The difference between industrial sewing machines and household models is enormous. It mainly consists of the number of items produced in a short time and the ability to perform a certain range of tasks. Large sewing workshops and small studios are usually equipped with professional equipment, which differ from each other in the degree of automation and class. For home use, a household unit is sufficient.

- Purpose of industrial sewing machines

- Classes and types

- Sewing machine class 22

- Sewing machine class 1022M

- Industrial sewing machine class 97

- Sewing machine class 23 - a "giant" among sewing machines

- Sewing machine class 852

- Special vehicle class 26

- Overlock class 51

- Buttonhole machine class 25

- Sewing machine class 2m

- Selection criteria

- Manufacturers

- Model overview

Purpose of industrial sewing machines

Industrial units work quickly and efficiently. At the same time, they are designed to perform specific functions. Currently, manufacturers offer the following varieties of these powerful units:

- for sewing and finishing bed linen;

- working with very dense fabrics;

- sewing and finishing of knitwear;

- sewing of fur products and fur processing;

- manufacturing of leather goods;

- sewing on zippers and buttons;

- overcasting and hemming the edge of the product;

- application of basting, applique and embroidery.

Please note! Regardless of the function performed, this type of machine performs work quickly and efficiently.

Excellent results are achieved through precise and complex adjustment of operations. It is impossible to achieve such indicators on household models.

Classes and types

Every person involved in sewing and repairing clothes needs to know the main classes of sewing machines. Such information will help you navigate the sewing world more easily and will also significantly broaden your horizons.

Sewing machine class 22

Despite the fact that this model is no longer produced, its representatives are still used in small sewing enterprises, as well as by amateurs of this industry. The sewing machine of class 22 is morally obsolete, but this has not affected its demand and popularity. According to professionals, in certain parameters it is not inferior even to modern models. The main advantage is considered to be reliability and versatility. Which is a rarity among industrial models. You can sew products from any fabric on this machine, as well as leather.

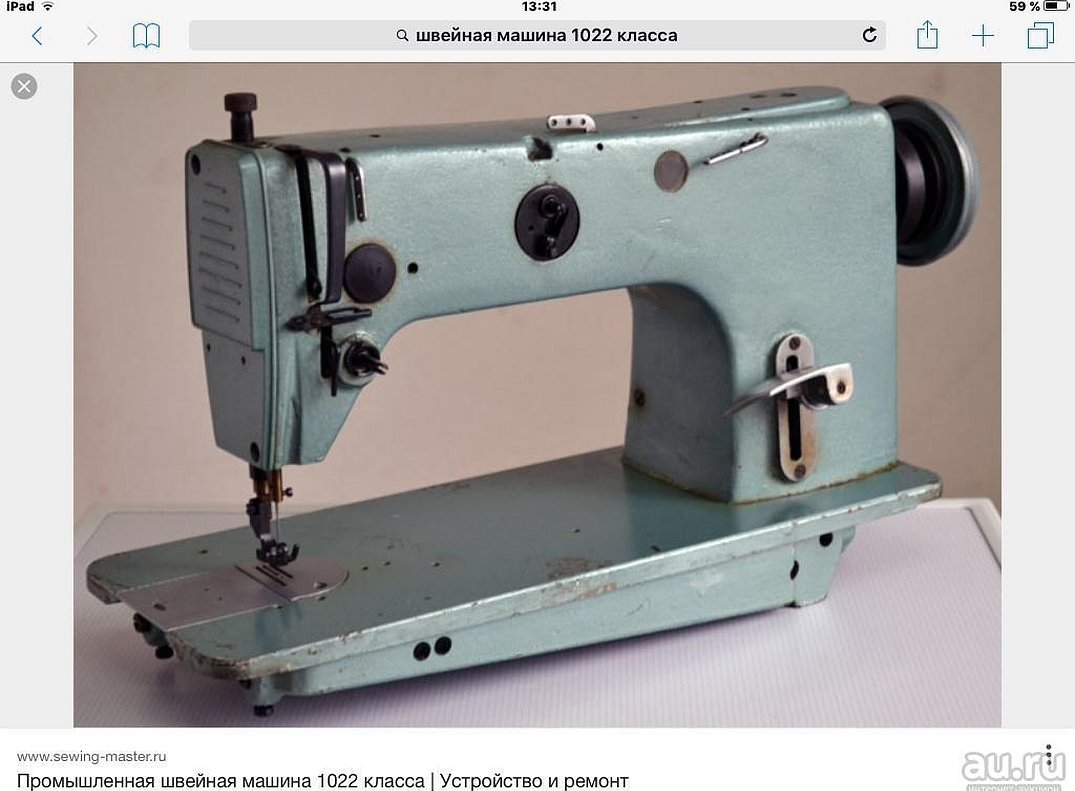

Sewing machine class 1022M

This machine is a modern modification of the class 22 unit. It differs from its predecessor in a more modern appearance. On the body, it has a stitch width regulator, an automatic thread winding device on the bobbin, a convenient reverse lever, and automatic lubrication is provided. Despite the mass of updates, the old model is still considered more successful. This is explained, first of all, by the fact that the class 22 machine is less noisy, 1022 m during operation makes a characteristic noise, which increases at high speeds. Otherwise, these two units are no different.

Industrial sewing machine class 97

The silent sewing machine features high speed, high-quality stitching, and forced continuous lubrication. The unit is designed for stitching suit and light materials with a two-thread shuttle stitch. If we compare it with previous models, it is not designed for sewing items from very strong fabrics, and it is also a little more difficult to set up, especially if you have no experience.

Sewing machine class 23 - a "giant" among sewing machines

It is distinguished by its impressive dimensions. The unit has a needle No. 150, so only thick threads should be used for sewing. The sewing machine class 23 is designed for sewing very thick materials and fabrics. With its help, belts, tents, soldiers' greatcoats and much more are sewn.

Sewing machine class 852

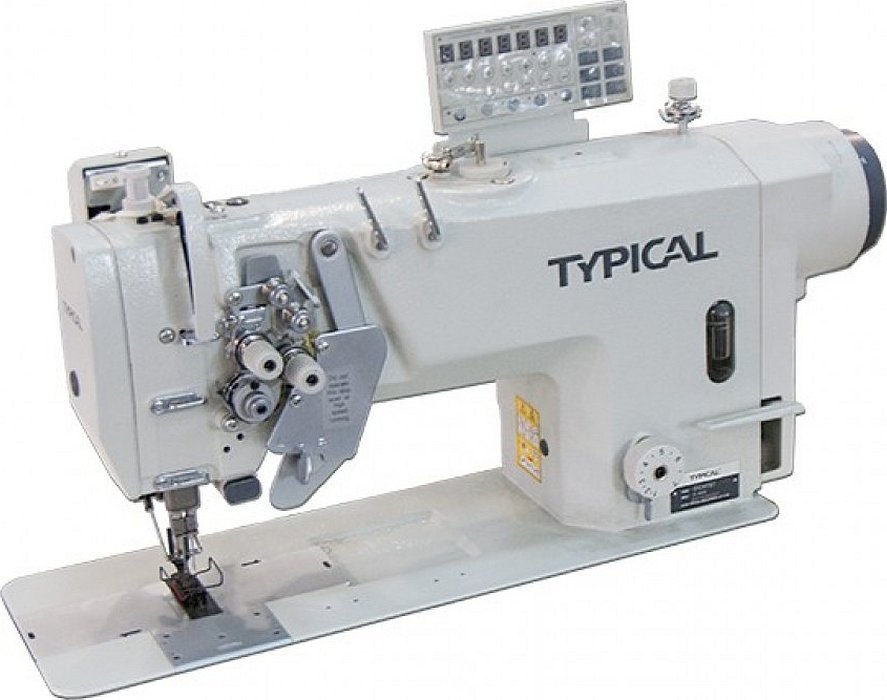

Often, sewing machine classes are derived from the basic model. Industrial sewing machine class 852 is the basic model. All its modifications have certain changes related to the distance between the needles. Otherwise, the units have the same design and are equipped with two needles.

Machine class 852 is designed for stitching with two parallel lines of lockstitch of clothing parts made of suit and light materials.

Special vehicle class 26

The unit is specially designed to perform zigzag stitching of shuttle weave. The stitch width is adjustable up to 9 mm, the length up to 5 mm. It is impossible to find such zigzag parameters in household machines.

Overlock class 51

One of the most common industrial sewing machines, which is used both in the studio and at home. Despite the fact that this equipment has long been outdated, in some cases it is impossible to qualitatively process modern materials without a sewing machine of class 51.

The unit is distinguished by the presence of a differential fabric engine. The overlock can overcast various types of fabric.

Buttonhole machine class 25

A reliable and virtually trouble-free machine, which, despite its impressive age, is still used both in small-scale production and in the studio. With its help, regular straight loops of a shuttle stitch are formed on the fabric by cutting a hole in the loop.

Sewing machine class 2m

Despite the advent of electronic and electromechanical sewing machines, this unit is considered one of the most common in everyday life. The sewing machine "Podolsk 2m class" is intended for sewing products from silk, wool and cotton fabrics with a regular two-thread seam. The line consists of stitches connected to each other, which are folded into a continuous row. The sewing machine class 2m produced by the Podolsk plant PMZ can be either with a manual or foot drive.

Selection criteria

When choosing an industrial unit, the main criterion is its purpose. Before purchasing a particular unit, it is necessary to determine exactly what items will be sewn on it and in what quantity. The technical characteristics will also depend on the goals set.

For a small studio or private sewing, it is best to purchase universal units.

When choosing a machine for industrial sewing of products, it is also necessary to pay attention to the working qualities, functionality and convenience. In addition, the noise level, smooth running, the amount of electricity consumed, lightness and operation of the motor are also important. An equally important criterion is the type of material with which the unit can work.

Manufacturers

Japanese manufacturers offer a wide variety of models with all sorts of functions. Among the units they produce, you can find everything that is needed in sewing production. The models are distinguished by reliability, functionality and reasonable cost. The most common and popular are JUKI sewing machines.

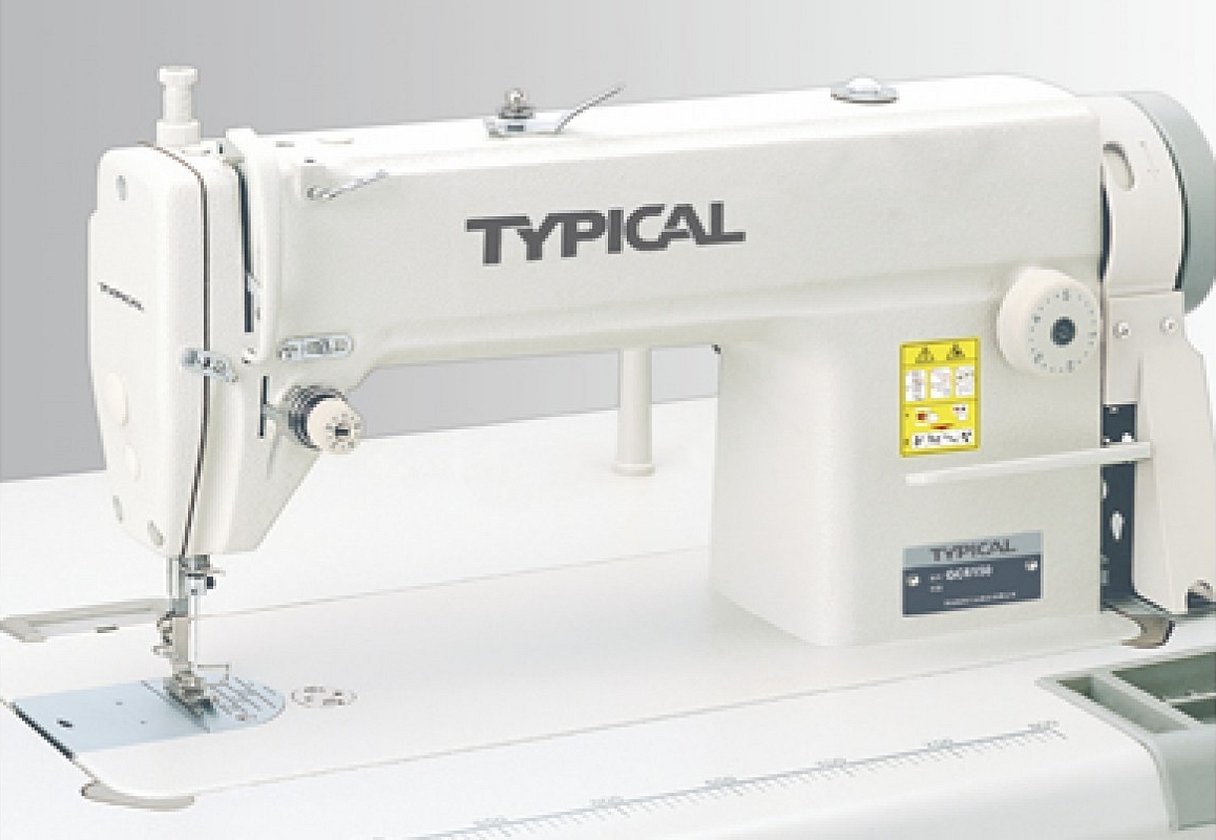

China can boast of good products. Manufacturers offer a wide range of units capable of handling all sorts of tasks. In addition to good quality and functionality, they are distinguished by a relatively low price. The most common Chinese machines are the following brands: SHUNFA, JACK and TYPICAL.

For sewing sportswear, workwear, outerwear, as well as protective uniforms and women's underwear, sewing companies often give preference to Pfaff machines, which are manufactured in Germany. The high quality and speed of the units has been the calling card of the manufacturers for many years.

Singer sewing machines have been in great demand for a long time. They are manufactured by an American corporation. You can only hear positive and enthusiastic reviews about the characteristics, functionality and speed of these units, and the quality is truly time-tested.

Model overview

As practice shows, studios and sewing factories generally prefer universal models. This is explained by the fact that they are capable of performing different types of stitches. In addition, they are much more convenient to work with, and they can be used when sewing products from different types of textiles.

Please note! When choosing an industrial unit, you need to consider the type of shuttle, the operation of the threader, the maximum stitch length, thread tension control, as well as the complete set of needles, feet and bobbins.

The most common models, which have proven themselves only on the positive side, are the following units:

- Brother B845 - has two threaders, the ability to adjust the stitch length and a horizontal shuttle.

- Brother B530 — according to the instructions, the main function of the unit is overcasting edges. At the same time, the machine can perform straight-line work. It has a swing-type threader.

- Juki LBH-780 U — the unit is equipped with a combined shuttle and an automated thread tension regulator. The foot pressure is adjusted from the panel, and the threader is equipped with a shield.

- JACK JK-210D — the machine is produced with a set of bobbins, needles and replaceable feet. Thread tension is adjustable. The unit performs a straight stitch and has the ability to turn off the reverse.

- Typical GC6150-H — the model is equipped with a wide pad on the working area. The unit can overcast edges, perform straight and overlock stitches. Equipped with a horizontal shuttle.

The list of models is endless. The most important thing when choosing a unit is to take into account the characteristics and features. It is worth choosing a model based on its intended purpose, since its cost directly depends on this.

Industrial sewing machines differ significantly from household modifications. Today, the market offers a wide range of units. At the same time, everyone who is associated with this industry should know about the classes of sewing machines, what they are, and have an idea of the most common options.