The correct choice of thread used for sewing can be considered one of the most important factors that ensures the perfect stitch. Even when using the highest quality sewing machine, you cannot be sure of quality work if the thread is not selected correctly. In order to make the right choice, you need to know what threads are needed for sewing machines, the rules that must be followed when choosing.

- Types of threads and their use for sewing equipment

- For sewing thin and medium fabrics

- Main types of sewing threads

- Nylon

- Reinforced

- Polyester or nylon

- Cotton fifty

- Do not use "old" cotton threads

- How to make the right choice

- Table of correspondence between needle numbers and thread markings

- How to check the quality of sewing thread

Types of threads and their use for sewing equipment

Sewing threads can be divided into three types:

- Those made from natural materials. These include silk, linen, and cotton fibers.

- Made using artificial materials.

- Those used include both natural and chemical fibers.

Most often, when using natural threads, cotton ones are chosen. Most often, this is done at the initial stages: they are used to sweep clothes or parts of them.

When choosing threads made of artificial materials for work, reinforced ones are usually used. They combine the positive qualities of natural threads and the strength of artificial ones.

In the store, on the packaging of threads, you can see letter designations, knowing which, you can find out what kind of thread it is.

Here are some of them:

- If there is a designation “COTTON”, we are talking about cotton threads.

- The designation "L" refers to polyester, which is used to create invisible stitches and decorative relief seams.

- The abbreviation "LSh" means "polyester staple". They are used for light and medium density fabrics.

- "LT" stands for "light textured". Their area of application is working with elastic knitwear.

- Polyamide fibers (designated by the code "K") are characterized by high strength and resistance to moisture.

There are elastic threads. They are a combination of thin rubber and regular threads. They are called "spandex".

For sewing thin and medium fabrics

Here are the threads for sewing on a sewing machine, which ones to choose for work:

- When planning to sew children's clothes or knitwear, the best choice would be cotton thread No. 40. It is suitable for working with cotton fabrics.

- If tulle or chiffon is used, it is recommended to use No. 70-80.

- Work with suit fabric is carried out using cotton thread No. 50-70.

- For satin or woolen materials, threads No. 40-70 are suitable, depending on the thickness of the material.

It may also be suitable to use silk thread. It is considered universal in its quality. It can be used to stitch most types of fabrics.

Main types of sewing threads

Thread classification can be considered in different ways. According to the method of their finishing, they are:

- matte (their distinctive feature is the absence of shine);

- glossy (creating a characteristic shine);

- harsh (made from material that is not designed to be bleached or cleaned);

- plain colored, black or white threads;

- those that have undergone special treatment and acquired special properties (for example, reflective or fire-resistant).

You can consider the varieties taking into account the material of manufacture (polyester, cotton, reinforced, silk, nylon and others).

Threads can be divided according to their purpose (for example, for darning, yarn, sewing, beading, creating embroidery).

There are those that are intended for a specific narrow purpose: for basting details obtained during cutting, for sewing on frills or other uses.

Nylon

These threads are relatively stiff. For this reason, they are often used to sew bags or some types of shoes. They come in two types: monofilament or twisted. When sewing clothes, this type of thread is used for blind stitching or hemming.

Reinforced

The peculiarity of this type of threads is elasticity, which is combined with high wear resistance. This is one of the answers to the question of what are the strongest threads for sewing.

Important! If you go to a store to buy reinforced threads, you will see that each of them has an alphanumeric code written on it. The first part consists of two single-letter designations. It contains information about what material the threads are made of.

Here are some examples:

- If the designation “LL” is used, then the materials used for production were lavsan and flax.

- When the designation "LH" appears, it means a combination of linen and cotton.

- In eichi with "LSh" wool and lavsan are used.

The digital part of the code is the marking of sewing threads by thickness.

Polyester or nylon

The use of threads made from artificial materials is beneficial when you want the product to look better and the stitching to look perfect.

Nylon thread is very strong, it is made in such a way that it cannot fray - therefore its use at the stage of final finishing of the product is justified. It can be used to reliably sew a seam. Synthetic threads are highly durable and will not break under slight tension.

Cotton fifty

If you plan to do the work not only with a Janome, Versailles or other sewing machine, but also manually, then the most convenient option would be to use cotton thread No. 50. They are not only one of the cheapest and most accessible, but also suitable for almost all types of fabrics used. The only exception would be when the material is too thin.

In this case, the cotton thread can tear it. Sometimes, when making stitches, breaks will occur. Another option when such a thread should not be used is a dense and hard material (for example, used for sewing jeans). It can easily tear the cotton thread. In these cases, it is necessary to switch to using a more suitable thickness or other types of threads.

Do not use "old" cotton threads

Nowadays, you can often find threads that are similar in quality to those produced in the USSR. Although at first glance they can be used, in reality things are different. Threads of this type have important disadvantages regardless of their numbering. Here are some of them:

- When working with old-style threads, stitching is poor.

- They tear easily.

- Such threads are not elastic enough and can gradually wear through the plastic shuttle.

If a seamstress has such threads, they can be selected only for marking or similar work. There are inexpensive threads of fairly high quality on sale, which will be useful for those who use a Singer or Podolsk sewing machine.

How to make the right choice

When determining how to choose threads for sewing machines, you need to consider the following factors.

When purchasing threads, it is important to consider that the choice of the appropriate thread depends on the fabric used for sewing. The type of sewing machine used is also important. If specialized devices are used (coverlocks, overlocks or flat-stitch machines), then a completely synthetic thread (for example, 100% polyester) will be a good choice for them.

This material is thin, strong and elastic. The width of such threads is the same throughout. Their use eliminates the risk of loops, sudden breaks, gaps and other problems associated with the use of low-quality threads.

When working with a certain product, it is recommended to use the same type of thread throughout the entire sewing process. At the same time, you should not change their number, type and manufacturer.

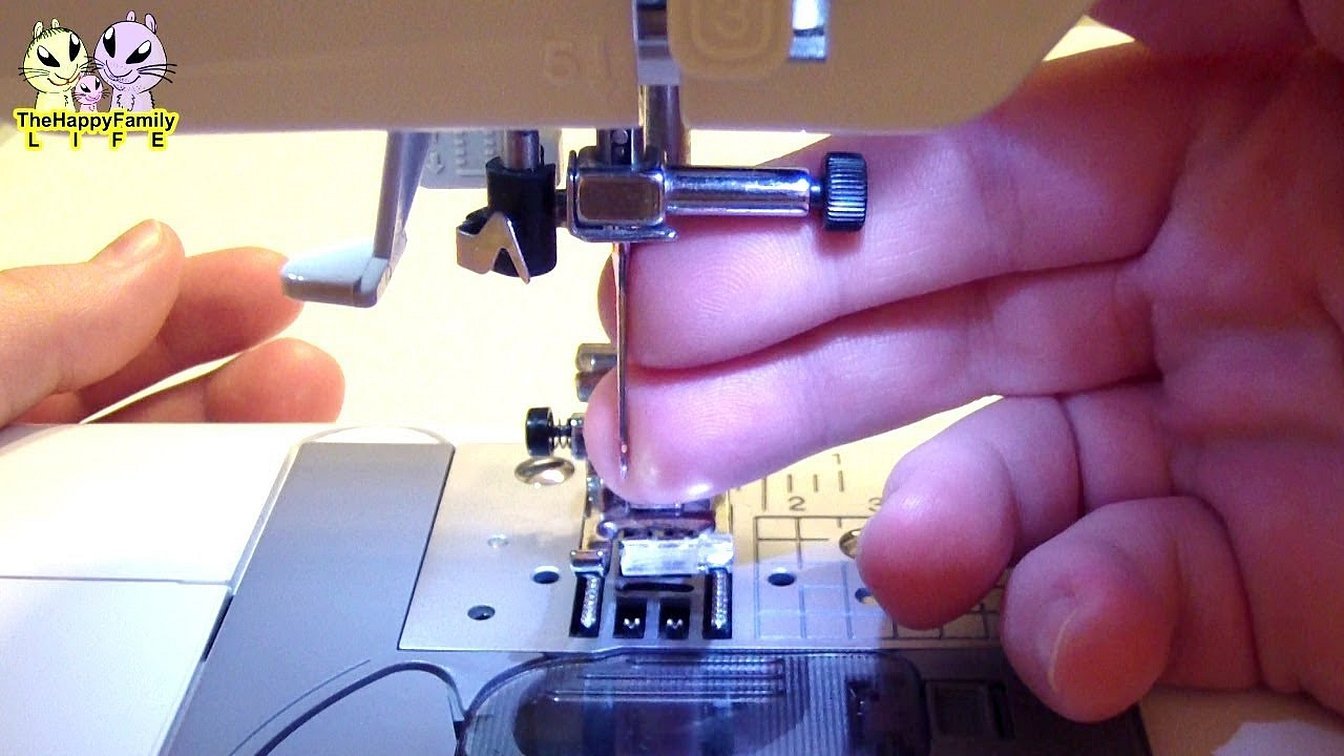

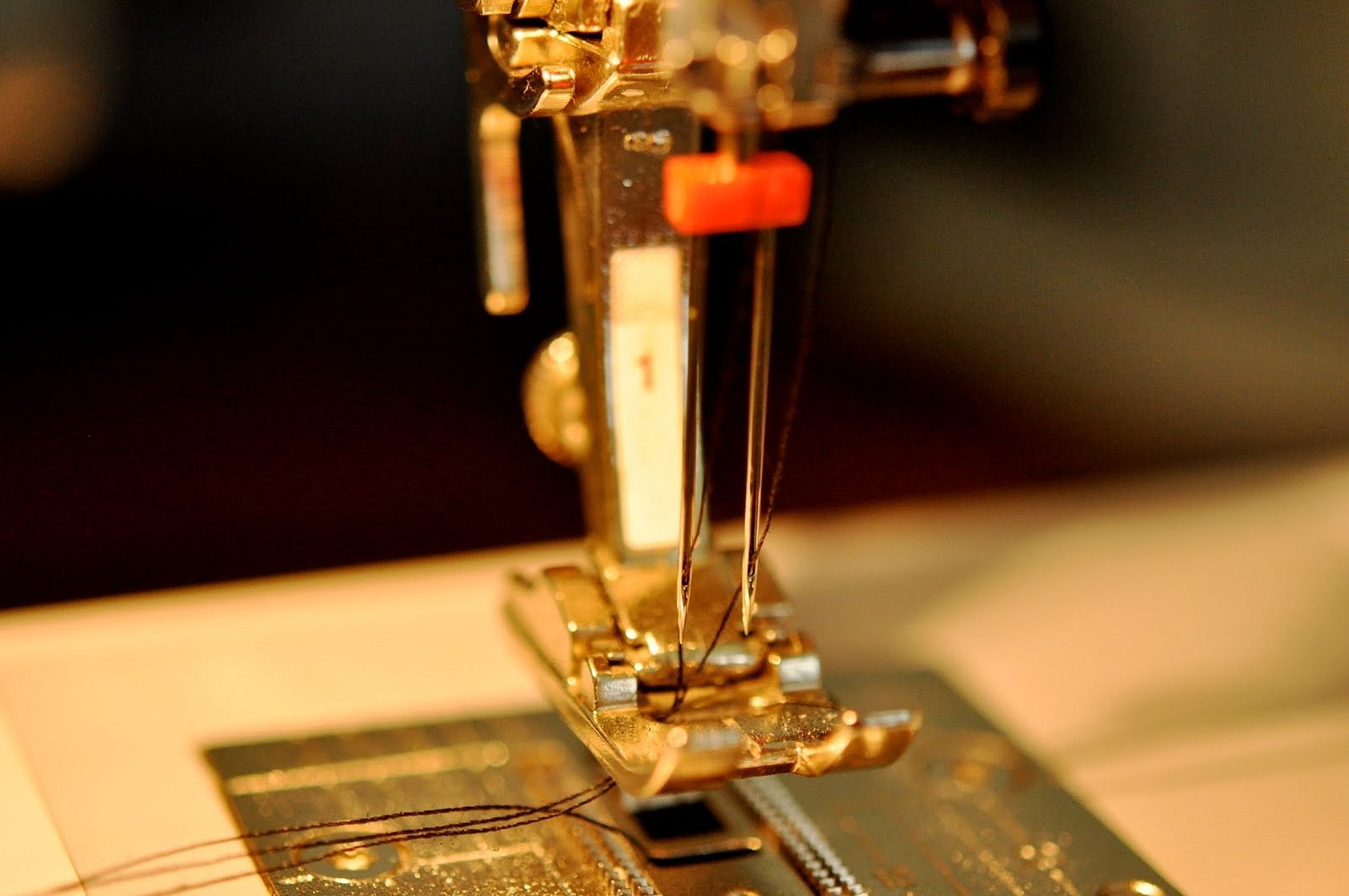

It is important to choose a thread that best suits the sewing needle being used. This part of the structure experiences maximum stress during operation.

For hidden fastening of parts, a thin, colorless nylon thread can be used.

It is also possible to formulate general requirements for selecting threads:

- A convenient reel or spool must be available.

- It is desirable that shrinkage be minimal.

- High-quality threads must have good resistance to moisture, temperature and other factors that destroy clothing.

- Tear resistance.

Please note! When choosing what threads to use on a sewing machine, it is recommended to use products from well-known brands that have been on the market for a long time.

Table of correspondence between needle numbers and thread markings

In order to determine the size of the needle, you need to know its number. It represents the thickness of the needle, which is measured in special units - hundredths of a millimeter.

The following table provides recommendations for selecting threads for different fabrics and sewing needles.

| Type of fabric used | Sewing needle number | Cotton thread number | Number and types of reinforced threads |

| Batiste or fine silk | 75 | 80 | |

| Chintz, silk, satin, fabrics for sewing underwear | 80 | 80 | |

| Sheet fabric, calico, woollen fine fabric, flannel, cotton heavy fabric, thick heavy silk | 90 | 50 | 35 LH (LL, LS) |

| Tick, woolen fabric for sewing suits | 100 | 40 | 45 LH (LL, LS) |

| Cloth, drape used for sewing coats, thick woolen fabric, leather | 110-120 | 40 | 45 LH (LL, LS) |

When using the table, it is important to remember that the choice must correspond to the type of fabric being processed and the tasks that the tailor needs to solve.

How to check the quality of sewing thread

Before using, you need to make sure that the thread is of sufficient quality and suitable for the job. There are necessary signs that will help you form your own opinion on this issue:

- It makes sense to examine the thread carefully and make sure that its thickness is the same everywhere. Low-quality thread has clearly distinguishable thick and thin sections. Uneven density increases the likelihood of breakage.

- When stretched, it should not immediately break. It is normal when it first stretches a little, and only then breaks.

Important! When carefully examining the spool of thread, it will be convenient to use a magnifying glass. You can also examine it against a contrasting background. For a light one, choose a dark one, and for a dark-colored thread, choose a light background.

Correctly selected threads will allow you to sew the product more efficiently. It is important to consider the type of needles used, the fabric and other important features of the product being created.