A sewing machine allows you to do large and complex work with high quality and in less time. It is possible to work with thick or thin material. However, incorrect use of equipment and materials can lead to problems, one of which is frequent skipping of stitches. To fix this, you need to know what causes this and what can be done in each case.

- How a stitch is formed

- The main reason for the appearance of gaps in the line

- Why the upper thread does not catch the lower thread: what to do

- Reason for failure of needle and shuttle settings: what to do

- Using a Round-Barbed Needle Causes Missing Blood: What to Do

- Using special needles for sewing knitwear and leather

- Damaged needle: what to do

- Choosing the right needles: causes and solutions

- The needle plate hole is badly broken: what to do

- Twisted thread: what to do

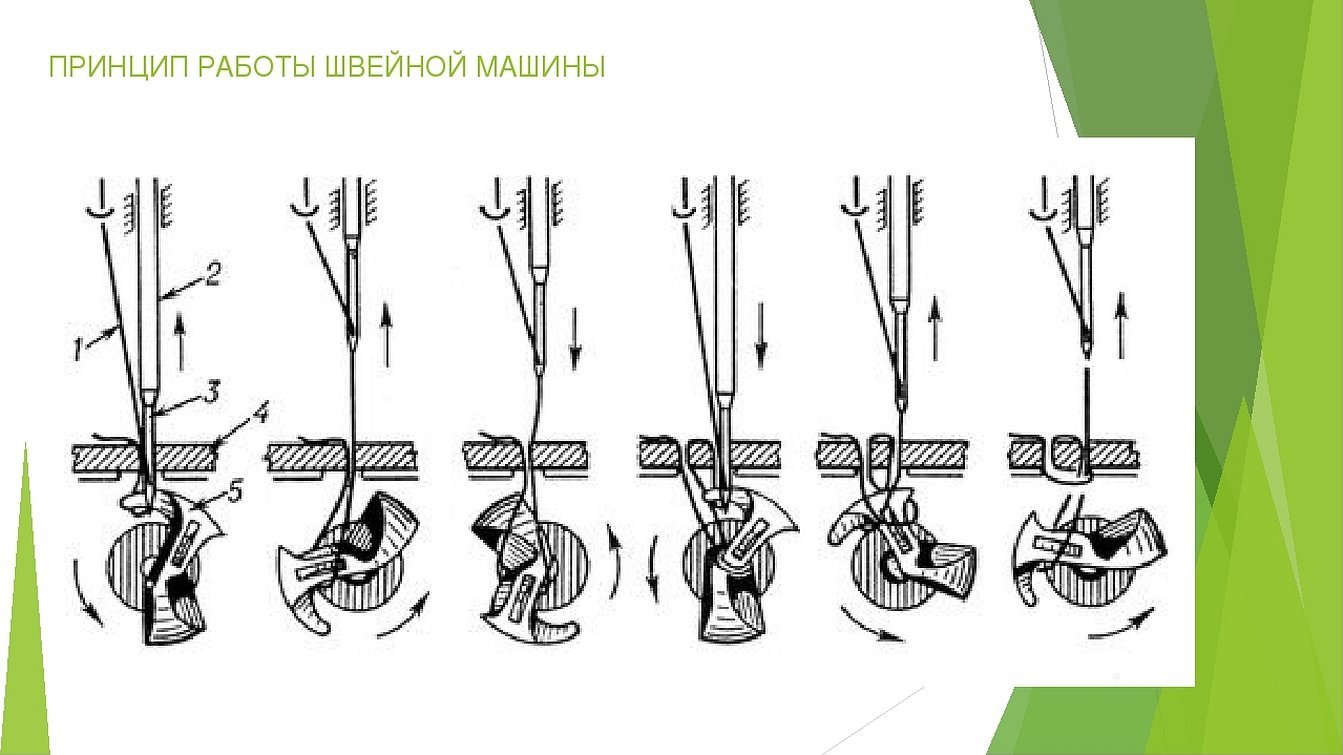

How a stitch is formed

The sewing machine is possible due to the high precision and synchronization of the movement of various parts. Here it is much more important than, for example, in a washing machine. When making stitches, two threads are used:

- The thread located at the top is wound from the spool and passed through the eye of the needle.

- The one that is wound from a bobbin located below the working surface of the machine.

The shuttle is a part that rotates and hooks the thread coming out of the eye of the needle. To create a stitch, this hook pulls the loop down, then the thread is pulled up and it hooks the thread coming from the bobbin. Then the machine starts a new stitch.

During these operations, the precision of the movements and the mutual position of the needle and shuttle are very important. It is also important to pay attention to the correct tension of the upper and lower threads: not too tight and not too loose. When creating a zigzag seam or other work is done in a similar way.

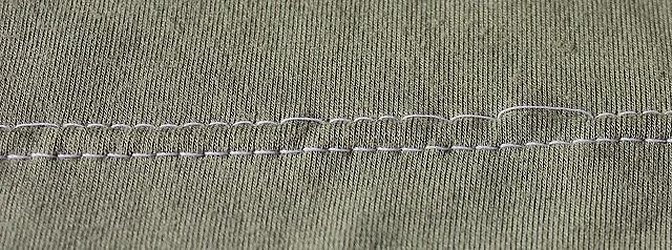

The main reason for the appearance of gaps in the line

If a Janome or other sewing machine skips a stitch, then a straight section of thread is visible on the fabric instead of a large number of stitches. The main reason why this happens is that the shuttle hook cannot catch the thread coming from the eye of the needle when moving down. Skipping stitches in a machine stitch happens if the seamstress does not pay attention to the defect in time. There may be various reasons for such a breakdown. In order to restore the correct operation of the sewing machine, it is necessary to understand why the sewing machine skips stitches when sewing.

Why the upper thread does not catch the lower thread: what to do

In order for the shuttle nose to be able to catch the thread when moving down, the distance between them must be 0.3 mm. If it is more or less, it will lead to the formation of skipped stitches. Such a defect in the stitching can also occur for other reasons. The tension force must be precisely set for the upper and lower thread.

The bobbin on the Brothers machine has a screw for this, which needs to be tightened in the right direction. You can check the correct tension by holding the bobbin by the thread and shaking it slightly. It should move down a little. If the bobbin is too tight, it will not move, and if it is too loose, it will start to unwind quickly.

Reason for failure of needle and shuttle settings: what to do

If all the parts are installed accurately, the machine will make neat seams. However, over time, the mechanism components may shift, which can lead to problems in operation.

The shuttle is a structure consisting of several parts. Some brands of the machine (for example, "Podolsk") use a plastic ring, which can lose its shape over time. To make it even again, you can use the following method:

- Prepare boiling water.

- Place the part in it for a few seconds.

- Remove and place on a clean piece of cloth.

- A cold iron should be placed against the side that needs to be straightened.

As a result, the part will become even, and the shuttle offset will be correct, after which the machine will stop skipping stitches.

Using a Round-Barbed Needle Causes Missing Blood: What to Do

For high-quality work with biflex or other fabric, you need to make sure that the correct type of needle with a round shank is installed.

Important! If it is taken from another model, this may lead to a violation of the distances with other elements of the mechanism.

The differences may be minor, but the needle will still tear the material. Minor differences in quality can cause problems.

Using special needles for sewing knitwear and leather

When stitches are skipped on a sewing machine, the reasons may be different. You also need to check the following: the needle matches the material. Sometimes there are difficulties with stitching certain types of fabrics (for example, suede, fur or leather), here it will be appropriate to use special numbers and shapes of needles.

Only in this case the needle will be able to easily pierce the knitwear or leather without tearing it. A needle specially adapted for working with this fabric will make high-quality stitches and reduce the risk of skipping them.

Damaged needle: what to do

Sometimes the reason for skipping is the use of a low-quality or damaged needle. This can happen in a situation where it is bent and tries to pierce thick fabric. This bend may be completely unnoticeable at first glance. Another reason for the problem may be a situation where the needle has become dull. This situation most often occurs when creating a multi-layer seam. It is necessary to replace the needle with a more suitable one.

Choosing the right needles: causes and solutions

The choice of thread is important for the quality of sewing. This is another reason why the sewing machine skips stitches. You need to use a thread of a certain thickness for use with a specific needle. Otherwise, it will move unpredictably during the operation of the sewing machine and will start skipping stitches. For example, a thick thread in a thin needle can quickly break. This happens because it will have difficulty passing through the fabric.

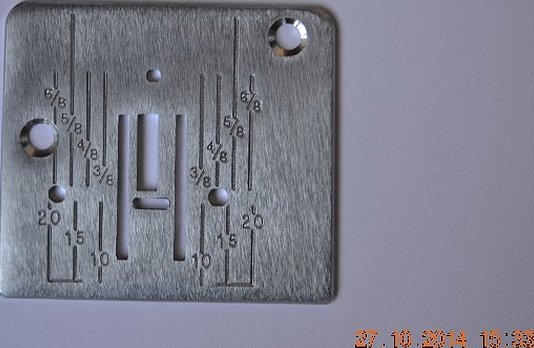

The needle plate hole is badly broken: what to do

In this case, the fabric in which the stitches are made will be pressed into the hole. This will lead to skipped stitches. The material will interfere with the passage of the needle with the thread. This is fraught with the fact that on the return stroke the thread will not form a loop, and the shuttle will not be able to capture it. In order to eliminate the cause of skipping on the sewing machine, you need to replace the damaged part with a working one.

Twisted thread: what to do

If a low-quality thread is used, it may behave unpredictably. If it is twisted, it will spontaneously begin to twist into knots. If it has an uneven thickness, it will not allow it to pass freely through fleece or other material. Such a defect may cause the loops to form incorrectly when the needle moves.

When selecting by hand, you need to choose threads of uniform thickness, moderately elastic, not twisted. For example, you can use those made of polyester. The thickness should correspond to the needle used and the material with which the work is performed.

If the sewing machine skips stitches, you need to make sure that the needle and threads are selected correctly, and the shuttle and needle are at a certain, precisely verified distance from each other. To correct the situation, you need to use high-quality parts and threads. It is important that they match the fabric you are working with. If you cannot fix the machine yourself, it makes sense to contact a specialist for this.