There are many ways to print an image on fabric, they differ in color rendering, quality and capabilities. Below are the basic methods of printing on a fabric base.

Description of various fabric printing technologies

The most popular fabric printing technologies are presented below.

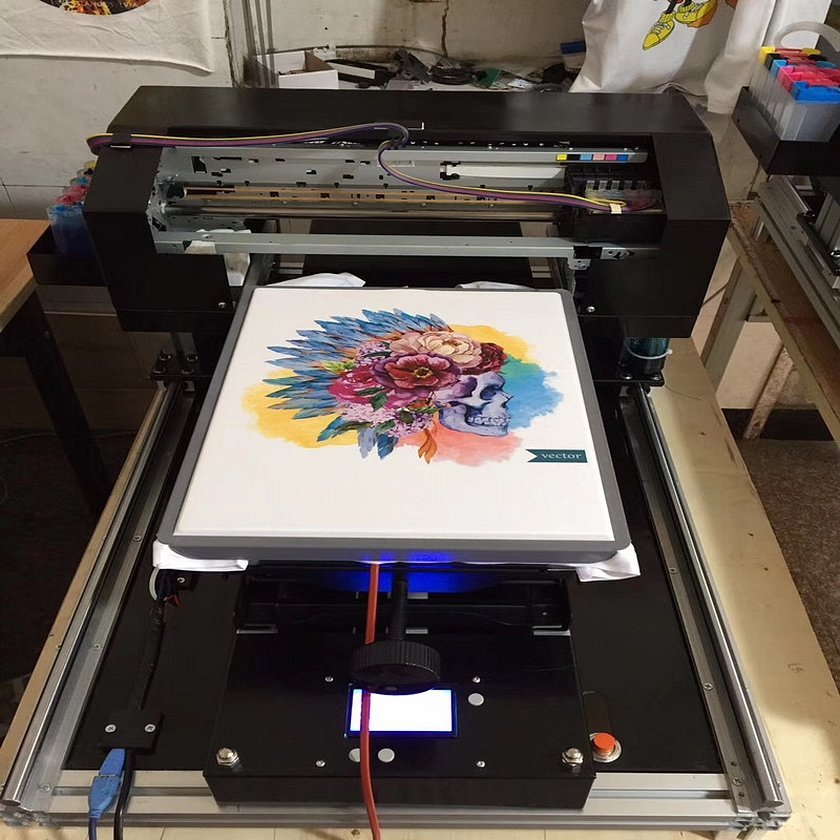

Digital printing

Digital printing on fabric involves applying an image using a printer without using paper or film. It is due to the absence of an intermediate carrier that this method is called direct.

Direct digital printing is used for both individual and batch orders. This technology is distinguished by the ability to quickly apply a print to textiles, print a T-shirt with a logo, decorate table and bed linen.

Because this method uses through-dyeing of the fabric, it is ideal for flag production.

Among the features of this technology for applying prints to textiles, the following are worth mentioning:

- the price of the service is lower than other types;

- high-quality printing is available, which allows you to print photos on fabric;

- To achieve the greatest stability of the pattern, it is necessary to select a light-colored fabric;

- the durability of the design on colored fabrics depends on the quality of the white ink, which is used as a base for the future image;

- The color range most often consists of either four colors (CMYK model) or six (CMYK Orange Blue model).

Important! When using the budget CMYK color model, it is impossible to convey rich blue tones.

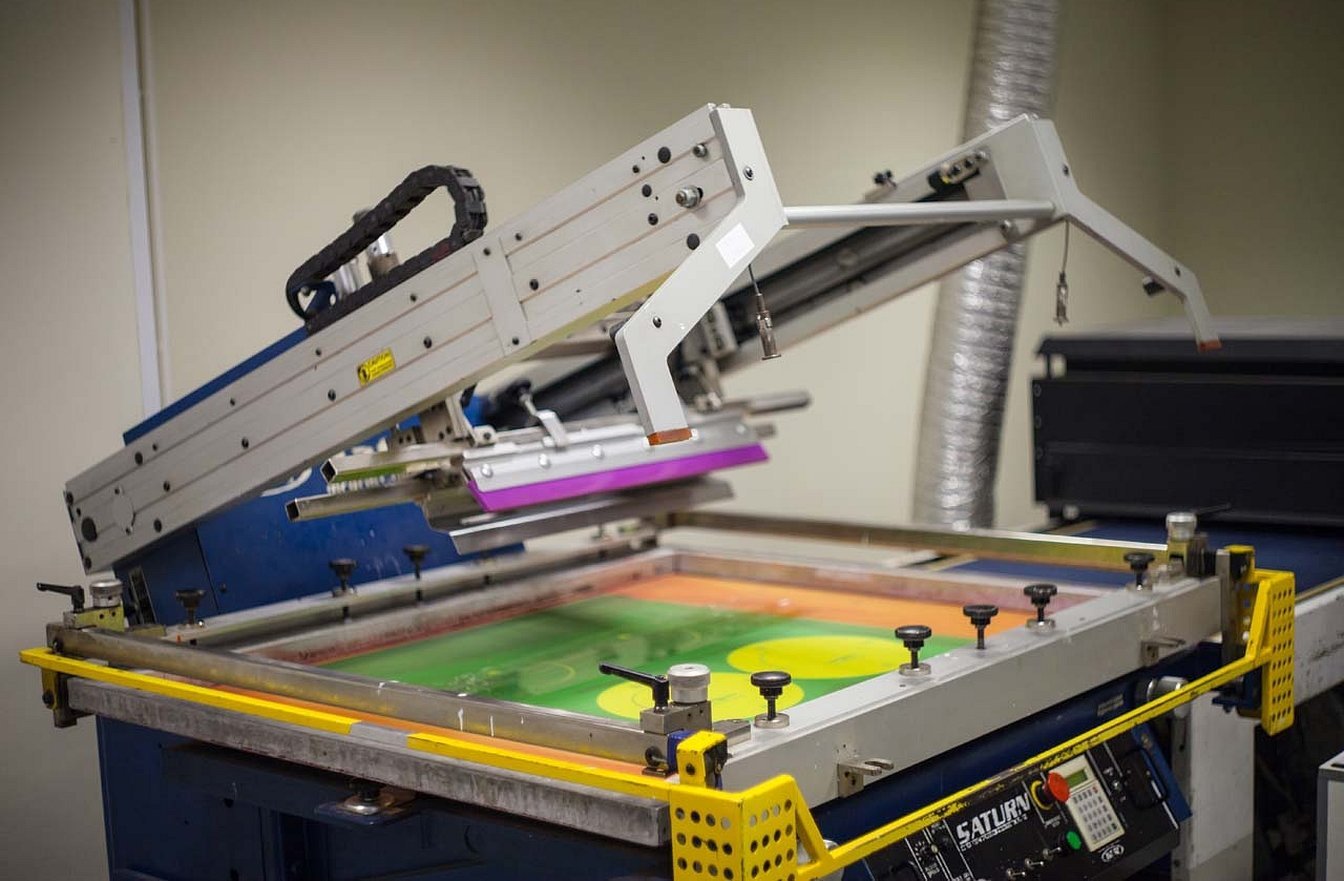

Screen printing

Silk-screen printing or screen printing of designs on fabric is carried out using special equipment with nylon nets. They are installed inside the screen printing machine. Each color has a separate net with a stencil applied, through which the paint penetrates into the fibers of the fabric. Screen silk-screen printing can be used on any type of fabric.

The use of this application method is limited to the use of vector images for transferring to textiles. That is why most orders for screen printing consist of making inscriptions on batches of clothing. An order for screen printing is most advantageous from a price point of view for a large order, in which the applied image will contain a small number of colors.

There are several types of silk-screen printing:

- Direct full-color silkscreen printing. Used to obtain rich colors with shade transitions.

- 3D printing. Allows you to create three-dimensional relief images.

- Foiling. It is used to create metallized images of various colors.

- Thermal lifting. Allows you to get a "foamed" image.

- Light effects. Allows you to get a glow-in-the-dark print.

Important! Due to the peculiarities of this method, silk-screen printing cannot display smooth gradient transitions from one color to another on the fabric.

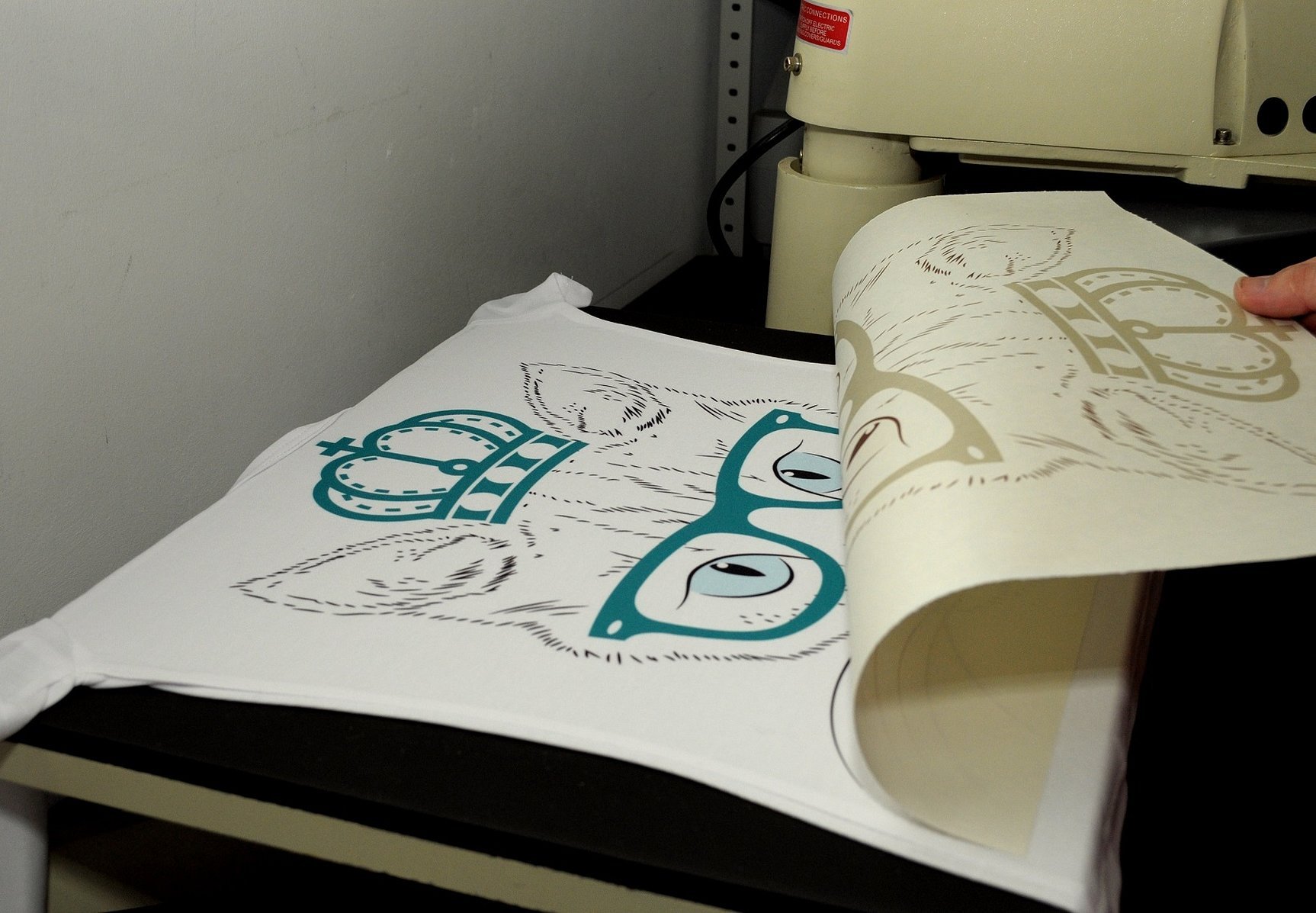

Thermal transfer

Thermal transfer literally translates as hot transfer. Thermal transfer technology involves transferring an image from a film to a product using a thermal press. First, the image is printed on transfer paper. The paper is covered with a thin layer of film, which is then transferred to the textile along with the image using a thermal press.

Thermal transfer is one of the most popular, simple and quick ways to decorate T-shirts and caps with designs.

This method of applying an image to the canvas has a number of advantages:

- the image does not lose color when transferred to textiles;

- suitable for any fabric composition;

- it is relatively inexpensive;

- The resulting print on the fabric withstands washing well.

Important! The quality of the final product directly depends on the quality of the dyes and transfer paper used.

Engraved shafts in printing

Printing a print on fabric in this way is done using copper cylinders, on which an engraved image is applied. The process of applying a picture to the canvas consists of the transfer of paint under pressure from the roller to the product.

This method is the most complex and technological. It is mainly used for roll application of non-multi-color prints on fabric.

Important! Engraved shafts are used only in factories in industrial production.

Sublimation printing

Sublimation is similar to thermal transfer technology in many ways. The printing process also occurs in two stages. First, the image is applied to photo transfer paper, which does not absorb paint. Then, using a thermal press, the dyes are transferred from the paper to the product and fixed there.

Sublimation printing is used to obtain a picture that is resistant to any external influences. This method of applying an image to textiles is often used to print large street flags.

Sublimation printing is distinguished by:

- photographic image quality;

- resistance of the image to fading;

- the possibility of applying dyes only to fabrics consisting of more than 50% synthetic fibers.

Important! High quality of the design is only possible when working with light fabrics.

What printing technologies are suitable for natural fabrics

The difficulty in applying an image to natural fabrics lies in the structure of the materials, which is not prone to easily incorporating dyes.

With the exception of sublimation, all of the above technologies are suitable for printing on natural fabrics. But some have difficulties working with natural fibers.

Regarding the digital printing method, it is worth saying that the durability of the pattern directly depends on the nap of the natural fabric. The more nappy the fabric base is used, the less durable the final image will be. This disadvantage is combated by smoothing the nap at high temperatures.

Using the screen printing method, it is possible to apply a pattern to all types of textiles by using different dyes for different fabric bases.

The technology of thermal transfer of an image onto natural fabric consists of using chemical inks, films and papers coated with polymer. Thermal transfer subsequently ensures the adhesion of dyes to the fibers of the fabric. The image obtained in this way is not felt on the product and remains for a long period.

What printing technologies are suitable for synthetic fabrics

Printing on synthetic fabric is quite unpretentious. The textile has pores that open during heat treatment, allowing them to absorb dye well. Therefore, when choosing custom synthetic fabric with your own design, you do not have to worry about any method not being suitable.

Printing images on bed linen

To create a design or print on bed linen, they usually resort to the services of large printing houses that have the equipment of the required size or a master in painting fabrics. Handwork is valued much more and takes a lot of time, which is why it is expensive per meter of fabric. Machine painting of bed linen is cheaper. There is also a combined technique for applying a picture, which includes the work of hands and a machine in shifts.

Bed linen is often subject to friction, so it is very important that the applied pattern is durable. It is also necessary that the textile does not become rough after dyeing and does not acquire an unpleasant chemical smell. This can be achieved by choosing the right paint.

The most popular method of dyeing bed linen from various fabrics is plastisol paints. They cover only the upper layers of the material and do not affect the softness of the fabric, while they do not lose color for a long time.

The main criteria for choosing a technology for printing an image on fabric are: the composition of the fabric and the properties of the paint. Textile printing methods differ not only in price and time of work, but also in some features of the final product.