More and more people are engaged in handicrafts. But for an effective and positive result in work, you need to have a good tool. In addition to sewing machines, needles and fabrics, you need to have a good and high-quality knife in your arsenal. It is necessary not only for home use, but also for large manufacturing factories and studios. Before buying, you need to know all the advantages and disadvantages of the tool, as well as the rules for choosing. This article tells you what a cutting knife is and how to choose it.

Advantages of the tool

Such tools have many advantages:

- It is more convenient and faster to cut than with scissors;

- Carefully cuts out patterns without damaging the fabric;

- You can cut two or three layers of fabric at once;

- Easily cuts thick fabrics such as felt;

- No need to sharpen.

There are some disadvantages:

- Price: Some models are indecently expensive;

- Massive size of the machines;

- Some types require constant sharpening of the blade;

- You need to carefully select a tool so that it is comfortable to hold and work with, otherwise it will be difficult to cut fabrics.

It is best to use knives with an electric motor. They save a lot of time and are easy to operate. The better the motor, the more layers of material can be cut.

They don't get dull because they have self-sharpening blades.

Types of cutting knives

Each type and model has individual options. The main types of cutting knives are described below.

Saber

It is also called vertical, used for vertical cutting. They are usually used to cut synthetic material, as well as fabrics that can resist when the tool moves along a horizontal line. They can wrinkle, form creases and change appearance. Saber products are very massive and differ from each other in various characteristics, such as the frequency of oscillation of the cutter, as well as the power of the motor. They are mainly used in various studios or in production.

A saber knife for cutting fabric has a number of nuances:

- The height of the machine is indicated only in inches and can be up to 12;

- The size should be selected depending on the floor height. If the knife is too big for the room, it will be unstable and will quickly deteriorate;

- The power is about 500 or 700 watts, there are also higher ones, but they are no longer used in textiles;

- Sharpening can be either manual or automatic.

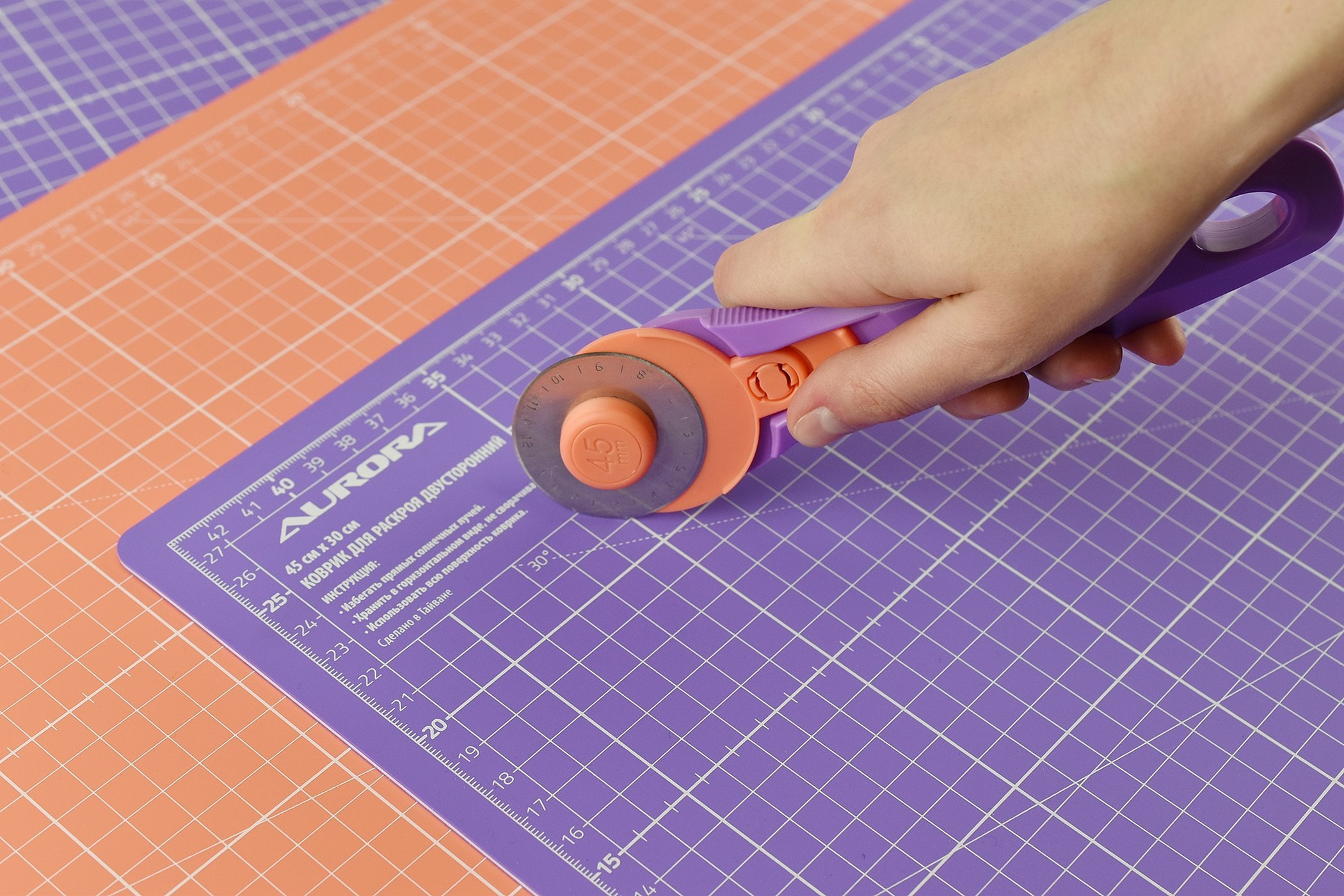

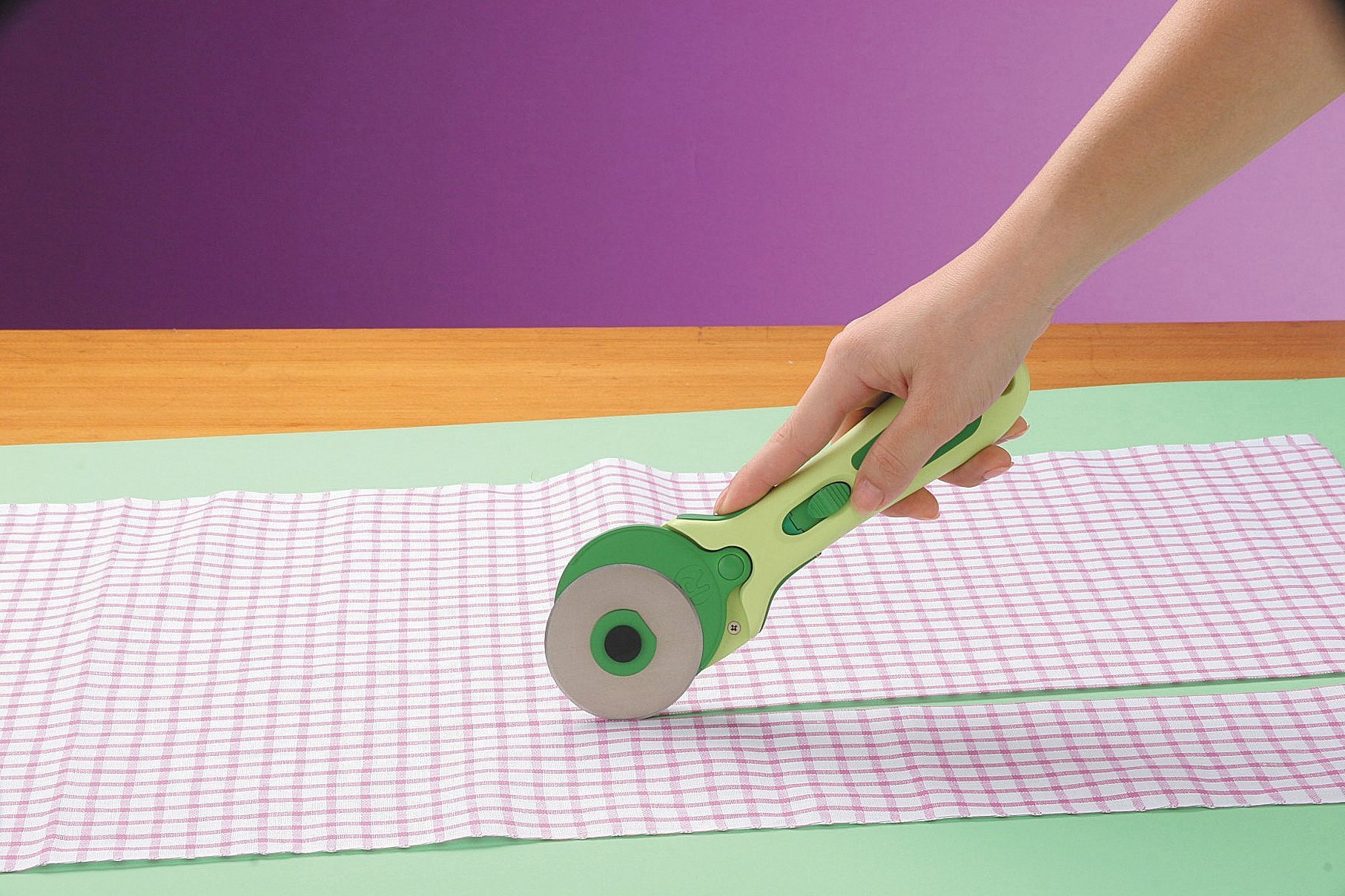

Disk

It is also called a roller. This cutting knife will be one of the most popular. Its cutters have a rounded appearance, and the cutting of the fabric occurs through a rotation around its axis during the work of the handle. On the body of the disk tool there is a surface with rollers, which presses tightly to the surface of the material.

This additionally provides the correct cut of the product. If there are small round patterns on the pattern, then it will be quite difficult to cut them with such a knife.

The disc knife for fabric needs to be sharpened constantly. Blades with a diameter of 30 mm, 40 mm, 65 mm can be sharpened on special equipment. To sharpen less often, you need to tilt the handle slightly during work so that the material is cut at an angle of approximately 45 degrees.

You need to put a plate under the roller knife. It is not advisable to put mats or boards under it. Because they can damage the blade itself.

Sometimes, many people, instead of sharpening an old blade, simply buy a new disc.

A circular knife for cutting fabric can be used in handicrafts; it cuts foil, cardboard, leather and other materials well.

Attention! Most needlewomen prefer this type of cutting knife for fabric, because it has a low price, especially if you take the type with mechanical control.

A more modern electric model of a circular knife is more practical, but the price will be much higher. It is good to use for patchwork (patchwork technique).

Ribbon

The most famous knife for seamstresses will be the band knife. It is more like a machine, mainly used in knitwear workshops. Its blades are quite powerful and strong, in addition to any fabrics, it can even cut a wooden beam.

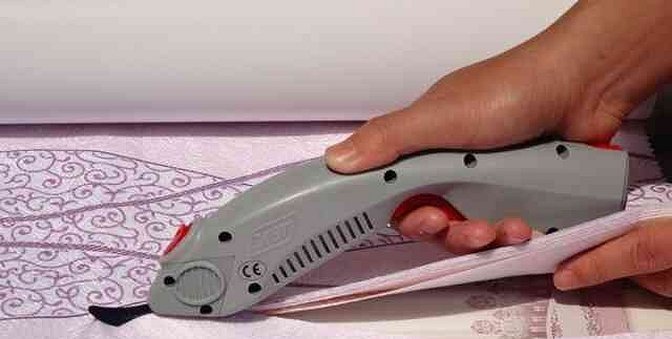

Electric

Sometimes called ultrasonic. It has the highest accuracy of all the presented models. Electric ones are convenient for cutting strong, thick products and coated fabrics. They are not very large, so they can be used at home. They work from the mains, which is very convenient.

There are also machines that are fully automated and computer controlled. However, very few factories in Russia can afford to buy such equipment because it is very expensive.

In addition to the knife, it is necessary to purchase a rug or mat. It is needed to avoid damaging the cutting table during work. Even the simplest roller tool will need a lining under the fabric in the form of a mat.

Selection rules

Before purchasing a tool for the material, it is advisable to pay attention to some nuances that may affect the work if you do not know them.

The most important thing is quality. When a knife starts to get dull, you can simply sharpen it, but there are models that do it themselves. It is advisable to buy it from high-carbon steel.

The size, handle and how it fits in your hand are very important. If the knife is not comfortable to hold, then the productivity will be low, and you can allow a lot of defective cutting.

When buying a knife that runs on electricity, you need to check the insulation before applying electricity. You can not buy such items that are produced by an unknown company.

It is recommended to use different knives for different materials.

As of June 2019, the cost of saber and band machines starts from 102,000 thousand rubles. Therefore, it is unlikely that such devices are suitable for home use. Before purchasing, it is better to first familiarize yourself with the types and models on the Internet, read the features, pros and cons. In the store, it is advisable to get a full consultation from a specialist.

Features of use

When using it, you need to follow a number of rules to avoid problems during work:

- A professional work mat should be placed under the material to avoid cutting the table. It should be changed at least once a month;

- After finishing work, the tool must be cleaned from pieces of fabric and threads. Only do this when the blade has completely cooled down;

- Before starting work, be sure to read the instructions for use;

- When using the tool, you must follow safety precautions, keep your fingers away from the blade. Do not allow children or pets near the blades;

- When working in a factory, you must wear protective gloves and a mask. Because shavings or scraps of fabric can get into your eyes, which can irritate the mucous membrane;

- It is forbidden to bring your hands near the machine while it is being switched off. You must wait until the blades have stopped completely and only then take the material from under the cutter;

- Do not allow the blades to overheat. Switch off the machine from time to time to prevent sparks or fires.

Every seamstress and craftswoman should have such knives. They make work and life much easier. For ordinary needlewomen working at home, it is necessary to purchase a disk cutting knife. Even a novice seamstress can use it.

Attention! It is imperative to comply with all operating rules.

If you plan to open your own small production, then saber models will do. And if you need to buy equipment for a factory for sewing products, then it is advisable to choose a large belt machine. It can cut materials much faster. There are also laser machines. To a greater extent, they are used in factories and small workshops. They have increased cutting accuracy along the sketch lines, very easily cut through several layers of fabric, the edges do not crumble, because they melt a little. But they have a high price and are massive.

There are many models of cutting knives for cutting fabric. Some are for home use, others for factory use. Before buying, you should definitely get advice from a specialist.