic.

Important! The brother especially needs high-quality wiping of excess oil after processing, as well as idle operation to consume the mechanisms.

Singer

High-quality Singer machines require lubrication much less often, but still require maintenance. Cleaning them should start with the needle plate. To do this, unscrew the screws and clean. Next, clean the shuttle: remove the cap and move the clamps apart. The shuttle parts are removed and cleaned of dust. The same is done with the rotation device itself.

Astralux

To service Astralux you need:

- Remove the needle plate by turning the handwheel until the needle is in the highest position;

- Clean the lower fabric feed. To do this, remove the bobbin cap and clean the feed with a brush;

- Clean the mechanisms and lubricate them. Remove the bobbin and cap and fold the two holders to the sides. When this is done, the shuttle will come out freely and you can lubricate the device;

- Replace the bobbin and cap by turning the handwheel.

Machines with vertical shuttle

They especially need lubrication, even imported ones. The steps are the same: remove the bobbin and move the locks apart, take out the shuttle parts and wipe them thoroughly. Put everything back. In such machines, it is important that the needle bar is in the upper position.

Machines with horizontal shuttle

Most of these machines have a lubrication-free shuttle, but this is a ploy to sell new equipment when the old one breaks down due to improper operation. Any moving mechanism needs lubrication.

Machines with a rotating rotary shuttle

This type of shuttle is the most reliable and lasts the longest. Another advantage is its high sewing speed. This is explained by its popularity in industrial machines. For long-term operation, it is necessary to clean it and drip three drops of oil.

How often should I clean and lubricate?

If the sewing machine is new, then at first it needs to be lubricated once every six months. As the machine ages, lubrication is done every three months. This largely depends on the intensity of work.

If a person uses the machine every day for several hours, it is necessary to constantly listen to it. If suddenly there are extraneous noises, knocking, creaking or rustling, this is a reason to disassemble it and clean it well, additionally applying a new portion of lubricants. This will prevent breakage and sudden failure of the sewing unit.

In conclusion, it can be said that a sewing machine, no matter how high-quality it is, needs repair and maintenance. In order not to repair a broken unit of an expensive product, it is necessary to follow simple rules and periodically inspect the device, listen to the sound of its operation, and lubricate it in a timely manner.