In the Soviet Union, many families had a sewing machine called "Podolsk 142", which was extremely popular and advanced for its time. You can still find one today: despite its age, the machine copes well with simple sewing and serves well. It works with both thin and thick fabrics.

- History of the sewing machine "Podolsk 142"

- Sewing machine "Podolsk 142"

- Device

- Equipment

- Machine operating instructions

- How to prepare for work

- How to thread

- How to wind thread on a bobbin

- How to operate the machine at work

- Machine care

- Lubrication

- Cleaning

- Repair of the mechanism

- How to Install a Sewing Machine Needle

- How to check fastenings, connections of units

- Checking the manual drive

- How to remove dried grease

- How to adjust the needle bar

- Pros and cons of the sewing machine "Podolsk 142"

History of the sewing machine "Podolsk 142"

The history of the sewing machine "Podolsk 142" is closely connected with the American company "Singer". The company's products were in great demand, but at the beginning of the 20th century, the price for them rose sharply: shipping overseas was not cheap. Competitors appeared, and the owners of "Singer" decided to open a separate plant in the Russian Empire. The sewing machines produced were to cover the needs of Russia, Turkey, China, Japan, Persia and the Balkans.

The plant began operating in 1902, in 1918 it was nationalized by the Bolsheviks, and work temporarily ceased. The factory resumed operation only in 1923 under the name "Gosshveymashina", and in 1931 it was renamed the Podolsk Mechanical Plant ("PMZ"). It successfully survived the Great Patriotic War and the 1990s, but in the early 2000s PMZ was closed, as the market was saturated with foreign products, and the Russian manufacturer was no longer in demand.

Important! "Podolsk 142" was first released in the 1980s.

Sewing machine "Podolsk 142"

The main difference of the Podolsk 142 is the ability to make a zigzag stitch and process fabric edges. Previous models could only sew straight, and the predecessor model Podolsk 132, although it had similar capabilities, was imperfect and required improvement.

Device

"Podolsk 142" is an improved modification of the "Podolsk 132" model. The main technical characteristics are as follows:

- Main shaft rotation frequency: up to 1 thousand revolutions/minute.

Important! You can sew faster, but at higher speeds, parts wear out faster.

- Weight: 39 kg for a foot-operated machine and 16 kg for an electric machine in a carrying case.

- Maximum straight stitch length: 4 mm.

- Maximum zigzag width: 5 mm.

- Needle offset: up to 2.5 mm from the center to the side.

- Maximum fabric thickness: 5 mm.

- Presser foot lift height: 8 mm.

Equipment

The kit included:

- The machine itself.

- Foot (with belt) or electric drive.

- A set of 5 regular and 3 double-rod needles.

- Several different feet, including for concealed zippers and buttons.

- 4 bobbins and a darning tool.

- Threader.

- Electric lamp.

- A suitcase-shaped cover or a wardrobe-table.

Many seamstresses are afraid to buy a model from someone, since the production of both the equipment and spare parts is closed. Their fears are in vain: the equipment itself is quite durable and can serve for a long time, the adjustment is simple, and the necessary parts can be found in specialized workshops.

Machine operating instructions

Seamstresses note that the operating instructions for the Podolsk 142 sewing machine are not necessary: it is very easy to work with, and the steps are quickly remembered.

How to prepare for work

Before starting work, it is necessary to check whether the equipment is in order, whether the settings are correct, and make adjustments if necessary. It is necessary to stitch the piece of fabric you plan to work with several times.

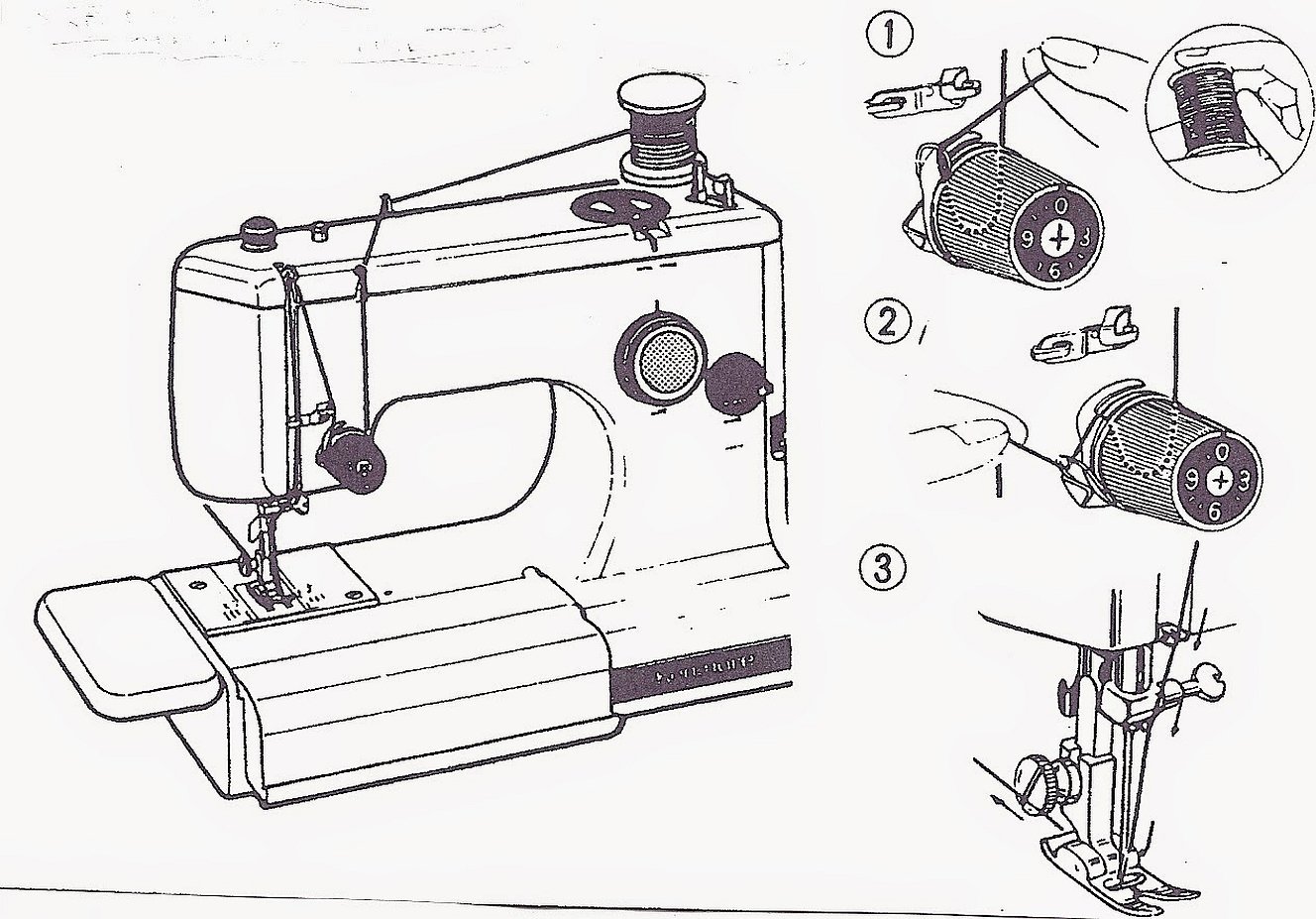

How to thread

There are two threads in the machine - the upper and the lower. Both need to be threaded. The upper thread is threaded in several steps. It is necessary:

- Place the spool of thread on the spool pin.

- Raise the needle to the top position.

- Pass the thread through the thread guide, then pass it between the washers responsible for regulating the thread tension, pass it through the eye of the lever and place it behind the hook of the thread guide, then behind the hook of the needle holder.

- At the end, thread the thread through the eye of the needle.

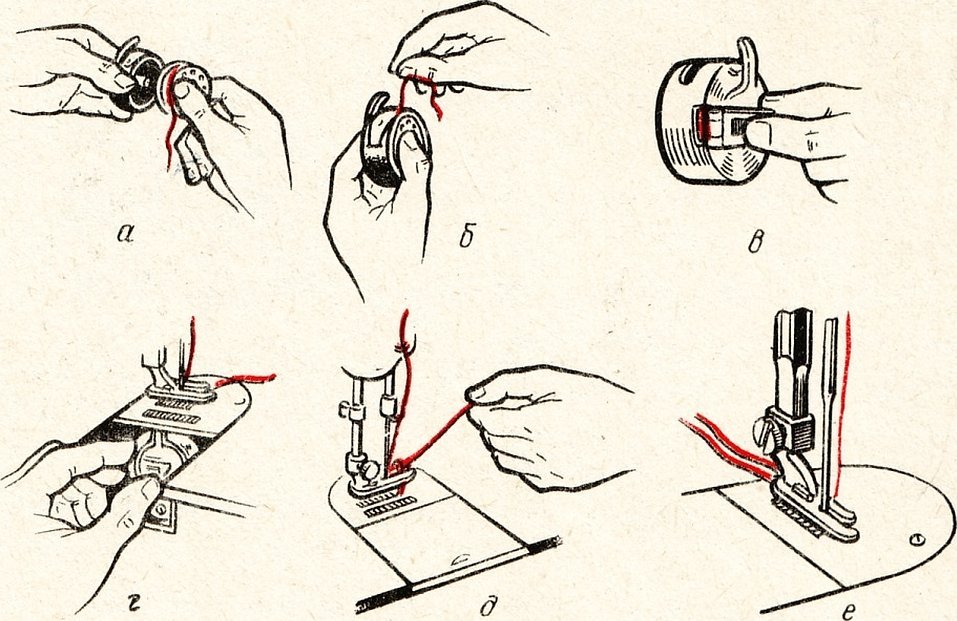

The lower thread is also easy to insert. You will need:

- Raise the needle.

- Remove the plate covering the compartment and take out the bobbin.

- Wind the thread around it and put it back.

- Turn the wheel slowly to pull the thread to the top.

The instructions for the Podolsk 142 sewing machine contain a visual diagram of the thread flow that you can use.

How to wind thread on a bobbin

The sewing machine has a special device that allows you to quickly wind the thread onto the bobbin.

- There is a special metal part on the top of the body that needs to be moved to the desired mode.

- The thread from the spool needs to be passed through the tension washers and manually wound a few turns onto the bobbin. This will help secure the thread.

- Press the pedal and make sure that the thread is wound evenly.

How to operate the machine at work

The control depends on the specific material and the required operations:

- Before you start sewing, you need to set the stitch length and height: for thick fabric it is better to choose “H”, for thin fabric – “W”, when darning – “H”.

- When sewing buttonholes and zippers, you will need to set a small step.

- When working with thin material, you need to pull it up by the foot. This will help to avoid tightening the seams.

- Having laid the fabric, the seamstress should lower the foot and press it firmly. Having finished sewing, the foot should be raised and the fabric pulled towards you, cut the thread, leaving a tail of several centimeters.

Machine care

Although the Podolsk 142 is considered to be a virtually “indestructible” vehicle, it needs to be looked after, otherwise its service life will be reduced several times.

Lubrication

The machine needs to be lubricated at least once a month, and twice a month if used frequently. This is easy to do: remove all accessible bolts and moving parts, remove dirt and apply oil to the units.

Important! It is recommended to use oil I-20A GOST 20799-75.

After assembling the machine, place a piece of unnecessary fabric under its foot and leave it for 1-2 days. During this time, excess oil will flow out and be absorbed into the cloth.

Cleaning

At the same time as applying the lubricant, you need to clean the parts. This is done after disassembling using a brush with elastic bristles.

Repair of the mechanism

It is best to entrust repairs to professionals, but a seamstress can fix some minor problems herself, using the manual.

How to Install a Sewing Machine Needle

When positioned correctly, the long groove on the needle for sliding the thread should be on the right side where the thread is inserted into the eye.

The needle must be inserted into the needle holder until it stops, then secured with the head screw.

Important! On some Podolsk sewing machines the location is different - it is better to check the instructions before starting work.

How to check fastenings, connections of units

The fixation is carried out by a self-loosening nut, so a screwdriver is required for the work. It is necessary to inspect the machine, if any play is detected, loosen the nut and tighten the bushing. The tension should not be tight, a small gap should be left.

Checking the manual drive

The most common problems are weak joints, a loose handle and lack of lubrication. It is necessary to tighten the screws "M" and "K" with a screwdriver and lubricate everything with oil, especially the screws themselves.

The weakest unit is the thread winder. The rubber rim wears out most often and needs to be replaced.

How to remove dried grease

This is done with a special brush with elastic and strong bristles. After disassembling the parts, the grease is cleaned off them.

How to adjust the needle bar

This is done with a special screw that is located inside the case. Since the screw is completely hidden, it can only be tightened by touch with a flat screwdriver.

It is necessary to turn the flywheel, bring the shuttle to the needle and tighten the screw.

Pros and cons of the sewing machine "Podolsk 142"

The advantages of the Podolsk 142 include reliability, durability, ease of operation and maintenance. Due to the small number of operations, switching from one to another does not cause difficulties, the control parts are marked on the body. Threading the upper and lower threads is simplified, which allows even novice seamstresses to cope with the machine. Seamstresses also note that the model works with almost any threads and needles, and does not pull or jam even complex fabrics when sewing.

Important! Sewing machines "Podolsk 142" can be found in labor classes at school: due to their ease of use, it is easy to learn how to sew.

The disadvantages include:

- Lack of electronic control in some models;

- Few available operations and limited scope of application because of this;

- Outdated design;

- Closure of production: you won't be able to buy a new car, but you can buy a well-preserved used one.

The Podolsk factory that produced the sewing machines of the same name closed more than 10 years ago, but its products continue to be in demand. The sewing machine "Podolsk 142" is a strong, easy-to-assemble and easy-to-use machine that can easily handle many jobs.